Sheabutter Processing

Introduction

Besides electricity and mechanical energy, thermal energy plays a key role for processing goods and offering services, particular in remote areas where biomass is often the only source of energy available. Thermal energy – used for heating, drying, smoking and baking – is incorporated within the production cycle of a broad variety of agricultural products. One example is the processing of sheabutter with the help of improved cook stoves.

The Energy Partnership Energising Development (EnDev) carries out a project in Benin, fostering this productive use of thermal energy in the regions of Atacora and Donga between 10/2005 and 12/2012.

In the district of Atacora wood is becoming a scarce resource due to the rapid increase of population and energy needs, resulting in deforestation. Therefore, the project engaged in the promotion of improved cookstoves to reduce the amount of wood needed to produce shea butter and to reduce smoke emission of the inefficient burning with the traditional wood stoves. Between 2005 and 2009, 5,812 people invested in improved cooking stoves for efficient production processes. Additionally, the project supported the producers of shea butter and soap to improve the quality of their products. Therefore trainings e.g. on the purchase of improved equipment for shea transformation, customer relations and marketing have been conducted with the micro entrepreneurs. On the energy supply side, the project trained stove producers, builders and resellers to improve technical and entrepreneurial skills in order to support the development of a local market on improved cooking stoves.

The Shea Market in Benin

Shea is a forest tree that grows only in Africa. Its nuts are collected from May to August, mainly by women. Shea is used for cosmetic products, food and medicine. In 2009, shea was the third largest agricultural export product of Benin, after cotton and cashew nuts. Its main derivative, butter, holds a strong international demand. Depending on the annual precipitation, a shea tree produces between 12 and 14 kg of dry nuts per year. In Benin, about 35,000 t dry nuts are harvested annually, representing only approximately 50% of the possible production. One woman collects about 300 kg of nuts/year. The government sets a reference price which is currently around FCFA 60 (USD 0,12)/kg for collectors. In some areas in Borgou, revenues from the collection of shea represent 55% of the total income of rural women; in Atacora-Donga 46%.

In rural areas, 7,800 t of processed nuts are collected for local use. 22,800t (74%) are sold to professional processing units and exporters. On the local market, the price of shea butter varies between FCFA 300 and 1,000 (USD 0,60 – 2,01)/kg depending on their quality. Internationally traded shea is concentrated in the hands of a few operators and suffers from a lack of transparency.

Technology

Technical Aspects of an Improved Stove

The “Fixed rocket mud stove” is an improved stove for households and institutional with one pot-hole where the pot sits within the stove body. It is built of a clay mixture, comprising mud and organic material such as chopped grass, saw dust or chopped dry banana leaves, which has an insulating effect to keep a high temperature of the fire. The combustion chamber and the opening for the firewood are L-shaped, the height between the underside of the pot and the fire has been metered exactly so that the wood burns completely and there are no toxic fumes. An extra air inlet on the side creates an undercurrent of air for an optimal combustion process. If used correctly, the stove saves over 50% of firewood compared to a three-stone fire.

Investment costs for the purchase of the “Fixed rocket mud stove” are around FCFA 20 000 (USD 40,00). There are savings of FCFA 350 (USD 0,70) per cooking and stove; and three cooking’s per day represent a total saving of FCFA 1,050 (USD 2,10) per day and stove. Thus, the investment into an efficient stove amortizes in less than 20 days. Maintenance costs total between FCFA 500 and 1500 (USD 1,00 – 3,00) per stove and per year, depending on the materials used.

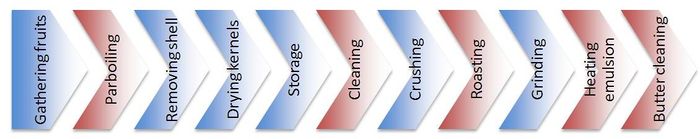

Processing Steps of Shea Butter and the Thermal Energy Inputs of Firewood

Figure 1: Steps of the preparation and processing of sheabutter and the thermal energy inputs in form of firewood (red).

Practical Experiences

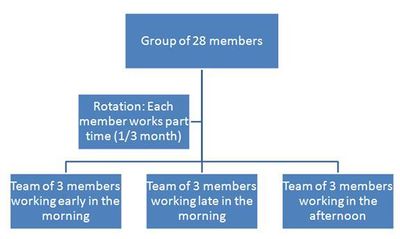

The enterprise SOUKATIGNINA is composed of a group of 28 businesswomen and is located in Kouandé, a community of Atacora. For their production of shea butter they are used to spend FCFA 500 (USD 1,00) per day on firewood for their traditional three stone fire. With an efficient stove, they save up to 70% of fuel. Thus, the profit margin increases because of reduced fuel costs, saving FCFA 350 (USD 0,70) each day.

|

All women work part-time, but now they can work more shifts and therefore, earn more money. Previously, there was one team of five who maintained just one three stone fire a day. Today, three teams of three people monitor even three stoves per day. Thus, with the fixed rocket stoves, they tripled production. This created higher revenues for the company, respecitvely for the entrepeneuer women, estimated at approximately twice the amount compared to what the company earned before.

Figure 2: Working process of the 28 women at Soukatignina. |

The quality of the shea butter also improves by using a rocket stove. With a traditional stove, the wind can easily spread ash on the butter in the last stage of processing, changing the colour of the butter. It is demonstrated that the fixed rocket mud stove protects against the wind, resulting in a white and pure final product, which gains higher prices on sale.

Testimonial by Mrs. Rebeka Boni, President of the group: "Monitoring of the open fire and our children to avoid burns required us to be more numerous. We had to stay close to the fire to monitor the fire and children."