Cooking with Agricultural Residues

Introduction

In general, any material that a plant has generated consists of hydrocarbons and can be used as a fuel. But not all of this biomass comes in the form of ‘firewood,’ which we picture as any wood in the form of logs or sticks that is collected or cut from trees or shrubs. Some plant-materials have a similar composition than wood, but are small in size and not stick-shaped. For instance, forest residues, wood-chips, saw-dust, nutshells, pods, are all such plant materials. On the other hand, there are plant materials which have a different composition than wood. They have less lignin, a higher content of silica, and often other components like starch, fats, or proteins. Examples for these materials are bark, softer leaves, straw, grass, agricultural residues (stalks, husks) or plant products such as grains, seeds, nuts etc.

What are Agricultural Residues?

Agricultural residues are generated in large volumes after each harvest season and are often discarded as waste. Solid crop residues are the largest source of non-timber biomass fuel: straw, stems, stalks, leaves, husks, shells, peels, lint, stones, pulp, stubble, and the like from all sorts of crops. The largest amounts are derived from annual plants such as cereals (e.g. rice, wheat, maize/corn, sorghum, barley, millet), cotton and legumes (e.g. pigeon peas, bean, soy, groundnut) complemented by woody pruning from perennial plantations like coffee, tea, cacao, olive, fruits (e.g. banana, mango, coco, cashew). In the developing countries most agricultural residues and residues from processing of agricultural products are used as fuels in their natural state with limited pre-treatment such as drying and cutting; compacting is rather rare. Compared to wood-fuels, crop residues typically have a high ash content, lower energy density and shorter burning time.

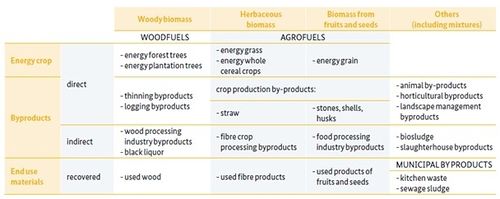

The list of usable feedstock is nearly endless and depends on what is readily available in a certain location. The following table originally from FAO gives some ideas of where to look for appropriate feedstock.

Cooking with Agricultural Residues

Compared to woodfuels, crop residues typically have a high content of volatile matter and ash, lower density and lower energy values. Conventional ‘stoves’ are mostly designed to burn firewood or charcoal. Micro-gasifiers are a good option to use agricultural residues, mostly in a densified way, because they are able to burn small energy carriers in a very efficient way.

For the use of any solid biomass as a fuel for cooking in a normal combustion process, they should adhere to the following characteristics:

- The biomass should be “dry”, which means moisture content preferably below 20%. Any water in the fuel evaporates at the expense of heat availability during actual cooking. High moisture content also makes the stove operation less stable.

- The biomass should be “energy-dense”. If the fuel has low energy density, the same cooking tasks requires the burning of much higher volumes as compared to firewood. This may result in inconveniences for the user. He/she either has to accept a very big stove (batch feed) or a very cumbersome cooking process (frequent refueling continuous feed stove).

There are also some non-technical factors to be considered in the choices of biomass fuels:

- The (production of the) fuel should not compete with resources necessary for food production (like land, water, labor, fertilizer etc.) and food itself or a higher value use as fuel, such as a building material.

- Fast growing fuels should not negatively impact the biodiversity of the locality.

- The supply of any biomass should be sustainably managed, so that it can be a truly renewable energy source.

- Any fuel must be economically viable in the long-run.

The direct use of unprocessed solid biomass waste for cooking in woodfuel stoves has some advantages and disadvantages:[1]

Advantages

- Agricultural residues are often available free of charge to poor rural families.

- Controlled burning in a stove is cleaner and more environmentally friendly than uncontrolled burning.

- The ash can be taken back to the field and used as plant nutrient.

- Lower impact on women’s time for harvesting.

- Agricultural wastes are often easier to light than wood and charcoal.

Disadvantages:

- When burnt in open fires or traditional improved stoves, residues can cause extreme air pollution. But they do burn well in gasifier stoves.

- They are often bulky and have to be carried to the homes. Storage requires more space inside a house or shelter.

- The seasonal availability of crop residues can limit their continuous use.

- The burning time is often shorter.

