Sustainable Energy Use in the Dairy Value Chain

Introduction

Throughout the world, more than six billion people consume milk and milk products, and the number is growing. At the same time, over 750 million people live in dairy farming households, particularly in emerging economies. Most dairy-farmers operate at a small-scale level; the global mean milk yield is 11 litres per farm per day, produced by an average number of two cows. Hence, the development of the small-scale dairy sector could be a powerful tool for reducing poverty and creating wealth in the developing world.[1]

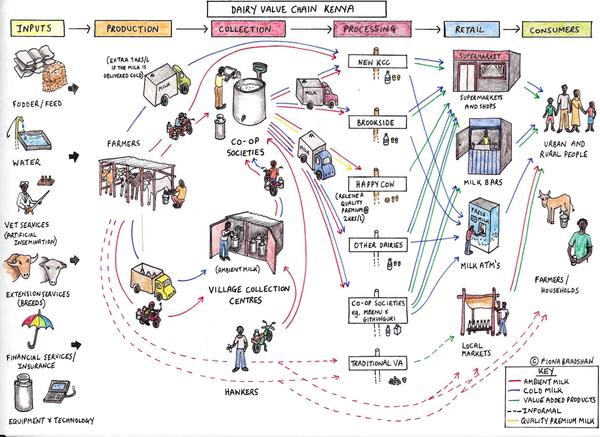

The milk value chain mainly goes through four steps: milking, transportation to milk collection centres, processing, and retail.

During the milking process, it is fundamental to fulfil the adequate hygienic standards that help to avoid a bacterial infection of the milk. In many countries, milk entering the formal sector is first chilled at village collection centres. However, some tough dairies and cooperatives control the quality of the collected milk and reject milk that is spoilt.

Enhancing milk handling practices and raising awareness of milk-borne diseases can help reduce health risks. Cleaning the equipment and regular animal husbandry are crucial measures to reduce losses and provide a better quality of produce. Access to veterinary support, the appropriate fodder, and ensuring water availability for the cattle is essential to improve milk yields.

Furthermore, introducing cooling facilities right after milking can reduce bacterial growth considerably. In fact, different technologies have been developed in order to provide an uninterrupted cooling chain until reaching the milk collection centres, reducing the amount of milk that is rejected, increasing farmers’ incomes and improving food security. Further, when cooling devices are run on renewable energy, they can be used off-grid and are climate-friendly, which eliminates additional costs from electricity supply. As initial upfront capital costs are often the main obstacles for adopting these innovative approaches, different financing options have been developed, enabling easy access to smallholder farmers.[2]

Increasing the energy efficiency in the dairy value chain implies using also its by-products. Cattle manure can be used for biogas production, which can generate heat for cooking, heating, band electricity – which in turn can power cooling systems and hence prevent spoilage of milk.

Conservation

Clean Energy Solutions for Milk Cooling in India and Kenya

In low-income countries, most of the milk is produced by smallholder farmers, as it is one of the few commodities that can be produced even by the landless. The surplus milk can be sold on the local markets. Due to its composition, milk at ambient temperature provides an ideal medium for bacterial growth, which can be a vector for infectious diseases, being hazardous for human consumption. Cooling milk slows down bacterial growth, reducing spoilage, increasing farmers’ income and providing a certain safety for the milk consumer.

In both Kenya and India, farmers tend not to own their own cooling facilities. In India, milk is collected and reaches dairy cooperatives within 3.5 hours after milking. However, maintaining an extensive network of collection facilities which frequently rely on diesel generators to back up the less reliable electricity grid imposes significant financial burdens. In Kenya, milk transportation to the collection centres with cooling facilities generally takes longer than 3.5 hours and evening milk needs to be consumed on-farm as collection centres only open in the morning. Due to the high costs for back-up electricity for cooling facilities, Kenyan cooperatives cope with the same financial burden Indian cooperatives.

The successful application of clean energy cooling technology in the milk value chain has the potential to improve the quality and increase the quantity of milk sold into the formal market, improving food safety for consumers, and increasing farmers’ incomes, while creating job opportunities within businesses that provide clean energy solutions.

