Difference between revisions of "Types of Biogas Digesters and Plants"

***** (***** | *****) |

***** (***** | *****) m (→References) |

||

| (22 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| − | + | [[Portal:Biogas|►Back to Biogas Portal]] | |

| + | |||

= Introduction = | = Introduction = | ||

| − | {| cellpadding="5" border="0" align="right" style="width: 309px; | + | {| cellpadding="5" border="0" align="right" style="width: 309px;" |

|- | |- | ||

| style="width: 250px;" | | | style="width: 250px;" | | ||

[[File:Digestneck.jpg|278px|RTENOTITLE]] | [[File:Digestneck.jpg|278px|RTENOTITLE]] | ||

| − | + | '''Construction of the digester neck with steel reinforcement'''<ref name="Photo: Krämer (TBW)">Photo: Krämer (TBW)</ref><br/> | |

|} | |} | ||

| − | From the standpoint of fluid dynamics and structural strength, an egg-shaped vessel is about the best possible solution. This type of construction, however, is comparatively expensive, | + | Choosing a right biogas digester is a very important while constructing a biogas plant. From the standpoint of fluid dynamics and structural strength, an egg-shaped vessel is about the best possible solution. This type of construction, however, is comparatively expensive, therefore, its use is usually restricted to large-scale sewage treatment plants. The Chinese [[Fixed-dome_Biogas_Plants|fixed-dome]] designs are of similar shape, but less expensive. The hemispherical CAMARTEC design is optimized in structural strength, but does not make optimal use of the excavation required. |

Simplified versions of such digester designs include cylinders with conical covers and bottoms. They are much easier to build and are sometimes available on the market as prefabricated units. Their disadvantage lies in their less favorable surface-volume ratio. The cylinder should have a height equal to its diameter. ''Prone cylinders'' have become quite popular on farms, since they are frequently the more favorable solution for small-scale bio-methanation. ''Cuboid digesters'' are often employed in batch-fed systems used primarily for fermenting solid material, so that fluid dynamics are of little interest. | Simplified versions of such digester designs include cylinders with conical covers and bottoms. They are much easier to build and are sometimes available on the market as prefabricated units. Their disadvantage lies in their less favorable surface-volume ratio. The cylinder should have a height equal to its diameter. ''Prone cylinders'' have become quite popular on farms, since they are frequently the more favorable solution for small-scale bio-methanation. ''Cuboid digesters'' are often employed in batch-fed systems used primarily for fermenting solid material, so that fluid dynamics are of little interest. | ||

| − | |||

| − | = < | + | = Types of Small-Scale Digesters = |

| + | |||

| + | == Fixed Dome Biogas Plants == | ||

| + | A fixed-dome plant comprises of a closed, dome-shaped digester with an immovable, rigid gas-holder and a displacement pit, also named 'compensation tank'. The gas is stored in the upper part of the digester. When gas production commences, the slurry is displaced into the compensating tank. Gas pressure increases with the volume of gas stored, i.e. with the height difference between the two slurry levels. If there is little gas in the gas-holder, the gas pressure is low.<br/> | ||

| + | |||

| + | [[Fixed-dome Biogas Plants#Fixed-dome Plants|►Read more here...]] | ||

| + | |||

| + | |||

| + | == Floating Drum Plants == | ||

| + | Floating-drum plants consist of an underground digester and a moving gas-holder. The gas-holder floats either directly on the fermentation slurry or in a water jacket of its own. The gas is collected in the gas drum, which rises or moves down, according to the amount of gas stored. | ||

| + | |||

| + | [[Floating Drum Biogas Plants|►Read more here...]] | ||

| + | |||

| + | |||

| + | |||

| + | == Low-Cost Polyethylene Tube Digester == | ||

| + | |||

| + | The Low-Cost Polyethylene Tube Digester model consist of tubular polyethylene film (two coats of 300 microns) bent at each end around a 6 inch PVC drainpipe and is wound with rubber strap of recycled tire-tubes. | ||

| + | |||

| + | [[Low-Cost_Polyethylene_Tube_Digester|►Read more here....]] | ||

| + | |||

| + | |||

| + | |||

| + | == Balloon Plants == | ||

| + | |||

| + | A balloon plant consists of a heat-sealed plastic or rubber bag (balloon), combining digester and gas-holder. The gas is stored in the upper part of the balloon. The inlet and outlet are attached directly to the skin of the balloon.<br/>[[Balloon_Digester_for_Biogas_Plants|►Read more here...]] | ||

