Difference between revisions of "Electricity Generation from Biogas"

***** (***** | *****) m |

***** (***** | *****) m (→The Technology) |

||

| (16 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

| + | |||

[[Biogas|►Back to Biogas Portal]] | [[Biogas|►Back to Biogas Portal]] | ||

= Overview<br/> = | = Overview<br/> = | ||

| − | [[Biogas Basics|Biogas technology]], the generation of a combustible gas from anaerobic biomass digestion, is a well-known technology. There are already millions of biogas plants in operation throughout the world. | + | [[Biogas Basics|Biogas technology]], the generation of a combustible gas from anaerobic biomass digestion, is a well-known technology. There are already millions of biogas plants in operation throughout the world.Whereas using the gas for direct combustion in household stoves or gas lamps is common, producing electricity from biogas is still relatively rare in most developing countries. In Germany and other industrialised countries, power generation is the main purpose of biogas plants; conversion of biogas to electricity has become a standard technology. |

| − | |||

| − | Whereas using the gas for direct combustion in household stoves or gas lamps is common, producing electricity from biogas is still relatively rare in most developing countries. In Germany and other industrialised countries, power generation is the main purpose of biogas plants; conversion of biogas to electricity has become a standard technology | ||

| − | |||

| − | |||

| − | The findings presented here are based mainly on available experience from [http://www.giz.de/en/ GTZ]-related pilot biogas power plants in different countries. They focus on more or less well-documented existing country cases even though little extensive documentation of practical long term | + | This document will discuss the potentials, obstacles and necessary framework conditions for the utilisation of biogas for small and medium scale electricity generation in developing countries. This paper will not address the biogas production process in general but focus uniquely on electricity generation. The findings presented here are based mainly on available experience from [http://www.giz.de/en/ GTZ]-related pilot biogas power plants in different countries. They focus on more or less well-documented existing country cases even though little extensive documentation of practical long term operating experience is available. Besides the cases described here, we know of further examples from other GTZ projects (e.g. [[Bolivia Energy Situation|Bolivia]], [[Tunisia Energy Situation|Tunisia]] and the [[Ivory Coast Energy Situation|Ivory Coast]]). However, there is not yet sufficient information concerning these to merit inclusion in this assessment. |

<br/> | <br/> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<br/> | <br/> | ||

| − | |||

| − | + | = The Technology = | |

| − | <br/> | + | Biogas is the gas resulting from an anaerobic digestion process. A biogas plant can convert animal manure, green plants, waste from agro industry and slaughterhouses into combustible gas.<br/>► For further information on the biogas production and fermentation process please refer to the '''[[Portal:Biogas|Biogas Portal on energypedia]]'''.<br/> |

| − | + | Biogas can be used in similar ways as natural gas in gas stoves, lamps or as fuel for engines. It consists of 50-75% methane, 25-45% carbon dioxide, 2-8% water vapour and traces of O2 N2, NH3 H2 H2S. Compare this with natural gas, which contains 80 to 90% methane. The energy content of the gas depends mainly on its methane content. High methane content is therefore desirable. A certain carbon dioxide and water vapour content is unavoidable, but '''sulphur content must be minimised''' - particularly for use in engines. | |

| − | + | The average calorific value of biogas is about 21-23.5 MJ/m³, so that 1 m³ of biogas corresponds to 0.5-0.6 l diesel fuel or about 6 kWh (FNR, 2009). | |

| − | + | The biogas yield of a plant depends not only on the type of feedstock, but also on the plant design, fermentation temperature and retention time. Maize silage for example - a common feedstock in Germany - yields about 8 times more biogas per ton than cow manure. In Germany, cow manure and energy crops are the main forms of feedstock. About 2 live-stock units (corresponding to about 2 cows or 12 rearing pigs) plus 1 ha of maize and grass are expected to yield a constant output of about 2 kWel (48kWhel per day. In the South Asian context, [https://www.esmap.org/ ESMAP] uses a typical specific input-output relation of about 14 kg of fresh cattle dung (the approximate production of one cow on one day) plus 0.06 l diesel fuel to produce 1kWh electricity. | |

| − | + | <br/><u>Gas Production Figures</u> If the daily amount of available dung (fresh weight) is known, gas production per day in warm tropical countries will approximately correspond to the following values: | |

| − | + | *1 kg cattle dung 40 liters biogas | |

| + | *1 kg buffalo dung 30 liter biogas | ||

| + | *1 kg pig dung 60 liter biogas | ||

| + | *1 kg chicken droppings 70 liter biogas | ||

| − | + | If the live weight of all animals whose dung is put into the biogas plant is known, the daily gas production will correspond approximately to the following values: | |

| − | + | *cattle, buffalo and chicken: 1,5 liters biogas per day per 1 kg live weight | |

| + | *pigs, humans: 30 liters biogas per day per 1 kg weight | ||

| − | + | For yield ranges and methane contents for 33 different substrates, please see [[Gas Yields and Methane Contents for Various Substrates|Gas Yields and Methane Contents for Various Substrates]]. | |

| − | <br/> | + | Some Additional Facts <br/> |

| − | == | + | <span lang="EN"><font size="3">Each kilogram of biodegradable material yields 0.4 m</font><sup><font size="2">3</font></sup><font size="3">(400 liters) of gas.</font></span> |

| − | + | <span lang="EN"><font size="3">Gas lights consume around 0.1m</font><sup><font size="2">3</font></sup><font size="3">(100 liters) of gas in one hour<ref name="http://www.small-farm-permaculture-and-sustainable-living.com/methane_generator.html ">http://www.small-farm-permaculture-and-sustainable-living.com/methane_generator.html </ref>.</font></span> | |

| − | <br/> | + | [[#toc|►Go to Top]]<br/> |

| − | + | == Conversion to Electricity == | |

| − | + | Theoretically, biogas can be converted directly into electricity by using a fuel cell. However, this process requires very clean gas and expensive fuel cells. Therefore, this option is still a matter for research and is not currently a practical option. The conversion of biogas to electric power by a generator set is much more practical. In contrast to natural gas, biogas is characterized by a high knock resistance and hence can be used in combustion motors with high compression rates. | |

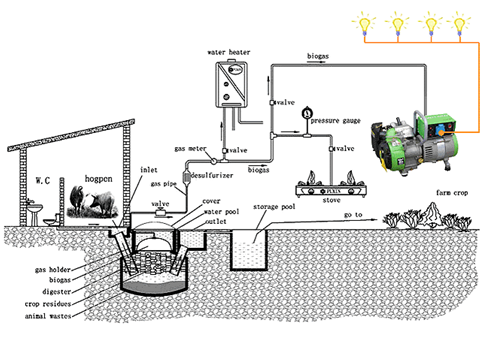

| − | + | <br/><u>Schematic of a biogas plant used for power generation :</u><ref name="www.Greenpower.cn">www.Greenpower.cn</ref><br/> | |

| − | + | [[File:Biogas plant used for power generation.png|thumb|center|534px|alt=Biogas plant used for power generation.png]]<br/> | |

| − | |||

| − | |||

| − | + | In most cases, biogas is used as fuel for combustion engines, which convert it to mechanical energy, powering an electric generator to produce electricity. The design of an electric generator is similar to the design of an electric motor. Most generators produce alternating AC electricity; they are therefore also called alternators or dynamos. Appropriate electric generators are available in virtually all countries and in all sizes. The technology is well known and maintenance is simple. In most cases, even universally available 3-phase electric motors can be converted into generators. Technologically far more challenging is the first stage of the generator set: the combustion engine using the biogas as fuel. In theory, biogas can be used as fuel in nearly all types of combustion engines, such as gas engines (Otto motor), diesel engines, gas turbines and Stirling motors etc. | |

