Tomato Processing by Solar Energy

Economic development in remote rural areas in Ethiopia can be enhanced by value adding on farmers’ agricultural raw products. Small scale agro processing must lead to consumable end products, which are food safe, conservable, transportable and marketable. The following case presents an example of how Solar Energy can support micro and small tomato processing enterprises in Ethiopia. This article is a fact sheet, for more details please see the article Business Plan for Solar Processing of Tomatoes.

Project

TAMPA (Tigray Agricultural Marketing Promotion Agency) started in April 2014 in collaboration with the Sustainable Land Management Program (GIZ SLMP) the promotion of micro and small enterprises for tomato processing using renewable energy. The target groups are cooperatives of tomato farmers producing in remote areas without access to electrical power (2014: only 14% of the Ethiopian population has access to grid power, see also Ethiopia Energy Situation).

Many agro processing steps need both thermic energy (heat) and electrical energy (power), both will be obtained from the sunlight. In Tigray, the availability of solar power is reliable and regular in the dry season. The tomato season starts around end of November and ends in the month of June. Then, the processing period will last for 7 months = 210 days. This climate smart technology helps to reduce post-harvest losses and enhances the tomato farmers to add value on their raw products.

The end products are tomato paste/sauce, tomato juice, dried tomatoes and tomato powder. These are conservable without cooling (paste 6 months, juice 1 month, dried tomatoes/powder up to 1 year) and allow the producers to receive better prices for their commercial products:

- 3,150 kg of fresh tomatoes are processed to 1,260 kg long conservable tomato paste, packed into 3,150 bags of each 200 gram plus 1,260 bags of 500g

- 1,050 kg of fresh tomatoes are processed to 735 liter of tomato juice, packed in 1,470 bottles (‘Highland’) of each 0.5 liters

- 5,000 kg of fresh tomatoes will be sun-dried to 675 kg dried tomato slices, and 75 kg tomato powder, packed into vacuum-sealed polyethylene bags

Please note: The solar system is all year around available and can be used for other income generating activities, like television, video, lighting, battery charging, water cooking, sterilization, other food processing, office services like scan/print/internet/email…

Technology

A room of 16 m2 should be sufficient as processing site. It will be built by the farmers’ men power contribution, stones are available onsite and construction material like cement, metal sheets for the roof and a metal door/window as well as tiles will be supplied by the GIZ SLM Program.

The solar panel will be placed on a metal stand, which allows daily cleaning to maintain its power for battery charging and processing work. Also, the stand allows turning around of the panel, by adjusting the direction, an optimal output from the sunlight may be obtained in case of need.

Special attention will be given to train the processing team in technical aspects of the photovoltaic power system. This includes the handling of the precious inverter, the regular cleaning of the panel and the maintenance of the acid batteries.

|

|

|

| Solar reflector used for tomato processing © TAMPA | Processing of tomatoes in Tembien © TAMPA | Tomato paste sterile packed into PET-bags © TAMPA |

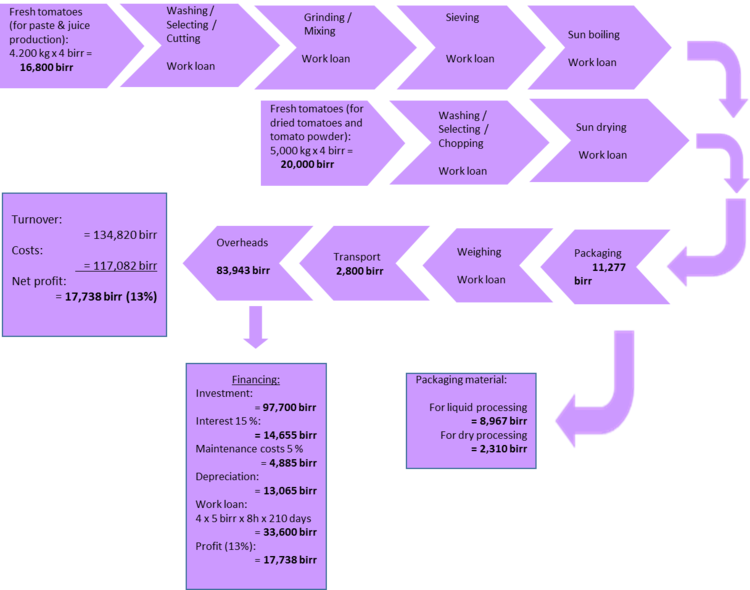

Quantified Tomato Value Chain

The quantified tomato processing value chain design (liquid and dry):

