Wind Turbine Technology

Overview

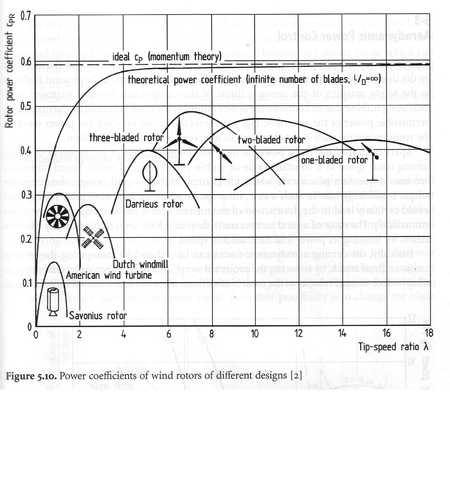

A wind turbine is a device that converts kinetic energy from the wind into electrical power[1].The role of wind turbines is to extract energy from wind and convert it to electrical energy. This extraction is subjected to certain limitations represented by Betz’s limit which is the maximum energy possible to convert kinetic energy into mechanical energy without any losses[2].

Basic Theory

An ideal wind turbine has a maximum power coefficient of 16/27.The theoretical limit cannot be exceeded and this caused by the aerodynamic losses due to conversion of angular momentum,tip and drag[3].

Turbine Power output can can be expressed as follows:

P= ½ * ρ* A * v³* Cp

where ρ is density of air, A is the area swept by rotor and v is the velocity of wind.

The extracted power is then converted into electrical power and is defined as:

P=VI

where P is the electrical power in watt

V is the voltage in V

I is the current in A

Betz Theory is the maximum possible Cp=16/27 which means 59% efficiency is the best a conventional wind turbine can do in extracting power from the wind.

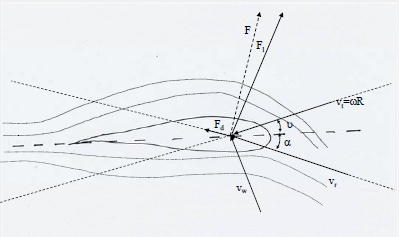

Aerodynamics

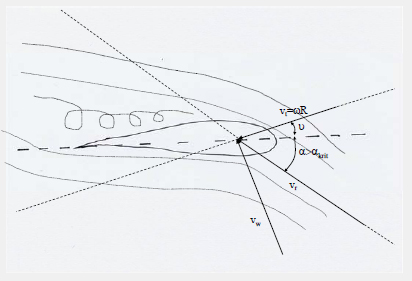

Stall

Stall Control:

- Passive Stall

- Power of the wind turbine is limited by the aerodynamic characteristics of the turbine.

Active Stall

Power of the wind turbine is limited additionally by decreasing the pitch angle (increasing the inflow angle ).

Pitch

Pitch Control:

- Power of the wind turbine is limited by increasing the pitch angle (decreasing the inflow angle α)

Wind Turbine Operation

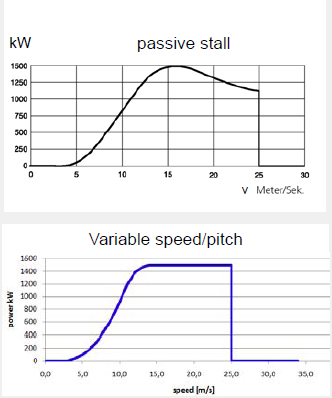

Operation of Fix Speed Wind Turbine (Passive Stall)

- Start up (with open breaker) if wind speed > cut-in wind speed

- Close breaker

- Operation at constant blade angle over the whole wind speed range

- In case of large wind speeds: Power limited by aerodynamic profile.

Operation of Variable Speed Wind-Turbines

Start up (with open breaker) if wind speed > cut-in wi

nd speed

• Close breaker

• Below rated wind-speed

– Maximum power coefficient (Max. Power Tracking)

– Evt: Speed Limitation

• Above rated wind-speed:

– P=Pr

ated (Limited by power electronics converter)

– Pitching

• Advantages of variable speed operation:

– Lower cut-in wind speeds

– Higher efficiency, especially at low wind speeds

– Lower power variations (compared to fixed speed turbines)

• Disadvantage: More expensive!

