Difference between revisions of "Parts of a Biogas Plant"

***** (***** | *****) |

***** (***** | *****) m (moved Parts of a biogas plant to Parts of a Biogas Plant) |

(No difference)

| |

Revision as of 09:39, 27 April 2012

Influent collecting tank

|

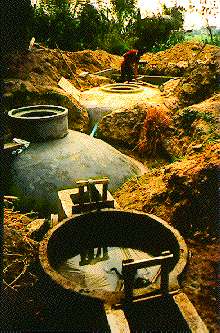

Installation of a fixed-dome plant in Thailand: The influent collecting tank is in front of the photo, the digester and the outlet are located behind it. |

Size and homogenization

Fresh substrate is usually gathered in an influent collecting tank prior to being fed into the digester. Depending on the type of system, the tank should hold one to two days' substrate. An influent collecting tank can also be used to homogenize the various substrates and to set up the required consistency, e.g. by adding water to dilute the mixture of vegetable solids (straw, grass, etc.), or by adding more solids in order to increase the bio-mass. The fibrous material is raked off the surface, if necessary, and any stones or sand settling at the bottom are cleaned out after the slurry is admitted to the digester. The desired degree of homogenization and solids content can be achieved with the aid of an agitator, pump or chopper. A rock or wooden plug can be used to close off the inlet pipe during the mixing process.

Location

A sunny location can help to warm the contents before they are fed into the digester in order to avoid thermal shock due to the cold mixing water. In the case of a biogas plant that is directly connected to the stable, it is advisable to install the mixing pit deep enough to allow installation of a floating gutter leading directly into the pit. Care must also be taken to ensure that the low position of the mixing pit does not result in premature digestion. For reasons of hygiene, toilets should have a direct connection to the inlet pipe.

Inlet and outlet

Size and material

The inlet (feed) and outlet (discharge) pipes lead straight into the digester at a steep angle. For liquid substrate, the pipe diameter should be 10-15 cm, while fibrous substrate requires a diameter of 20-30 cm. The inlet and the outlet pipe mostly consist of plastic or concrete.

Position of inlet and outlet

Both the inlet and the outlet pipe must be freely accessible and straight, so that a rod can be pushed through to eliminate obstructions and agitate the digester contents. The pipes should penetrate the digester wall at a point below the lowest slurry level (i.e. not through the gas storage). The points of penetration should be sealed and reinforced with mortar.

The inlet pipe ends higher in the digester than the outlet pipe in order to promote more uniform flow of the substrate. In a fixed-dome plant, the inlet pipe defines the bottom line of the gas-holder, acting like a security valve to release over-pressure. In a floating-drum plant, the end of the outlet pipe determines the digester's (constant) slurry level.

Inlet and outlet pipe must be placed in connection with brick-laying. It is not advisable to break holes into the spherical shell afterwards, this would weaken the masonry structure.

Toilet connection at the inlet

--> Household toilets can be connected to a biogas digester.

Digester

Requirements

No matter which design is chosen, the digester (fermentation tank) must meet the following requirements:

- Water/gastightness - watertightness in order to prevent seepage and the resultant threat to soil and groundwater quality; gastightness in order to ensure proper containment of the entire biogas yield and to prevent air entering into the digester (which could result in the formation of an explosive mixture).

- Insulation - if and to which extent depends on the required process temperature, the local climate and the financial means; heat loss should be minimized if outside temperatures are low, warming up of the digester should be facilitated when outside temperatures are high.

- Minimum surface area - keeps cost of construction to a minimum and reduces heat losses through the vessel walls. A spherical structure has the best ratio of volume and surface area. For practical construction, a hemispherical construction with a conical floor is close to the optimum.

- Structural stability - sufficient to withstand all static and dynamic loads, durable and resistant to corrosion.

Internal and external forces

Two relevant forces act on the digester. The external active earth pressure causes compressive forces within the masonry. The internal hydrostatic and gas pressures causes tensile stress in the masonry. Thus, the external pressure applied by the surrounding earth must be greater at all points than the internal forces. Round and spherical shapes are able to accept the highest forces and distribute them uniformly. Edges and corners lead to peak tensile stresses which can result in cracking.

