Difference between revisions of "Types of Biogas Digesters and Plants"

***** (***** | *****) |

***** (***** | *****) |

||

| Line 4: | Line 4: | ||

== Digester Types in Industrialized Countries<br/> == | == Digester Types in Industrialized Countries<br/> == | ||

| − | {| class="IMGright FCK__ShowTableBorders" border="0" cellpadding="10" align="right" | + | {| class="IMGright FCK__ShowTableBorders" border="0" cellpadding="10" align="right" style="width: 378px;" |

|- | |- | ||

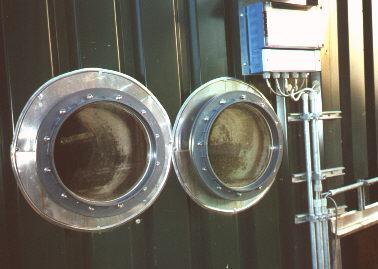

| − | | | + | | [[File:Indsolcontrol.jpg|378px|RTENOTITLE]]<small class="IMGLEGEND">Control glasses for an industrial digester for solid organic waste, Germany</small><ref name="TBW">TBW</ref><br/> |

|} | |} | ||

To give an overview, some fictitious designs have been chosen as they could be found in, for example, Europe. The designs are selected in a way that all the typical elements of modern biogas technology appear at least once. All designs are above-ground, which is common in Europe. Underground structures, however, do exist. | To give an overview, some fictitious designs have been chosen as they could be found in, for example, Europe. The designs are selected in a way that all the typical elements of modern biogas technology appear at least once. All designs are above-ground, which is common in Europe. Underground structures, however, do exist. | ||

| + | |||

| + | <br/> | ||

'''Mixing pit''' varies in size and shape according to the nature of substrate. It is equipped with propellers for mixing and/or chopping the substrate and often with a pump to transport the substrate into the digester. At times, the substrate is also pre-heated in the mixing pit in order to avoid a temperature shock inside the digester. | '''Mixing pit''' varies in size and shape according to the nature of substrate. It is equipped with propellers for mixing and/or chopping the substrate and often with a pump to transport the substrate into the digester. At times, the substrate is also pre-heated in the mixing pit in order to avoid a temperature shock inside the digester. | ||

| + | |||

| + | <br/> | ||

'''Fermenter or digester''' is insulated and made of concrete or steel. To optimize the flow of substrate, large digesters have a longish channel form. Large digesters are almost always agitated by slow rotating paddles or rotors or by injected biogas. Co-fermenters have two or more separated fermenters. The gas can be collected inside the digester, then usually with a flexible cover. The digester can also be filled completely and the gas stored in a separate gas-holder. | '''Fermenter or digester''' is insulated and made of concrete or steel. To optimize the flow of substrate, large digesters have a longish channel form. Large digesters are almost always agitated by slow rotating paddles or rotors or by injected biogas. Co-fermenters have two or more separated fermenters. The gas can be collected inside the digester, then usually with a flexible cover. The digester can also be filled completely and the gas stored in a separate gas-holder. | ||

| + | |||

| + | <br/> | ||

'''Gas-holder''' is usually of flexible material, therefore to be protected against weather. It can be placed either directly above the substrate, then it acts like a balloon plant, or in a separate 'gas-bag'. | '''Gas-holder''' is usually of flexible material, therefore to be protected against weather. It can be placed either directly above the substrate, then it acts like a balloon plant, or in a separate 'gas-bag'. | ||

| + | |||

| + | <br/> | ||

'''slurry store''' for storage of slurry during winter. The store can be open (like conventional open liquid manure storage) or closed and connected to the gas-holder to capture remaining gas production. Normally, the store is not heated and only agitated before the slurry is spread on the field. | '''slurry store''' for storage of slurry during winter. The store can be open (like conventional open liquid manure storage) or closed and connected to the gas-holder to capture remaining gas production. Normally, the store is not heated and only agitated before the slurry is spread on the field. | ||

| + | |||

| + | <br/> | ||

'''Gas use element''' is in Europe in 95% of the cases a thermo-power unit which produces electricity for the farm, the grid and heat for the house, greenhouses and other uses. The thermo-power unit has the advantage, that the required energy can be produced in any mixture of gas and fossil energy. It can, therefore, react to periods of low gas production and high energy requirements or vice versa. | '''Gas use element''' is in Europe in 95% of the cases a thermo-power unit which produces electricity for the farm, the grid and heat for the house, greenhouses and other uses. The thermo-power unit has the advantage, that the required energy can be produced in any mixture of gas and fossil energy. It can, therefore, react to periods of low gas production and high energy requirements or vice versa. | ||

| − | {| style="width: | + | <br/> |

| + | |||

| + | {| style="width: 500px;" class="IMGcenter FCK__ShowTableBorders" border="0" cellpadding="0" cellspacing="0" align="center" | ||

|- | |- | ||

| − | | | + | | <p style="text-align: center;">[[File:Concretedigest1.gif|550px|RTENOTITLE]]</p> |

| − | |||

| − | |||

<small class="IMGLEGEND">'''Concrete digester with two chambers (one heated, one unheated for storage)'''</small><ref name="TBW">TBW</ref> | <small class="IMGLEGEND">'''Concrete digester with two chambers (one heated, one unheated for storage)'''</small><ref name="TBW">TBW</ref> | ||

|} | |} | ||

| − | {| style="width: | + | {| style="width: 500px;" class="IMGcenter FCK__ShowTableBorders" border="0" cellpadding="0" cellspacing="0" align="center" |

|- | |- | ||

| | | | ||

| − | + | [[File:Concretedigest2.gif|550px|RTENOTITLE]] | |

<small class="IMGLEGEND">'''Concrete digester with integrated plastic gas-holder'''</small><ref name="TBW">TBW</ref> | <small class="IMGLEGEND">'''Concrete digester with integrated plastic gas-holder'''</small><ref name="TBW">TBW</ref> | ||

| Line 39: | Line 49: | ||

|} | |} | ||

| − | {| style="width: | + | {| style="width: 500px;" class="IMGcenter FCK__ShowTableBorders" border="0" cellpadding="0" cellspacing="0" align="center" |

|- | |- | ||

| | | | ||

| − | + | [[File:Concretedigest3.gif|550px|RTENOTITLE]] | |

| − | |||

| + | <br/> | ||

'''<small class="IMGLEGEND">Steelvessel fermenter with seperate ballon gas-holder</small><ref name="TBW">TBW</ref>''' | '''<small class="IMGLEGEND">Steelvessel fermenter with seperate ballon gas-holder</small><ref name="TBW">TBW</ref>''' | ||

| Line 50: | Line 60: | ||

|} | |} | ||

| − | + | <br/> | |

== Selection of Appropriate Design<br/> == | == Selection of Appropriate Design<br/> == | ||

| Line 56: | Line 66: | ||

In developing countries, the design selection is determined largely be the prevailing design in the region, which, in turn takes the climatic, economic and substrate specific conditions into consideration. Large plants are designed on a case-to-case basis. | In developing countries, the design selection is determined largely be the prevailing design in the region, which, in turn takes the climatic, economic and substrate specific conditions into consideration. Large plants are designed on a case-to-case basis. | ||

| − | + | <br/> | |

<u>Typical design criteria are:</u> | <u>Typical design criteria are:</u> | ||

| Line 68: | Line 78: | ||

'''Available substrate''' determines not only the size and shape of mixing pit but the digester volume (retention time!), the heating and agitation devices. Agitation through gas injection is only feasible with homogenous substrate and a dry matter content below 5%. Mechanical agitation becomes problematic above 10% dry matter. | '''Available substrate''' determines not only the size and shape of mixing pit but the digester volume (retention time!), the heating and agitation devices. Agitation through gas injection is only feasible with homogenous substrate and a dry matter content below 5%. Mechanical agitation becomes problematic above 10% dry matter. | ||

| + | <br/> | ||

| + | === Balloon Plants<br/> === | ||

| − | + | A balloon plant consists of a heat-sealed plastic or rubber bag (balloon), combining digester and gas-holder. The gas is stored in the upper part of the balloon. The inlet and outlet are attached directly to the skin of the balloon. Gas pressure can be increased by placing weights on the balloon. If the gas pressure exceeds a limit that the balloon can withstand, it may damage the skin. Therefore, safety valves are required. If higher gas pressures are needed, a gas pump is required. Since the material has to be weather- and UV resistant, specially stabilized, reinforced plastic or synthetic caoutchouc is given preference. Other materials which have been used successfully include RMP (red mud plastic), Trevira and butyl. The useful life-span does usually not exceed 2-5 years. | |

| − | + | <br/> | |

| − | '''Advantages''': Standardized prefabrication at low cost, | + | '''Advantages''': Standardized prefabrication at low cost, low construction sophistication, ease of transportation, shallow installation suitable for use in areas with a high groundwater table; high digester temperatures in warm climates; uncomplicated cleaning, emptying and maintenance; difficult substrates like water hyacinths can be used. |