| + | |||

| + | |||

| + | == Horizontal Plants<br/> == | ||

| + | |||

| + | Disadvantages''': Problems with gas-space leakage, difficult elimination of scum.'''<br/> | ||

| + | |||

| + | [[#toc|►Go to Top]]<br/> | ||

| + | |||

| + | |||

| + | == Earth-pit Plants<br/> == | ||

| + | |||

| + | Masonry digesters are not necessary in stable soil (e.g. laterite). It is sufficient to line the pit with a thin layer of cement (wire-mesh fixed to the pit wall and plastered) in order to prevent seepage. The edge of the pit is reinforced with a ring of masonry that also serves as anchorage for the gas-holder. The gas-holder can be made of metal or plastic sheeting. If plastic sheeting is used, it must be attached to a quadratic wooden frame that extends down into the slurry and is anchored in place to counter its buoyancy. The requisite gas pressure is achieved by placing weights on the gas-holder. An overflow point in the peripheral wall serves as the slurry outlet'''. | ||

| + | |||

| + | |||

| + | '''Advantages''' | ||

| + | *Low cost of installation (as little as 20% of a floating-drum plant); | ||

| + | *high potential for self help approaches. | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | '''Disadvantages''' | |

| + | *Short useful life; serviceable only in suitable, impermeable types of soil. | ||

| + | *Earth-pit plants can only be recommended for installation in impermeable soil located above the groundwater table. Their construction is particularly inexpensive in connection with plastic sheet gas-holders. | ||

<br/> | <br/> | ||

| − | <br/> | + | [[Fixed-dome_Biogas_Plants#toc|►Go to Top]]<br/> |

| + | |||

| + | == Ferro-cement Plants == | ||

| + | |||

| + | The ferro-cement type of construction can be applied either as a self-supporting shell or an earth-pit lining. The vessel is usually cylindrical. Very small plants (Volume under 6 m<sup>3</sup>) can be prefabricated. As in the case of a fixed-dome plant, the ferrocement gasholder requires special sealing measures (proven reliability with cemented-on aluminium foil). | ||

| + | |||

| − | + | '''Disadvantages''' | |

| + | *Substantial consumption of essentially good-quality cement; | ||

| + | *workmanship must meet high quality standards; | ||

| + | *uses substantial amounts of expensive wire mesh; | ||

| + | *construction technique not yet adequately time-tested; | ||

| + | *special sealing measures for the gas-holder are necessary. Ferro-cement biogas plants are only recommended in cases where special ferro-cement know-how is available. | ||

| − | |||

| − | <br/> | + | [[#toc|►Go to Top]]<br/> |

| − | + | = Industrial Digester Types = | |

| − | <br/> | + | {| class="IMGright FCK__ShowTableBorders" border="0" cellpadding="10" align="right" style="width: 378px;" |

| + | |- | ||

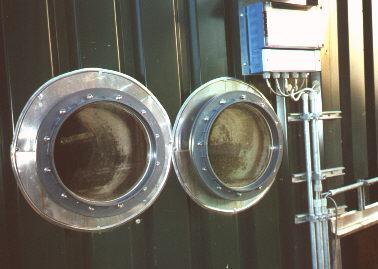

| + | | [[File:Indsolcontrol.jpg|378px|RTENOTITLE]]<small class="IMGLEGEND">Control glasses for an industrial digester for solid organic waste, Germany</small><ref name="TBW">TBW</ref><br/> | ||

| + | |} | ||

| − | + | To give an overview, some fictitious designs have been chosen as they could be found in, for example, Europe. The designs are selected in a way that all the typical elements of modern biogas technology appear at least once. All designs are above-ground, which is common in Europe. Underground structures, however, do exist. | |

| − | |||

'''Mixing pit''' varies in size and shape according to the nature of substrate. It is equipped with propellers for mixing and/or chopping the substrate and often with a pump to transport the substrate into the digester. At times, the substrate is also pre-heated in the mixing pit in order to avoid a temperature shock inside the digester. | '''Mixing pit''' varies in size and shape according to the nature of substrate. It is equipped with propellers for mixing and/or chopping the substrate and often with a pump to transport the substrate into the digester. At times, the substrate is also pre-heated in the mixing pit in order to avoid a temperature shock inside the digester. | ||