| − | + | [[#toc|►Go to Top]]<br/> | |

<br/> | <br/> | ||

| − | |||

| − | + | = Appropriate Combustion Engine = | |

| − | |||

| − | |||

| − | |||

| − | + | == External Combustion Engines (EC Engines) == | |

| − | + | *'''Stirling Motors:''' In such motors, biogas is combusted externally, which in turn heats the stirling motor through a heat exchanger. The gas in the stirling motor hence expands and thereby moves the mechanism of the engine. The resulting work is used to generate electricity. Stirling motors have the advantage of being tolerant of fuel composition and quality. They are, however, relatively expensive and characterised by low efficiency. Their use is therefore limited to a number of very specific applications. | |

| − | |||

| − | The | ||

| − | |||

| − | |||

| − | + | In most commercially run biogas power plants today, internal combustion motors have become the standard technology either as gas or diesel motors. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<br/> | <br/> | ||

| − | + | == Internal Combustion Engines == | |

| − | + | *'''Diesel Engines''' operate on biogas only in dual fuel mode. To facilitate the ignition of the biogas, a small amount of ignition gas is injected together with the biogas. Modern pilot injection gas engines (“Zündstrahlmotoren”) need about 2% additional ignition oil. Almost every diesel engine can be converted into a pilot injection gas engine. These motors running in dual fuel mode have the advantage that they can also use gas with low heating value. But in that case, they consume a considerable amount of diesel. Up to engine sizes of about 200kW the pilot injection engines seem to have advantages against gas motors due to slightly higher efficiency (3-4% higher) and lower investment costs. | |

| + | *'''Gas Motors''' with spark ignition (Otto system) can operate on biogas alone. In practice, a small amount of petrol (gasoline) is often used to start the engine. This technology is used for very small generator sets (~ 0.5-10 kW) as well as for large power plants. Especially in Germany, these engines have advantages as they do not need additional fossil fuels that would lead to lower feed-in tariffs according to the Renewable Energy Law (EEG). | ||

| + | *'''Gas Turbines '''are occasionally used as biogas engines especially in the US. They are very small and can meet the strict exhaust emissions requirements of the California Air Resources Board (CARB) for operation on landfill and digester gases. Small biogas turbines with power outputs of 30-75 kW are available in the market. However, they are rarely used for small-scale applications in developing countries. They are expensive and due to their spinning at very high speeds and the high operating temperatures, the design and manufacturing of gas turbines is a challenging issue from both the engineering and material point of view. Maintenance of such a turbine is very different from well-known maintenance of a truck engine and therefore requires specific skills. | ||

| − | + | Today, experience of the use of combustion motors to produce electricity from biogas is extensive; this can be regarded as a proven standard technology. Over 4,000 biogas plants with internal combustion motors are in operation in Germany. | |

| − | + | However, it has taken lengthy and determined effort to make this technology as durable and reliable as it is today. Internal combustion motors have high requirements in terms of fuel quality. Harmful components - especially hydrogen sulphide (H2S)¬ - in the gas can shorten the lifetime of a motor considerably and cause serious damage. | |

| − | + | <u>This must be addressed in two ways :</u> | |

| − | + | *Production of clean biogas; and | |

| + | *Use of appropriate and robust motors and components. | ||

| − | + | <br/>In theory, most engines originally intended for cars, trucks, ships or stationary use can run on biogas as fuel and are available almost everywhere within a power range between 10 and 500 kW. This holds true especially in the case of dual fuel use. Robust engines with a certain sulphur resistance are mostly free of non-ferrous metal (German: “Buntmetalle”), as these materials are highly prone to damage through sulphur-rich biogas. | |

| − | |||

| − | |||

<br/> | <br/> | ||

| − | + | [[#toc|►Go to Top]]<br/> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<br/> | <br/> | ||

| − | + | == Appropriate Gas Quality == | |

| − | + | <u>For use in gas or diesel engines, the gas must fulfil certain requirements :</u> | |

| − | + | *The methane content should be as high as possible as this is the main combustible part of the gas; | |

| + | *The water vapour and CO2 content should be as low as possible, mainly because they lead to a low calorific value of the gas; | ||

| + | *The sulphur content in particular, mainly in form of H2S, must be low, as it is converted to corrosion-causing acids by condensation and combustion. | ||

<br/> | <br/> | ||

| − | + | The '''water vapour '''content can be reduced by condensation in the gas storage or on the way to the engine. | |

| − | + | The reduction of the '''hydrogen sulphide (H2S) '''content in the biogas can be addressed via a range of technical methods. These can be classified as chemical, biological, or physical and divided into internal and external methods. Much experimentation has been carried out in the last two decades.<br/> | |

| − | + | <u>However, as complete elimination is unnecessary for use in robust engines, the following simple methods have generally established themselves as standard :</u> | |

| − | <br/> | + | *An '''optimised steady fermentation process '''with continuous availability of appropriate feedstock is important to produce a gas of homogenous quality.<br/> |

| − | + | *The '''injection of a small amount of oxygen '''(air) into the headspace of the storage fermenter leads to oxidation of H2S by microorganisms and hence the elimination of a considerable part of the sulphur from the gaseous phase. This is the most frequently used method for desulphurisation. It is cheap and can eliminate up to 95% of the sulphur content in the biogas. However, the right proportioning of air still seems to be a challenge.<br/> | |

| − | + | *Another option is '''external chemical treatment in a filter'''. The active material may be: | |

| − | + | **1.Iron-hydroxide: Fe (OH)2 + H2S -> FeS + 2 H2O. This process is reversible and the filter can be regenerated by adding oxygen. Adsorption material may be iron-rich soils, waste material from steel or aluminium production ;<br/> | |

| − | + | **2. Activated carbon: Certain companies provide activated carbon filters as a standard component in their gensets. | |

| − | |||

| − | |||

<br/> | <br/> | ||

| − | + | Standard quality sulphur filters and filter material can be purchased on the market. | |

| − | |||

| − | |||

| − | |||

<br/> | <br/> | ||

| − | + | = Energy requirement for heating the slurry = | |

| − | |||

| − | |||

| − | + | Energy required for heating the slurry in digester can be calculated by using the formulae below. | |

| − | + | Q<sub>T </sub>= m×c× (T<sub>2</sub>-T<sub>1</sub>) - equation 1 | |

| − | + | Where | |

| − | < | + | Q<sub>T </sub>is the total heat(Energy required for heating the slurry) and is expressed in Kilo-joule(Kj). |

| − | |||

| − | |||

| − | + | m is the mass of the slurry and is expressed in Kilo-gram(Kg). | |

| − | + | c is the specific heat of slurry and is expressed in Kj/Kg°C. | |

| − | < | + | T<sub>2</sub> is the desired temperature of slurry and is expressed in °C. |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | T<sub>1</sub> is the current temperature of slurry and is expressed in °C. | |

| − | + | mass of slurry = volume of digester (V) × density of slurry(ρ) and is expressed in Kg. - equation 2 | |

| − | + | Where V is the volume of digester, expressed in m<sup>3</sup> and ρ is the density of slurry, expressed in Kg/m<sup>3</sup> . | |

| − | + | Density of slurry (ρ) = density of water + density of cow dung - equation 3 | |

| − | + | Density of water is 1000 Kg/m<sup>3</sup> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Density of cow dung is 0.13 Kg/m<sup>3</sup> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Putting these values in equation 2 | |

