Difference between revisions of "Biomass Briquettes - Production"

***** (***** | *****) m (→Manual) |

***** (***** | *****) m (→Roller Presses) |

||

| Line 88: | Line 88: | ||

== Roller Presses == | == Roller Presses == | ||

| − | Densification of biomass using roller presses works on the principle of pressure and agglomeration, where pressure is applied between two counter-rotating rolls. Ground biomass, when forced through the gap between the two rollers, is pressed into a die, or small pockets, forming the densified product. Roller presses are considered the world standard technology to produce ovoid (pillow-shaped) charcoal briquettes from a variety of biomass types. In a roller press, a mixture of charcoal and binder is fed to the tangential pockets of two rollers to produce briquettes. The smooth production of charcoal briquettes using this technology requires high-quality rollers with smooth surfaces on which the briquettes are shaped. The type of roller determines the shape of the briquettes. Currently, roll presses available in developed countries have production capacities of 1 t/hr and more. The 1 tonne/hr capacity press with controlled feeding device costs about $ 320,000. Much cheaper roller-type charcoal briquetting machines can be sourced in India and China: Seboka (2009) indicates that a roller press with a capacity of 1.5 tonne/hr costing $ 19,000 can be found in India<ref>Seboka, Y. (2009): Charcoal Production: Opportunities and Barriers for Improving Efficiency and Sustainability. In: Bio-carbon Opportunities in Eastern & Southern Africa, UNDP, 2009</ref>. | + | Densification of biomass using roller presses works on the principle of pressure and agglomeration, where pressure is applied between two counter-rotating rolls. Ground biomass, when forced through the gap between the two rollers, is pressed into a die, or small pockets, forming the densified product. Roller presses are considered the world standard technology to produce ovoid (pillow-shaped) charcoal briquettes from a variety of biomass types. In a roller press, a mixture of charcoal and binder is fed to the tangential pockets of two rollers to produce briquettes. The smooth production of charcoal briquettes using this technology requires high-quality rollers with smooth surfaces on which the briquettes are shaped. The type of roller determines the shape of the briquettes. Currently, roll presses available in developed countries have production capacities of 1 t/hr and more. The 1 tonne/hr capacity press with controlled feeding device costs about $ 320,000. Much cheaper roller-type charcoal briquetting machines can be sourced in India and China: Seboka (2009) indicates that a roller press with a capacity of 1.5 tonne/hr costing $ 19,000 can be found in India<ref>Seboka, Y. (2009): Charcoal Production: Opportunities and Barriers for Improving Efficiency and Sustainability. In: Bio-carbon Opportunities in Eastern & Southern Africa, UNDP, 2009</ref>. |

| − | |||

| − | [[File:Figure 10 roller press.jpg|thumb|left|300px|Roller | + | [[File:Figure 10 roller press.jpg|thumb|left|300px|Figure 8: Roller Presses<ref name="Eriksson 1990">Picture: Eriksson, S. and Prior, M. (1990): The briquetting of agricultural wastes for fuel, FAO Environment and Energy Paper 11, FAO of the UN, Rome, 1990</ref>|alt=Figure 10 roller press.jpg]] |

| + | |||

== <br/>Agglomeration == | == <br/>Agglomeration == | ||

Revision as of 14:49, 27 January 2015

Overview

„The Art of Briquetting [1]“

The reduction of material density is the reason for undertaking briquetting as it determines both the savings in transport and handling costs and any improvement in combustion over the original material: the art of briquetting. This art essentially involves two parts: the compaction under pressure of loose material to reduce its volume and to agglomerate the material so that the product remains in the compressed state.

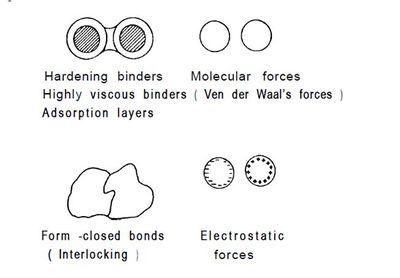

Later effect, the cohesion of the particles, is based on three main mechanisms[2]:

- Generating a positive coupling of particles by fibre connections

- Attraction forces between particles through hydrogen bonds

- Creating of form-closed bonds through the sticking effect of several biomass contents (lignin, protein, starch) or added binders