Balloon biogas plants are recommended, if local repair is or can be made possible and the cost advantage is substantial. | Balloon biogas plants are recommended, if local repair is or can be made possible and the cost advantage is substantial. | ||

| + | |||

| + | <br/> | ||

'''Disadvantages''': Low gas pressure may require gas pumps; scum cannot be removed during operation; the plastic balloon has a relatively short useful life-span and is susceptible to mechanical damage and usually not available locally. In addition, local craftsmen are rarely in a position to repair a damaged balloon. There is only little scope for the creation of local employment and, therefore, limited self-help potential. | '''Disadvantages''': Low gas pressure may require gas pumps; scum cannot be removed during operation; the plastic balloon has a relatively short useful life-span and is susceptible to mechanical damage and usually not available locally. In addition, local craftsmen are rarely in a position to repair a damaged balloon. There is only little scope for the creation of local employment and, therefore, limited self-help potential. | ||

| + | |||

| + | <br/> | ||

'''Variations:''' A variation of the balloon plant is the channel-type digester, which is usually covered with plastic sheeting and a sunshade (fig.1-E). Balloon plants can be recommended wherever the balloon skin is not likely to be damaged and where the temperature is even and high. | '''Variations:''' A variation of the balloon plant is the channel-type digester, which is usually covered with plastic sheeting and a sunshade (fig.1-E). Balloon plants can be recommended wherever the balloon skin is not likely to be damaged and where the temperature is even and high. | ||

| + | <br/> | ||

| − | + | {| class="IMGright FCK__ShowTableBorders" border="0" cellpadding="10" align="center" style="width: 348px;" | |

| − | {| class="IMGright FCK__ShowTableBorders" border="0" cellpadding="10" align="center" | ||

|- | |- | ||

| | | | ||

| − | [[File:Foilplant.jpg|RTENOTITLE]] <small class="IMGLEGEND">Photo<ref name="Henning"> Henning</ref>:Small "foil-plant" (Ivory Coast)</small> | + | [[File:Foilplant.jpg|348px|RTENOTITLE]] <small class="IMGLEGEND">Photo<ref name="Henning"> Henning</ref>:Small "foil-plant" (Ivory Coast)</small> |

| | | | ||

| − | [[File:Plant-types s.gif| | + | [[File:Plant-types s.gif|Plant-types s.gif|alt=Plant-types s.gif]] <small class="IMGLEGEND">Fig. 1<ref name="Biogas Plants, L. Sasse, GATE, 1988, p. 14">Biogas Plants, L. Sasse, GATE, 1988, p. 14</ref>: Simple biogas plants. Floating-drum plant (A), fixed-dome plant (B), fixed-dome plant with separate gas holder (C), balloon plant (D), channel-type digester with plastic sheeting and sunshade (E).</small> |

|} | |} | ||

| + | |||

| + | <br/> | ||

=== Horizontal Plants<br/> === | === Horizontal Plants<br/> === | ||

| Line 102: | Line 120: | ||

'''Disadvantages''': Problems with gas-space leakage, difficult elimination of scum. | '''Disadvantages''': Problems with gas-space leakage, difficult elimination of scum. | ||

| − | + | <br/> | |

<blockquote></blockquote> | <blockquote></blockquote> | ||

=== Earth-pit Plants<br/> === | === Earth-pit Plants<br/> === | ||

| Line 112: | Line 130: | ||

'''Disadvantages''': Short useful life; serviceable only in suitable, impermeable types of soil. | '''Disadvantages''': Short useful life; serviceable only in suitable, impermeable types of soil. | ||

| − | + | <br/> | |

Earth-pit plants can only be recommended for installation in impermeable soil located above the groundwater table. Their construction is particularly inexpensive in connection with plastic sheet gas-holders. | Earth-pit plants can only be recommended for installation in impermeable soil located above the groundwater table. Their construction is particularly inexpensive in connection with plastic sheet gas-holders. | ||

| − | + | <br/> | |

=== Ferrocement Plants<br/> === | === Ferrocement Plants<br/> === | ||

| Line 124: | Line 142: | ||

'''''Advantages''''': Low cost of construction, especially in comparison with potentially high cost of masonry for alternative plants; mass production possible; low material input. | '''''Advantages''''': Low cost of construction, especially in comparison with potentially high cost of masonry for alternative plants; mass production possible; low material input. | ||

| − | '''Disadvantages''': Substantial consumption of essentially good-quality cement; workmanship must meet high quality standards; uses substantial amounts of expensive wire mesh; construction technique not yet adequately time-tested; special sealing measures for the gas-holder are necessary. Ferro-cement biogas plants are only recommended in cases where special ferro-cement know-how is available.<!-- Navigation Footer --> | + | '''Disadvantages''': Substantial consumption of essentially good-quality cement; workmanship must meet high quality standards; uses substantial amounts of expensive wire mesh; construction technique not yet adequately time-tested; special sealing measures for the gas-holder are necessary. Ferro-cement biogas plants are only recommended in cases where special ferro-cement know-how is available. <!-- Navigation Footer --> |

| − | |||

| + | <br/> | ||

= Biogas Digester Types<br/> = | = Biogas Digester Types<br/> = | ||

| − | In this | + | In this section, the most important types of biogas plants are described: |

| − | <u>Wet fermentation:</u> | + | '''<u>Wet fermentation:</u>''' |

| − | + | *[[Types of Biogas Digesters and Plants#Fixed-dome Plants|Fixed-dome plants]] | |

| − | *[[Types of Biogas Digesters and Plants#Fixed- | + | *[[Types of Biogas Digesters and Plants#Floating-drum Plants|Floating-drum plants]] |

| − | *[[Types of Biogas Digesters and Plants#Floating- | + | *[[Types of Biogas Digesters and Plants#Low-Cost Polyethylen Tube Digester|Low-Cost Polyethylene Tube Digester]] |

| − | *[[Types of Biogas Digesters and Plants#Low- | ||

*Balloon plants | *Balloon plants | ||

| + | <br/> | ||

| − | + | '''<u>Dry fermentation:</u>''' | |

| − | <u>Dry fermentation:</u> | ||

| − | |||

*'''...''' | *'''...''' | ||

<br/>Of these, the two most familiar types in developing countries are the '''fixed-dome plants''' and the '''floating-drum''' plants. | <br/>Of these, the two most familiar types in developing countries are the '''fixed-dome plants''' and the '''floating-drum''' plants. | ||

| − | Typical [[Types of Biogas Digesters and Plants# | + | Typical [[Types of Biogas Digesters and Plants#Digester types in industrialized countries|designs in industrialized countries]] and [[Types of Biogas Digesters and Plants#Selection of appropriate design|appropriate design selection criteria]] have also been considered. |

| − | |||

| + | <br/> | ||

= Wet Fermentation Plants<br/> = | = Wet Fermentation Plants<br/> = | ||

| Line 161: | Line 177: | ||

The construction of fixed dome plants is labor-intensive, thus creating local employment. Fixed-dome plants are not easy to build. They should only be built where construction can be supervised by experienced biogas technicians. Otherwise plants may not be gas-tight (porosity and cracks). | The construction of fixed dome plants is labor-intensive, thus creating local employment. Fixed-dome plants are not easy to build. They should only be built where construction can be supervised by experienced biogas technicians. Otherwise plants may not be gas-tight (porosity and cracks). | ||

| − | + | <br/> | |

The basic elements of a fixed dome plant (here the '''Nicarao Design''') are shown in the figure below. | The basic elements of a fixed dome plant (here the '''Nicarao Design''') are shown in the figure below. | ||

| − | {| class="FCK__ShowTableBorders" border="0" cellpadding="0" cellspacing="0" | + | {| class="FCK__ShowTableBorders" border="0" cellpadding="0" cellspacing="0" align="center" style="width: 500px;" |

|- | |- | ||

| − | | | + | | style="width: 45%;" | <br/> |

| − | | [[File:Nicarao biogas.gif|RTENOTITLE]] <small class="IMGLEGEND">Fixed dome plant Nicarao design<ref name="TBW">TBW</ref>''': 1. Mixing tank with inlet pipe and sand trap. 2. Digester. 3. Compensation and removal tank. 4. Gasholder. 5. Gaspipe. 6. Entry hatch, with gastight seal. 7. Accumulation of thick sludge. 8. Outlet pipe. 9. Reference level. 10. Supernatant scum, broken up by varying level.'''</small><br/> | + | | [[File:Nicarao biogas.gif|555px|RTENOTITLE]] <small class="IMGLEGEND">Fixed dome plant Nicarao design<ref name="TBW">TBW</ref>''': 1. Mixing tank with inlet pipe and sand trap. 2. Digester. 3. Compensation and removal tank. 4. Gasholder. 5. Gaspipe. 6. Entry hatch, with gastight seal. 7. Accumulation of thick sludge. 8. Outlet pipe. 9. Reference level. 10. Supernatant scum, broken up by varying level.'''</small><br/> |

| − | | | + | | style="width: 45%;" | <br/> |

|} | |} | ||

| − | {| class="IMGright FCK__ShowTableBorders" style="width: 397px; | + | <br/> |

| + | |||

| + | <br/> | ||

| + | |||

| + | {| class="IMGright FCK__ShowTableBorders" style="width: 397px; height: 472px;" border="0" cellpadding="10" align="center" | ||

|- | |- | ||

| − | | [[File:Fixdomscheme.gif|RTENOTITLE]] <small class="IMGLEGEND">picture<ref name="OEKOTOP">OEKOTOP</ref>:Basic function of a fixed-dome biogas plant, 1 Mixing pit, 2 Digester, 3 Gasholder, 4 Displacement pit, 5 Gas pipe</small><br/> | + | | [[File:Fixdomscheme.gif|366px|RTENOTITLE]] <small class="IMGLEGEND">picture<ref name="OEKOTOP">OEKOTOP</ref>:Basic function of a fixed-dome biogas plant, 1 Mixing pit, 2 Digester, 3 Gasholder, 4 Displacement pit, 5 Gas pipe</small><br/> |

|} | |} | ||

| − | + | === <span style="font-size: 17px;">Function</span> === | |

| − | |||

| − | === Function === | ||

A fixed-dome plant comprises of a closed, dome-shaped digester with an immovable, rigid gas-holder and a displacement pit, also named 'compensation tank'. The gas is stored in the upper part of the digester. When gas production commences, the slurry is displaced into the compensating tank. Gas pressure increases with the volume of gas stored, i.e. with the height difference between the two slurry levels. If there is little gas in the gas-holder, the gas pressure is low. | A fixed-dome plant comprises of a closed, dome-shaped digester with an immovable, rigid gas-holder and a displacement pit, also named 'compensation tank'. The gas is stored in the upper part of the digester. When gas production commences, the slurry is displaced into the compensating tank. Gas pressure increases with the volume of gas stored, i.e. with the height difference between the two slurry levels. If there is little gas in the gas-holder, the gas pressure is low. | ||

| − | + | <br/> | |

=== Digester === | === Digester === | ||

The digesters of fixed-dome plants are usually masonry structures, structures of cement and ferro-cement exist. Main parameters for the choice of material are: | The digesters of fixed-dome plants are usually masonry structures, structures of cement and ferro-cement exist. Main parameters for the choice of material are: | ||

| − | |||

*Technical suitability (stability, gas- and liquid tightness); | *Technical suitability (stability, gas- and liquid tightness); | ||

*cost-effectiveness; | *cost-effectiveness; | ||

*availability in the region and transport costs; | *availability in the region and transport costs; | ||

*availability of local skills for working with the particular building material. | *availability of local skills for working with the particular building material. | ||

| + | |||

| + | <br/> | ||

Fixed dome plants produce just as much gas as floating-drum plants, ''if they are gas-tight''. However, utilization of the gas is less effective as the gas pressure fluctuates substantially. Burners and other simple appliances cannot be set in an optimal way. If the gas is required at constant pressure (e.g., for engines), a gas pressure regulator or a floating gas-holder is necessary. | Fixed dome plants produce just as much gas as floating-drum plants, ''if they are gas-tight''. However, utilization of the gas is less effective as the gas pressure fluctuates substantially. Burners and other simple appliances cannot be set in an optimal way. If the gas is required at constant pressure (e.g., for engines), a gas pressure regulator or a floating gas-holder is necessary. | ||

| − | {| class="FCK__ShowTableBorders" border="0" cellpadding="10" align=" | + | {| class="FCK__ShowTableBorders" border="0" cellpadding="10" align="center" style="width: 327px;" |

|- | |- | ||

| | | | ||

| − | + | <small class="IMGLEGEND">'''[[File:Biogastunesia01.jpg|333px|RTENOTITLE]]'''</small> | |

| − | <small class="IMGLEGEND"> | + | <small class="IMGLEGEND">Fixed-dome plant in Tunesia. The final layers of the masonry structure are being fixed.</small><ref name="gtz/GATE">gtz/GATE</ref> |

|} | |} | ||

| − | + | <br/> | |

=== Gas-Holder === | === Gas-Holder === | ||

| − | The top part of a fixed-dome plant (the gas space) must be gas-tight. Concrete, masonry and cement rendering are not gas-tight. The gas space must therefore be painted with a [[Plasters and coats for digesters and gas-holder|gas-tight layer]] (e.g. 'Water-proofer', Latex or synthetic paints). A possibility to reduce the risk of cracking of the gas-holder consists in the construction of a [[Optional Parts of a biogas plant# | + | The top part of a fixed-dome plant (the gas space) must be gas-tight. Concrete, masonry and cement rendering are not gas-tight. The gas space must therefore be painted with a [[Plasters and coats for digesters and gas-holder|gas-tight layer]] (e.g. 'Water-proofer', Latex or synthetic paints). A possibility to reduce the risk of cracking of the gas-holder consists in the construction of a [[Optional Parts of a biogas plant#Weak ring|weak-ring]] in the masonry of the digester. This "ring" is a flexible joint between the lower (water-proof) and the upper (gas-proof) part of the hemispherical structure. It prevents cracks that develop due to the hydrostatic pressure in the lower parts to move into the upper parts of the gas-holder. |

| − | |||

| − | |||

| + | <br/> | ||

| + | <br/> | ||

=== Types of Fixed-dome Plants<br/> === | === Types of Fixed-dome Plants<br/> === | ||

| Line 222: | Line 241: | ||

*'''CAMARTEC model''' has a simplified structure of a hemispherical dome shell based on a rigid foundation ring only and a calculated joint of fraction, the so-called weak / strong ring. It was developed in the late 80s in [[Biogas Technology in Tanzania|Tanzania]]. | *'''CAMARTEC model''' has a simplified structure of a hemispherical dome shell based on a rigid foundation ring only and a calculated joint of fraction, the so-called weak / strong ring. It was developed in the late 80s in [[Biogas Technology in Tanzania|Tanzania]]. | ||

| + | <br/> | ||

| − | + | {| class="IMGcenter FCK__ShowTableBorders" border="0" cellpadding="0" cellspacing="0" style="width: 500px;" align="center" | |

| − | |||

| − | |||

| − | {| class="IMGcenter FCK__ShowTableBorders" border="0" cellpadding="0" cellspacing="0" | ||

|- | |- | ||

| − | | | + | | style="width: 45%;" | <br/> |

| − | | [[File:Camartecfixdome.gif|RTENOTITLE]]<small class="IMGLEGEND">'''Fixed dome plant CAMARTEC design'''</small><ref name="TBW">TBW</ref><br/> | + | | [[File:Camartecfixdome.gif|550px|RTENOTITLE]]<small class="IMGLEGEND">'''Fixed dome plant CAMARTEC design'''</small><ref name="TBW">TBW</ref><br/> |

| − | | | + | | style="width: 45%;" | <br/> |

|} | |} | ||

| − | + | <br/> | |

=== Climate and Size<br/> === | === Climate and Size<br/> === | ||

| Line 239: | Line 256: | ||

Fixed-dome plants must be covered with earth up to the top of the gas-filled space to counteract the internal pressure (up to 0,15 bar). The earth cover insulation and the option for internal heating makes them suitable for colder climates. Due to economic parameters, the recommended minimum size of a fixed-dome plant is 5 m<sup>3</sup>. Digester volumes up to 200 m<sup>3</sup> are known and possible. | Fixed-dome plants must be covered with earth up to the top of the gas-filled space to counteract the internal pressure (up to 0,15 bar). The earth cover insulation and the option for internal heating makes them suitable for colder climates. Due to economic parameters, the recommended minimum size of a fixed-dome plant is 5 m<sup>3</sup>. Digester volumes up to 200 m<sup>3</sup> are known and possible. | ||

| − | + | <br/> | |

=== Summary === | === Summary === | ||

| Line 246: | Line 263: | ||

Advantages are the relatively low construction costs, the absence of moving parts and rusting steel parts. If well constructed, fixed dome plants have a long life span. The underground construction saves space and protects the digester from temperature changes. The construction provides opportunities for skilled local employment. | Advantages are the relatively low construction costs, the absence of moving parts and rusting steel parts. If well constructed, fixed dome plants have a long life span. The underground construction saves space and protects the digester from temperature changes. The construction provides opportunities for skilled local employment. | ||

| + | |||

| + | <br/> | ||

'''Disadvantages:''' Masonry gas-holders require special sealants and high technical skills for gas-tight construction; gas leaks occur quite frequently; fluctuating gas pressure complicates gas utilization; amount of gas produced is not immediately visible, plant operation not readily understandable; fixed dome plants need exact planning of levels; excavation can be difficult and expensive in bedrock. | '''Disadvantages:''' Masonry gas-holders require special sealants and high technical skills for gas-tight construction; gas leaks occur quite frequently; fluctuating gas pressure complicates gas utilization; amount of gas produced is not immediately visible, plant operation not readily understandable; fixed dome plants need exact planning of levels; excavation can be difficult and expensive in bedrock. | ||

| Line 252: | Line 271: | ||

''Fixed dome plants can be recommended only where construction can be supervised by experienced biogas technicians.'' | ''Fixed dome plants can be recommended only where construction can be supervised by experienced biogas technicians.'' | ||

| + | <br/> | ||

'''''Variations:''' Some companies are now looking into small pre-fab fixed dome plants made of fibreglass which appears to be a low cost alternative'' to construction intensive masoned plants. A custom made plant can be produced in 2 days and -after transport- installed in less than 1 day! | '''''Variations:''' Some companies are now looking into small pre-fab fixed dome plants made of fibreglass which appears to be a low cost alternative'' to construction intensive masoned plants. A custom made plant can be produced in 2 days and -after transport- installed in less than 1 day! | ||

| − | + | <br/> | |

== Floating-drum Plants<br/> == | == Floating-drum Plants<br/> == | ||

| Line 261: | Line 281: | ||

Floating-drum plants consist of an underground digester and a moving gas-holder. The gas-holder floats either directly on the fermentation slurry or in a water jacket of its own. The gas is collected in the gas drum, which rises or moves down, according to the amount of gas stored. The gas drum is prevented from tilting by a guiding frame. If the drum floats in a water jacket, it cannot get stuck, even in substrate with high solid content. | Floating-drum plants consist of an underground digester and a moving gas-holder. The gas-holder floats either directly on the fermentation slurry or in a water jacket of its own. The gas is collected in the gas drum, which rises or moves down, according to the amount of gas stored. The gas drum is prevented from tilting by a guiding frame. If the drum floats in a water jacket, it cannot get stuck, even in substrate with high solid content. | ||

| − | + | {| class="IMGleft FCK__ShowTableBorders" border="0" cellpadding="0" cellspacing="0" align="center" | |

| − | |||

| − | {| class="IMGleft FCK__ShowTableBorders" border="0" cellpadding="0" cellspacing="0" align=" | ||

|- | |- | ||

| | | | ||

| − | [[File:Floating drum mauretania.jpg|RTENOTITLE]] | + | [[File:Floating drum mauretania.jpg|333px|RTENOTITLE]] |

| − | <small class="IMGLEGEND">''' | + | <small class="IMGLEGEND">'''Floating-drum plant in Mauretania'''</small>'''<ref name="gtz/GATE">gtz/GATE</ref>''' |

|} | |} | ||

| − | + | <br/> | |

=== The Drum<br/> === | === The Drum<br/> === | ||

| Line 278: | Line 296: | ||

In the past, floating-drum plants were mainly built in India. A floating-drum plant consists of a cylindrical or dome-shaped digester and a moving, floating gas-holder, or drum. The gas-holder floats either directly in the fermenting slurry or in a separate water jacket. The drum in which the biogas collects has an internal and/or external guide frame that provides stability and keeps the drum upright. If biogas is produced, the drum moves up, if gas is consumed, the gas-holder sinks back. | In the past, floating-drum plants were mainly built in India. A floating-drum plant consists of a cylindrical or dome-shaped digester and a moving, floating gas-holder, or drum. The gas-holder floats either directly in the fermenting slurry or in a separate water jacket. The drum in which the biogas collects has an internal and/or external guide frame that provides stability and keeps the drum upright. If biogas is produced, the drum moves up, if gas is consumed, the gas-holder sinks back. | ||

| − | + | <br/> | |

=== Size === | === Size === | ||

Floating-drum plants are used chiefly for digesting animal and human feces on a continuous-feed mode of operation, i.e. with daily input. They are used most frequently by small- to middle-sized farms (digester size: 5-15m<sup>3</sup>) or in institutions and larger agro-industrial estates (digester size: 20-100m<sup>3</sup>)'''''.''''' | Floating-drum plants are used chiefly for digesting animal and human feces on a continuous-feed mode of operation, i.e. with daily input. They are used most frequently by small- to middle-sized farms (digester size: 5-15m<sup>3</sup>) or in institutions and larger agro-industrial estates (digester size: 20-100m<sup>3</sup>)'''''.''''' | ||

| + | |||

| + | ''<br/> | ||

'''Advantages''' | '''Advantages''' | ||

| + | <br/> | ||

'''Disadvantages''': The steel drum is relatively expensive and maintenance-intensive. Removing rust and painting has to be carried out regularly. The life-time of the drum is short (up to 15 years; in tropical coastal regions about five years). If fibrous substrates are used, the gas-holder shows a tendency to get "stuck" in the resultant floating scum. | '''Disadvantages''': The steel drum is relatively expensive and maintenance-intensive. Removing rust and painting has to be carried out regularly. The life-time of the drum is short (up to 15 years; in tropical coastal regions about five years). If fibrous substrates are used, the gas-holder shows a tendency to get "stuck" in the resultant floating scum. | ||

| − | {| class="IMGleft FCK__ShowTableBorders" border="0" cellpadding="10" align=" | + | <br/> |

| + | |||

| + | {| class="IMGleft FCK__ShowTableBorders" border="0" cellpadding="10" align="center" style="width: 300px;" | ||

|- | |- | ||

| − | | [[File:Floatdrumschemewaterjack s.gif|RTENOTITLE]]<small class="IMGLEGEND">'''Water-jacket plant with external guide frame | + | | [[File:Floatdrumschemewaterjack s.gif|300px|RTENOTITLE]]<small class="IMGLEGEND">'''Water-jacket plant with external guide frame: 1 Mixing pit, 11 Fill pipe, 2 Digester, 3 Gasholder, 31 Guide frame, 4 Slurry store, 5 Gas pipe'''</small>'''<ref name="Sasse, 1984">Sasse, 1984</ref>''' |

|} | |} | ||

| − | + | <br/> | |

=== Water-jacket Floating-drum Plants<br/> === | === Water-jacket Floating-drum Plants<br/> === | ||

| Line 299: | Line 322: | ||

Water-jacket plants are universally applicable and easy to maintain. The drum cannot get stuck in a scum layer, even if the substrate has a high solids content. Water-jacket plants are characterized by a long useful life and a more aesthetic appearance (no dirty gas-holder). Due to their superior sealing of the substrate (hygiene!), they are recommended for use in the fermentation of night soil. The extra cost of the masonry water jacket is relatively modest. | Water-jacket plants are universally applicable and easy to maintain. The drum cannot get stuck in a scum layer, even if the substrate has a high solids content. Water-jacket plants are characterized by a long useful life and a more aesthetic appearance (no dirty gas-holder). Due to their superior sealing of the substrate (hygiene!), they are recommended for use in the fermentation of night soil. The extra cost of the masonry water jacket is relatively modest. | ||

| − | + | <br/> | |

=== Material of Digester and Drum<br/> === | === Material of Digester and Drum<br/> === | ||

| Line 307: | Line 330: | ||

Floating-drums made of glass-fiber reinforced plastic and high-density polyethylene have been used successfully, but the construction costs are higher compared to using steel. Floating-drums made of wire-mesh-reinforced concrete are liable to hairline cracking and are intrinsically porous. They require a gas-tight, elastic internal coating. PVC drums are unsuitable because they are not resistant to UV. | Floating-drums made of glass-fiber reinforced plastic and high-density polyethylene have been used successfully, but the construction costs are higher compared to using steel. Floating-drums made of wire-mesh-reinforced concrete are liable to hairline cracking and are intrinsically porous. They require a gas-tight, elastic internal coating. PVC drums are unsuitable because they are not resistant to UV. | ||

| − | + | <br/> | |

=== Guide Frame<br/> === | === Guide Frame<br/> === | ||

| Line 315: | Line 338: | ||

The floating gas drum can be replaced by a balloon above the digester. This reduces construction costs but in practice problems always arise with the attachment of the balloon to the digester and with the high susceptibility to physical damage. | The floating gas drum can be replaced by a balloon above the digester. This reduces construction costs but in practice problems always arise with the attachment of the balloon to the digester and with the high susceptibility to physical damage. | ||

| − | + | <br/> | |

=== Types of Floating-drum Plants<br/> === | === Types of Floating-drum Plants<br/> === | ||

<u>There are different types of floating-drum plants:</u> | <u>There are different types of floating-drum plants:</u> | ||

| − | |||

*'''KVIC model''' with a cylindrical digester, the oldest and most widespread floating drum biogas plant from India. | *'''KVIC model''' with a cylindrical digester, the oldest and most widespread floating drum biogas plant from India. | ||

*'''Pragati model''' with a hemisphere digester | *'''Pragati model''' with a hemisphere digester | ||

| Line 326: | Line 348: | ||

*floating-drum plant made of pre-fabricated reinforced concrete compound units | *floating-drum plant made of pre-fabricated reinforced concrete compound units | ||

*floating-drum plant made of fibre-glass reinforced polyester | *floating-drum plant made of fibre-glass reinforced polyester | ||

| − | *low cost floating-drum plants made of plastic water containers or fiberglass drums: [[ARTI Biogas Plant| | + | *low cost floating-drum plants made of plastic water containers or fiberglass drums: [[ARTI Biogas Plant|ARTI Biogas plants]] |

*'''BORDA model: '''The BORDA-plant combines the static advantages of hemispherical digester with the process-stability of the floating-drum and the longer life span of a water jacket plant. | *'''BORDA model: '''The BORDA-plant combines the static advantages of hemispherical digester with the process-stability of the floating-drum and the longer life span of a water jacket plant. | ||

| − | + | <br/> | |

=== Summary<br/> === | === Summary<br/> === | ||

'''Advantages: '''Advantages are the simple, easily understood operation - the volume of stored gas is directly visible. The gas pressure is constant, determined by the weight of the gas holder. The construction is relatively easy, construction mistakes do not lead to major problems in operation and gas yield. | '''Advantages: '''Advantages are the simple, easily understood operation - the volume of stored gas is directly visible. The gas pressure is constant, determined by the weight of the gas holder. The construction is relatively easy, construction mistakes do not lead to major problems in operation and gas yield. | ||

| + | |||

| + | <br/> | ||

'''Disadvantages: '''Disadvantages are high material costs of the steel drum, the susceptibility of steel parts to corrosion. Because of this, floating drum plants have a shorter life span than fixed-dome plants and regular maintenance costs for the painting of the drum. | '''Disadvantages: '''Disadvantages are high material costs of the steel drum, the susceptibility of steel parts to corrosion. Because of this, floating drum plants have a shorter life span than fixed-dome plants and regular maintenance costs for the painting of the drum. | ||

| + | <br/> | ||

| + | = Further Information<br/> = | ||

| − | + | <u>'''English'''</u><br/> | |

| − | |||

| − | |||

| − | |||

*Amaratunga, M.: Structural Behaviour and Stress Conditions of Fixed Dome Type of Biogas Units. Elhalwagi, M.M. (Ed.): Biogas Technology, Transfer and Diffusion, London & New York, pp. 295-301. 1986. 0001182; ISBN: 1-85166-000-3 | *Amaratunga, M.: Structural Behaviour and Stress Conditions of Fixed Dome Type of Biogas Units. Elhalwagi, M.M. (Ed.): Biogas Technology, Transfer and Diffusion, London & New York, pp. 295-301. 1986. 0001182; ISBN: 1-85166-000-3 | ||

*van Buren, A.; Crook, M.: A Chinese Biogas Manual - Popularising Technology in the Countryside. Intermediate Technology Publications Ltd. London (UK), 1979, sixth impression 1985, 135 P. ISBN: 0903031655 | *van Buren, A.; Crook, M.: A Chinese Biogas Manual - Popularising Technology in the Countryside. Intermediate Technology Publications Ltd. London (UK), 1979, sixth impression 1985, 135 P. ISBN: 0903031655 | ||

| Line 349: | Line 372: | ||

*Sasse, L. - GATE, Bremer Arbeitsgemeinschaft für Überseeforschung und Entwicklung (BORDA): Biogas Plants - Design and Details of Simple Biogas Plants. 2nd edition, 1988, 85 P., ISBN: 3-528-02004-0 | *Sasse, L. - GATE, Bremer Arbeitsgemeinschaft für Überseeforschung und Entwicklung (BORDA): Biogas Plants - Design and Details of Simple Biogas Plants. 2nd edition, 1988, 85 P., ISBN: 3-528-02004-0 | ||

*Werner, U., St�hr, U., Hees, N. - GATE: Biogas Plants in Animal Husbandry - A Practical Guide. Friedr. Vieweg & Sohn, Braunschweig/Wiesbaden (Germany), 1989; 153 p., ISBN: 3-528-02048-2 | *Werner, U., St�hr, U., Hees, N. - GATE: Biogas Plants in Animal Husbandry - A Practical Guide. Friedr. Vieweg & Sohn, Braunschweig/Wiesbaden (Germany), 1989; 153 p., ISBN: 3-528-02048-2 | ||

| − | |||

*Sasse, L. - Centro de Investigacion, Estudios y Documentacion (CIED) Lima (Peru): La Planta de Biogas - Bosquejo y Detaille de Plantas Simples. Reciclaje de la Materia Organica 3. 1986. 103 p. | *Sasse, L. - Centro de Investigacion, Estudios y Documentacion (CIED) Lima (Peru): La Planta de Biogas - Bosquejo y Detaille de Plantas Simples. Reciclaje de la Materia Organica 3. 1986. 103 p. | ||

| + | <br/> | ||

| − | + | <u>'''Deutsch'''</u><br/> | |

| − | |||

| − | |||

*Sasse, L. - GATE; Bremer Arbeitsgemeinschaft für Überseeforschung und Entwicklung (BORDA): Die Biogas-Anlage - Entwurf und Detail einfacher Anlagen. 2. Aufl. 1987, 85 P., ISBN: 3-528-01003-2 | *Sasse, L. - GATE; Bremer Arbeitsgemeinschaft für Überseeforschung und Entwicklung (BORDA): Die Biogas-Anlage - Entwurf und Detail einfacher Anlagen. 2. Aufl. 1987, 85 P., ISBN: 3-528-01003-2 | ||

*Sasse, L.: Biogas in der GTZ - Zur Statik von Festdomanlagen. Biogas Information Nr. 27. 1988, pp. 19-24 | *Sasse, L.: Biogas in der GTZ - Zur Statik von Festdomanlagen. Biogas Information Nr. 27. 1988, pp. 19-24 | ||

*Werner, U.; St�hr, U.; Hees, N.: Praktischer Leitfaden für Biogasanlagen in der Tierproduktion. Sonderpublikation der GTZ Nr. 180. 1986. ISBN: 3-88085-311-8 | *Werner, U.; St�hr, U.; Hees, N.: Praktischer Leitfaden für Biogasanlagen in der Tierproduktion. Sonderpublikation der GTZ Nr. 180. 1986. ISBN: 3-88085-311-8 | ||

| − | + | <br/> | |

== Low-Cost Polyethylen Tube Digester<br/> == | == Low-Cost Polyethylen Tube Digester<br/> == | ||

| Line 366: | Line 387: | ||

=== Digester === | === Digester === | ||

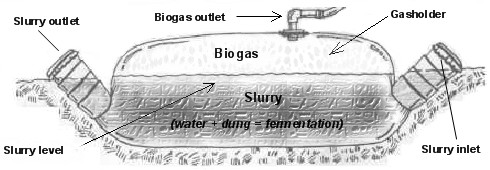

| − | In the case of the Low-Cost Polyethylene Tube Digester model which is applied in [[Low-Cost Polyethylene Tube Digesters in Bolivia|Bolivia]] (Peru, Ecuador, Colombia, Centro America and Mexico), the tubular polyethylene film (two coats of 300 microns) is bended at each end around a 6 inch PVC drainpipe and is wound with rubber strap of recycled tire-tubes. With this system a hermetic isolated tank is obtained (figure td1). | + | In the case of the Low-Cost Polyethylene Tube Digester model which is applied in [[Low-Cost Polyethylene Tube Digesters in Bolivia|Bolivia]] (Peru, Ecuador, Colombia, Centro America and Mexico), the tubular polyethylene film (two coats of 300 microns) is bended at each end around a 6 inch PVC drainpipe and is wound with rubber strap of recycled tire-tubes. With this system a hermetic isolated tank is obtained (figure td1). |

| − | {| class="FCK__ShowTableBorders" border="0" cellpadding="1" cellspacing="1" align="center" | + | {| class="FCK__ShowTableBorders" border="0" cellpadding="1" cellspacing="1" align="center" style="width: 500px;" |

|- | |- | ||

| − | | | + | | style="width: 384px;" | |

| − | [[File:In Outlet winding Tube Digester.jpg| | + | [[File:In Outlet winding Tube Digester.jpg|In Outlet winding Tube Digester.jpg|alt=In Outlet winding Tube Digester.jpg]] |

| − | Picture td2<ref name="GTZ / EnDev Bolivia">GTZ / EnDev Bolivia</ref> | + | Picture td2: Winding In-/Outlet Tube Digester<ref name="GTZ / EnDev Bolivia">GTZ / EnDev Bolivia</ref>'''''.''''' |

| − | | colspan="2" | + | | colspan="2" style="width: 853px;" | |

| − | <br/>[[File:Low Cost Polyethylene Tube Digester Scheme.jpg| | + | <br/>[[File:Low Cost Polyethylene Tube Digester Scheme.jpg|Low Cost Polyethylene Tube Digester Scheme.jpg|alt=Low Cost Polyethylene Tube Digester Scheme.jpg]] |

| − | Figure td1 | + | Figure td1: Scheme of Low-Cost Polyethylene Tube Digester'''''<span style="font-size: 10pt; line-height: 115%" lang="EN-US">.</span>'''''<ref name="GTZ / EnDev Bolivia">GTZ / EnDev Bolivia</ref> |

| − | One of the 6" PVC drainpipes serves as inlet and the other one as the outlet of the slurry. In the tube digester finally, a hydraulic level is set up by itself, so that as much quantity of added prime matter (the mix of dung and water) as quantity of fertilizer leave by the outlet.<br/>Because the tubular polyethylene is flexible, it is necessary to construct a "cradle" which will accommodate the reaction tank, so that a trench is excavated (picture td3). | + | ''One of the 6" PVC drainpipes serves as inlet and the other one as the outlet of the slurry. In the tube digester finally, a hydraulic level is set up by itself, so that as much quantity of added prime matter (the mix of dung and water) as quantity of fertilizer leave by the outlet.<br/>Because the tubular polyethylene is flexible, it is necessary to construct a "cradle" which will accommodate the reaction tank, so that a trench is excavated (picture td3).'' |

| − | |||

| − | |||

|} | |} | ||

| − | + | <br/> | |

=== Gasholder and Gas Storage Reservoir<br/> === | === Gasholder and Gas Storage Reservoir<br/> === | ||

| Line 394: | Line 413: | ||

To overcome the problem of low gas flow rates, two 200 microns tubular polyethylene reservoirs are installed close to the kitchen, which gives a 1,3 m³ additional gas storage (picture td4). | To overcome the problem of low gas flow rates, two 200 microns tubular polyethylene reservoirs are installed close to the kitchen, which gives a 1,3 m³ additional gas storage (picture td4). | ||

| + | <br/> | ||

| − | + | {| style="width: 500px;" border="0" cellpadding="1" cellspacing="1" align="center" | |

| − | {| style="width: | ||

|- | |- | ||

| | | | ||

| − | [[File:Gas Storage Reservoir double inside.jpg|border|center| | + | [[File:Gas Storage Reservoir double inside.jpg|border|center|350px|Gas Storage Reservoir double inside.jpg|alt=Gas Storage Reservoir double inside.jpg]] |

| | | | ||

| − | [[File:Biodigestor familiar bolivia altiplano.jpg|thumb|center|Biodigestor familiar bolivia altiplano.jpg]] | + | [[File:Biodigestor familiar bolivia altiplano.jpg|thumb|center|180px|Biodigestor familiar bolivia altiplano.jpg]] |

|- | |- | ||

| − | | Picture td4<ref name="GTZ / EnDev Bolivia">GTZ / EnDev Bolivia</ref | + | | Picture td4: Gas Storage Reservoir<ref name="GTZ / EnDev Bolivia">GTZ / EnDev Bolivia</ref> |

| − | | Picture td3<ref name="GTZ / EnDev Bolivia">GTZ / EnDev Bolivia</ref | + | | Picture td3: Tube Digester - Bolivia Altiplano<ref name="GTZ / EnDev Bolivia">GTZ / EnDev Bolivia</ref> |

|} | |} | ||

| − | + | ||

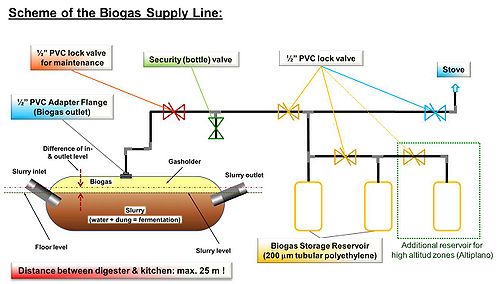

=== Biogas Supply Line<br/> === | === Biogas Supply Line<br/> === | ||

| Line 415: | Line 434: | ||

The track of biogas up to the kitchen is realised directly. The digester system works with a biogas pressure between 15 - 20 cm water column. A security valve, which is constructed of a 1, 5 l or 2, 0 l PET refreshment bottle (picture td5), controlls the pressure. For the supply line a 1/2" flexible PVC tube is used. | The track of biogas up to the kitchen is realised directly. The digester system works with a biogas pressure between 15 - 20 cm water column. A security valve, which is constructed of a 1, 5 l or 2, 0 l PET refreshment bottle (picture td5), controlls the pressure. For the supply line a 1/2" flexible PVC tube is used. | ||

| + | <br/> | ||

| − | + | {| style="width: 500px;" border="0" cellpadding="1" cellspacing="1" align="center" | |

| − | {| style="width: | ||

|- | |- | ||

| | | | ||

| − | [[File:Tube Digester Security Valve.jpg|border|center|200px|Tube Digester Security Valve.jpg]] | + | [[File:Tube Digester Security Valve.jpg|border|center|200px|Tube Digester Security Valve.jpg|alt=Tube Digester Security Valve.jpg]] |

| | | | ||

| − | ''[[File:Scheme of the biogas supply line tube digester.jpg|border|center|500px|Scheme of the biogas supply line tube digester.jpg]]'' | + | ''[[File:Scheme of the biogas supply line tube digester.jpg|border|center|500px|Scheme of the biogas supply line tube digester.jpg|alt=Scheme of the biogas supply line tube digester.jpg]]'' |

|- | |- | ||

| | | | ||

| − | Picture td5<ref name="GTZ / EnDev Bolivia">GTZ / EnDev Bolivia</ref> | + | Picture td5: Tube Digester Security Valve<ref name="GTZ / EnDev Bolivia">GTZ / EnDev Bolivia</ref> |

| | | | ||

| − | Figure td6<ref name="GTZ / EnDev Bolivia">GTZ / EnDev Bolivia</ref> | + | Figure td6: Scheme of the gas supply line<ref name="GTZ / EnDev Bolivia">GTZ / EnDev Bolivia</ref> |

|} | |} | ||

| + | <br/> | ||

| − | + | === Modification === | |

| − | === | ||

To be able to work in different altitudes and climate zones, in Bolivia the Low-Cost Polyethylene Tube Digester was modified into three climate types.<br/>The three implanted types are calculated for 4 - 5 hours of Biogas using per day. The digesters differ in size and protection of the system. | To be able to work in different altitudes and climate zones, in Bolivia the Low-Cost Polyethylene Tube Digester was modified into three climate types.<br/>The three implanted types are calculated for 4 - 5 hours of Biogas using per day. The digesters differ in size and protection of the system. | ||

| − | The biodigester for the Bolivian Altiplano (picture td7) is enclosed in a greenhouse of polyethylene (250 microns), supported by two lateral adobe walls of 40 cm thickness above the hole length of the trench. This lateral walls accumulate the heat of the greenhouse effect, that with freezing temperatures during winter nights, they maintain the digester in function, by the own high thermal inertia. | + | The biodigester for the Bolivian Altiplano (picture td7) is enclosed in a greenhouse of polyethylene (250 microns), supported by two lateral adobe walls of 40 cm thickness above the hole length of the trench. This lateral walls accumulate the heat of the greenhouse effect, that with freezing temperatures during winter nights, they maintain the digester in function, by the own high thermal inertia. So it is possible to realise the installation of a working digester in an altitude of more than 4.500 m about sea level. |

For the digesters in the valley and tropical zones (picture td8) there is no need to install a greenhouse, but it is to protect the polyethylene of the biodigester about the direct solar radiation with a half shade red or better a roof. Additional it is recommended to protect this systems with a wire-mesh fence against animals like e.g. cows or chickens. | For the digesters in the valley and tropical zones (picture td8) there is no need to install a greenhouse, but it is to protect the polyethylene of the biodigester about the direct solar radiation with a half shade red or better a roof. Additional it is recommended to protect this systems with a wire-mesh fence against animals like e.g. cows or chickens. | ||

| − | {| class="FCK__ShowTableBorders" style="width: | + | {| class="FCK__ShowTableBorders" style="height: 322px; width: 500px;" border="0" cellpadding="1" cellspacing="1" align="center" |

|- | |- | ||

| − | | | + | | style="width: 520px;" | |

| − | [[File:Low Cost Tube Digester Altiplano.JPG| | + | [[File:Low Cost Tube Digester Altiplano.JPG|Low Cost Tube Digester Altiplano.JPG|alt=Low Cost Tube Digester Altiplano.JPG]] |

Picture td7<ref name="GTZ / EnDev Bolivia">GTZ / EnDev Bolivia</ref>: Low-Cost Tube Digester Altiplano of Bolivia | Picture td7<ref name="GTZ / EnDev Bolivia">GTZ / EnDev Bolivia</ref>: Low-Cost Tube Digester Altiplano of Bolivia | ||

| − | | | + | | style="width: 520px;" | |

| − | [[File:Low Cost Tube Digester Valley.JPG| | + | [[File:Low Cost Tube Digester Valley.JPG|Low Cost Tube Digester Valley.JPG|alt=Low Cost Tube Digester Valley.JPG]] |

Picture td8<ref name="GTZ / EnDev Bolivia">GTZ / EnDev Bolivia</ref>: Low-Cost Tube Digester - Valley | Picture td8<ref name="GTZ / EnDev Bolivia">GTZ / EnDev Bolivia</ref>: Low-Cost Tube Digester - Valley | ||

| Line 458: | Line 477: | ||

|} | |} | ||

| − | + | <br/> | |

=== Advantages === | === Advantages === | ||

| Line 464: | Line 483: | ||

Advantages are that tubular polyethylene is produced in most countries. The choice of supplementary fittings and related materials has been limited to those available locally on farms or in rural markets; they are the basic components of sanitary installations which are similar all over the world. The polyethylene tubular film biodigester technology is a cheap and simple way to produce gas. | Advantages are that tubular polyethylene is produced in most countries. The choice of supplementary fittings and related materials has been limited to those available locally on farms or in rural markets; they are the basic components of sanitary installations which are similar all over the world. The polyethylene tubular film biodigester technology is a cheap and simple way to produce gas. | ||

| − | + | <br/> | |

=== Disadvantages === | === Disadvantages === | ||

| Line 470: | Line 489: | ||

Disadvantages are the lower gas pressure (20 cm water column / 19,6 mbar) than in the fixed-dom system or floating drum system<span style="font-style: italic">. </span>You can't walk or use the area over the digester like in the case of the underground plants. There is a need to protect the tubular polyethylene against e.g. cows, because it could burst when the animal jumps into the digester. | Disadvantages are the lower gas pressure (20 cm water column / 19,6 mbar) than in the fixed-dom system or floating drum system<span style="font-style: italic">. </span>You can't walk or use the area over the digester like in the case of the underground plants. There is a need to protect the tubular polyethylene against e.g. cows, because it could burst when the animal jumps into the digester. | ||

| − | {| class="FCK__ShowTableBorders" border="0" cellpadding="1" cellspacing="2" align="center" | + | {| class="FCK__ShowTableBorders" border="0" cellpadding="1" cellspacing="2" align="center" style="width: 850px;" |

|- | |- | ||

| | | | ||

| − | [[File:Tube Digester Altiplano Carabuco Bolivia.JPG| | + | [[File:Tube Digester Altiplano Carabuco Bolivia.JPG|Tube Digester Altiplano Carabuco Bolivia.JPG|alt=Tube Digester Altiplano Carabuco Bolivia.JPG]] |

| − | Tube Digester Altiplano - Carabuco | + | Tube Digester Altiplano - Carabuco / Bolivia<ref name="GTZ / EnDev Bolivia">GTZ / EnDev Bolivia</ref> |

| | | | ||

| − | + | [[File:Tube Digester Altiplano inside.jpg|Tube Digester Altiplano inside.jpg|alt=Tube Digester Altiplano inside.jpg]] | |

Tube Digester Altiplano inside / Bolivia<ref name="GTZ / EnDev Bolivia">GTZ / EnDev Bolivia</ref> | Tube Digester Altiplano inside / Bolivia<ref name="GTZ / EnDev Bolivia">GTZ / EnDev Bolivia</ref> | ||

| Line 484: | Line 503: | ||

|} | |} | ||

| − | + | <br/> | |

To contrast these simple biogas plants, figure 2 gives an impression about dimensions of industrial plants which are, for example, built in Europe. | To contrast these simple biogas plants, figure 2 gives an impression about dimensions of industrial plants which are, for example, built in Europe. | ||

| − | {| style="width: | + | {| style="width: 500px;" class="IMGcenter FCK__ShowTableBorders" border="0" cellpadding="0" cellspacing="0" align="center" |

|- | |- | ||

| | | | ||

| − | [[File:Indplant.gif|RTENOTITLE]] | + | [[File:Indplant.gif|605px|RTENOTITLE]] |

| − | <small class="IMGLEGEND">Fig. 2 | + | <small class="IMGLEGEND">Fig. 2: Industrial biogas plant with utilization of domestic organic wastes</small><ref name="TBW">TBW</ref> |

|} | |} | ||

| − | + | <br/> | |

=== Experience with Plythylene Biogas Digester (PBD)<br/> === | === Experience with Plythylene Biogas Digester (PBD)<br/> === | ||

| Line 503: | Line 522: | ||

[[Experience with Polyethylene Biogas Digester (PBD) from some countries|Experience with Polyethylene Biogas Digester (PBD) from some countries (click HERE)]] | [[Experience with Polyethylene Biogas Digester (PBD) from some countries|Experience with Polyethylene Biogas Digester (PBD) from some countries (click HERE)]] | ||

| − | + | <br/> | |

=== Variation Tyre Tube Household Digester<br/> === | === Variation Tyre Tube Household Digester<br/> === | ||

| − | [https://energypedia.info/TyreTube | + | [https://energypedia.info/TyreTube Biogas Plant Variation tyre tube household digester] |

| − | |||

| + | <br/> | ||

= Dry Fermentation Plants<br/> = | = Dry Fermentation Plants<br/> = | ||

| − | Dry fermentation is an anaerobic process in which micro-organism break down biodegradable material. Renewable organic feedstocks are used as a the source of energy for the process. The nutrient-rich solids | + | Dry fermentation is an anaerobic process in which micro-organism break down biodegradable material. Renewable organic feedstocks are used as a the source of energy for the process. The nutrient-rich solids resulting from the digestion can be used as a fertiliser subsequently. |

Almost any organic material can be processed with dry fermentation. This includes biodegradable waste materials such as waste paper, grass clippings, leftover food, sewage and animal waste. | Almost any organic material can be processed with dry fermentation. This includes biodegradable waste materials such as waste paper, grass clippings, leftover food, sewage and animal waste. | ||

| − | + | <br/> | |

==== Process<br/> ==== | ==== Process<br/> ==== | ||

| Line 523: | Line 542: | ||

[[:file:VTI Dry fermentation biogas in Germany.pdf|Dry fermentation in germany]] (vTI presentation, 2 MB) | [[:file:VTI Dry fermentation biogas in Germany.pdf|Dry fermentation in germany]] (vTI presentation, 2 MB) | ||

| − | + | <br/> | |

= References<br/> = | = References<br/> = | ||

| Line 529: | Line 548: | ||

<references /> | <references /> | ||

| − | + | <br/> | |

<br/>[[Biogas|--> Back to "Biogas" section]] | <br/>[[Biogas|--> Back to "Biogas" section]] | ||

</div></div> | </div></div> | ||

| + | <br/> | ||

| + | [[Category:Biogas]] | ||

[[Category:Bioenergy]] | [[Category:Bioenergy]] | ||

| − | |||

Revision as of 11:45, 12 July 2013

Biogas Plant Designs

Digester Types in Industrialized Countries

Control glasses for an industrial digester for solid organic waste, Germany[1] Control glasses for an industrial digester for solid organic waste, Germany[1] |

To give an overview, some fictitious designs have been chosen as they could be found in, for example, Europe. The designs are selected in a way that all the typical elements of modern biogas technology appear at least once. All designs are above-ground, which is common in Europe. Underground structures, however, do exist.

Mixing pit varies in size and shape according to the nature of substrate. It is equipped with propellers for mixing and/or chopping the substrate and often with a pump to transport the substrate into the digester. At times, the substrate is also pre-heated in the mixing pit in order to avoid a temperature shock inside the digester.

Fermenter or digester is insulated and made of concrete or steel. To optimize the flow of substrate, large digesters have a longish channel form. Large digesters are almost always agitated by slow rotating paddles or rotors or by injected biogas. Co-fermenters have two or more separated fermenters. The gas can be collected inside the digester, then usually with a flexible cover. The digester can also be filled completely and the gas stored in a separate gas-holder.

Gas-holder is usually of flexible material, therefore to be protected against weather. It can be placed either directly above the substrate, then it acts like a balloon plant, or in a separate 'gas-bag'.

slurry store for storage of slurry during winter. The store can be open (like conventional open liquid manure storage) or closed and connected to the gas-holder to capture remaining gas production. Normally, the store is not heated and only agitated before the slurry is spread on the field.

Gas use element is in Europe in 95% of the cases a thermo-power unit which produces electricity for the farm, the grid and heat for the house, greenhouses and other uses. The thermo-power unit has the advantage, that the required energy can be produced in any mixture of gas and fossil energy. It can, therefore, react to periods of low gas production and high energy requirements or vice versa.

|

Concrete digester with two chambers (one heated, one unheated for storage)[1] |

|

Concrete digester with integrated plastic gas-holder[1] |

|

Steelvessel fermenter with seperate ballon gas-holder[1] |

Selection of Appropriate Design

In developing countries, the design selection is determined largely be the prevailing design in the region, which, in turn takes the climatic, economic and substrate specific conditions into consideration. Large plants are designed on a case-to-case basis.

Typical design criteria are:

Space: determines mainly the decision if the fermenter is above-ground or underground, if it is to be constructed as an upright cylinder or as a horizontal plant.

Existing structures may be used like a liquid manure tank, an empty hall or a steel container. To reduce costs, the planner may need to adjust the design to theses existing structures.

Minimizing costs can be an important design parameter, especially when the monetary benefits are expected to be low. In this case a flexible cover of the digester is usually the cheapest solution. Minimizing costs is often opposed to maximizing gas yield.

Available substrate determines not only the size and shape of mixing pit but the digester volume (retention time!), the heating and agitation devices. Agitation through gas injection is only feasible with homogenous substrate and a dry matter content below 5%. Mechanical agitation becomes problematic above 10% dry matter.

Balloon Plants

A balloon plant consists of a heat-sealed plastic or rubber bag (balloon), combining digester and gas-holder. The gas is stored in the upper part of the balloon. The inlet and outlet are attached directly to the skin of the balloon. Gas pressure can be increased by placing weights on the balloon. If the gas pressure exceeds a limit that the balloon can withstand, it may damage the skin. Therefore, safety valves are required. If higher gas pressures are needed, a gas pump is required. Since the material has to be weather- and UV resistant, specially stabilized, reinforced plastic or synthetic caoutchouc is given preference. Other materials which have been used successfully include RMP (red mud plastic), Trevira and butyl. The useful life-span does usually not exceed 2-5 years.

Advantages: Standardized prefabrication at low cost, low construction sophistication, ease of transportation, shallow installation suitable for use in areas with a high groundwater table; high digester temperatures in warm climates; uncomplicated cleaning, emptying and maintenance; difficult substrates like water hyacinths can be used.

Balloon biogas plants are recommended, if local repair is or can be made possible and the cost advantage is substantial.

Disadvantages: Low gas pressure may require gas pumps; scum cannot be removed during operation; the plastic balloon has a relatively short useful life-span and is susceptible to mechanical damage and usually not available locally. In addition, local craftsmen are rarely in a position to repair a damaged balloon. There is only little scope for the creation of local employment and, therefore, limited self-help potential.

Variations: A variation of the balloon plant is the channel-type digester, which is usually covered with plastic sheeting and a sunshade (fig.1-E). Balloon plants can be recommended wherever the balloon skin is not likely to be damaged and where the temperature is even and high.

|

|

|

Horizontal Plants

Horizontal biogas plants are usually chosen when shallow installation is called for (groundwater, rock). They are made of masonry or concrete.

Advantages: Shallow construction despite large slurry space.

Disadvantages: Problems with gas-space leakage, difficult elimination of scum.

Earth-pit Plants

Masonry digesters are not necessary in stable soil (e.g. laterite). It is sufficient to line the pit with a thin layer of cement (wire-mesh fixed to the pit wall and plastered) in order to prevent seepage. The edge of the pit is reinforced with a ring of masonry that also serves as anchorage for the gas-holder. The gas-holder can be made of metal or plastic sheeting. If plastic sheeting is used, it must be attached to a quadratic wooden frame that extends down into the slurry and is anchored in place to counter its buoyancy. The requisite gas pressure is achieved by placing weights on the gas-holder. An overflow point in the peripheral wall serves as the slurry outlet.

Advantages: Low cost of installation (as little as 20% of a floating-drum plant); high potential for self help approaches.

Disadvantages: Short useful life; serviceable only in suitable, impermeable types of soil.

Earth-pit plants can only be recommended for installation in impermeable soil located above the groundwater table. Their construction is particularly inexpensive in connection with plastic sheet gas-holders.

Ferrocement Plants

The ferro-cement type of construction can be applied either as a self-supporting shell or an earth-pit lining. The vessel is usually cylindrical. Very small plants (Volume under 6 m3) can be prefabricated. As in the case of a fixed-dome plant, the ferrocement gasholder requires special sealing measures (proven reliability with cemented-on aluminium foil).

Advantages: Low cost of construction, especially in comparison with potentially high cost of masonry for alternative plants; mass production possible; low material input.

Disadvantages: Substantial consumption of essentially good-quality cement; workmanship must meet high quality standards; uses substantial amounts of expensive wire mesh; construction technique not yet adequately time-tested; special sealing measures for the gas-holder are necessary. Ferro-cement biogas plants are only recommended in cases where special ferro-cement know-how is available.

Biogas Digester Types

In this section, the most important types of biogas plants are described:

Wet fermentation:

Dry fermentation:

- ...

Of these, the two most familiar types in developing countries are the fixed-dome plants and the floating-drum plants.

Typical designs in industrialized countries and appropriate design selection criteria have also been considered.

Wet Fermentation Plants

Fixed-dome Plants

A fixed-dome plant consists of a digester with a fixed, non-movable gas holder, which sits on top of the digester. When gas production starts, the slurry is displaced into the compensation tank. Gas pressure increases with the volume of gas stored and the height difference between the slurry level in the digester and the slurry level in the compensation tank.

The costs of a fixed-dome biogas plant are relatively low. It is simple as no moving parts exist. There are also no rusting steel parts and hence a long life of the plant (20 years or more) can be expected. The plant is constructed underground, protecting it from physical damage and saving space. While the underground digester is protected from low temperatures at night and during cold seasons, sunshine and warm seasons take longer to heat up the digester. No day/night fluctuations of temperature in the digester positively influence the bacteriological processes.

The construction of fixed dome plants is labor-intensive, thus creating local employment. Fixed-dome plants are not easy to build. They should only be built where construction can be supervised by experienced biogas technicians. Otherwise plants may not be gas-tight (porosity and cracks).

The basic elements of a fixed dome plant (here the Nicarao Design) are shown in the figure below.

Fixed dome plant Nicarao design[1]: 1. Mixing tank with inlet pipe and sand trap. 2. Digester. 3. Compensation and removal tank. 4. Gasholder. 5. Gaspipe. 6. Entry hatch, with gastight seal. 7. Accumulation of thick sludge. 8. Outlet pipe. 9. Reference level. 10. Supernatant scum, broken up by varying level. Fixed dome plant Nicarao design[1]: 1. Mixing tank with inlet pipe and sand trap. 2. Digester. 3. Compensation and removal tank. 4. Gasholder. 5. Gaspipe. 6. Entry hatch, with gastight seal. 7. Accumulation of thick sludge. 8. Outlet pipe. 9. Reference level. 10. Supernatant scum, broken up by varying level. |

picture[4]:Basic function of a fixed-dome biogas plant, 1 Mixing pit, 2 Digester, 3 Gasholder, 4 Displacement pit, 5 Gas pipe picture[4]:Basic function of a fixed-dome biogas plant, 1 Mixing pit, 2 Digester, 3 Gasholder, 4 Displacement pit, 5 Gas pipe |

Function

A fixed-dome plant comprises of a closed, dome-shaped digester with an immovable, rigid gas-holder and a displacement pit, also named 'compensation tank'. The gas is stored in the upper part of the digester. When gas production commences, the slurry is displaced into the compensating tank. Gas pressure increases with the volume of gas stored, i.e. with the height difference between the two slurry levels. If there is little gas in the gas-holder, the gas pressure is low.

Digester

The digesters of fixed-dome plants are usually masonry structures, structures of cement and ferro-cement exist. Main parameters for the choice of material are:

- Technical suitability (stability, gas- and liquid tightness);

- cost-effectiveness;

- availability in the region and transport costs;

- availability of local skills for working with the particular building material.

Fixed dome plants produce just as much gas as floating-drum plants, if they are gas-tight. However, utilization of the gas is less effective as the gas pressure fluctuates substantially. Burners and other simple appliances cannot be set in an optimal way. If the gas is required at constant pressure (e.g., for engines), a gas pressure regulator or a floating gas-holder is necessary.

|

Fixed-dome plant in Tunesia. The final layers of the masonry structure are being fixed.[5] |

Gas-Holder

The top part of a fixed-dome plant (the gas space) must be gas-tight. Concrete, masonry and cement rendering are not gas-tight. The gas space must therefore be painted with a gas-tight layer (e.g. 'Water-proofer', Latex or synthetic paints). A possibility to reduce the risk of cracking of the gas-holder consists in the construction of a weak-ring in the masonry of the digester. This "ring" is a flexible joint between the lower (water-proof) and the upper (gas-proof) part of the hemispherical structure. It prevents cracks that develop due to the hydrostatic pressure in the lower parts to move into the upper parts of the gas-holder.

Types of Fixed-dome Plants

- Chinese fixed-dome plant is the archetype of all fixed dome plants. Several million have been constructed in China. The digester consists of a cylinder with round bottom and top.

- Janata model was the first fixed-dome design in India, as a response to the Chinese fixed dome plant. It is not constructed anymore. The mode of construction lead to cracks in the gasholder - very few of these plant had been gas-tight.

- Deenbandhu, the successor of the Janata plant in India, with improved design, was more crack-proof and consumed less building material than the Janata plant. with a hemisphere digester

- CAMARTEC model has a simplified structure of a hemispherical dome shell based on a rigid foundation ring only and a calculated joint of fraction, the so-called weak / strong ring. It was developed in the late 80s in Tanzania.

Fixed dome plant CAMARTEC design[1] Fixed dome plant CAMARTEC design[1] |

Climate and Size

Fixed-dome plants must be covered with earth up to the top of the gas-filled space to counteract the internal pressure (up to 0,15 bar). The earth cover insulation and the option for internal heating makes them suitable for colder climates. Due to economic parameters, the recommended minimum size of a fixed-dome plant is 5 m3. Digester volumes up to 200 m3 are known and possible.

Summary

Advantages: Low initial costs and long useful life-span; no moving or rusting parts involved; basic design is compact, saves space and is well insulated; construction creates local employment.

Advantages are the relatively low construction costs, the absence of moving parts and rusting steel parts. If well constructed, fixed dome plants have a long life span. The underground construction saves space and protects the digester from temperature changes. The construction provides opportunities for skilled local employment.

Disadvantages: Masonry gas-holders require special sealants and high technical skills for gas-tight construction; gas leaks occur quite frequently; fluctuating gas pressure complicates gas utilization; amount of gas produced is not immediately visible, plant operation not readily understandable; fixed dome plants need exact planning of levels; excavation can be difficult and expensive in bedrock.

Disadvantages are mainly the frequent problems with the gas-tightness of the brickwork gas holder (a small crack in the upper brickwork can cause heavy losses of biogas). Fixed-dome plants are, therefore, recommended only where construction can be supervised by experienced biogas technicians. The gas pressure fluctuates substantially depending on the volume of the stored gas. Even though the underground construction buffers temperature extremes, digester temperatures are generally low.

Fixed dome plants can be recommended only where construction can be supervised by experienced biogas technicians.

Variations: Some companies are now looking into small pre-fab fixed dome plants made of fibreglass which appears to be a low cost alternative to construction intensive masoned plants. A custom made plant can be produced in 2 days and -after transport- installed in less than 1 day!

Floating-drum Plants

Floating-drum plants consist of an underground digester and a moving gas-holder. The gas-holder floats either directly on the fermentation slurry or in a water jacket of its own. The gas is collected in the gas drum, which rises or moves down, according to the amount of gas stored. The gas drum is prevented from tilting by a guiding frame. If the drum floats in a water jacket, it cannot get stuck, even in substrate with high solid content.

|

Floating-drum plant in Mauretania[5] |

The Drum

In the past, floating-drum plants were mainly built in India. A floating-drum plant consists of a cylindrical or dome-shaped digester and a moving, floating gas-holder, or drum. The gas-holder floats either directly in the fermenting slurry or in a separate water jacket. The drum in which the biogas collects has an internal and/or external guide frame that provides stability and keeps the drum upright. If biogas is produced, the drum moves up, if gas is consumed, the gas-holder sinks back.

Size

Floating-drum plants are used chiefly for digesting animal and human feces on a continuous-feed mode of operation, i.e. with daily input. They are used most frequently by small- to middle-sized farms (digester size: 5-15m3) or in institutions and larger agro-industrial estates (digester size: 20-100m3).

Advantages

Disadvantages: The steel drum is relatively expensive and maintenance-intensive. Removing rust and painting has to be carried out regularly. The life-time of the drum is short (up to 15 years; in tropical coastal regions about five years). If fibrous substrates are used, the gas-holder shows a tendency to get "stuck" in the resultant floating scum.

Water-jacket plant with external guide frame: 1 Mixing pit, 11 Fill pipe, 2 Digester, 3 Gasholder, 31 Guide frame, 4 Slurry store, 5 Gas pipe[6] Water-jacket plant with external guide frame: 1 Mixing pit, 11 Fill pipe, 2 Digester, 3 Gasholder, 31 Guide frame, 4 Slurry store, 5 Gas pipe[6]

|

Water-jacket Floating-drum Plants

Water-jacket plants are universally applicable and easy to maintain. The drum cannot get stuck in a scum layer, even if the substrate has a high solids content. Water-jacket plants are characterized by a long useful life and a more aesthetic appearance (no dirty gas-holder). Due to their superior sealing of the substrate (hygiene!), they are recommended for use in the fermentation of night soil. The extra cost of the masonry water jacket is relatively modest.

Material of Digester and Drum