Wind Energy - Climate Change

Environmental Advantages of Wind Energy Utilisation

Certified Emission Reduction (CER) - a By-product

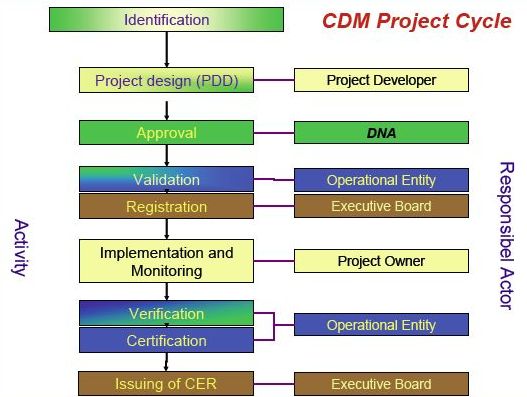

Clean Development Mechanism (CDM) Project Cycle

Assessing Potentials for CDM Project[3]

The extent to which a wind energy project can be developed into a Clean Development Mechanism (CDM) pursuant to Article 12 of the Kyoto Protocol, with positive impacts on the economic efficiency of the project, is investigated below. The first step in that direction is

- to describe and appraise essential institutional framework conditions for CDM projects in a country.

- This will be followed by a check-through of the planned project on the basis of formal criteria.

- Finally, a cost-benefit assessment of project development with utilisation of CDM has to be made.

Local Institutional Framework Conditions

- Kyoto Protocol: A first important prerequisite for CDM projects in cooperation with the industrialised countries is that the countries have committed themselves to reducing emissions, as listed in Annex B of the Kyoto Protocol.

- National authority: With regard to concrete projects, the establishment of a Designated National Authorityfor the national approval and institutional backstopping of CDM projects would be of major significance.

- Capacity building: for climate protection projects; training measures for the implementation of future CDM projects

Formal Project Appraisal

The following formal project appraisal is oriented on the baseline methods developed by OECD/IEA and CERUPT for CDM projects in the electric power sector and on the simplified rules for so-called small-scale CDM projects presented according to decision 5/COP6, as defined in connection with 7th Conference of Parties in Marrakech.

Example: Gao/Mali (calculation acc. to OECD/IEA for "mini-grids with diesel generator, but without storage")

The planned project involves an isolated system comprising a diesel generating unit with an installed capacity of 4,000 kW and a newly added wind energy conversion system with an output of approx. 1,000 kW. Since the total output of the resultant wind-diesel hybrid system remains below 15 MW, the project falls within the category off-grid systems, which covers all mini-grid projects up to that capacity limit. The planned project does not include an energy store. Hence, the emission reduction effects attributable to the project must be calculated according to the standardised baseline methods (OECD/IEA) for the project category "mini-grids with diesel generator, but without storage“. The emission reduction will result from the substitution

of diesel fuel by wind energy.

The supplementary nature of the project is indicated here by way of a brief "barrier analysis". This analysis counts as confirmation of supplementarity, if at least one barrier exists that would have ruled out implementation of the project without CDM:

- Investment barrier: a system designed under purely financial aspects would have employed a different technology with higher specific emission levels.

- Technology barrier: under risk aspects, a technologically less progressive technology with higher specific emissions would have been employed (applies in particular to technologies with still-load levels of market penetration).

- Barrier due to prevailing practice: the dominant market practice and/or the legal framework conditions of licensing would have led to the use of a different technology with higher specific emissions.

- Other hindrances: institutional, organisational obstacles, lack of financial resources, lack of expert knowledge.

Of these four categories, at least the one entitled "technology barrier" and the closely related "barrier to prevailing practice“ can be regarded as fulfilled for the proposed project.

The need for a detailed examination of the supplementarity of the planned project no longer applies, if the project is recognised as a product type corresponding to the "Simplified Modalities and Procedures for Small-Scale CDM Project Activities“ of the CDM Executive Boards (here: Group I.D.). Hence, any future application of the project as a CDM can take place on the basis of the "Simplified Project Design Documents for Small-Scale Project Activities“ (SSC-PDD).

Cost-benefit Considerations for CDM Project Development

Calculation of Emission Reduction (Wind-Diesel Hybrid)

The emission reduction attributable to a project is first calculated in application of the baseline methods stated in the "Simplified Modalities and Procedures for Small Scale CDM Project Activities“ of the CDM Executive Board. The subsequent detailed calculation is then performed on the basis of the design data of the planned wind farm.