| − | < | + | Density of slurry (ρ) = (1000+0.13) Kgm<sup>-3</sup>/2 ≈ 500 Kg/m<sup>3</sup> |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | From equation 1 we can get the mass of slurry by multiplying volume of digester with density of slurry calculated above. | |

| − | + | Specific heat of slurry = {specific heat of water (4.2Kj/Kg°c) + specific heat of cow dung (2.8Kj/Kg°c)}/2 | |

| − | + | = 3.5Kg/Kg°c | |

| − | + | Putting these values in equation one we can know the energy required for heating the slurry. The unit of energy is Kj(Kilo joule)<ref name="http://www.aepc.gov.np/docs/resource/subreport/20140708034742_Final%20Report_Digester%20Heating.pdf">http://www.aepc.gov.np/docs/resource/subreport/20140708034742_Final%20Report_Digester%20Heating.pdf</ref>. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | The | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<br/> | <br/> | ||

| − | + | [[#toc|►Go to Top]]<br/> | |

| − | + | = Favorable Temperature for MethaneGeneration<br/> = | |

| − | + | The time period for which material can be kept in digester depends on the temperature of the digester. 50°c is needed for holding the material (slurry/organic waste) for 2 weeks while at 15°c temperature it can be prolonged for 2 months. Average is around 1 month. Gauge the Amount of material kept in the digester per day and then multiply by 30 to calculate the size of digester. | |

| − | + | Anaerobic digestion occurs in the temperature range of 0°c to 65°c. The optimum temperature for methane production is 29°c to 35°c as in this range microbial activity takes place. Little gas production occurs below 16°c<ref name="http://www.small-farm-permaculture-and-sustainable-living.com/methane_generator.html ">http://www.small-farm-permaculture-and-sustainable-living.com/methane_generator.html </ref>. | |

| − | + | = Examples = | |

| − | + | For examples of countries where electricity is generated from biogas, please see [[Generating Electricity from Biogas - Examples|Generating Electricity from Biogas - Examples]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

= Overall Appraisal = | = Overall Appraisal = | ||

| Line 296: | Line 179: | ||

== Energy Production Potential == | == Energy Production Potential == | ||

| − | Appropriate feedstock for electricity-generating biogas plants is available in adequate | + | Appropriate feedstock for electricity-generating biogas plants is available in adequate quantity in many countries. Small and medium-size biogas plants could provide a considerable contribution to national electricity generation in such countries. However, in comparison to industrialised countries, only very few small and medium sized biogas plants are used for electricity generation in Africa, Latin America and even Asia. |

Electricity production from biogas can be a very efficient method for producing electricity from a renewable energy source. However, this applies only if the emerging heat from the power generator can be used in an economically and ecologically sound way. The average calorific value of biogas is about 21-23.5 MJ/m³, meaning that 1 m³ of biogas corresponds to 0.5-0.6 l diesel fuel or an energy content of about 6 kWh. However, due to conversion losses, 1m³ of biogas can be converted only to around 1.7 kWhel. | Electricity production from biogas can be a very efficient method for producing electricity from a renewable energy source. However, this applies only if the emerging heat from the power generator can be used in an economically and ecologically sound way. The average calorific value of biogas is about 21-23.5 MJ/m³, meaning that 1 m³ of biogas corresponds to 0.5-0.6 l diesel fuel or an energy content of about 6 kWh. However, due to conversion losses, 1m³ of biogas can be converted only to around 1.7 kWhel. | ||

| Line 302: | Line 185: | ||

Bigger biogas plants are generally more cost-efficient than smaller ones. However, electricity generation from biogas is a technology appropriate even for relatively small applications in the range of 10-100kW. | Bigger biogas plants are generally more cost-efficient than smaller ones. However, electricity generation from biogas is a technology appropriate even for relatively small applications in the range of 10-100kW. | ||

| − | <br/> | + | [[#toc|►Go to Top]]<br/> |

== Technical Aspects == | == Technical Aspects == | ||

| Line 308: | Line 191: | ||

There is mature, reliable high quality technology available on the global market. The techno-logical difficulties with which small biogas plants were confronted two decades ago have been resolved. | There is mature, reliable high quality technology available on the global market. The techno-logical difficulties with which small biogas plants were confronted two decades ago have been resolved. | ||

| − | Different methods of desulphurisation have been successfully established and combustion motors tolerant to biogas that have proven their durability are available in the market. | + | Different methods of desulphurisation have been successfully established and combustion motors tolerant to biogas that have proven their durability are available in the market. Sufficient know-how for planning and constructing reliable biogas power plants is also available. |

Germany is one of the leading countries in terms of high quality components and know-how required for electricity-generating biogas plants. Know-how and technical components are also available in China, Thailand and other Asian countries as well as in Brazil. Electricity generation from biogas in Africa is still limited to a few pilot plants, with Kenya apparently being one of the centres of development and experience. For the construction of efficient and reliable biogas power plants, at least some technical core components must be imported from industrialised countries. | Germany is one of the leading countries in terms of high quality components and know-how required for electricity-generating biogas plants. Know-how and technical components are also available in China, Thailand and other Asian countries as well as in Brazil. Electricity generation from biogas in Africa is still limited to a few pilot plants, with Kenya apparently being one of the centres of development and experience. For the construction of efficient and reliable biogas power plants, at least some technical core components must be imported from industrialised countries. | ||

| − | The electricity generation component of a biogas power plant does not require much more know-how and effort for maintenance than a normal generator set for fossil fuels with a well functioning biogas fermentation process as an indispensable prerequisite.<br/> | + | The electricity generation component of a biogas power plant does not require much more know-how and effort for maintenance than a normal generator set for fossil fuels with a well-functioning biogas fermentation process as an indispensable prerequisite.<br/> |

| − | <br/> | + | [[#toc|►Go to Top]]<br/> |

== Economic Aspects == | == Economic Aspects == | ||

<u>Economically, electricity from biogas must compete with electricity generation from fossil fuels and other renewable energies such as hydro power. Supporting factors are:</u> | <u>Economically, electricity from biogas must compete with electricity generation from fossil fuels and other renewable energies such as hydro power. Supporting factors are:</u> | ||

| + | |||

*Rising prices of fossil fuels | *Rising prices of fossil fuels | ||

*Low reliability of electricity provision from national grids with persistent risk of power cuts and vulnerability of hydro power to drought. | *Low reliability of electricity provision from national grids with persistent risk of power cuts and vulnerability of hydro power to drought. | ||

<u>Inhibiting factors are:</u> | <u>Inhibiting factors are:</u> | ||

| + | |||

*Relatively low prices of fossil fuels | *Relatively low prices of fossil fuels | ||

*Need to buy high quality components from industrialised countries | *Need to buy high quality components from industrialised countries | ||

| − | * | + | *Unfavorable conditions for selling electricity |

| − | *Lack of awareness, capacity and experience preventing the economic operation of | + | *Lack of awareness, capacity and experience preventing the economic operation of infrastructure components. |

<u>The economic feasibility of a biogas plant depends on the economic value of the entire range of plant outputs. These are:</u> | <u>The economic feasibility of a biogas plant depends on the economic value of the entire range of plant outputs. These are:</u> | ||

| + | |||

*Electricity or mechanical power | *Electricity or mechanical power | ||

*Biogas<br/> | *Biogas<br/> | ||

| Line 339: | Line 225: | ||

Most of the commercially run biogas power plants in developing countries are of medium size and are installed in industrial contexts, primarily using organic waste material from agro-industrial production processes such as cow, pig and chicken manure, slaughterhouse waste, or residues from sisal and coffee processing. | Most of the commercially run biogas power plants in developing countries are of medium size and are installed in industrial contexts, primarily using organic waste material from agro-industrial production processes such as cow, pig and chicken manure, slaughterhouse waste, or residues from sisal and coffee processing. | ||

| − | Assessments of economic feasibility are contradictory or inconsistent. Many press releases and information from biogas power plant producers refer to payback periods of only 1.5 – 2.5 years. In such cases, the electricity from biogas plants can be compared to the price of | + | Assessments of economic feasibility are contradictory or inconsistent. Many press releases and information from biogas power plant producers refer to payback periods of only 1.5 – 2.5 years. In such cases, the electricity from biogas plants can be compared to the price of electricity provided through the national grid or the price of bottled LPG. |