| Line 48: | Line 99: | ||

<br/> | <br/> | ||

| − | '''Fermenter or digester''' is insulated and made of concrete or steel. To optimize the flow of substrate, large digesters have a longish channel form. Large digesters are almost always agitated by slow rotating paddles or rotors or by injected | + | '''Fermenter or digester''' is insulated and made of concrete or steel. To optimize the flow of substrate, large digesters have a longish channel form. Large digesters are almost always agitated by slow rotating paddles or rotors or by injected biogas. Co-fermenters have two or more separated fermenters. The gas can be collected inside the digester, then usually with a flexible cover. The digester can also be filled completely and the gas stored in a separate gas-holder. |

<br/> | <br/> | ||

| Line 93: | Line 144: | ||

<br/> | <br/> | ||

| − | + | [[#toc|►Go to Top]] | |

| − | + | == Batch plants == | |

| − | |||

| − | == | ||

Batch plants are filled and then emptied completely after a fixed retention time. Each design and each fermentation material is suitable for batch filling, but batch plants require high labor input. As a major disadvantage, their gas-output is not steady. | Batch plants are filled and then emptied completely after a fixed retention time. Each design and each fermentation material is suitable for batch filling, but batch plants require high labor input. As a major disadvantage, their gas-output is not steady. | ||

| − | + | [[#toc|►Go to Top]] | |

=== Continuous plants<br/> === | === Continuous plants<br/> === | ||

| Line 107: | Line 156: | ||

Continuous plants are fed and emptied continuously. They empty automatically through the overflow whenever new material is filled in. Therefore, the substrate must be fluid and homogeneous. Continuous plants are suitable for rural households as the necessary work fits well into the daily routine. Gas production is constant, and higher than in batch plants. Today, nearly all biogas plants are operating on a continuous mode. | Continuous plants are fed and emptied continuously. They empty automatically through the overflow whenever new material is filled in. Therefore, the substrate must be fluid and homogeneous. Continuous plants are suitable for rural households as the necessary work fits well into the daily routine. Gas production is constant, and higher than in batch plants. Today, nearly all biogas plants are operating on a continuous mode. | ||

| − | + | [[#toc|►Go to Top]] | |

=== Semi-batch basis<br/> === | === Semi-batch basis<br/> === | ||

| Line 113: | Line 162: | ||

If straw and dung are to be digested together, a biogas plant can be operated on a semi-batch basis. The slowly digested straw-type material is fed in about twice a year as a batch load. The dung is added and removed regularly. | If straw and dung are to be digested together, a biogas plant can be operated on a semi-batch basis. The slowly digested straw-type material is fed in about twice a year as a batch load. The dung is added and removed regularly. | ||

| − | + | [[#toc|►Go to Top]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | [[# | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

= Dry Fermentation Plants<br/> = | = Dry Fermentation Plants<br/> = | ||

| − | Dry fermentation is an anaerobic process in which micro-organism break down biodegradable material. Renewable organic | + | Dry fermentation is an anaerobic process in which micro-organism break down biodegradable material. Renewable organic feedstocks are used as a the source of energy for the process. The nutrient-rich solids resulting from the digestion can be used as a fertiliser subsequently. |

Almost any organic material can be processed with dry fermentation. This includes biodegradable waste materials such as waste paper, grass clippings, leftover food, sewage and animal waste. | Almost any organic material can be processed with dry fermentation. This includes biodegradable waste materials such as waste paper, grass clippings, leftover food, sewage and animal waste. | ||

| Line 158: | Line 174: | ||

<u>'''Process'''</u><br/> | <u>'''Process'''</u><br/> | ||

| − | *[[:file: | + | *[[:file:VTI_Dry_fermentation_biogas_in_Germany.pdf|Dry fermentation in germany]] (vTI presentation, 2 MB) |