The main barriers to upscale renewable energy solutions for cooling in milk value chains are the high upfront cost of technology combined with a lack of financing mechanisms for clean energy. A second barrier is the lack of awareness of available technology among farmers, dairies and cooperatives. The relevant policies and regulations for food safety are not consistently enforced, and on informal markets, quality testing is not carried out. Besides temperature, other factors can affect the quality of the milk, like hygienic practices or poor animal handling tend to cause contamination soon after milking. This supports the argument for the deployment of other awareness raising efforts and of further clean energy solution in the value chain, such as solar water heaters for equipment cleaning.

However, small dairies are less likely to have access to the knowledge and capital required to invest in modern technology for their cooling facilities and processing plants. Enhancing access to finance may allow to invest in energy efficient and clean energy solutions, which would lead to reduced costs, and increase farmers’ incomes. Read more…

Biogas Milk Chilling for Dairy Farmers

In the emerging dairy industry in East Africa, the demand is expected to double in the coming years. However, only 15 percent of milk produced reaches the formal market, partly due to the lack of access to a reliable power grid for cooling. As there had been a lack of solutions available on the market to provide milk chilling technologies at micro-scale, SimGas together with SNV developed a small-scale biogas-powered milk chiller for smallholder farmers in Kenya, Tanzania and Rwanda. Read more…

Biogas-Powered Evaporative Cooling for the Dairy Industry

The growing dairy industry throughout sub-Saharan Africa suffers from a lack of proper refrigeration options, which causes farmers to lose 20-50 percent of their milk to spoilage. The University of Georgia Research Foundation (UGARF) together with the Smallholder Fortunes’ small scale demonstration dairy farm in Uganda have developed the EvaKuula: a biogas unit that works with cow manure and allows a mild heat treatment of the milk, followed by a gentle evaporative cooling process, keeping the milk fresh overnight. Working with local manufacturers, financing models are being developed to bring the local production to commercial scale. Using the EvaKuula, smallholder dairy farmers not only profit from access to clean energy, which can be used for lighting and cooking, but also reduce greenhouse gas emissions from cow manure fermentation. 42 farmers (50 percent of them being women) have so far benefitted from the deployment of this device. Read more…

SunDanzer: Solar Powered Refrigeration for Kenyan Dairy Farms

In Kenya, 85 percent of dairy farms do not have access to refrigerated storage and transportation due to limited electrification in rural areas, leading to dramatic losses from milk spoilage. SunDanzer together with Winrock International have developed an affordable small-scale portable cooling system: the photovoltaic refrigerator (PVR) runs on solar energy and uses phase-change materials – substances capable of storing and releasing large amounts of energy – and therefore needs no battery. Additionally, the innovators have developed milk can blankets to retain the temperature during transportation. 60 solar-powered milk cooling refrigerators have been installed so far in Kenya and two in Rwanda. Users of SunDanzer’s refrigerators have stated that the technology has delivered many benefits, including increased financial security for households, increased food preservation, and saved time. Read more…

Reducing Milk Spoilage through Solar-Powered Chilling

Perishable food worth of 10 billion US Dollars is wasted annually in India because of unreliable cold-chain supply networks. Especially in farming areas and villages, the lack of reliable electricity is a challenge for running refrigeration systems. With India being the largest consumer and producer of milk in the world, Promethean Power Systems together with Hatsun Agro and Orb Energy have developed a solar milk cooling system that uses an innovative thermal energy battery pack. Charging on intermittent power sources such as solar power and/or a few hours of grid electricity, it allows changing the local food situation considerably. Read more…

Transportation

Solar Milk Cooling with Insulated Milk Cans

Milk produced on small- to medium-scale farms is usually transported to milk collection facilities. The spoilage caused by bacterial growth during transportation due to warm temperatures leads to milk being refused by vendors. Secondly, many farmers do not sell their evening milk to the collection centres, as it cannot be stored adequately overnight. Instead, they sell the milk to neighbours or use it themselves. This can increase the on-farm losses and reduce income. The solar milk cooling system developed by the University of Hohenheim (Germany) uses solar energy for ice production. The produced ice is used to cool the milk by putting it into an ice-compartment of an insulated milk can. This system allows lower temperatures during transportation and overnight storage, increasing the farms production and income. On-field implementations have taken place in Tunisia (10 installed systems), Kenya (4 installed systems), and Colombia (also 4 installed systems). Read more…

