Low-Cost Polyethylene Tube Digesters in Bolivia

Brief description of the technology

Low-Cost Polyethylen Tube Digesters at the present moment have a cost between 93,- € and 148,- €. To operate a digester, the producer has to charge it day to day with 20 kg of cow dung (or other animal dung), mixed with 60 liters of water. Once the digester starts its operation (between 30 to 60 days), produces daily around 4 and 5 hours of biogas, for cooking or other applications like use of gas lamps. Furthermore the digester provides daily 80 liters of ecologic fertilizer which helps to increase the production of agriculture. The digester system has a pressure between 15 - 20 cm of water column.

The household tube digesters possess a triple win situation:

- In the economic sense; the producer does not have to buy liquid gas, firewood or chemical fertilizer.

- In the health sense; the family is not exposed to health treats by exhaust gas by cooking.

- In the ecological sense; the environment threat is reduced due to the decrease in the use of chemical fertilizers and organic waste exposures. Furthermore, it also helps with reduction of the deforestation by consumption of firewood.

|

Tube Digester Type-Valley installed in a greenhouse |

Woman is cooking with Biogas / Bolivia |

Objective of the project

Convert household tube digesters into an additional tool within the productive uses of families in the rural areas of Bolivia, in such a manner that the knowledge will be transferred to local technicians.

- In the short term: Train more local technicians in installation and management of household bio digester projects in Bolivia, so as to disseminate the technology between rural families.

- In the medium term: Spread the tube digester technology at a national wide level, so that families may learn about the method and from this, under their own criteria, decide if they will incorporate such technology into their productive system.

- In the long term: Democratize the technology in such a manner that communities, producer associations, municipalities, etc. may develop and manage their own tube digester projects without external assistance or technological subsidies.

|

Farmer using undiluted fertilizer produced by his own Tube Digester / Bolivia |

Farmer using filtered and diluted fertilizer for spraying onions/ Bolivia |

Support provided by GTZ / EnDev Bolivia

|

In order to reach the objective, GTZ provides the following support:

|

Certificated local technicians in Carabuco / Bolivia |

Fact Sheets

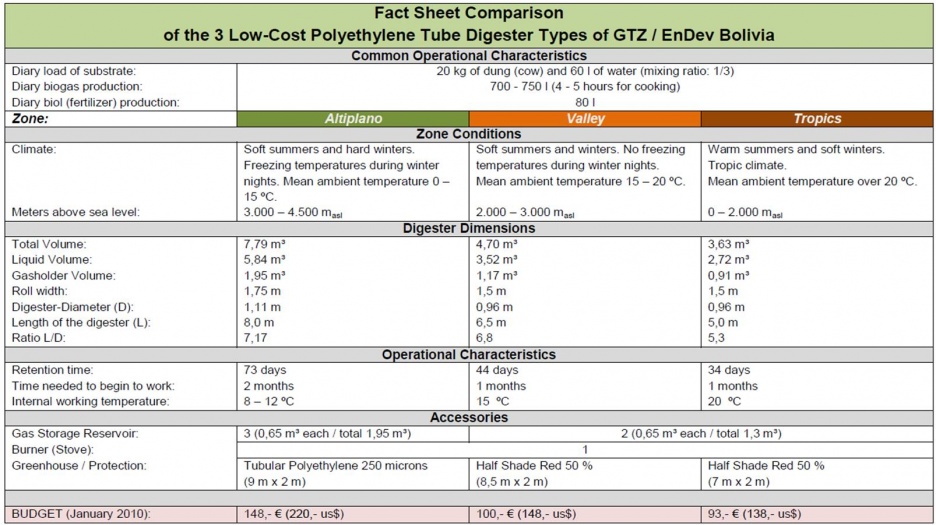

To be able to work in different altitudes and climate zones, in Bolivia it was modified the Low-Cost Polyethylene Tube Digester into three climate types.

The three implanted types are calculated for 4 - 5 hours of Biogas using per day. The digesters differ in size and protection of the system.

The biodigester for the Bolivian Altiplano (picture td7) is enclosed in a greenhouse of polyethylene (250 microns) supported by two lateral adobe walls of 40 cm thickness. This lateral walls accumulate the heat of the greenhouse effect, that with freezing temperatures during winter nights they yet maintain the digester in function, by the own high thermal inertia. So it is possible to realise the installation a working digester in an altitude of more than 4.500 m about sea level.

- Download: Fact Sheet Low-Cost Polyethylene Tube Digester Altiplano Bolivia - (3.000 - 4.500 m above sea level)

- Download: Fact Sheet Low-Cost Polyethylene Tube Digester Valley Bolivia - (2.000 - 3.000 m above sea level)

- Download: Fact Sheet Low-Cost Polyethylene Tube Digester Tropics Bolivia - (0 - 2.000 m above sea level)

- Download: Fact Sheet Comparison of the Low-Cost Polyethylene Tube Digester Types of GTZ / EnDev Bolivia

back to "Biogas" section