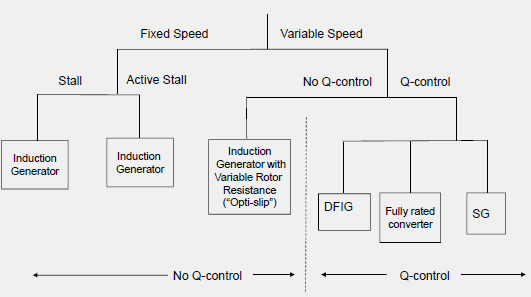

Generator Concepts

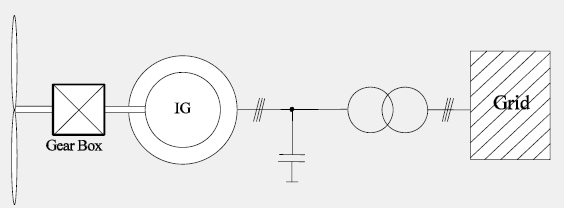

Fixed Speed Induction Generator

Only fix speed operation possible (stall control required)

• Reactive power compensation required

• No reactive power control capability. Additional devices required:

– TSCs (Thyristor switched capacitors)

– STATCOMs

• Risk of dynamic voltage collapse

GTZ Expert Workshop 2010: Grid and System Integration of Wind Energy, 22/23.11.2010, Berlin/Germany

y g p

– > Typically, wind generators based on induction generators are asked to

disconnect in case of voltage dips

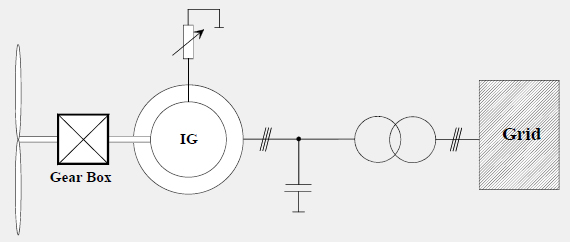

Induction Generator with Variable Rotor Resistance

Simple concept for variable speed operation.

• Reactive power compensation required.

• No reactive power control capability. Additional devices required:

– TSCs (Thyristor switched capacitors)

– STATCOMs

• Limited LVRT capability. Dynamic voltage collapse problems have to

GTZ Expert Workshop 2010: Grid and System Integration of Wind Energy, 22/23.11.2010, Berlin/Germany

be mitigated by:

– Fast increase of rotor resistance during faults

– Additional reactive power compensation devices (typically TSCs)

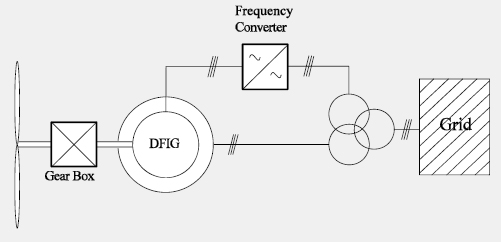

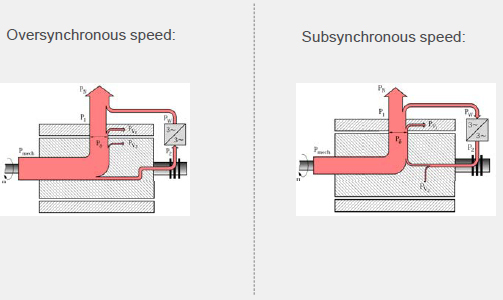

Doubly-Fed Induction Generator

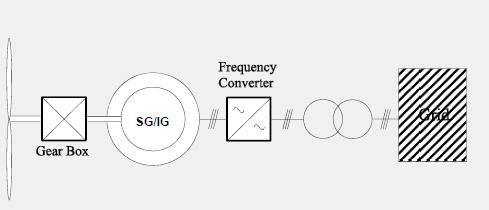

Generator with Fully Rated Converter

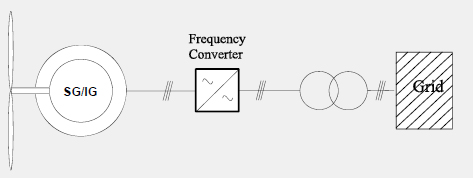

Generator with Fully Rated Converter and Direct Drive

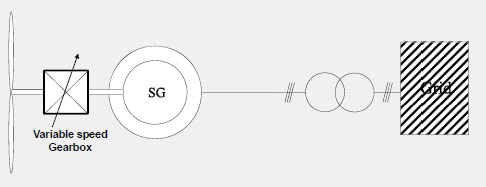

Directly Coupled Synchronous Generator with Variable Gear Box

Further Information

References

- ↑ http://en.wikipedia.org/wiki/Wind_turbine

- ↑ J. F. Manwell, J. G. McGowan and A. L. Rogers. WIND ENERGY; Theory, Design and Application. United Kingdom : John Wiley & Sons Ltd, 2009

- ↑ DESIGN AND POWER CHARACTERIZATION OF A SMALL WIND TURBINE MODEL IN PARTIAL LOAD REGION by Abdulkarim Abdulrazek

- ↑ 4.00 4.01 4.02 4.03 4.04 4.05 4.06 4.07 4.08 4.09 4.10 4.11 Weigel S., Poeller M. (2010) Wind Turbine Generators (WTGs) Physical Principals and Generator Concepts, Presentation prepared by DigSILENT GmbH for the Wind Energy and Development Dialogue 2010, retrieved 27.8.2011 [[1]]