Densification Options for Agricultural Residues

Many non-timber solid biomass materials are of low energy-density. Their direct usage is inconvenient as compared to stick-wood. One option to improve their properties for cooking is densification.

The term ‘briquette’ is commonly used for a sizeable ‘chunk’ of densified product of any shape and compaction level where the smallest side-length is above 25 mm in size. Briquettes are normally pressed into a mold that grants the briquette its final shape. For more information on biomass briquettes, their production and marketing please see the article “Biomass Briquettes – Production and Marketing” on energypedia.

The term ‘pellet’ is used for short, roundish sticks of 6-25 mm in diameter as a product of a high-pressure agglomeration process. Pellets are shaped by pressing dry biomass at very high pressure through a die with many round holes (like an oversized spaghetti maker).

Compacted and densified fuel, also known as processed fuel, has several advantages:[1]

- It has a higher heating value per volume (more carbon per volume).

- It reduces transport costs (more fuel, less water and air to be transported).

- It has more predictable performance in a stove due to more uniform size, shape, density etc.

- It is often easier and cleaner to handle (less dust, easier packing etc.).

- It is more convenient as it comes in the right size ready-to-use (no chopping required).

- It has better storability (less moisture absorption, less mould, less spontaneous fires through self-ignition, less insect-infestation than natural fuel).

- It can be a solution to waste management problems.

- It adds value to low-value residues, often creating employment in the process.

In order to gain processed, densified fuel, special equipment and labor are required, which need to be paid for. This increases the cost of the fuel. Densified biomass is likely to be viable only where[1]

- Fuel is already a commodity (like in many urban areas).

- Households have purchasing power.

- There is a large source of un-used ‘wasted’ residual biomass (which does not compete with the use as manure or compost).

- There is a feasible link between the source of biomass and the market of the densified fuel (relation of distance, transport costs and the value of the fuel).

- Fuel densification can be run as an income generating business.

- There is electricity so that larger scale operations can be done. Without electricity, only manual production at a small scale is feasible.

The important steps for fuel processing are drying, sizing and densification. Unfavorable burning properties of native residues used in conventional burners can be overcome by the use of micro-gasifier that are best equipped to handle this type of fuel. The table below provides some guidance on feedstock and its potential processing requirements.

Densification Methods

Various binding and compaction methods are used to ‘glue’ the loose biomass material together to form a compact dense shape, which does not immediately fall apart during drying, handling and use as fuel. The intended use of the product and the envisaged scale of operation determine size, shape, and the needed degree of compaction of the product.

The processes of biomass densification can be clustered into three main groups:[1]

1. Wet, Ambient Temperature, Low Pressure (10-15 bar) Process

An added binder is optional; binding is carried out through the random rearrangement of softened and detached natural fibers. It can be done with a wide variety of agricultural residues e.g. sawdust, rice husk, bagasse, coffee/peanut shells. Additionally, charcoal dust and crumbs can be added as part of the matrix as long as the fibers are able to encapsulate the fuel material into a tight, non-elastic mass when compressed. Emphasis is on the careful blending and pre-preparation of feedstock for pliability, combustibility and other characteristics. Densification and shaping can be carried out using one’s hand to squeeze the material into shape, or simply human force to press the material into a mold. Over 25 designs for hand-operated or mechanized versions of presses are in use, based on various methods for creating pressure: levers, hydraulic jacks, screw platens, treadle/peddles, etc. Equipment can typically be purchased in the range of 50 to 750 USD. The achievable fuel density is normally low, ranging from 0.3 to 0.5 kg/l. Please see for some examples chapter 3 of “Micro-gasification: cooking with gas from dry biomass”.

2. Moist-dry, Ambient Temperature, Low-medium Pressure (10-50 bars) Process

This process involves some form of binder (clay, starch, banana peel paste, waxes, glues, molasses, etc.) with temperatures still near ambient but with water being either minimal or absent. The relatively dry feedstock mix allows for the use of loose augurs (‘screws’), rams or pillow compression cylinders and the above-mentioned ‘wet process’ presses. Over 10 designs for hand-driven or mechanized presses using various augurs and rams are in use. Investment costs for equipment can start at 50 USD for hand-driven devices. Achievable fuel density ranges from 0.3 to 0.7 kg/l. The product range includes waxed logs and briquettes from char dust, which are finding increased acceptance in developing countries. Please see for some examples chapter 3 of “Micro-gasification: cooking with gas from dry biomass”.

