Difference between revisions of "Parts of a Biogas Plant"

***** (***** | *****) m (→Biogas Piping) |

***** (***** | *****) m |

||

| Line 74: | Line 74: | ||

= Gas Pipe, Valves and Accessories<br/> = | = Gas Pipe, Valves and Accessories<br/> = | ||

| − | |||

== Biogas Piping<br/> == | == Biogas Piping<br/> == | ||

| Line 93: | Line 92: | ||

<br/> | <br/> | ||

| − | [[ | + | [[Gas Pipe, Valves and Accessories#Gas Pipe|Read More here...]] |

== Water Traps == | == Water Traps == | ||

| − | [[ | + | [[Gas Pipe, Valves and Accessories#Water traps|►]][[Gas Pipe, Valves and Accessories#Water traps|Read more here....]] |

== Valves == | == Valves == | ||

| − | [[ | + | [[Gas Pipe, Valves and Accessories#Valves|►]][[Gas Pipe, Valves and Accessories#Valves|Read more here...]] |

== Gas Analysis Equipment == | == Gas Analysis Equipment == | ||

| − | [[ | + | [[Gas Pipe, Valves and Accessories#Gas Analysis Equipment|►]][[Gas Pipe, Valves and Accessories#Gas Analysis Equipment|Read more here...]] |

| + | <br/> | ||

= Stirring Facilities<br/> = | = Stirring Facilities<br/> = | ||

| Line 147: | Line 147: | ||

<br/> | <br/> | ||

| − | [[Digester Heating|►]][[ | + | [[Digester Heating|►]][[Digester Heating|More information here...]]. |

= Pumps = | = Pumps = | ||

| Line 155: | Line 155: | ||

== Types of Pumps == | == Types of Pumps == | ||

| − | [[ | + | [[Pumps for Biogas Plants|Read more here....]] |

= Weak Ring<br/> = | = Weak Ring<br/> = | ||

| Line 214: | Line 214: | ||

Radar (pre-pits)<br/>Wheel loader scales | Radar (pre-pits)<br/>Wheel loader scales | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<div><br/></div> | <div><br/></div> | ||

= BiogasBox = | = BiogasBox = | ||

Revision as of 10:40, 20 March 2014

Overview

The feed material is mixed with water in the influent collecting tank The fermentation slurry flows through the inlet into the digester. The bacteria from the fermentation slurry are intended to produce biogas in the digester. For this purpose, they need time. Time to multiply and to spread throughout the slurry. The digester must be designed in a way that only fully digested slurry can leave it. The bacteria are distributed in the slurry by stirring (with a stick or stirring facilities). The fully digested slurry leaves the digester through the outlet into the slurry storage.The biogas is collected and stored until the time of consumption in the gasholder. The gas pipe carries the biogas to the place where it is consumed by gas appliances. Condensation collecting in the gas pipe is removed by a water trap.

Depending on the available building material and type of plant under construction, different variants of the individual components are possible. The following (optional) components of a biogas plant can also play an important role and are described seperatly: Heating systems, pumps, weak ring.

Influent Collecting Tank

|

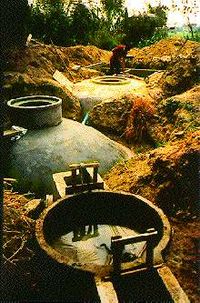

Installation of a fixed-dome plant in Thailand: The influent collecting tank is in front of the photo, the digester and the outlet are located behind it.[1] |

Size and Homogenization

Fresh substrate is usually gathered in an influent collecting tank prior to being fed into the digester. Depending on the type of system, the tank should hold one to two days' substrate. An influent collecting tank can also be used to homogenize the various substrates and to set up the required consistency, e.g. by adding water to dilute the mixture of vegetable solids (straw, grass, etc.), or by adding more solids in order to increase the bio-mass. The fibrous material is raked off the surface, if necessary, and any stones or sand settling at the bottom are cleaned out after the slurry is admitted to the digester. The desired degree of homogenization and solids content can be achieved with the aid of an agitator, pump or chopper. A rock or wooden plug can be used to close off the inlet pipe during the mixing process.