However these figures are unrealistic, except for direct thermal energy use as for cooking energy, or in very few locations with extremely expensive diesel fuel. | However these figures are unrealistic, except for direct thermal energy use as for cooking energy, or in very few locations with extremely expensive diesel fuel. | ||

| Line 345: | Line 231: | ||

More realistic figures seem to be those calculated by GTZ experts in Kenya for medium and large plants (>50kW):<br/> | More realistic figures seem to be those calculated by GTZ experts in Kenya for medium and large plants (>50kW):<br/> | ||

| − | They anticipate payback periods for plants under the DBFZ tariff scheme (~0.15 US$/kWh) of 6 years under very favourable conditions, and 9 years for | + | They anticipate payback periods for plants under the DBFZ tariff scheme (~0.15 US$/kWh) of 6 years under very favourable conditions, and 9 years for unfavorable but still economically viable investments.<br/> |

| − | In spite of this theoretical profitability, recent examples from Africa show that electricity | + | In spite of this theoretical profitability, recent examples from Africa show that electricity generation from biogas has not really captured the market as a ‘profitable’ technology. None of the plants described here could have been installed without international technical and financial support. This is due to the pilot status of the market and barriers such as a lack of awareness, experience, local capacity, upfront financing for project development (for own consumption projects, i.e. where there is no feed-in component) and the existence of policy barriers in cases where feed-in is required. |

Many new studies come to the conclusion that biogas power plants are not commercially viable without subsidies or guaranteed high prices (~0,20US$) for the produced outputs. In Germany and other industrialised countries, only guaranteed feed-in tariffs have led to a breakthrough. Almost all well-known biogas power plants in developing countries depend on financial support from a third international party. | Many new studies come to the conclusion that biogas power plants are not commercially viable without subsidies or guaranteed high prices (~0,20US$) for the produced outputs. In Germany and other industrialised countries, only guaranteed feed-in tariffs have led to a breakthrough. Almost all well-known biogas power plants in developing countries depend on financial support from a third international party. | ||

| Line 353: | Line 239: | ||

We have little experience to draw on concerning the possibility of using biogas power plants to cover the basic energy needs of the rural population. Most biogas power plants are connected to agro-industrial facilities and provide electricity only to very few immediate neighbours. However, calculations show that biogas could play a role in supplying isolated grids, where it represents a least cost option. | We have little experience to draw on concerning the possibility of using biogas power plants to cover the basic energy needs of the rural population. Most biogas power plants are connected to agro-industrial facilities and provide electricity only to very few immediate neighbours. However, calculations show that biogas could play a role in supplying isolated grids, where it represents a least cost option. | ||

| − | <br/> | + | [[#toc|►Go to Top]]<br/> |

== Necessary Framework Conditions == | == Necessary Framework Conditions == | ||

| − | In Germany, power generation from biogas is only profitable due to grid connection and sup-porting feed-in tariffs. By contrast, power generation in most developing countries seems to be especially profitable in settings far away from the national grid and other energy sources, as the legal framework conditions and the lack of appropriate feed-in tariffs do not support feeding into the grid. However, there are the first signs of financial and legal support for | + | In Germany, power generation from biogas is only profitable due to grid connection and sup-porting feed-in tariffs. By contrast, power generation in most developing countries seems to be especially profitable in settings far away from the national grid and other energy sources, as the legal framework conditions and the lack of appropriate feed-in tariffs do not support feeding into the grid. However, there are the first signs of financial and legal support for feeding in electricity from biogas power plants in countries such as Brazil. Output-oriented support schemes (such as the German EEG) have proved to be more successful than investment-oriented financial support. |

Direct subsidies and public financial contributions to installation costs have been crucial for the installation of some pilot plants. However, they have not provided incentives for proper and efficient operation. By contrast, the establishment of appropriate feed-in tariffs stimulates the construction of efficient plants and their continuous and efficient operation. | Direct subsidies and public financial contributions to installation costs have been crucial for the installation of some pilot plants. However, they have not provided incentives for proper and efficient operation. By contrast, the establishment of appropriate feed-in tariffs stimulates the construction of efficient plants and their continuous and efficient operation. | ||

| Line 364: | Line 250: | ||

<u>However, besides price considerations, there remain many barriers to market penetration and development of the biogas sector:</u> | <u>However, besides price considerations, there remain many barriers to market penetration and development of the biogas sector:</u> | ||

| + | |||

*Lack of awareness of biogas opportunities | *Lack of awareness of biogas opportunities | ||

*High upfront costs for potential assessments and feasibility studies | *High upfront costs for potential assessments and feasibility studies | ||

*Lack of access to finance | *Lack of access to finance | ||

*Lack of local capacity for project design, construction, operation and maintenance | *Lack of local capacity for project design, construction, operation and maintenance | ||

| − | *Legal framework conditions that complicate alternative energy production and | + | *Legal framework conditions that complicate alternative energy production and commercialisation: for example, the right to sell electricity at local level has to be in place. |

As long as the national framework conditions are not favourable, electricity generation from biogas will remain limited to a few pilot applications. | As long as the national framework conditions are not favourable, electricity generation from biogas will remain limited to a few pilot applications. | ||

| − | <br/> | + | [[#toc|►Go to Top]]<br/> |

= Further Information = | = Further Information = | ||

| Line 379: | Line 266: | ||

*[[:File:Small-scale Electricity Generation From Biomass Part-2.pdf|Small-scale Electricity Generation From Biogas Part-2.pdf]] (GIZ, 2010) | *[[:File:Small-scale Electricity Generation From Biomass Part-2.pdf|Small-scale Electricity Generation From Biogas Part-2.pdf]] (GIZ, 2010) | ||

*[[:File:Small-scale Electricity Generation From Biomass Part-3.pdf|Small-scale Electricity Generation From Vegetable Oil Part-3.pdf]] (GIZ, 2010) | *[[:File:Small-scale Electricity Generation From Biomass Part-3.pdf|Small-scale Electricity Generation From Vegetable Oil Part-3.pdf]] (GIZ, 2010) | ||

| + | *[[Gas Yields and Methane Contents for Various Substrates|Gas Yields and Methane Contents for Various Substrates]] | ||

<br/> | <br/> | ||

| Line 387: | Line 275: | ||

*COPEL DISTRIBUIÇÃO S A: VENCEDORES DA CHAMADA PÚBLICA, 2009, 2.p List of winners of a tender to sell electricity to the grid in the state of Paraná, Brazil.<br/> | *COPEL DISTRIBUIÇÃO S A: VENCEDORES DA CHAMADA PÚBLICA, 2009, 2.p List of winners of a tender to sell electricity to the grid in the state of Paraná, Brazil.<br/> | ||

