Difference between revisions of "Biogas Recovery"

***** (***** | *****) m |

***** (***** | *****) m |

||

| Line 1: | Line 1: | ||

| − | + | [[Portal:Biogas|►Back to Biogas Portal]] | |

= Overview = | = Overview = | ||

Revision as of 09:35, 8 April 2015

Overview

Digester Design

The links between digester design and the fermentation process are close. Substrate fermentation can be achieved by processes with full intermixing (stirredtank reactors), plug-flow processes or special processes.

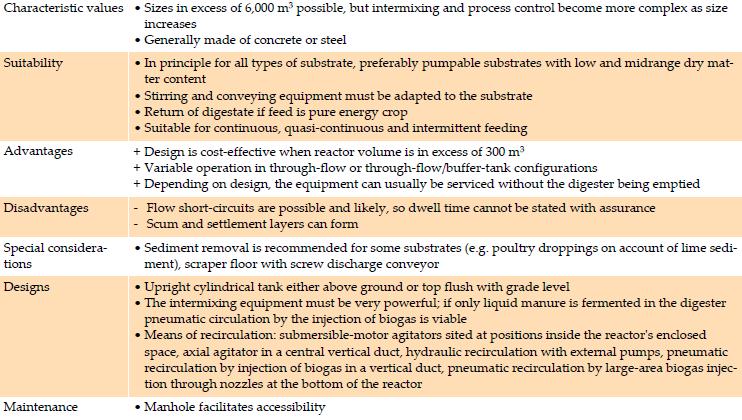

Process with Full Intermixing (Stirred-Tank Reactors)

Cylindrical, Upright Stirred-Tank Reactors

Cylindrical, upright stirred-tank reactors are used primarily in agricultural plants for biogas production. At this time (2009), this type accounts for about 90% of the installed base. The digester consists of a tank with concrete bottom and sides made of steel or reinforced concrete. The tank can be sited either completely or partly sub-grade, or above ground. The cover on top of the tank is gastight, though the design specifics can vary depending on requirements and mode of construction. Concrete covers and plastic sheeting are the most common. The substrate is stirred by agitators sited in or beside the reactor.

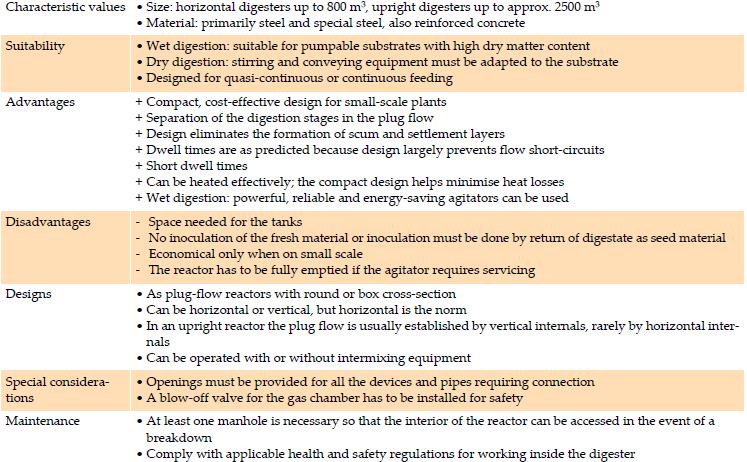

Plug-Flow Process

Biogas plants with plug flow – the wet-digestion version is also known as a tank through-flow arrangement – use the expeller effect of fresh substrate infeed to create a plug flow through a digester of round or box section. Mixing transverse to the direction of flow is usually achieved by paddle shafts or specially designed baffles.

Broadly speaking, there are horizontal and upright plug-flow digesters. Virtually all the digesters used in agricultural plants are of the horizontal type. At this time, upright digesters operating on the plug-flow principle are rare and they are not considered in this study.

The digesters are usually horizontal steel tanks, factory-built and then delivered to site. This necessitates transport of the digesters to site, which is possible only up to a certain size of tank. Possible uses are as main digesters for small-scale plants or as preliminary digesters for larger plants with stirred-tank reactors (round tanks). Horizontal digesters arranged in batteries for parallel operation can increase throughput. The plug-flow principle reduces the possibility of unintentionally discharging undigested substrate from the reactor, and dwell time can be maintained very reliably for all the material[1].