Shapes of digesters

From the standpoint of fluid dynamics and structural strength, an egg-shaped vessel is about the best possible solution. This type of construction, however, is comparatively expensive, so that its use is usually restricted to large-scale sewage treatment plants. The Chinese fixed-dome designs are of similar shape, but less expensive. The hemispherical CAMARTEC design is optimized in structural strength, but does not make optimal use of the excavation required.

Simplified versions of such digester designs include cylinders with conical covers and bottoms. They are much easier to build and are sometimes available on the market as prefabricated units. Their disadvantage lies in their less favorable surface-volume ratio. The cylinder should have a height equal to its diameter. Prone cylinders have become quite popular on farms, since they are frequently the more favorable solution for small-scale bio-methanation. Cuboid digesters are often employed in batch-fed systems used primarily for fermenting solid material, so that fluid dynamics are of little interest.

|

Construction of the digester neck with steel reinforcement |

Building material of digester

Digesters can be made from any of the following materials:

Steel vessels

Steel vessels are inherently gas-tight, have good tensile strength, and are relatively easy to construct (by welding). In many cases, a discarded steel vessel of appropriate shape and size can be salvaged for use as a biogas digester. Susceptibility to corrosion both outside (atmospheric humidity) and inside (aggressive media) can be a severe problem. As a rule, some type of anticorrosive coating must be applied and checked at regular intervals. Steel vessels are only cost-effective, if second-hand vessels (e.g. train or truck tankers) can be used.

Concrete vessels

Concrete vessels have gained widespread acceptance in recent years. The requisite gas-tightness necessitates careful construction and the use of gas-tight coatings, linings and/or seal strips in order to prevent gas leakage. Most common are stress cracks at the joints of the top and the sides. The prime advantage of concrete vessels are their practically unlimited useful life and their relatively inexpensive construction. This is especially true for large digesters in industrialized countries.

Masonry

Masonry is the most frequent construction method for small scale digesters. Only well-burnt clay bricks, high quality, pre-cast concrete blocks or stone blocks should be used in the construction of digesters. Cement-plastered/rendered masonry is a suitable - and inexpensive - approach for building an underground biogas digester, whereby a dome-like shape is recommended. For domes larger than 20 m3 digester volume, steel reinforcement is advisable. Masons who are to build masonry digesters have to undergo specific training and, initially, require close supervision.

|

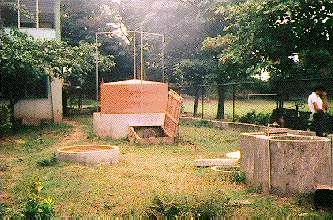

Construction of the dome for a 30 m3 digester in Cuba |

Plastics

Plastics have been in widespread use in the field of biogas engineering for a long time. Basic differentiation is made between flexible materials (sheeting) and rigid materials (PE, GRP, etc.). Diverse types of plastic sheeting can be used for constructing the entire digesting chamber (balloon gas holders) or as a vessel cover in the form of a gas-tight "bonnet".

Sheeting made of caoutchouc (india rubber), PVC, and PE of various thickness and description have been tried out in numerous systems. The durability of plastic materials exposed to aggressive slurry, mechanical stress and UV radiation, as well as their gas permeability, vary from material to material and on the production processes employed in their manufacture. Glass-fibre reinforced plastic (GRP) digesters have proven quite suitable, as long as the in-service static stresses are accounted for in the manufacturing process. GRP vessels display good gas-tightness and corrosion resistance. They are easy to repair and have a long useful life span. The use of sandwich material (GRP - foam insulation - GRP) minimizes the on-site insulating work and reduces the cost of transportation and erection.

Wood

A further suitable material for use in the construction of biogas systems is wood. It is often used for building liquid-manure hoppers and spreaders. Wooden digesters require a vapor-proof membrane to protect the insulation. Closed vessels of any appreciable size are very hard to render gas-tight without the aid of plastic sheeting. Consequently, such digesters are very rare.