*ESMAP (2005) Advancing Bioenergy for Sustainable Development - Guideline for Policy-makers and Investors. Report 300/05. | *ESMAP (2005) Advancing Bioenergy for Sustainable Development - Guideline for Policy-makers and Investors. Report 300/05. | ||

| − | *Fachagentur Nachwachsende Rohstoffe e.V. (FNR) (2009): Biogas Basisdaten Deutschland – Stand: Oktober 2008. 7p. Very short but comprehensive overview of the biogas situation in Germany. | + | *Fachagentur Nachwachsende Rohstoffe e.V. (FNR) (2009): Biogas Basisdaten Deutschland – Stand: Oktober 2008. 7p. Very short but comprehensive overview of the biogas situation in Germany. |

| − | *Franz, Michael (2009): Zielmarktanalyse (ZMA). Der Markt für Biogas in Kenia. Studie des Projektentwicklungsprogramm Ostafrika im Rahmen der Exportinitiative Erneuerbare Ener-gien des BMWi. Description of the status in Kenya of biogas technology, available local know-how, market potential as well as legal and economic framework conditions. Detailed discussion of a biogas plant at a sisal plantation in Kilifi and lessons learned. | + | *Franz, Michael (2009): Zielmarktanalyse (ZMA). Der Markt für Biogas in Kenia. Studie des Projektentwicklungsprogramm Ostafrika im Rahmen der Exportinitiative Erneuerbare Ener-gien des BMWi. Description of the status in Kenya of biogas technology, available local know-how, market potential as well as legal and economic framework conditions. Detailed discussion of a biogas plant at a sisal plantation in Kilifi and lessons learned. |

| − | *Franz, Michael and Klaus v. Mitzlaff (2009): The Biogas Market in Kenya - Status Quo and Potentials. Presentation for Combined Biogas Business and Study Trip from Kenya and Tan-zania, to Hannover, November 13, 2009. German Technical Cooperation (GTZ). | + | *Franz, Michael and Klaus v. Mitzlaff (2009): The Biogas Market in Kenya - Status Quo and Potentials. Presentation for Combined Biogas Business and Study Trip from Kenya and Tan-zania, to Hannover, November 13, 2009. German Technical Cooperation (GTZ). |

*Grope, Johann (2009): Optimierung eines Biogasanlagenmodells unter Berücksichtigung der spezifischen Rahmenbedingungen Südbrasiliens. Study of DBFZ on behalf of GTZ. 84 p. Describes framework conditions of biogas activities in southern Brazil and current technol-ogy. Develops proposals for optimised biogas technology. | *Grope, Johann (2009): Optimierung eines Biogasanlagenmodells unter Berücksichtigung der spezifischen Rahmenbedingungen Südbrasiliens. Study of DBFZ on behalf of GTZ. 84 p. Describes framework conditions of biogas activities in southern Brazil and current technol-ogy. Develops proposals for optimised biogas technology. | ||

| − | *GTZ (2010): Agro-Industrial Biogas in Kenya – Potentials, Estimates for Tariffs, Policy and Business Recommendations. Study of Deutsches Biomasse Forschungs Zentrum (DBFZ) on behalf of GTZ, Renewable Energy Project Development Programme East Africa. 69p. This comprehensive study documents the high potential for electricity production in Kenya from municipal solid waste and agro-industrial production, especially sisal and coffee produc-tion. About 16% of actual electricity consumption could be covered by electricity from biogas. The costs of different plant types and sizes are calculated. Grid connection and appropriate feed-in-tariffs are identified as the main prerequisites for commercial investment in this sector. The proposed basic feed-in-tariffs are within a price range similar to current levels in Germany (0.10 – 0.2 US$ /kWh el. | + | *GTZ (2010): Agro-Industrial Biogas in Kenya – Potentials, Estimates for Tariffs, Policy and Business Recommendations. Study of Deutsches Biomasse Forschungs Zentrum (DBFZ) on behalf of GTZ, Renewable Energy Project Development Programme East Africa. 69p. This comprehensive study documents the high potential for electricity production in Kenya from municipal solid waste and agro-industrial production, especially sisal and coffee produc-tion. About 16% of actual electricity consumption could be covered by electricity from biogas. The costs of different plant types and sizes are calculated. Grid connection and appropriate feed-in-tariffs are identified as the main prerequisites for commercial investment in this sector. The proposed basic feed-in-tariffs are within a price range similar to current levels in Germany (0.10 – 0.2 US$ /kWh el. |

| − | *GTZ-PURE (2005): Feasibility Study on Biogas from Poultry Droppings in Bangladesh, Pre-pared By Bangladesh Centre for Advanced Studies (BCAS) in collaboration with Energy Consulting Services (ECS), December 28, 2005. Surveys biogas activities in Bangladesh and discusses briefly the possibilities and profitability of electricity generation in Bangladesh. | + | *GTZ-PURE (2005): Feasibility Study on Biogas from Poultry Droppings in Bangladesh, Pre-pared By Bangladesh Centre for Advanced Studies (BCAS) in collaboration with Energy Consulting Services (ECS), December 28, 2005. Surveys biogas activities in Bangladesh and discusses briefly the possibilities and profitability of electricity generation in Bangladesh. |

*Mitzlaff, Klaus von (1988): Engines for Biogas. GTZ-GATE /Viehweg. 164p. Documents early approaches of GTZ towards electricity generation from biogas. Describes the essential basics of internal combustion engines and properties of biogas as a fuel for internal combustion engines. Suggests parameters for planning a biogas engine system, with an overview of commercially available systems. | *Mitzlaff, Klaus von (1988): Engines for Biogas. GTZ-GATE /Viehweg. 164p. Documents early approaches of GTZ towards electricity generation from biogas. Describes the essential basics of internal combustion engines and properties of biogas as a fuel for internal combustion engines. Suggests parameters for planning a biogas engine system, with an overview of commercially available systems. | ||

| − | *Muchel, H. and H. Zimmermann (1985): Purification of Biogas. GTZ: Aus der Arbeit von GATE, 33p. Viehweg Documents early GTZ approaches towards electricity generation from biogas. Describes the properties and origins of hydrogen sulphide in biogas plants, its effects on the gas-utilisation equipment and methods for removing H2S from biogas. | + | *Muchel, H. and H. Zimmermann (1985): Purification of Biogas. GTZ: Aus der Arbeit von GATE, 33p. Viehweg Documents early GTZ approaches towards electricity generation from biogas. Describes the properties and origins of hydrogen sulphide in biogas plants, its effects on the gas-utilisation equipment and methods for removing H2S from biogas. |

*Practical Action (2009): Small-Scale Bioenergy Initiatives: Brief description and preliminary lessons on livelihood impacts from case studies in Asia, Latin America and Africa. Final re-port, prepared for PISCES and FAO by Practical Action Consulting. Jan. 2009. 135p. | *Practical Action (2009): Small-Scale Bioenergy Initiatives: Brief description and preliminary lessons on livelihood impacts from case studies in Asia, Latin America and Africa. Final re-port, prepared for PISCES and FAO by Practical Action Consulting. Jan. 2009. 135p. | ||

*Raninger, Bernhard (2009): Biomass-Waste Management - a contribution to a Low CO2-Circular Economy and an Environmental Sound Urban & Rural Development. Presentation to International Symposium on ‘City Group Development Model’, Changsha, Hunan, China, Dec. 3 to Dec. 4, 2009. | *Raninger, Bernhard (2009): Biomass-Waste Management - a contribution to a Low CO2-Circular Economy and an Environmental Sound Urban & Rural Development. Presentation to International Symposium on ‘City Group Development Model’, Changsha, Hunan, China, Dec. 3 to Dec. 4, 2009. | ||

| Line 401: | Line 289: | ||

<references /> | <references /> | ||

| + | <br/> | ||

| + | |||

| + | [[#toc|►Go to Top]]<br/> | ||

| + | |||

| + | [[Category:Germany]] | ||

| + | [[Category:China]] | ||

| + | [[Category:India]] | ||

| + | [[Category:Electricity]] | ||

| + | [[Category:Bangladesh]] | ||

| + | [[Category:Tanzania]] | ||

| + | [[Category:Kenya]] | ||

| + | [[Category:Biogas]] | ||

[[Category:Brazil]] | [[Category:Brazil]] | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Latest revision as of 13:42, 20 April 2016

Overview

Biogas technology, the generation of a combustible gas from anaerobic biomass digestion, is a well-known technology. There are already millions of biogas plants in operation throughout the world.Whereas using the gas for direct combustion in household stoves or gas lamps is common, producing electricity from biogas is still relatively rare in most developing countries. In Germany and other industrialised countries, power generation is the main purpose of biogas plants; conversion of biogas to electricity has become a standard technology.

