Digestate Storage and Retreatment

Overview

Properties, Nutrients and Value-giving Substances:

The properties and constituents of digestate are determined essentially by the materials used for anaerobic digestion as well as by the digestion process itself. Agricultural biogas plants in Germany use mainly cattle and pig slurry, cattle and pig dung and poultry manure from poultry fattening. Less common is the use of farm fertiliser from laying hen farming, on account of the high concentrations of ammonium and residues from the supplementary feeding of calcium.

Owing to the rules on remuneration laid down in the Renewable Energy Sources Act (EEG), only few plant operators continue to focus exclusively on the use of energy crops.

Nevertheless, mention should be made of the long-known and valued effects of the digestion of farm fertiliser on the properties of digestate:

- reduced odour emissions through degradation of volatile organic compounds;

- extensive degradation of short-chain organic acids and consequent minimisation of the risk of leaf burn;

- improved rheological (flow) properties and consequent reduction of leaf fouling on fodder plants and simpler homogenisation;

- improved short-term nitrogen efficiency through increased concentration of rapid-action nitrogen;

- killing-off or inactivation of weed seeds and germs (human pathogens, zoopathogens and phytopathogens).

| The fact that it is mainly the carbon fraction of the substrate that undergoes change through digestion means that the nutrients it contains are preserved in their entirety. |

They are, if anything, made more readily soluble by the anaerobic degradation process and therefore more easily absorbable[1]. Where mainly energy crops are used to produce biogas, the biological processes with similar substrates/ feedstuffs are comparable with those that take place in the digestive tracts of livestock. This is therefore bound to lead to the production of a digestate with properties similar to those of a liquid farm fertiliser. This is confirmed by a study carried out by LTZ Augustenberg (Agricultural Technology Centre Augustenberg), which examined digestates from working farms in Baden- Württemberg with regard to quality and quantity of nutrients, value-giving substances and fertilising effect[2].The study dealt with digestates from the digestion of cattle manure and energy crops; pig manure and energy crops; mainly energy crops; and wastes (sometimes mixed with energy crops). To support the results, control samples of untreated manures were analysed.

The key findings from the study are:

- the dry matter content of digestate (7% of FM on average) is around 2% lower than that of raw manure;

- the total nitrogen concentration in digestates with 4.6 to 4.8 kg/t FM is slightly higher than in cattle manure;

- the C:N ratio in digestates is approximately 5 or 6 and thus significantly lower than in raw manure (C:N 10);

- the degradation of organic matter causes organically bound nitrogen to be converted into inorganically bound nitrogen and therefore results in the ammonium fraction making up a higher proportion (approx. 60% to 70%) of total nitrogen in digestates;

- digestates mixed with pig-manure digestate and biowaste digestate tend to have higher concentrations of phosphorus and ammonium nitrogen, but lower concentrations of dry matter and potassium as well as lower concentrations of organic matter than digestates from cattle manure or energy crops or mixtures of the two;

- no significant differences are detectable with regard to magnesium, calcium or sulphur.

Use of Digestate

A sufficient delivery of organic matter to soil fauna, as well as a supply of nutrients matched to the needs of crops and type of soil, are fundamental prerequisites for the sustainable utilisation of agricultural land. The rise in the price of mineral fertilisers in recent years has made the transport and field spreading of digestates and farm fertilisers economically worthwhile, with the consequence that digestates, because of their nutrient value, are normally worth the cost of transport. Also, fertilisation strategies based on digestates and farm fertilisers are more beneficial in terms of their energy balance than strategies that are founded exclusively on mineral fertilisers [3].

In terms of their properties, the solids from the separation process are comparable with fresh compost and can, like fresh compost, be used as fertiliser and to increase the concentration of organic matter in soils. The German Federal Compost Quality Association (BGK) has developed quality criteria for solid digestates and awards a seal of quality. Fresh compost, however, is used mainly in agriculture, as there can be an odour nuisance in connection with its storage and spreading on fields. A marketable product first requires stabilisation of the digestate, for example by composting. This, however, is uneconomic at approx. €40/t of solid. An alternative is to dry the solids as described above. This results in a storable and transportable product that can be used for targeted application of P and K soils with a high nitrogen loading. Another option is to incinerate the dried solids. With regard to nutrient-depleted or nutrient-free treatment products of the liquid phase, the economic calculations did not assume any utilisation costs or revenues. Revenues are possible here if offtakers can be found for process water [4].

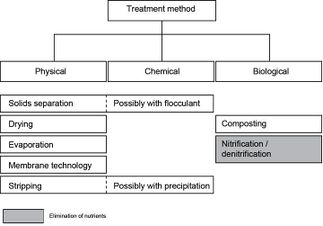

Treatment of Digestate

Post treatment is useful:

- in areas with high nutrient surplus

- for large biogas plants

- in areas focussing on living and recreational quality

- if there is a market for treatment products

Further Information

- Biogas Portal on energypedia

- Assessment of the Economic Potential of Digestate Reuse Concepts Tupandi, Brazil

References

- ↑ H. Döhler, K. Schiessl, M. Schwab (1999): BMBF – Förderschwerpunkt, Umweltverträgliche Gülleaufbereitung und –verwertung. KTBL working paper 272. KTBL Darmstadt.

- ↑ LTZ (2008): Inhaltsstoffe in Gärprodukten und Möglichkeiten zu ihrer geordneten pflanzenbaulichen Verwertung. Project report, Landwirtschaftliches Technologiezentrum Augustenberg (LTZ).

- ↑ Döhler, H. (1996): Landbauliche Verwertung stickstoffreicher Abfallstoffe, Komposte und Wirtschaftsdünger. In Wasser und Boden, 48 Jahrgang. 11/1996

- ↑ FNR, 2012: Guide to biogas