<br/> | <br/> | ||

| + | |||

| + | [[Types_of_Biogas_Digesters_and_Plants#toc|►Go to Top]] | ||

<br/> | <br/> | ||

= Further Information<br/> = | = Further Information<br/> = | ||

| − | |||

<u>'''English'''</u><br/> | <u>'''English'''</u><br/> | ||

| − | * | + | *Amaratunga, M.: Structural Behaviour and Stress Conditions of Fixed Dome Type of Biogas Units. Elhalwagi, M.M. (Ed.): Biogas Technology, Transfer and Diffusion, London & New York, pp. 295-301. 1986. 0001182; ISBN: 1-85166-000-3 |

| − | *van Buren, A.; Crook, M.: A Chinese | + | *van Buren, A.; Crook, M.: A Chinese Biogas Manual – Popularizing Technology in the Countryside. Intermediate Technology Publications Ltd. London (UK), 1979, sixth impression 1985, 135 P. ISBN: 0903031655 |

| − | * | + | *Fulford, D.: Fixed Concrete Dome Design. Biogas - Challenges and Experience from Nepal. Vol I. United Mission to Nepal, 1985, pp.3.1-3.10. |

| − | * | + | *Ringkamp , M. – FH Hildesheim Holzminden/Faculty of Civil Engineering Holzminden (Germany): Regional Biogas Extension Programme GCR - Final Report on Statistical and Structural Examination of Caribbean Biogas Plants. 1989, 60 P. |

| − | * | + | *Sasse, L. - GATE, Bremer Arbeitsgemeinschaft für Überseeforschung Entwicklung (BORDA): Biogas Plants - Design and Details of Simple Biogas Plants. 2nd edition, 1988, 85 P., ISBN: 3-528-02004-0 |

| − | *Werner, U., | + | *Werner, U., Stoh, U., Hees, N. - GATE: Biogas Plants in Animal Husbandry - A Practical Guide. Friedr. Vieweg & Sohn, Braunschweig/Wiesbaden (Germany), 1989; 153 p., ISBN: 3-528-02048-2 |

| − | * | + | * Sasse, L. - Centro de Investigacion, Estudios y Documentacion (CIED) Lima (Peru): La Planta de Biogas - Bosquejo y Detaille de Plantas Simples. Reciclaje de la Materia Organica 3. 1986. 103 p. |

<br/> | <br/> | ||

| − | [http://www.biogaspartner.de/en/biowhat-biomethane/value-chain/biogas-upgrade.html How to upgrade biogas on BIOGASPARTNER] | + | <u>Articles on energypedia</u> |

| + | *[http://www.biogaspartner.de/en/biowhat-biomethane/value-chain/biogas-upgrade.html How to upgrade biogas on BIOGASPARTNER] | ||

| + | *[http://www1.agric.gov.ab.ca/$department/deptdocs.nsf/all/bdv11206/$file/biogasplantdatasheets0606.pdf?OpenElement Data sheets of biogas plants] | ||

| + | *[[Plastic Tube Digesters in Kenya|Plastic tube digester (domestic).]] | ||

| + | *[[Low-Cost Polyethylene Tube Digesters in Bolivia|Polyethylene digester in Bolivia.]] | ||

| + | *[[Biogas Technology in India|Biogas technology in India.]] | ||

| + | *[https://energypedia.info/index.php/Types_of_Biogas_Digesters_and_Plants Types of biogas digesters and plants (mainly domestic applications)] | ||

| − | |||

| − | [ | + | [[#toc|►Go to Top]] |

| − | |||

| − | + | = References<br/> = | |

| − | + | This article is based on the following publication: | |

| − | + | GTZ: [[:File:Biogas gate volume 2.pdf|Biogas Digest Volume II: Biogas - Application and Product Development]] | |

| − | |||

| − | [ | ||

| − | |||

| − | |||

| − | |||

| − | |||

<references /> | <references /> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

[[Category:Bioenergy]] | [[Category:Bioenergy]] | ||

[[Category:Biogas]] | [[Category:Biogas]] | ||

Latest revision as of 14:27, 15 December 2015

Introduction

|

Construction of the digester neck with steel reinforcement[1] |

Choosing a right biogas digester is a very important while constructing a biogas plant. From the standpoint of fluid dynamics and structural strength, an egg-shaped vessel is about the best possible solution. This type of construction, however, is comparatively expensive, therefore, its use is usually restricted to large-scale sewage treatment plants. The Chinese fixed-dome designs are of similar shape, but less expensive. The hemispherical CAMARTEC design is optimized in structural strength, but does not make optimal use of the excavation required.