This document will discuss the potentials, obstacles and necessary framework conditions for the utilisation of biogas for small and medium scale electricity generation in developing countries. This paper will not address the biogas production process in general but focus uniquely on electricity generation. The findings presented here are based mainly on available experience from GTZ-related pilot biogas power plants in different countries. They focus on more or less well-documented existing country cases even though little extensive documentation of practical long term operating experience is available. Besides the cases described here, we know of further examples from other GTZ projects (e.g. Bolivia, Tunisia and the Ivory Coast). However, there is not yet sufficient information concerning these to merit inclusion in this assessment.

The Technology

Biogas is the gas resulting from an anaerobic digestion process. A biogas plant can convert animal manure, green plants, waste from agro industry and slaughterhouses into combustible gas.

► For further information on the biogas production and fermentation process please refer to the Biogas Portal on energypedia.

Biogas can be used in similar ways as natural gas in gas stoves, lamps or as fuel for engines. It consists of 50-75% methane, 25-45% carbon dioxide, 2-8% water vapour and traces of O2 N2, NH3 H2 H2S. Compare this with natural gas, which contains 80 to 90% methane. The energy content of the gas depends mainly on its methane content. High methane content is therefore desirable. A certain carbon dioxide and water vapour content is unavoidable, but sulphur content must be minimised - particularly for use in engines.

The average calorific value of biogas is about 21-23.5 MJ/m³, so that 1 m³ of biogas corresponds to 0.5-0.6 l diesel fuel or about 6 kWh (FNR, 2009).

The biogas yield of a plant depends not only on the type of feedstock, but also on the plant design, fermentation temperature and retention time. Maize silage for example - a common feedstock in Germany - yields about 8 times more biogas per ton than cow manure. In Germany, cow manure and energy crops are the main forms of feedstock. About 2 live-stock units (corresponding to about 2 cows or 12 rearing pigs) plus 1 ha of maize and grass are expected to yield a constant output of about 2 kWel (48kWhel per day. In the South Asian context, ESMAP uses a typical specific input-output relation of about 14 kg of fresh cattle dung (the approximate production of one cow on one day) plus 0.06 l diesel fuel to produce 1kWh electricity.

Gas Production Figures If the daily amount of available dung (fresh weight) is known, gas production per day in warm tropical countries will approximately correspond to the following values:

- 1 kg cattle dung 40 liters biogas

- 1 kg buffalo dung 30 liter biogas

- 1 kg pig dung 60 liter biogas

- 1 kg chicken droppings 70 liter biogas

If the live weight of all animals whose dung is put into the biogas plant is known, the daily gas production will correspond approximately to the following values:

- cattle, buffalo and chicken: 1,5 liters biogas per day per 1 kg live weight

- pigs, humans: 30 liters biogas per day per 1 kg weight

For yield ranges and methane contents for 33 different substrates, please see Gas Yields and Methane Contents for Various Substrates.

Some Additional Facts

Each kilogram of biodegradable material yields 0.4 m3(400 liters) of gas.

Gas lights consume around 0.1m3(100 liters) of gas in one hour[1].

Conversion to Electricity

Theoretically, biogas can be converted directly into electricity by using a fuel cell. However, this process requires very clean gas and expensive fuel cells. Therefore, this option is still a matter for research and is not currently a practical option. The conversion of biogas to electric power by a generator set is much more practical. In contrast to natural gas, biogas is characterized by a high knock resistance and hence can be used in combustion motors with high compression rates.

Schematic of a biogas plant used for power generation :[2]

In most cases, biogas is used as fuel for combustion engines, which convert it to mechanical energy, powering an electric generator to produce electricity. The design of an electric generator is similar to the design of an electric motor. Most generators produce alternating AC electricity; they are therefore also called alternators or dynamos. Appropriate electric generators are available in virtually all countries and in all sizes. The technology is well known and maintenance is simple. In most cases, even universally available 3-phase electric motors can be converted into generators. Technologically far more challenging is the first stage of the generator set: the combustion engine using the biogas as fuel. In theory, biogas can be used as fuel in nearly all types of combustion engines, such as gas engines (Otto motor), diesel engines, gas turbines and Stirling motors etc.

Appropriate Combustion Engine

External Combustion Engines (EC Engines)

- Stirling Motors: In such motors, biogas is combusted externally, which in turn heats the stirling motor through a heat exchanger. The gas in the stirling motor hence expands and thereby moves the mechanism of the engine. The resulting work is used to generate electricity. Stirling motors have the advantage of being tolerant of fuel composition and quality. They are, however, relatively expensive and characterised by low efficiency. Their use is therefore limited to a number of very specific applications.

In most commercially run biogas power plants today, internal combustion motors have become the standard technology either as gas or diesel motors.

Internal Combustion Engines

- Diesel Engines operate on biogas only in dual fuel mode. To facilitate the ignition of the biogas, a small amount of ignition gas is injected together with the biogas. Modern pilot injection gas engines (“Zündstrahlmotoren”) need about 2% additional ignition oil. Almost every diesel engine can be converted into a pilot injection gas engine. These motors running in dual fuel mode have the advantage that they can also use gas with low heating value. But in that case, they consume a considerable amount of diesel. Up to engine sizes of about 200kW the pilot injection engines seem to have advantages against gas motors due to slightly higher efficiency (3-4% higher) and lower investment costs.

- Gas Motors with spark ignition (Otto system) can operate on biogas alone. In practice, a small amount of petrol (gasoline) is often used to start the engine. This technology is used for very small generator sets (~ 0.5-10 kW) as well as for large power plants. Especially in Germany, these engines have advantages as they do not need additional fossil fuels that would lead to lower feed-in tariffs according to the Renewable Energy Law (EEG).

- Gas Turbines are occasionally used as biogas engines especially in the US. They are very small and can meet the strict exhaust emissions requirements of the California Air Resources Board (CARB) for operation on landfill and digester gases. Small biogas turbines with power outputs of 30-75 kW are available in the market. However, they are rarely used for small-scale applications in developing countries. They are expensive and due to their spinning at very high speeds and the high operating temperatures, the design and manufacturing of gas turbines is a challenging issue from both the engineering and material point of view. Maintenance of such a turbine is very different from well-known maintenance of a truck engine and therefore requires specific skills.

Today, experience of the use of combustion motors to produce electricity from biogas is extensive; this can be regarded as a proven standard technology. Over 4,000 biogas plants with internal combustion motors are in operation in Germany.

However, it has taken lengthy and determined effort to make this technology as durable and reliable as it is today. Internal combustion motors have high requirements in terms of fuel quality. Harmful components - especially hydrogen sulphide (H2S)¬ - in the gas can shorten the lifetime of a motor considerably and cause serious damage.

This must be addressed in two ways :

- Production of clean biogas; and

- Use of appropriate and robust motors and components.