Batch Processes

Batch processes use mobile containers or stationary box-type digesters. These processes have achieved commercial maturity in recent years and are established on the market. Reinforced-concrete box digesters are particularly common for fermenting bulk substrates such as maize and grass silage. In the batch process the digesters are filled with biomass and sealed airtight. The microorganisms in the seed substrate mixed through the fresh substrate to inoculate it heat the substrate in the first phase, in

which air is fed into the digester. A composting process associated with the release of heat takes place. When the biomass reaches operating temperature, the supply of air is shut off. Once the supply of entrained oxygen has been consumed, microorganisms become active and convert the biomass into biogas as in wet digestion. The biogas is trapped in the gas headers connected to the digester and piped off for energy extraction [2].

Batteries with between 2 and 8 boxes have proved practical, and the most common arrangement is a 4-box battery. This arrangement suffices to achieve quasi-continuous gas production. A digester battery should also have a leachate tank to catch the seepage liquid from the reactors so that it too can be converted into biogas. The leachate is also sprinkled over the fermentation mass in the reactor to inoculate the material.

Structure of Digester

Digesters consist of the digestion tank as such, which is thermally insulated, plus a heating system, mixer systems and discharge systems for sediments and the spent substrate.

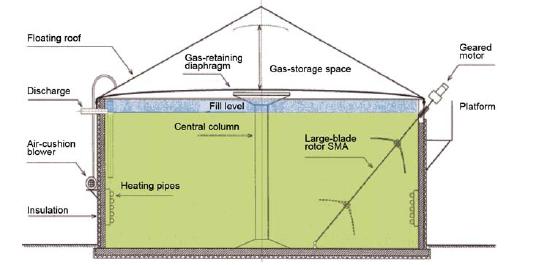

Tank Design

Digester tanks are made of steel, special steel, or reinforced concrete. Reinforced concrete is rendered sufficiently gastight

by water saturation. The moisture required for this purpose is contained in the substrate and the biogas. The digesters are cast on site using cast-in-place (CIP) concrete or assembled from prefabricated parts or precastings. Concrete tanks can be sited partly or entirely sub-grade, if the subsoil conditions are suitable.The tank cover can be made of concrete and the concrete tops of sub-grade tanks can be rated to carry vehicular traffic, with the biogas stored separately in an external gas storage tank. Digesters also designed for gas storage have gastight tops made of heavy-gauge plastic sheeting. As of a certain tank size a central column is necessary to support the weight of a concrete top slab. If the work is not to professional standard there is a risk of the top slab cracking. In the past cracking, leaks and concrete corrosion were not uncommon, and in extreme cases digesters affected by these problems have had to be demolished.

The use of high-grade concrete and professional planning of the digesters are essential to avoid problems of this nature. Tanks made of steel and special steel are set on concrete foundations, to which they are connected. Coiled sheet metal strip and welded or bolted steel plates are used. The bolted joins must be adequately sealed. Steel digesters are always of above-ground

design. In most instances the roof structure is utilised for gas storage and gastight heavy-gauge plastic sheeting is used.

Mixing and Stirring

There are several reasons why it is important to ensure that the contents of the digester are thoroughly mixed:

- inoculation of fresh substrate by contact with seed material in the form of biologically active digester fluid;

- uniform distribution of heat and nutrients inside the digester;

- prevention of settlement and scum layers, and the breaking up of these layers if they have the opportunity to form;

- good degassing of the biogas from the substrate.

The fermenting substrate is minimally mixed by the introduction of fresh substrate, by thermal convective flows and by gas bubbles rising through the fermenting mass. This passive mixing, however, is not enough, so the mixing process has to be actively assisted.

Mixing can be done mechanically by systems such as agitators inside the reactor, hydraulically by pumps sited in close proximity outside the digester, or pneumatically by blowing biogas into the tank. The last two of these methods are of lesser significance.

In Germany, mechanical mixers or agitators are used in about 85 to 90% of plants[2].

