Difference between revisions of "Cogeneration"

***** (***** | *****) |

***** (***** | *****) |

||

| Line 29: | Line 29: | ||

<br/> | <br/> | ||

| + | |||

= Technologies<br/> = | = Technologies<br/> = | ||

| Line 43: | Line 44: | ||

<br/> | <br/> | ||

| + | |||

= Efficiency<br/> = | = Efficiency<br/> = | ||

Revision as of 13:29, 22 June 2016

Overview

Cogeneration or combined heat and power (CHP) is the use of a heat engine to simultaneously generate both electricity and useful heat.

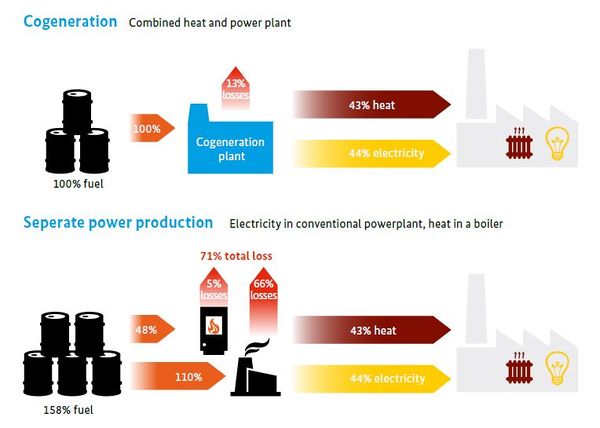

Thermal power plants and heat engines in general, do not convert all of the available primary energy into electricity. In most heat engines, more than 50% of the primary energy is wasted as excess heat. By capturing the excess heat, CHP uses heat that would be wasted in a conventional power plant, potentially reaching an efficiency of up to 70%, compared with at most 40% for the conventional plants. This means that less fuel needs to be consumed to produce the same amount of useful energy. As well, less pollution is produced for a given economic benefit.

Applications

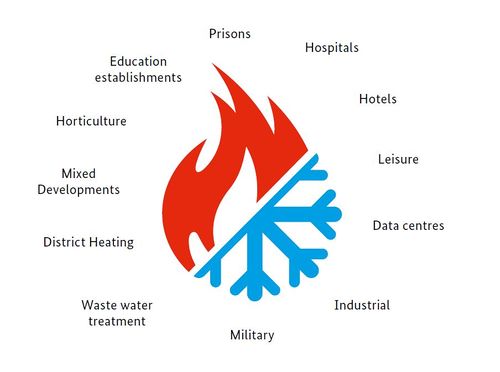

Cogeneration technology is applicable in a wide range of sector segments as shown in the figure below. For instance, cogeneration plants are commonly found in central heating systems for hospitals, hotels and industrial plants with large heating needs adding to their electricity demand.

Another field of application with high potential is the use within the powering agriculture context: By employing cogeneration technology, food processing plants can utilize biomass by-products to generate heat and power, which in return can be used for the production process.

Obviously, cogeneneration plants are ideally suited for on-site generation and thus can be an important building block for the establishment of an energy system based on distributed generation. System capacities depend on the field of application, but usually range between a few kilowatts electric (kWel) up to 20 megawatts electric (MWel) when cogeneration technology is used in projects related to international development cooperation.

Technologies

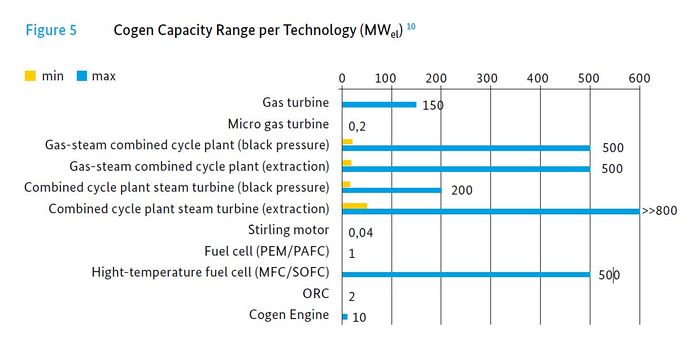

Cogen encompasses a wide range of proven technologies. Combined heat and power technologies can be divided into small scale applications, starting from some 1 kWelengines that are usually focused on thermal energy supply, up to large-scale powerplants mainly focused on electric power production. These types of cogen plants canbe differentiated by technology and feasible capacity, as illustrated below.

Cogeneration plants are fired by biomass or industrial and municipal waste.

Efficiency

CHP is most efficient when the heat can be used on site or very close to it. Overall efficiency is reduced when the heat must be transported over longer distances. This requires heavily insulated pipes, which are expensive and inefficient; whereas electricity can be transmitted along a comparatively simple wire, and over much longer distances for the same energy loss.

Technology

There are two categories of cogeneration plants:

- Topping cycle - produces electricity first, and then the exhausted steam is used for heating. The hot water from condensed steam is well-suited for space and water heating.

- Bottoming cycle - produces high heats for an industrial process, and then a waste heat recovery boiler feeds an electrical plant. Bottoming cycle plants are only used when the industrial process requires very high temperatures, such as furnaces for glass and metal manufacturing hence rare.

Common CHP plant types are:

- Gas turbine CHP plants using the waste heat in the flue gas of gas turbines

- Combined cycle power plants adapted for CHP

- Steam turbine CHP plants that use the heating system as the steam condenser for the steam turbine.

Further Information

- Guide: Cogeneration & Trigeneration - How to produce energy efficiently (GIZ, 2016)

- wikipedia.org: Cogeneration

- cogen.org: what is CHP

- localpower.org