In theory, most engines originally intended for cars, trucks, ships or stationary use can run on biogas as fuel and are available almost everywhere within a power range between 10 and 500 kW. This holds true especially in the case of dual fuel use. Robust engines with a certain sulphur resistance are mostly free of non-ferrous metal (German: “Buntmetalle”), as these materials are highly prone to damage through sulphur-rich biogas.

Appropriate Gas Quality

For use in gas or diesel engines, the gas must fulfil certain requirements :

- The methane content should be as high as possible as this is the main combustible part of the gas;

- The water vapour and CO2 content should be as low as possible, mainly because they lead to a low calorific value of the gas;

- The sulphur content in particular, mainly in form of H2S, must be low, as it is converted to corrosion-causing acids by condensation and combustion.

The water vapour content can be reduced by condensation in the gas storage or on the way to the engine.

The reduction of the hydrogen sulphide (H2S) content in the biogas can be addressed via a range of technical methods. These can be classified as chemical, biological, or physical and divided into internal and external methods. Much experimentation has been carried out in the last two decades.

However, as complete elimination is unnecessary for use in robust engines, the following simple methods have generally established themselves as standard :

- An optimised steady fermentation process with continuous availability of appropriate feedstock is important to produce a gas of homogenous quality.

- The injection of a small amount of oxygen (air) into the headspace of the storage fermenter leads to oxidation of H2S by microorganisms and hence the elimination of a considerable part of the sulphur from the gaseous phase. This is the most frequently used method for desulphurisation. It is cheap and can eliminate up to 95% of the sulphur content in the biogas. However, the right proportioning of air still seems to be a challenge.

- Another option is external chemical treatment in a filter. The active material may be:

- 1.Iron-hydroxide: Fe (OH)2 + H2S -> FeS + 2 H2O. This process is reversible and the filter can be regenerated by adding oxygen. Adsorption material may be iron-rich soils, waste material from steel or aluminium production ;

- 2. Activated carbon: Certain companies provide activated carbon filters as a standard component in their gensets.

- 1.Iron-hydroxide: Fe (OH)2 + H2S -> FeS + 2 H2O. This process is reversible and the filter can be regenerated by adding oxygen. Adsorption material may be iron-rich soils, waste material from steel or aluminium production ;

Standard quality sulphur filters and filter material can be purchased on the market.

Energy requirement for heating the slurry

Energy required for heating the slurry in digester can be calculated by using the formulae below.

QT = m×c× (T2-T1) - equation 1

Where

QT is the total heat(Energy required for heating the slurry) and is expressed in Kilo-joule(Kj).

m is the mass of the slurry and is expressed in Kilo-gram(Kg).

c is the specific heat of slurry and is expressed in Kj/Kg°C.

T2 is the desired temperature of slurry and is expressed in °C.

T1 is the current temperature of slurry and is expressed in °C.

mass of slurry = volume of digester (V) × density of slurry(ρ) and is expressed in Kg. - equation 2

Where V is the volume of digester, expressed in m3 and ρ is the density of slurry, expressed in Kg/m3 .

Density of slurry (ρ) = density of water + density of cow dung - equation 3

Density of water is 1000 Kg/m3

Density of cow dung is 0.13 Kg/m3

Putting these values in equation 2

Density of slurry (ρ) = (1000+0.13) Kgm-3/2 ≈ 500 Kg/m3

From equation 1 we can get the mass of slurry by multiplying volume of digester with density of slurry calculated above.

Specific heat of slurry = {specific heat of water (4.2Kj/Kg°c) + specific heat of cow dung (2.8Kj/Kg°c)}/2

= 3.5Kg/Kg°c

Putting these values in equation one we can know the energy required for heating the slurry. The unit of energy is Kj(Kilo joule)[3].

Favorable Temperature for MethaneGeneration

The time period for which material can be kept in digester depends on the temperature of the digester. 50°c is needed for holding the material (slurry/organic waste) for 2 weeks while at 15°c temperature it can be prolonged for 2 months. Average is around 1 month. Gauge the Amount of material kept in the digester per day and then multiply by 30 to calculate the size of digester.

Anaerobic digestion occurs in the temperature range of 0°c to 65°c. The optimum temperature for methane production is 29°c to 35°c as in this range microbial activity takes place. Little gas production occurs below 16°c[1].

Examples

For examples of countries where electricity is generated from biogas, please see Generating Electricity from Biogas - Examples

Overall Appraisal

Energy Production Potential

Appropriate feedstock for electricity-generating biogas plants is available in adequate quantity in many countries. Small and medium-size biogas plants could provide a considerable contribution to national electricity generation in such countries. However, in comparison to industrialised countries, only very few small and medium sized biogas plants are used for electricity generation in Africa, Latin America and even Asia.

Electricity production from biogas can be a very efficient method for producing electricity from a renewable energy source. However, this applies only if the emerging heat from the power generator can be used in an economically and ecologically sound way. The average calorific value of biogas is about 21-23.5 MJ/m³, meaning that 1 m³ of biogas corresponds to 0.5-0.6 l diesel fuel or an energy content of about 6 kWh. However, due to conversion losses, 1m³ of biogas can be converted only to around 1.7 kWhel.

Bigger biogas plants are generally more cost-efficient than smaller ones. However, electricity generation from biogas is a technology appropriate even for relatively small applications in the range of 10-100kW.

Technical Aspects

There is mature, reliable high quality technology available on the global market. The techno-logical difficulties with which small biogas plants were confronted two decades ago have been resolved.

Different methods of desulphurisation have been successfully established and combustion motors tolerant to biogas that have proven their durability are available in the market. Sufficient know-how for planning and constructing reliable biogas power plants is also available.

Germany is one of the leading countries in terms of high quality components and know-how required for electricity-generating biogas plants. Know-how and technical components are also available in China, Thailand and other Asian countries as well as in Brazil. Electricity generation from biogas in Africa is still limited to a few pilot plants, with Kenya apparently being one of the centres of development and experience. For the construction of efficient and reliable biogas power plants, at least some technical core components must be imported from industrialised countries.

The electricity generation component of a biogas power plant does not require much more know-how and effort for maintenance than a normal generator set for fossil fuels with a well-functioning biogas fermentation process as an indispensable prerequisite.

Economic Aspects

Economically, electricity from biogas must compete with electricity generation from fossil fuels and other renewable energies such as hydro power. Supporting factors are:

- Rising prices of fossil fuels

- Low reliability of electricity provision from national grids with persistent risk of power cuts and vulnerability of hydro power to drought.

Inhibiting factors are:

- Relatively low prices of fossil fuels

- Need to buy high quality components from industrialised countries

- Unfavorable conditions for selling electricity

- Lack of awareness, capacity and experience preventing the economic operation of infrastructure components.

The economic feasibility of a biogas plant depends on the economic value of the entire range of plant outputs. These are:

- Electricity or mechanical power

- Biogas

- Heat, co-generated by the combustion engine

- The sanitation effect with COD and BOD (chemical and biological oxygen demand) reduction in the runoff of agro-industrial settings

- Slurry used as fertiliser.

Most of the commercially run biogas power plants in developing countries are of medium size and are installed in industrial contexts, primarily using organic waste material from agro-industrial production processes such as cow, pig and chicken manure, slaughterhouse waste, or residues from sisal and coffee processing.

Assessments of economic feasibility are contradictory or inconsistent. Many press releases and information from biogas power plant producers refer to payback periods of only 1.5 – 2.5 years. In such cases, the electricity from biogas plants can be compared to the price of electricity provided through the national grid or the price of bottled LPG.