Further Reading:

Hohlfeld, J.; Sasse, L. (Deutsche Gesellschaft für Technische Zusammenarbeit): Production and utilization of biogas in rural areas of industrialized and developing countries. TZ-Verlagsgesellschaft mbH, Roßdorf, 1986, 278 S.

Gasholders

Basically, there are different designs of construction for gasholders used in simple biogas plants:

Floating-drum gasholders

Most floating-drum gas-holders are made of 2-4 mm thick sheet steel, with the sides made of thicker material than the top in order to compensate for the higher degree of corrosive attack. Structural stability is provided by L-bar bracing that also serves to break up surface scum when the drum is rotated. A guide frame stabilizes the gas drum and prevents it from tilting and rubbing against the masonry. The two equally suitable and most frequently used types are:

- an internal rod & pipe guide with a fixed (concrete-embedded) cross pole (an advantageous configuration in connection with an internal gas outlet);

- external guide frame supported on three wooden or steel legs.

For either design, substantial force can be necessary to rotate the drum, especially if it is stuck in a heavy layer of floating scum. Any gas-holder with a volume exceeding 5 m3 should be equipped with a double guide (internal and external).

All grades of steel normally used for gas-holders are susceptible to moisture-induced rusting both in- and outside. Consequently, a long service life requires proper surface protection, including:

- thorough de-rusting and de-soiling

- primer coat of minimum 2 layers

- 2 or 3 cover coats of plastic or bituminous paint.

The cover coats should be reapplied annually. A well-kept metal gas-holder can be expected to last between 3 and 5 years in humid, salty air or 8-12 years in a dry climate.

Materials regarded as suitable alternatives to standard grades of steel are galvanized sheet metal, plastics (glass-fiber reinforced plastic (GRP), plastic sheeting) and ferro-cement with a gas-tight lining. The gas-holders of water-jacket plants have a longer average service life, particularly when a film of used oil is poured on the water seal to provide impregnation.

Fixed-dome gasholders

A fixed-dome gas-holder can be either the upper part of a hemispherical digester (CAMARTEC design) or a conical top of a cylindrical digester (e.g. Chinese fixed-dome plant). In a fixed-dome plant the gas collecting in the upper part of the dome displaces a corresponding volume of digested slurry. The following aspects must be considered with regard to design and operation:

- An overflow into and out of the compensation tank must be provided to avoid over-filling of the plant.

- The gas outlet must be located about 10 cm higher than the overflow level to avoid plugging up of the gas pipe.

- A gas pressure of 1 m WC or more can develop inside the gas space. Consequently, the plant must be covered sufficiently with soil to provide an adequate counter-pressure.

- Special care must be taken to properly close the man hole, which may require to weigh down the lid with 100 kg or more. The safest method is to secure the lid with clamps.

The following structural measures are recommended to avoid cracks in the gas-holder:

- The foot of the dome (gas-holder) should be stabilized by letting the foundation slab project out enough to allow for an outer ring of mortar.

- A rated break/pivot ring should be provided at a point located between 1/2 and 2/3 of the minimum slurry level. This in order to limit the occurrence or propagation of cracks in the vicinity of the dome foot and to displace forces through its stiffening/articulating effect such that tensile forces are reduced around the gas space. Alternatively, the lowest point of the gas-holder should be reinforced by a steel ring or the whole gas-holder be reinforced with chicken mesh wire.

Normally, masonry, mortar and concrete are not gas-tight, with or without mortar additives. Gas-tightness can only be achieved through good, careful workmanship and special coatings. The main precondition is that masonry and plaster are strong and free of cracks. Cracked and sandy rendering must be removed. In most cases, a plant with cracked masonry must be dismantled, because not even the best seal coating can render cracks permanently gas-tight.