Simplified versions of such digester designs include cylinders with conical covers and bottoms. They are much easier to build and are sometimes available on the market as prefabricated units. Their disadvantage lies in their less favorable surface-volume ratio. The cylinder should have a height equal to its diameter. Prone cylinders have become quite popular on farms, since they are frequently the more favorable solution for small-scale bio-methanation. Cuboid digesters are often employed in batch-fed systems used primarily for fermenting solid material, so that fluid dynamics are of little interest.

Types of Small-Scale Digesters

Fixed Dome Biogas Plants

A fixed-dome plant comprises of a closed, dome-shaped digester with an immovable, rigid gas-holder and a displacement pit, also named 'compensation tank'. The gas is stored in the upper part of the digester. When gas production commences, the slurry is displaced into the compensating tank. Gas pressure increases with the volume of gas stored, i.e. with the height difference between the two slurry levels. If there is little gas in the gas-holder, the gas pressure is low.

Floating Drum Plants

Floating-drum plants consist of an underground digester and a moving gas-holder. The gas-holder floats either directly on the fermentation slurry or in a water jacket of its own. The gas is collected in the gas drum, which rises or moves down, according to the amount of gas stored.

Low-Cost Polyethylene Tube Digester

The Low-Cost Polyethylene Tube Digester model consist of tubular polyethylene film (two coats of 300 microns) bent at each end around a 6 inch PVC drainpipe and is wound with rubber strap of recycled tire-tubes.

Balloon Plants

A balloon plant consists of a heat-sealed plastic or rubber bag (balloon), combining digester and gas-holder. The gas is stored in the upper part of the balloon. The inlet and outlet are attached directly to the skin of the balloon.

►Read more here...

Horizontal Plants

Disadvantages: Problems with gas-space leakage, difficult elimination of scum.

Earth-pit Plants

Masonry digesters are not necessary in stable soil (e.g. laterite). It is sufficient to line the pit with a thin layer of cement (wire-mesh fixed to the pit wall and plastered) in order to prevent seepage. The edge of the pit is reinforced with a ring of masonry that also serves as anchorage for the gas-holder. The gas-holder can be made of metal or plastic sheeting. If plastic sheeting is used, it must be attached to a quadratic wooden frame that extends down into the slurry and is anchored in place to counter its buoyancy. The requisite gas pressure is achieved by placing weights on the gas-holder. An overflow point in the peripheral wall serves as the slurry outlet.

Advantages

- Low cost of installation (as little as 20% of a floating-drum plant);

- high potential for self help approaches.

Disadvantages

- Short useful life; serviceable only in suitable, impermeable types of soil.

- Earth-pit plants can only be recommended for installation in impermeable soil located above the groundwater table. Their construction is particularly inexpensive in connection with plastic sheet gas-holders.

Ferro-cement Plants

The ferro-cement type of construction can be applied either as a self-supporting shell or an earth-pit lining. The vessel is usually cylindrical. Very small plants (Volume under 6 m3) can be prefabricated. As in the case of a fixed-dome plant, the ferrocement gasholder requires special sealing measures (proven reliability with cemented-on aluminium foil).

Disadvantages

- Substantial consumption of essentially good-quality cement;

- workmanship must meet high quality standards;

- uses substantial amounts of expensive wire mesh;

- construction technique not yet adequately time-tested;

- special sealing measures for the gas-holder are necessary. Ferro-cement biogas plants are only recommended in cases where special ferro-cement know-how is available.

Industrial Digester Types

Control glasses for an industrial digester for solid organic waste, Germany[2] Control glasses for an industrial digester for solid organic waste, Germany[2] |

To give an overview, some fictitious designs have been chosen as they could be found in, for example, Europe. The designs are selected in a way that all the typical elements of modern biogas technology appear at least once. All designs are above-ground, which is common in Europe. Underground structures, however, do exist.

Mixing pit varies in size and shape according to the nature of substrate. It is equipped with propellers for mixing and/or chopping the substrate and often with a pump to transport the substrate into the digester. At times, the substrate is also pre-heated in the mixing pit in order to avoid a temperature shock inside the digester.

Fermenter or digester is insulated and made of concrete or steel. To optimize the flow of substrate, large digesters have a longish channel form. Large digesters are almost always agitated by slow rotating paddles or rotors or by injected biogas. Co-fermenters have two or more separated fermenters. The gas can be collected inside the digester, then usually with a flexible cover. The digester can also be filled completely and the gas stored in a separate gas-holder.