Mechanical Mixing

The substrate is mechanically mixed by agitators. A distinction can be drawn between shear-action and kneading agitators. Viscosity and dry matter content of the medium are the definitive factors regarding the type of agitator used. Combinations of the two are not uncommon. They interwork for better effect. The agitators operate continuously or intermittently. Practice has shown that the stirring intervals have to be optimised empirically on a case-to-case basis to suit the specifics of the biogas plant, which include

Submersible-Motor Agitators (SMA)

Submersible-motor agitators (SMA) are frequently used in upright digesters operating on the stirredtank principle. A distinction is drawn between highspeed SMAs with two- or three-blade propellers and low-speed SMAs with two large rotor blades. These shear-action agitators can be driven by gearless and geared electric motors. They are completely submerged in the substrate, so their housings have to be jacketed for pressure-watertightness and corrosion resistance, and in this way they are cooled by the surrounding medium.

Alternative siting for the motor of a shear-based long-shaft agitator is at the end of an agitator shaft slanting through the digester. The motor is outside the digester, with the shaft passing through a gastight gland in the digester top slab or at a point in the side wall close to the top in the case of a reactor with plastic- sheeting cover. The shafts can be supported by extra bearers on the base of the digester and fitted with one or more small-diameter propellers or largediameter agitators.

Axial Agitators

Axial agitators are another means of achieving shearbased mechanical mixing of the substrate inside the digester. They are commonplace in biogas plants in Denmark and operate continuously. They rotate on a shaft usually dropped from the centre of the digester roof. The input speed from the drive motor, mounted outside the digester, is geared down to no more than a few revolutions

per minute. These agitators are designed to create a constant flow inside the digester, the direction of circulation being downward close to the centre and upward at the sides.

Paddle (or paddle-wheel) Agitators

Paddle (or paddle-wheel) agitators are low-speed, long-shaft stirrers. The stirring effect is achieved not by shear action but by kneading the substrate, and good mixing is claimed for substrates with a very high dry matter content. These agitators are used in upright stirred-tank reactors and in horizontal digesters of plug-flow design. In horizontal digesters the agitator shaft is of necessity horizontal. This shaft carries the paddles that stir the substrate. The horizontal plug flow is maintained by batched infeed of fresh material into the digester. The agitators often have heating coils integrated into the shafts and the stirrer arms to heat the substrate. The agitator operates for short periods at low speed several times a day. In upright stirred-tank digesters the horizontal agitator shaft is carried on a steel supporting structure. It is not possible to change the orientation of the shaft. Good intermixing inside the digester is achieved with the aid of a corresponding, shear-based agitator.

Pneumatic Mixing

Pneumatic mixing of substrate is offered by a few manufacturers, but it is not of major significance in agricultural biogas plants.It involves blowing biogas into the digester through nozzles at floor level. The gas bubbling up through the substrate creates vertical movement, mixing the substrate.

The advantage of these systems is that the mechanical components necessary for mixing (pumps and compressors) are sited outside the digester and are therefore subject to no more than low rates of wear. These techniques are not suitable for breaking up scum, so they can be used only for runny substrates with no more than slight tendency to scumming.

Hydraulic Mixing

When it is mixed hydraulically, substrate is forced into the digester by pumps and horizontally or horizontally and vertically swivelling agitator nozzles. The substrate has to be extracted and returned in such a way that the contents of the digester are stirred as thoroughly as possible. Hydraulically mixed systems also have the advantage of siting the mechanical components necessary.

Heating

Thermal Insulation

Thermal insulation of the digester require additional thermal insulation in order to reduce heat loss. Commercially available materials can be used for thermal insulation, although in terms of their properties the materials used should be selected to suit the location (close proximity to the ground, etc.) Trapezoidal metal sheeting or wood panelling is used to protect the insulating material against the effects of the weather.

Digester Heating

The temperature inside the digester has to be uniform, in order to ensure an optimum digestion process. In this respect it is not so much maintaining the specified temperature to within one tenth of a degree that is important as keeping temperature fluctuations within tight limits. This applies to temperature fluctuations over time and also to temperature imbalance in different parts of the digester[1]. Severe fluctuations and excursions above or below certain temperature levels can impede the digestion process or even bring it to a complete standstill under worst-case conditions.

The causes of temperature fluctuations are many and varied:

- infeed of fresh substrate;

- temperature stratification or temperature zone formation on account of insufficient thermal insulation, ineffective or incorrectly planned heating,

- insufficient mixing;

- positioning of the heating elements;

- extreme ambient temperatures in summer and winter;

- equipment failures.