Some tried and proven seal coats and plasters:

- multi-layer bitumen, applied cold (hot application poses the danger of injury by burns and smoke-poisoning; solvents cause dangerous/explosive vapors). Two to four thick coats required;

- bitumen with aluminum foil, thin sheets of overlapping aluminum foil applied to the still-sticky bitumen, followed by the next coat of bitumen;

- plastics, e.g. epoxy resin or acrylic paint; very good but expensive;

- paraffin, diluted with 2-5% kerosene, heated up to 100°C and applied to the preheated masonry, thus providing an effective (deep) seal. Use kerosene/gas torch to heat masonry.

- multi-layer cement plaster with water-proof elements

In any case, a pressure test must be carried out before the plant is put in service.

Plastic gas-holders

Gas-holders made of plastic sheeting serve as integrated gas-holders, as separate balloon/bag-type gas-holders and as integrated gas-transport/storage elements. For plastic (sheet) gas-holders, the structural details are of less immediate interest than the question of which materials can be used.

Separate gas-holders

Differentiation is made between:

- low-pressure, wet and dry gas-holders (10-50 mbar). Basically, these gas-holders are identical to integrated and/or plastic (sheet) gas-holders. Separate gas-holders cost more and are only worthwhile in case of substantial distances (at least 50-100 m) or to allow repair of a leaky fixed-dome plant. This type of separate gas-holder is also used to buffer extreme differences between gas-production and gas-use patterns.

- medium- or high-pressure gas-holders (8-10 bar / 200 bar)

Biogas plant with seperate gasholder in Nicaragua Biogas plant with seperate gasholder in NicaraguaPhoto: gtz/GATE |

Neither system can be considered for use in small-scale biogas plants. Even for large-scale plants, they cannot be recommended under the conditions in most developing countries. High-pressure gas storage in steel cylinders (as fuel for vehicles) is presently under discussion. While that approach is possible in theory, it would be complicated and, except in special cases, prohibitively expensive. It would also require the establishment of stringent safety regulations.

Gas pipe, valves and accessories

Biogas piping

At least 60% of all non-functional biogas units are attributable to defect gas piping. Utmost care has to be taken, therefore, for proper installation. For the sake of standardization, it is advisable to select a single size for all pipes, valves and accessories.

The requirements for biogas piping, valves and accessories are essentially the same as for other gas installations. However, biogas is 100% saturated with water vapor and contains hydrogen-sulfide. Consequently, no piping, valves or accessories that contain any amounts of ferrous metals may be used for biogas piping, because they would be destroyed by corrosion within a short time. The gas lines may consist of standard galvanized steel pipes. Also suitable (and inexpensive) is plastic tubing made of rigid PVC or rigid PE. Flexible gas pipes laid in the open must be UV-resistant.

Steel pipes

Galvanized steel water supply pipes are used most frequently, because the entire piping system (gas pipe, valves and accessories) can be made of universally applicable English/U.S. Customary system components, i.e. with all dimensions in inches. Pipes with nominal dimensions of 1/2" or 3/4" are adequate for small-to-midsize plants of simple design and pipe lengths of less than 30 m. For larger plants, longer gas pipes or low system pressure, a detailed pressure-loss (pipe-sizing) calculation must be performed.

When installing a gas pipe, special attention must be paid to:

- gas-tight, friction-type joints

- line drainage, i.e. with a water trap at the lowest point of the sloping pipe in order to empty water accumulation

- protection against mechanical impact

|

Stirring device for a european biodigester |

Stirring facilities

Optimum stirring substantially reduces the retention time. If agitation is excessive, the bacteria have "no time to eat". The ideal is gentle but intensive stirring about every four hours. Of similar importance is the breaking up of a scum layer which has lost contact with the main volume of substrate and is, therefore, not further digested. This top layer can form an impermeable barrier for biogas to move up from the digester to the gas holder.

As a rule of thumb it can be stated that stirring facilities are more important in larger plants than in small scale farm plants.

Stirring facilities in the digester Stirring facilities in the digesterSource: OEKOTOP |

Types of stirring facilities

- The impeller stirrer has given good results especially in sewage treatment plants.

- The horizontal shaft stirs the fermentation channel without mixing up the phases. Both schemes originate from large-scale plant practice.

- For simple household plants, poking with a stick is the simplest and safest stirring method.