Greenhouse gas emissions can be attributed to any of four source categories:

- direct emissions or emission reductions "on-site", e.g., from combustion processes

- direct emissions or emission reductions "off-site", e.g., from upstream and downstream steps of the supply chain

- indirect emissions or emission reductions "on-site" from so-called rebound effects, e.g., reduction of a building's heating requirements by adding insulation (affluency effect)

- indirect emissions or emission reductions "off-site" due to leakage effects, e.g., mediumterm changes in the supply structure resulting from technology diffusion or the like.

In case of projects belonging to the "Small-scale CDM" category, only direct on-site emissions are normally accounted for. For wind-diesel hybrid systems without storage, this means, in a conservative approach, that the emission reduction is to be calculated on the basis of the diesel fuel saved by the provision of wind-generated electricity. The estimated emission factor for diesel units supplying power to a mini-grid 24 hours a day and having an installed capacity in excess of 200 kW amounts to 0.8 kg CO2eq/kWhelectr.24 The annual electric work totalling approx. 1.1 GWH/a estimated for wind-power generation is to be evaluated

with this emission factor. The annual emission reduction calculated for the wind farm according to that simplified approach amounts to approx. 880 t CO2eq/a.

The above estimate ignores some of the emission-reducing effects dealt with below. Since the use of an appropriately expanded baseline method would lead to significant additional costs in connection with transportation (whereas the project would no longer be able to utilise the other, simplified rules for small-scale CDM projects, e.g., the SSC-PDD), such an approach would, considering the size of the project, rule itself out (due to inadequate cash-flow for covering the additional costs). The following calculation therefore serves indicative purposes enabling an assessment of the error that would be made with the simplified method of

calculation.

The following effects are accounted for in the detailed calculation of the specific emission reduction resulting from the generation of wind power:

- Wind power generation only replaces diesel power generation to the fractional amount of kwind feed-in. Calculations and simulations based on the design data, the wind characteristics at the planned WECS site, and the load structure yield a factor of 99.5 %.

- Due to its fluctuating structure, wind power feed-in causes a loss of efficiency for the diesel unit. Technical calculations and measurements conducted on the existing plant indicate an anticipated increase in specific fuel consumption from 281 ldiesel/MWhelectr to 286

- ldiesel/MWhelectr. The value 3.2 kg CO2/kg diesel serves here as the conversion factor for diesel. The specific gravity, or relative weight, of diesel amounts to 820 - 845 kg/m³ (DIN 590), i.e., some 0.833 kg/l on average. The specific CO2 emissions therefore amount to:

The diesel fuel, or more precisely: the DDO = distillate diesel oil) for the project in question has to be trucked in an average distance of 2,646 km. Considering that each road tanker making the trip with a load of 30,000 l consumes an average of 45 l per 100 km, then each delivered litre of diesel fuel is responsible for the consumption of approx. 0.04 l diesel fuel. This yields an add-on factors of ktransport = 1.04 for CO2 emissions from diesel power generation.

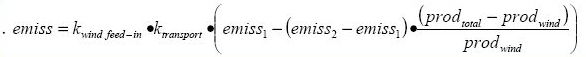

The emission reduction, . emiss, resulting from the feed-in of wind power is calculated with allowance for all such effects both for an annual wind power yield of prodwind = 1.1 GWh/a and a total demand of prodtotal = 9.0 GWh/a according to the following equation:

This yields a specific emission reduction of 0.678 kg CO2eq/kWhelectr. Hence, the detailed calculation shows the emission reductions to be about 15 % lower than in the case of the estimate calculation permitted for small-scale projects. For the project sponsor, then, there is no reason to pursue project development outside of the "Simplified Modalities and Procedures for Small Scale CDM Project Activities" of the CDM Executive Board.

Further Information

References

- ↑ GTZ-CaPP 2004: Windenergie: Option für CDM in China. http://www.gtz.de/de/dokumente/de-windenergie-fachgespraeche-liptow-cdmchina-2005.pdf

- ↑ GTZ-CaPP 2004: Windenergie: Option für CDM in China. http://www.gtz.de/de/dokumente/de-windenergie-fachgespraeche-liptow-cdmchina-2005.pdf

- ↑ content prepared based on: GTZ 2004: Feasibility Study Gao Wind Farm, Mali – Wind-Diesel System. Final Report. Page Environmental Benefits - 7.1 Environmental Advantages of Wind Energy Utilisation, Evaluation as a Potential CDM Project http://www.gtz.de/de/dokumente/en-windenergy-mali-feasibility-study-gao-2004.pdf