3. Dry, High-pressure Process

These densification processes require pressure of about 400 to 600 bars and drying equipment to assure moisture content of below 20% of the feedstock. Compression by a ram or augur often requires added heating jackets which raise the barrel/cylinder temperatures up to around 200° C. This combination of pressure and temperature effectively scorches the exterior wall of the resulting log, and it tends to melt the lignin of the biomass to accomplish binding. The process requires an assured supply of feedstock of a known type, grade and moisture content. Investment costs for these industrialized machines start at 3,000 USD, with hardly any upper limit.

Carbonized Biomass Briquettes

Another processing method is the carbonization of raw biomass and the shaping into briquettes similar to conventional charcoal lumps. There are two paths that lead there:

- Carbonizing the biomass, milling up the char, adding a binder and shaping the briquette. This is also a good way to recycle the fine residues that are left when handling conventional charcoal char or the char created in pyrolytic TLUD gasifier-cookstoves as a byproduct of cooking (link to the gasifier manual). Binders can be any porridge from a starchy substance (flour, banana peels, etc.) or clay.

- Making a briquette first and then carbonize the entire briquette in a kiln.

A comprehensive overview of densification equipment and purchasing addresses is provided by Christa Roth (2014). The availability of required inputs such as water, electricity, capital, labor, and so on is critical for the success of any densification project. Generally, product quality increases with rising compaction pressure, which entails:

- Higher temperatures: Causing the lignin contained in the feedstock itself to ‘melt’, acting like wax as the sole binder; additional binders may be unnecessary.

- Less water needed for the feedstock preparation: Thus, less drying time and space are needed afterwards; lower moisture content of product, meaning higher heating values.

- Rising electricity requirements (can be well in excess of 100 kW for large equipment)

- Higher costs for investment and operation: capital investment for machinery with able to produce more than 1 ton of fuel grade pellets per hour typically exceeds 100,000 EUR.

- Decreasing labor intensity which reduces job creation in the production phase, with the potential for more local job creation on the fuel distribution chain.

Further Information

- Biomass Briquettes – Production and Marketing, article on energypedia

- Gasifier Stoves, article on energypedia

- Water and Energy for Food (WE4F) portal on energypedia

- Micro-gasification: Cooking with gas from dry biomass by Roth, C. et al. / GIZ Sector Programme “Basic Energy Services” (HERA) (2014): Chapter 3 presents various fuel processing options for un-carbonised, processed, low-moisture biomass fuels.

- Evidence Based Assessment of the Sustainability and Replicability of Integrated Food-Energy Systems by FAO (2014).

- The Forest-Agriculture interface: a zone for enhanced productivity by FAO (2012). This article by Anne Bogdanski and Christa Roth on integrated food-energy systems also shows the example of Malawi.

- Alternative Charcoal Tool (ACT) developed by Biomass Technology Group BV (BTG) on behalf of NL Agency (2013). The Alternative Charcoal Tool provides insights in the potential of charcoal production from alternative feedstocks on a regional or country level for small and medium enterprises, policy makers as well as NGOs in developing countries. Examples are charcoal dust, harvest residues like cotton stalks, processing residues and invasive species.

- Solid biomass fuels for cooking - beyond firewood and charcoal. By Frank Helbig & Christa Roth, GIZ 2017. This publication highlights the most common forms of solid biomass compounds, the options regarding their production, and how they can be used for daily cooking. It also presents cook stove technologies that efficiently transfer the energy contained in solid biomass fuels to pots and pans. A selection of projects from international colleagues illustrate marketing approaches and the practical implications of utilizing solid biomass beyond firewood and charcoal for cooking.

- Cooking Fuels, an article on energypedia

References

This article was originally published by GIZ HERA. It is basically based on experiences, lessons learned and information gathered by GIZ cook stove projects. You can find more information about the authors and experts of the original “Cooking Energy Compendium” in the Imprint.

- ↑ 1.0 1.1 1.2 1.3 Roth, C. et al. / GIZ Sector Programme “Basic Energy Services” (HERA) (2014): Micro-gasification: Cooking with gas from dry biomass. https://energypedia.info/images/0/05/Micro_Gasification_2.0_Cooking_with_gas_from_dry_biomass.pdf