However these figures are unrealistic, except for direct thermal energy use as for cooking energy, or in very few locations with extremely expensive diesel fuel.

More realistic figures seem to be those calculated by GTZ experts in Kenya for medium and large plants (>50kW):

They anticipate payback periods for plants under the DBFZ tariff scheme (~0.15 US$/kWh) of 6 years under very favourable conditions, and 9 years for unfavorable but still economically viable investments.

In spite of this theoretical profitability, recent examples from Africa show that electricity generation from biogas has not really captured the market as a ‘profitable’ technology. None of the plants described here could have been installed without international technical and financial support. This is due to the pilot status of the market and barriers such as a lack of awareness, experience, local capacity, upfront financing for project development (for own consumption projects, i.e. where there is no feed-in component) and the existence of policy barriers in cases where feed-in is required.

Many new studies come to the conclusion that biogas power plants are not commercially viable without subsidies or guaranteed high prices (~0,20US$) for the produced outputs. In Germany and other industrialised countries, only guaranteed feed-in tariffs have led to a breakthrough. Almost all well-known biogas power plants in developing countries depend on financial support from a third international party.

We have little experience to draw on concerning the possibility of using biogas power plants to cover the basic energy needs of the rural population. Most biogas power plants are connected to agro-industrial facilities and provide electricity only to very few immediate neighbours. However, calculations show that biogas could play a role in supplying isolated grids, where it represents a least cost option.

Necessary Framework Conditions

In Germany, power generation from biogas is only profitable due to grid connection and sup-porting feed-in tariffs. By contrast, power generation in most developing countries seems to be especially profitable in settings far away from the national grid and other energy sources, as the legal framework conditions and the lack of appropriate feed-in tariffs do not support feeding into the grid. However, there are the first signs of financial and legal support for feeding in electricity from biogas power plants in countries such as Brazil. Output-oriented support schemes (such as the German EEG) have proved to be more successful than investment-oriented financial support.

Direct subsidies and public financial contributions to installation costs have been crucial for the installation of some pilot plants. However, they have not provided incentives for proper and efficient operation. By contrast, the establishment of appropriate feed-in tariffs stimulates the construction of efficient plants and their continuous and efficient operation.

Through its projects and programmes, GTZ therefore recommends the establishment of guaranteed feed-in price schemes similar to the one in Germany.

However, besides price considerations, there remain many barriers to market penetration and development of the biogas sector:

- Lack of awareness of biogas opportunities

- High upfront costs for potential assessments and feasibility studies

- Lack of access to finance

- Lack of local capacity for project design, construction, operation and maintenance

- Legal framework conditions that complicate alternative energy production and commercialisation: for example, the right to sell electricity at local level has to be in place.

As long as the national framework conditions are not favourable, electricity generation from biogas will remain limited to a few pilot applications.

Further Information

- Small-scale Electricity Generation From Biomass Part-1.pdf (GIZ, 2010)

- Small-scale Electricity Generation From Biogas Part-2.pdf (GIZ, 2010)

- Small-scale Electricity Generation From Vegetable Oil Part-3.pdf (GIZ, 2010)

- Gas Yields and Methane Contents for Various Substrates

References

- Burkard, Thilo (2009): Project cases of Biogas-plants in Kenya. Presentation for Biogas Delegation Trip, Agritechnica 2009. Clearly presented detailed analysis of the technical and economic aspects of 5 biogas power plants in Kenya.

- COPEL DISTRIBUIÇÃO S A: VENCEDORES DA CHAMADA PÚBLICA, 2009, 2.p List of winners of a tender to sell electricity to the grid in the state of Paraná, Brazil.

- ESMAP (2005) Advancing Bioenergy for Sustainable Development - Guideline for Policy-makers and Investors. Report 300/05.

- Fachagentur Nachwachsende Rohstoffe e.V. (FNR) (2009): Biogas Basisdaten Deutschland – Stand: Oktober 2008. 7p. Very short but comprehensive overview of the biogas situation in Germany.

- Franz, Michael (2009): Zielmarktanalyse (ZMA). Der Markt für Biogas in Kenia. Studie des Projektentwicklungsprogramm Ostafrika im Rahmen der Exportinitiative Erneuerbare Ener-gien des BMWi. Description of the status in Kenya of biogas technology, available local know-how, market potential as well as legal and economic framework conditions. Detailed discussion of a biogas plant at a sisal plantation in Kilifi and lessons learned.

- Franz, Michael and Klaus v. Mitzlaff (2009): The Biogas Market in Kenya - Status Quo and Potentials. Presentation for Combined Biogas Business and Study Trip from Kenya and Tan-zania, to Hannover, November 13, 2009. German Technical Cooperation (GTZ).

- Grope, Johann (2009): Optimierung eines Biogasanlagenmodells unter Berücksichtigung der spezifischen Rahmenbedingungen Südbrasiliens. Study of DBFZ on behalf of GTZ. 84 p. Describes framework conditions of biogas activities in southern Brazil and current technol-ogy. Develops proposals for optimised biogas technology.

- GTZ (2010): Agro-Industrial Biogas in Kenya – Potentials, Estimates for Tariffs, Policy and Business Recommendations. Study of Deutsches Biomasse Forschungs Zentrum (DBFZ) on behalf of GTZ, Renewable Energy Project Development Programme East Africa. 69p. This comprehensive study documents the high potential for electricity production in Kenya from municipal solid waste and agro-industrial production, especially sisal and coffee produc-tion. About 16% of actual electricity consumption could be covered by electricity from biogas. The costs of different plant types and sizes are calculated. Grid connection and appropriate feed-in-tariffs are identified as the main prerequisites for commercial investment in this sector. The proposed basic feed-in-tariffs are within a price range similar to current levels in Germany (0.10 – 0.2 US$ /kWh el.

- GTZ-PURE (2005): Feasibility Study on Biogas from Poultry Droppings in Bangladesh, Pre-pared By Bangladesh Centre for Advanced Studies (BCAS) in collaboration with Energy Consulting Services (ECS), December 28, 2005. Surveys biogas activities in Bangladesh and discusses briefly the possibilities and profitability of electricity generation in Bangladesh.

- Mitzlaff, Klaus von (1988): Engines for Biogas. GTZ-GATE /Viehweg. 164p. Documents early approaches of GTZ towards electricity generation from biogas. Describes the essential basics of internal combustion engines and properties of biogas as a fuel for internal combustion engines. Suggests parameters for planning a biogas engine system, with an overview of commercially available systems.

- Muchel, H. and H. Zimmermann (1985): Purification of Biogas. GTZ: Aus der Arbeit von GATE, 33p. Viehweg Documents early GTZ approaches towards electricity generation from biogas. Describes the properties and origins of hydrogen sulphide in biogas plants, its effects on the gas-utilisation equipment and methods for removing H2S from biogas.

- Practical Action (2009): Small-Scale Bioenergy Initiatives: Brief description and preliminary lessons on livelihood impacts from case studies in Asia, Latin America and Africa. Final re-port, prepared for PISCES and FAO by Practical Action Consulting. Jan. 2009. 135p.

- Raninger, Bernhard (2009): Biomass-Waste Management - a contribution to a Low CO2-Circular Economy and an Environmental Sound Urban & Rural Development. Presentation to International Symposium on ‘City Group Development Model’, Changsha, Hunan, China, Dec. 3 to Dec. 4, 2009.

- Tomowsky, Arno (2006): GTZ Biogas-experience in Africa. Presentation held at international Workshop on the Biogas Sanitation Initiative for Africa’. Amsterdam, Oct. 2006. Unpublished. A brief summary of lessons learned by GTZ over more than 20 years of biogas activity in Africa.