Financial Plan

Costs

Fix costs (= overheads) = 83,943 birr

+ Variable costs = 50,877 birr Total costs = 134,820 birr

Annual Turnover

Liquid tomato products:

1,260 bags of paste, 500 g x 25.0 birr = 31,500 birr 3,150 bags of paste, 200 g x 12.0 birr = 37,800 birr 1,470 bottles of juice, 0.5l x 12.0 birr = 17,640 birr Dry tomato products: 3,360 bags of slices, 200 g x 10.5 birr = 35,280 birr 2,520 bags of powder, 30 g x 5.0 birr = 12,600 birr Total turnover = 134,820 birr

Investment Costs and Depreciation

| Description | Purchase prize (ETB)per unit | Purchase prize (ETB)total | Supplier | Depreciation years | Depreciation (ETB)/a |

| 2 solar panels, 90 Wp | 6,000 | 12,000 | LYDETCO 0911207283 | 20 | 600 |

| 1 regulator, 12 V/20A | 2,500 | 2,500 | LYDETCO 0911207283 | 10 | 250 |

| 2 lorry batteries, 12 V/120 Ah | 4,000 | 8,000 | Mekele shops | 4 | 2,000 |

| 1 metal stand for solar panels | 2,500 | 2,500 | Sami metal shop Mekele | 20 | 125 |

| 1 wooden/metal box for batteries (60x70x40cm), with metal cover | 1,600 | 1,600 | Carpenter Mekele | 10 | 160 |

| Cables, fuses, switches, sockets | 1,000 | 1,000 | Mekele shops | 5 | 200 |

| 1 Inverter, sine 500 W, with switch/fuse | 20,000 | 20,000 | LYDETCO 0911207283 | 5 | 4,000 |

| 4 Solar cookers, parabolic dish, SK 14 | 4,500 | 18,000 | Bereket Solar Addis Abeba (0911 225131) | 20 | 900 |

| 1 Mixer, 220 V, 200 – 400 W | 1,000 | 1,000 | Mekele shops | 1 | 1,000 |

| 1 Sealing machine, twin sealing, 220V, 65W | 8,300 | 8,300 | Germany / TAMPA | 10 | 830 |

| 1 Balance, digital, 0 – 5000g | 500 | 500 | Addis Abeba shops | 2 | 250 |

| 1 Balance, analog, 20kg | 500 | 500 | Mekele market & shops | 5 | 100 |

| 1 Water container with water tap and metal stand, 20 liters for tomato washing | 2,000 | 2,000 | Mekele metal workshops | 10 | 200 |

| Sieves, spoons, washing pans, baskets | 1,000 | 1,000 | Mekele market | 2 | 500 |

| 1 Sterilization kettle, 20 liter | 1,500 | 1,500 | Mekele market & shops | 10 | 150 |

| 1 Sterilization thermometer (110°Celsius) | 300 | 300 | Mekele market & shops | 3 | 100 |

| 1 Working table, 3m x 1m | 2,000 | 2,000 | Mekele carpenter | 3 | 100 |

| 1 solar dryer, 5m x 2m | 15,000 | 15,000 | Mekele metal workshops | 10 | 1,500 |

| Total (ETB) | 97,700 | 13,065 |

For more details on the business plan, please see this article.

Further Information

- Business Plan for Solar Processing of Tomatoes

- Flyer TAMPA

- GIZ Sustainable land management, Ethiopia

- Ethiopia Energy Situation

- TAMPA project "Small Scale Oil Seeds Processing"

- Energy within Food and Agricultural Value Chains

- PoweringAg Technology Database - Solar Technologies

- Water and Energy for Food (WE4F) portal on energypedia

Reference

- German Development Cooperation