Location

A sunny location can help to warm the contents before they are fed into the digester in order to avoid thermal shock due to the cold mixing water. In the case of a biogas plant that is directly connected to the stable, it is advisable to install the mixing pit deep enough to allow installation of a floating gutter leading directly into the pit. Care must also be taken to ensure that the low position of the mixing pit does not result in premature digestion. For reasons of hygiene, toilets should have a direct connection to the inlet pipe.

Inlet and Outlet

The inlet (feed) and outlet (discharge) pipes lead straight into the digester at a steep angle. For liquid substrate, the pipe diameter should be 10-15 cm, while fibrous substrate requires a diameter of 20-30 cm. The inlet and the outlet pipe mostly consist of plastic or concrete.

Position

Both the inlet and the outlet pipe must be freely accessible and straight, so that a rod can be pushed through to eliminate obstructions and agitate the digester contents. The pipes should penetrate the digester wall at a point below the lowest slurry level (i.e. not through the gas storage). The points of penetration should be sealed and reinforced with mortar.

The inlet pipe ends higher in the digester than the outlet pipe in order to promote more uniform flow of the substrate. In a fixed-dome plant, the inlet pipe defines the bottom line of the gas-holder, acting like a security valve to release over-pressure. In a floating-drum plant, the end of the outlet pipe determines the digester's (constant) slurry level.

Inlet and outlet pipe must be placed in connection with brick-laying. It is not advisable to break holes into the spherical shell afterwards, this would weaken the masonry structure.

Toilet Connection at the Inlet

--> Household Toilets can be connected to a Biogas Digester.

Digester

In general terms, digesters consist of the digestion tank as such, which is thermally insulated, plus a heating system, mixer systems and discharge systems for sediments and the spent substrate

Raw Material for Biogas Digesters

Types of Biogas Digesters

Types of Gasholders for Biogas Plants

Gas Pipe, Valves and Accessories

Biogas Piping

|

Stirring device for a european biodigester[2] |

At least 60% of all non-functional biogas units are attributable to defect gas piping. Utmost care has to be taken, therefore, for proper installation. For the sake of standardization, it is advisable to select a single size for all pipes, valves and accessories.

The requirements for biogas piping, valves and accessories are essentially the same as for other gas installations. However, biogas is 100% saturated with water vapor and contains hydrogen-sulfide. Consequently, no piping, valves or accessories that contain any amounts of ferrous metals may be used for biogas piping, because they would be destroyed by corrosion within a short time. The gas lines may consist of standard galvanized steel pipes. Also suitable (and inexpensive) is plastic tubing made of rigid PVC or rigid PE. Flexible gas pipes laid in the open must be UV-resistant.

Water Traps

Valves

Gas Analysis Equipment

Stirring Facilities

|

Stirring facilities in the digester[3] |

Optimum stirring substantially reduces the retention time. If agitation is excessive, the bacteria have "no time to eat". The ideal is gentle but intensive stirring about every four hours. Of similar importance is the breaking up of a scum layer which has lost contact with the main volume of substrate and is, therefore, not further digested. This top layer can form an impermeable barrier for biogas to move up from the digester to the gas holder.

As a rule of thumb it can be stated that stirring facilities are more important in larger plants than in small scale farm plants.

Types of Stirring Facilities

- The impeller stirrer has given good results especially in sewage treatment plants.

- The horizontal shaft stirs the fermentation channel without mixing up the phases. Both schemes originate from large-scale plant practice.

- For simple household plants, poking with a stick is the simplest and safest stirring method.

Heating Systems

Normally, because of the rather high involved costs, small-scale biogas plants are built without heating systems. But even for small scale plants, it is of advantage for the bio-methanation process to warm up the influent substrate to its proper process temperature before it is fed into the digester. If possible, cold zones in the digester should be avoided (see also substrate temperature).

In the following, a number of different ways to get the required amount of thermal energy into the substrate are described.

In principle, one can differentiate between:

- direct heating in the form of steam or hot water, and

- indirect heating via heat exchanger, whereby the heating medium, usually hot water, imparts heat while not mixing with the substrate.