The substrate has to be heated in order to achieve the necessary process temperatures and to compensate for heat losses; this can be done by heat exchangers or heaters either installed externally or integrated into the digester.[2] Integrated heaters heat the substrate inside the digester.

External heat exchangers heat the substrate before it is fed into the digester, so the substrate is preheated before entering the digester. This helps avoid temperature fluctuations associated with substrate infeed. When external heat exchangers are used, either substrate recirculation through the heat exchanger must be continuous or an extra internal heater inside the digester is indispensable, in order to maintain a constant temperature inside the digester.

To achieve the optimum biogas yield, the anaerobic digestion needs constant environmental conditions, preferably close to the process optimum. The digester temperature is of prime importance. In temperate areas, a heating system and an insulation of the digester is necessary. Hence, the needed temperature for digestion can be reached and a loss of energy by transmission is compensated.

Because of the high costs for material and installation of a heating system, a low-cost biogas plant, as needed in developing countries, can only be build without heating. To boost the biogas yield for those plants, the building of a bigger digester to increase the retention time would be cheaper. A bigger digester reduces the required maintenance, while a heating system, increases maintenance requirements. A bigger digester serves also as a buffer for sediments, pH-variations and gas storage. For example, a fixed dome plant sized 50% bigger, is only 10% more expensive.

The mean surrounding temperature and it's seasonal variations are very important. Biogas plants without heating system work, therefore, only in warmer regions for the whole year. In regions with extreme temperature variations, for instance in Turkey (hot summer, cold winter), the biogas plant should be built under the stable. Hence the biogas yield would be lower in summer, but constant over the year and at the end higher. Before implementation, at least an approximated average temperature profile and expected extremes over the year should be available for the site.

A biogas plant with heating system and co-generation can be operated with process energy. Nevertheless the dimensioning of such a heating system is difficult, as the substrate, which has to be heated up, is not homogenous.A guiding figure for a digester with a hydraulic retention time of 20 days is 270 W/m3 digester volume. The increasing of the hydraulic retention time makes it possible to reduce the heating power per volume. With a hydraulic retention time of 40 days the digester needs only 150 W/m3.

Following figures are for heating systems with a heating water temperature difference of 20 K:

| hydr. retention time |

40 days | 30 days | 20 days |

|---|---|---|---|

| temperature difference |

20 K | 20 K | 20 K |

| heating power | 150 kW/m3 | 210 kW/m3 | 270 kW/m3 |

A heating system located in the digester produces a thermal circulation, which is, especially for non-agitated digesters, very important.

An indirect energy transfer by heat exchanger is most common. Exceptions are steam injection, liquefying of solid manure with heated water and the heating by pre-aeration.

Internal and External Heating Systems

External heating systems have a forced flow on both sides. Due to the turbulent flow patterns of both media, a very good heat transportation can be reached. Therefore, the surface of the heat exchanger can be comparatively small. Nevertheless those systems cannot be recommended for non-agitated digesters. The proper dimensions of an internal heating system seems to be more difficult because of the different currents due to pumping, agitation, thermo-convection adn the inflow of bio-mass.

Under-floor heating systems have been very popular, as they have no disturbing parts in the digester itself. Due to sedimentation and the resulting worsening of heat transportation into the digester, under-floor heating is no longer recommended. With the growth of digester volumes and the need of bigger heating systems, it is also more difficult to build under-floor heating big enough to provide the necessary heat.

Heating coils installed at the inner wall of the digester are a rather new practice. Heating coils made out of steel are much more expensive than heating coils out of plastic material (PE). Materials developed during the last years make such a system more stable while not increasing the costs of the heating system.

Another option is to construct two digesters connected in series, the first heated, the second unheated. The first digester can be used as sedimentation tank , in which the substrate is heated up. The second digester is well isolated to reduce loss of heat.

Further Information

References

- ↑ 1.0 1.1 Jäkel, K.: Management document 'Landwirtschaftliche Biogaserzeugung und -verwertung', Sächsische Landesanstalt für Landwirtschaft, 1998/2002

- ↑ 2.0 2.1 2.2 Schulz, H.; Eder, B.: Biogas-Praxis: Grundlagen, Planung, Anlagenbau, Beispiel, 2nd revised edition, Ökobuch Verlag, Staufen bei Freiburg, 1996, 2001, 2006