Gas-holder is usually of flexible material, therefore to be protected against weather. It can be placed either directly above the substrate, then it acts like a balloon plant, or in a separate 'gas-bag'.

Slurry store for storage of slurry during winter. The store can be open (like conventional open liquid manure storage) or closed and connected to the gas-holder to capture remaining gas production. Normally, the store is not heated and only agitated before the slurry is spread on the field.

Gas use element is in Europe in 95% of the cases a thermo-power unit which produces electricity for the farm, the grid and heat for the house, greenhouses and other uses. The thermo-power unit has the advantage, that the required energy can be produced in any mixture of gas and fossil energy. It can, therefore, react to periods of low gas production and high energy requirements or vice versa.

|

Concrete digester with two chambers (one heated, one unheated for storage)[2] |

|

Concrete digester with integrated plastic gas-holder[2] |

|

Steelvessel fermenter with seperate ballon gas-holder[2] |

Batch plants

Batch plants are filled and then emptied completely after a fixed retention time. Each design and each fermentation material is suitable for batch filling, but batch plants require high labor input. As a major disadvantage, their gas-output is not steady.

Continuous plants

Continuous plants are fed and emptied continuously. They empty automatically through the overflow whenever new material is filled in. Therefore, the substrate must be fluid and homogeneous. Continuous plants are suitable for rural households as the necessary work fits well into the daily routine. Gas production is constant, and higher than in batch plants. Today, nearly all biogas plants are operating on a continuous mode.

Semi-batch basis

If straw and dung are to be digested together, a biogas plant can be operated on a semi-batch basis. The slowly digested straw-type material is fed in about twice a year as a batch load. The dung is added and removed regularly.

Dry Fermentation Plants

Dry fermentation is an anaerobic process in which micro-organism break down biodegradable material. Renewable organic feedstocks are used as a the source of energy for the process. The nutrient-rich solids resulting from the digestion can be used as a fertiliser subsequently.

Almost any organic material can be processed with dry fermentation. This includes biodegradable waste materials such as waste paper, grass clippings, leftover food, sewage and animal waste.

Process

- Dry fermentation in germany (vTI presentation, 2 MB)

Further Information

English

- Amaratunga, M.: Structural Behaviour and Stress Conditions of Fixed Dome Type of Biogas Units. Elhalwagi, M.M. (Ed.): Biogas Technology, Transfer and Diffusion, London & New York, pp. 295-301. 1986. 0001182; ISBN: 1-85166-000-3

- van Buren, A.; Crook, M.: A Chinese Biogas Manual – Popularizing Technology in the Countryside. Intermediate Technology Publications Ltd. London (UK), 1979, sixth impression 1985, 135 P. ISBN: 0903031655

- Fulford, D.: Fixed Concrete Dome Design. Biogas - Challenges and Experience from Nepal. Vol I. United Mission to Nepal, 1985, pp.3.1-3.10.

- Ringkamp , M. – FH Hildesheim Holzminden/Faculty of Civil Engineering Holzminden (Germany): Regional Biogas Extension Programme GCR - Final Report on Statistical and Structural Examination of Caribbean Biogas Plants. 1989, 60 P.

- Sasse, L. - GATE, Bremer Arbeitsgemeinschaft für Überseeforschung Entwicklung (BORDA): Biogas Plants - Design and Details of Simple Biogas Plants. 2nd edition, 1988, 85 P., ISBN: 3-528-02004-0

- Werner, U., Stoh, U., Hees, N. - GATE: Biogas Plants in Animal Husbandry - A Practical Guide. Friedr. Vieweg & Sohn, Braunschweig/Wiesbaden (Germany), 1989; 153 p., ISBN: 3-528-02048-2

- Sasse, L. - Centro de Investigacion, Estudios y Documentacion (CIED) Lima (Peru): La Planta de Biogas - Bosquejo y Detaille de Plantas Simples. Reciclaje de la Materia Organica 3. 1986. 103 p.

Articles on energypedia

- How to upgrade biogas on BIOGASPARTNER

- Data sheets of biogas plants

- Plastic tube digester (domestic).

- Polyethylene digester in Bolivia.

- Biogas technology in India.

- Types of biogas digesters and plants (mainly domestic applications)

References

This article is based on the following publication:

GTZ: Biogas Digest Volume II: Biogas - Application and Product Development