Energy production

By-products from the milk value chain can be utilized for purposes such as energy generation or organic soil fertilizers. Biogas is a renewable energy source, which can be produced at different scales and is thus, a clean energy solution for cattle farms of all sizes.

Biogas for Power Generation from Dairy Cattle – INVESTA Study

Biogas is produced through anaerobic digestion (AD), a biochemical process that involves the decomposition of organic matter by symbiotic bacteria living in anaerobic environments. Biogas produced from cattle manure can be directly combusted for heating, cooking, producing electricity and producing methane.

From one tonne of dairy cattle manure, the biogas produced can generate around 125 kWh of electricity. Depending on the farm size, different applications can be used. Commercial applications require higher capital investments and give more efficient large-scale technology. Pro-poor applications are suitable for less than 10 head of cattle per plant and allow mixing manure with other feedstocks to increase electricity production. The electricity produced usually even exceeds the farm’s needs for cooling and milking.

As a by-product of the anaerobic digestion process, the digestate (consisting of indigestible material and dead micro-organisms) can be used as a soil conditioner and fertilizer, as nutrient content remains the same, whilst eliminating most toxins and pathogens. Synthetic fertilizers, which require high-energy inputs during manufacturing, can be substituted and thus, reduce the carbon footprint.

Biogas systems provide clean energy to dairy farmers and enable them to diversify their income (when biogas is sold), decrease dependency on imported energy sources, generate manure treatment and sanitation, and produce quality soil conditioner. Biogas is an alternative form of energy access that helps avoid food losses in case of unreliable power supply for cooling. Read more…

Financial Viability

Costs and Benefits of Clean-Energy-Technologies in the Milk Value Chain

Despite the importance of the milk sector for income generation among small-scale farmers in countries like Tanzania, Kenya, and Tunisia, only a reduced amount has access to extension services, which could improve their productivity. Raw milk is usually transported to milk collection facilities, where it is often rejected due to low quality, as it is not cooled during transportation. The lack of a reliable electricity grid hinders most rural households from using adequate refrigeration systems.

Cooling technologies can significantly improve milk quality and add value along the milk value chain. Since grid electricity does not reach many rural areas, off-grid renewable energy (RE) solutions to cool milk can be a viable option. Biogas domestic milk chillers and solar milk coolers are attractive from a financial point of view and have socio-economic and environmental net co-benefits. Policies, financing mechanisms and capacity building activities to facilitate the adoption of renewable energy cooling solutions for milk include: the development of a clear national strategy for the milk sector, strict milk quality standards and a price premium for quality refrigerated milk, the establishment of controls and fines against illegal milk commercialization, eradication of counterfeit RE products, financial incentives, extension services, technical assistance, information programmes and training. [:File:https://energypedia.info/images/5/58/Costs_and_Benefits_of_Clean_Energy_Technologies_in_the_Milk,_Vegetable_and_Rice_Value_Chains.pdf Read more ...]

Costs and Benefits of Clean Energy Technologies in the Milk, Vegetable and Rice Value Chains

Building upon the report Opportunities for Agri-Food Chains to become Energy-Smart, a second report presents the economics related to the energetic transition aimed in sustainable agri-food systems. The report focuses three value chains and concentrates on key clean energy technologies. The costs, benefits, sustainability potentials and unintended impacts are analysed here at the intervention level (e.g. at famer or food processor level). A methodological approach has been developed to provide a sound and comprehensive cost-benefit analysis (CBA). It highlights hidden environmental and socio-economic costs of interventions, such as government-subsidized fossil fuel. The potentially added value of these technologies for different stakeholders is further considered using selected case. Read more…

References