Pumps

Pumps become necessary parts of a biogas unit, when the amounts of substrate require fast movement and when gravity cannot be used for reasons of topography or substrate characteristics. Pumps transport the substrate from the point of delivery through all the stages of fermentation. Therefore, several pumps and types of pumps may be needed. Pumps are usually found in large scale biogas units.

Types of Pumps

Weak Ring

The weak/strong ring improves the gas-tightness of fixed-dome plants It was first introduced in Tanzania and showed promising results. The weak ring separates the lower part of the hemispherical digester, (filled with digesting substrate), from the upper part (where the gas is stored). Vertical cracks, moving upwards from the bottom of the digester, are diverted in this ring of lean mortar into horizontal cracks. These cracks remain in the slurry area where they are of no harm to the gas-tightness. The strong ring is a reinforcement of the bottom of the gas-holder, it could also be seen as a foundation of the gas-holder. It is an additional device to prevent cracks from entering the gas-holder. Weak and strong ring have been successfully combined in the CAMARTEC design

| Photo[4]: Construction of the weak/strong ring of a 16 m3, Tanzania |

Materials and Construction

The weak ring consists of mortar of a mixture of sand, lime and cement (15:3:1). The top of the weak ring restores the horizontal level. It is interrupted only by the inlet pipe passing through. The strong ring rests on the weak ring and is the first layer of the upper part of the hemispherical shell. It consists of a row of header bricks with a concrete package at the outside. In case of soft or uncertain ground soil one may place a ring reinforcement bar in the concrete of the strong ring. The brick of the strong ring should be about three times wider than the brickwork of the upper wall. A detailed description of the weak/strong ring construction can be found in Sasse, Kellner, Kimaro (1991).

Pre-digestion pit for storage of substrates

Sizing depends on:

substrate arisings, digester capacity, length of time to be bridged between successive deliveries, land-use specifics and yield of co-substrates, supply contracts for substrates from off-site sources, possible disruptions in operation

Special considerations:

- Avoid the possibility of storage plant freezing, for example by siting storage tanks indoors, heating storage containers or locating the plant for pits below grade level

- Avoid biodegradation processes that reduce gas yield

- Do not permit intermingling of hygienically problematic and hygienically acceptable substrates

- Implement suitable structural measures to minimise odours

- Avoid material emissions to soil and to the surface and underground water system

Designs

Containers for storing solid substrates in widespread use in agriculture, such as mobile silos, upright silos, plastic-tunnel silos and round-bale silos and open or roofed storage areas (e.g. solid-manure deposits) and pits/hoppers

Containers for storing liquid substrates in widespread use in agriculture, such as tanks and predigester pits

Costs

Storage facilities are generally in place; when new builds are needed the price has to be calculated on

a case-to-case basis factoring in the multiplicity of influencing variables indicated above

Measurement instruments

Flow-measuring devices (in the pipes)

Ultrasonically (pre pits)

Radar (pre-pits)

Wheel loader scales

BiogasBox

Documents on the contruction of biogas plants.

Web

http://biogas.ifas.ufl.edu/ad_development/documents/biogasplants.pdf

https://energypedia.info/index.php/Construction_of_a_Biogas_Plant

http://www.haase-energietechnik.de/en/Products_and_Services/24-e_BiogasBrochure_Feb2011_1.pdf

References

- Ringkamp, M.; Tentscher, W.; Schiller, H.: Preliminary results on: statical optimization of family-sized fixed-dome digesters. Tilche, A.; Rozzi, A. (ed.): Poster Papers. Fifth International Symposium on Anaerobic Digestion, Bologna 1988, pp. 321-324

- Sasse, L.; Kellner, Ch.; Kimaro, A.: Improved Biogas Unit for Developing Countries. Deutsche Gesellschaft für Technische Zusammenarbeit (GTZ) GmbH, Vieweg & Sohn Verlagsgesellschaft Braunschweig, 1991

- J.; Sasse, L. (Deutsche Gesellschaft für Technische Zusammenarbeit): Production and utilization of biogas in rural areas of industrialized and developing countries. TZ-Verlagsgesellschaft mbH, Roßdorf, 1986, 278 S.</span>

This section provides detailed information on materials and devices used in the construction of biogas plants: