Types of Biogas Digesters and Plants

Introduction

|

Construction of the digester neck with steel reinforcement[1] |

From the standpoint of fluid dynamics and structural strength, an egg-shaped vessel is about the best possible solution. This type of construction, however, is comparatively expensive, so that its use is usually restricted to large-scale sewage treatment plants. The Chinese fixed-dome designs are of similar shape, but less expensive. The hemispherical CAMARTEC design is optimized in structural strength, but does not make optimal use of the excavation required.

Simplified versions of such digester designs include cylinders with conical covers and bottoms. They are much easier to build and are sometimes available on the market as prefabricated units. Their disadvantage lies in their less favorable surface-volume ratio. The cylinder should have a height equal to its diameter. Prone cylinders have become quite popular on farms, since they are frequently the more favorable solution for small-scale bio-methanation. Cuboid digesters are often employed in batch-fed systems used primarily for fermenting solid material, so that fluid dynamics are of little interest.

Industrial Digester Types

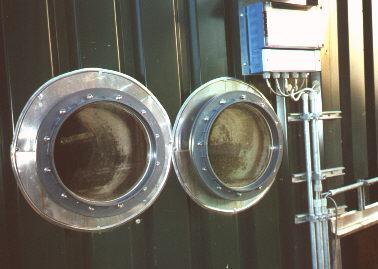

Control glasses for an industrial digester for solid organic waste, Germany[2] Control glasses for an industrial digester for solid organic waste, Germany[2] |

To give an overview, some fictitious designs have been chosen as they could be found in, for example, Europe. The designs are selected in a way that all the typical elements of modern biogas technology appear at least once. All designs are above-ground, which is common in Europe. Underground structures, however, do exist.

Mixing pit varies in size and shape according to the nature of substrate. It is equipped with propellers for mixing and/or chopping the substrate and often with a pump to transport the substrate into the digester. At times, the substrate is also pre-heated in the mixing pit in order to avoid a temperature shock inside the digester.

Fermenter or digester is insulated and made of concrete or steel. To optimize the flow of substrate, large digesters have a longish channel form. Large digesters are almost always agitated by slow rotating paddles or rotors or by injected biogas. Co-fermenters have two or more separated fermenters. The gas can be collected inside the digester, then usually with a flexible cover. The digester can also be filled completely and the gas stored in a separate gas-holder.

Gas-holder is usually of flexible material, therefore to be protected against weather. It can be placed either directly above the substrate, then it acts like a balloon plant, or in a separate 'gas-bag'.

Slurry store for storage of slurry during winter. The store can be open (like conventional open liquid manure storage) or closed and connected to the gas-holder to capture remaining gas production. Normally, the store is not heated and only agitated before the slurry is spread on the field.

Gas use element is in Europe in 95% of the cases a thermo-power unit which produces electricity for the farm, the grid and heat for the house, greenhouses and other uses. The thermo-power unit has the advantage, that the required energy can be produced in any mixture of gas and fossil energy. It can, therefore, react to periods of low gas production and high energy requirements or vice versa.

|

Concrete digester with two chambers (one heated, one unheated for storage)[2] |

|

Concrete digester with integrated plastic gas-holder[2] |

|

Steelvessel fermenter with seperate ballon gas-holder[2] |

Batch plants

Batch plants are filled and then emptied completely after a fixed retention time. Each design and each fermentation material is suitable for batch filling, but batch plants require high labor input. As a major disadvantage, their gas-output is not steady.

Continuous plants

Continuous plants are fed and emptied continuously. They empty automatically through the overflow whenever new material is filled in. Therefore, the substrate must be fluid and homogeneous. Continuous plants are suitable for rural households as the necessary work fits well into the daily routine. Gas production is constant, and higher than in batch plants. Today, nearly all biogas plants are operating on a continuous mode.

Semi-batch basis

If straw and dung are to be digested together, a biogas plant can be operated on a semi-batch basis. The slowly digested straw-type material is fed in about twice a year as a batch load. The dung is added and removed regularly.

Dry Fermentation Plants

Dry fermentation is an anaerobic process in which micro-organism break down biodegradable material. Renewable organic feedstocks are used as a the source of energy for the process. The nutrient-rich solids resulting from the digestion can be used as a fertiliser subsequently.

Almost any organic material can be processed with dry fermentation. This includes biodegradable waste materials such as waste paper, grass clippings, leftover food, sewage and animal waste.

Process

- Dry fermentation in germany (vTI presentation, 2 MB)

Further Information

English

- Amaratunga, M.: Structural Behaviour and Stress Conditions of Fixed Dome Type of Biogas Units. Elhalwagi, M.M. (Ed.): Biogas Technology, Transfer and Diffusion, London & New York, pp. 295-301. 1986. 0001182; ISBN: 1-85166-000-3

- van Buren, A.; Crook, M.: A Chinese Biogas Manual - Popularising Technology in the Countryside. Intermediate Technology Publications Ltd. London (UK), 1979, sixth impression 1985, 135 P. ISBN: 0903031655

- Fulford, D.: Fixed Concrete Dome Design. Biogas - Challenges and Experience from Nepal. Vol I. United Mission to Nepal, 1985, pp. 3.1-3.10.

- Ringkamp, M. - FH Hildesheim/Holzminden/Faculty of Civil Engineering Holzminden (Germany): Regional Biogas Extension Programme GCR - Final Report on Statical and Structural Examination of Caribbean Biogas Plants. 1989, 60 P.

- Sasse, L. - GATE, Bremer Arbeitsgemeinschaft für Überseeforschung und Entwicklung (BORDA): Biogas Plants - Design and Details of Simple Biogas Plants. 2nd edition, 1988, 85 P., ISBN: 3-528-02004-0

- Werner, U., St�hr, U., Hees, N. - GATE: Biogas Plants in Animal Husbandry - A Practical Guide. Friedr. Vieweg & Sohn, Braunschweig/Wiesbaden (Germany), 1989; 153 p., ISBN: 3-528-02048-2

- Sasse, L. - Centro de Investigacion, Estudios y Documentacion (CIED) Lima (Peru): La Planta de Biogas - Bosquejo y Detaille de Plantas Simples. Reciclaje de la Materia Organica 3. 1986. 103 p.

Articles on energypedia

- How to upgrade biogas on BIOGASPARTNER

- Data sheets of biogas plants

- Plastic tube digester (domestic).

- Polyethylene digester in Bolivia.

- Biogas technology in India.

- Types of biogas digesters and plants (mainly domestic applications)

References