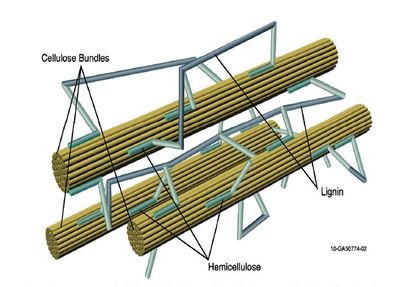

FA binding agent is necessary to prevent the compressed material from springing back and eventually returning to its original form. This agent can either be added to the process or, when compressing ligneous material, be part of the material itself in form of lignin. Ligning is a constituent in most agricultural residues. It can be defined as the thermo plastic polymer, which begins to soften at temperatures above 100°C and is flowing at higher temperatures. The softening of lignin and its subsequent cooling while the material is still under pressure is the key factor in high pressure briquetting. It is a physic-chemical process related largely to the temperature reached in the briquetting process and the amount of lignin in the original material. The temperature in many machines is closely related to the pressure though in some, external heat is applied.

In general there are two immediate ways of classifying briquetting processes. One distinction is whether or not an external binding agent must be added to agglomerate the compressed material. The second way of classifying follows the pressure applied while briquetting: high, medium or low pressure.

For a rough distinction the following numbers might be adopted:

- Low pressure up to 5 MPa

- Medium pressure 5 – 100 MPa

- High pressure above 100 MPa

Usually high pressure processes will release sufficient lignin to agglomerate the briquette. Medium pressure machines may or may not require binders, depending upon the raw material whilst low-pressure machines invariably require binders. Such external binders might be: starch, clay, molasses or wood tar etc.. All briquettes using inherent binders (lignin) or external hydrophilic binders (starch, molasses, gum, clay) are not waterproof and will disintegrate when they come into contact with water or stored under humid conditions.

Briquetting of charcoal

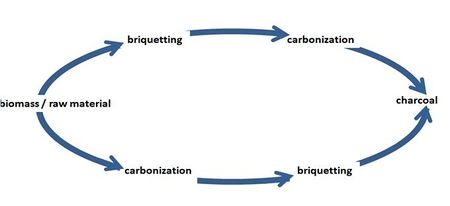

Charcoal is produced in many countries around the world. The basic idea is quite similar to briquetting: the densification of energy. Therefore, biomass is pyrolized in kilns by a controlled burning process lacking sufficient oxygen for a complete burning of the raw material. Briquetting can be combined with carbonization to further improve the densification of the charcoal.

Basically the two processes can be applied one after the other - Figure 6: From biomass to charcoal:

But, during the carbonization process, the biomass is losing its lignin content and thereby an important binder for briquetting. Charcoal is a material totally lacking plasticity and hence needs addition of a sticking or agglomerating material to enable a briquette to be formed. The binder should preferably be combustible, though a non-combustible binder effective at low concentrations can be suitable.

Further information:

- “Charcoal Production from Alternative Feedstocks” by NL Agency (2013) provides a good overview on charcoal production technologies, on carbonization of biomass and suitable binders including the description of three supply chains presented as case studies. Download the publication here.

- Alternative Charcoal Tool (ACT)

Briquetting Technologies

Industrial methods of briquetting date back to the second part the the 19th century. Since then there has been widespread use of briquettes made from brown coal, peat and coal fines. The briquetting of organic materials requires higher pressure as additional force is needed to overcome the natural springiness of these materials. Essentially, this involves the destruction of the cell walls through some combination of pressure and heat. The following overview presents the most common machines used for briquetting biomass.

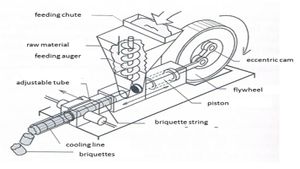

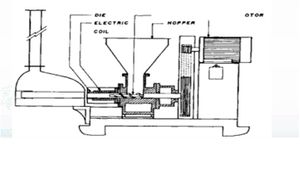

Piston Presses

In piston presses, pressure is applied discontinuously by the action of a piston on material packed into a cylinder. They may have a mechanical coupling and fly wheel or utilize hydraulic action on the piston. The incoming raw material is pressed against the compacted material inside the pressing tube and leaves the die in the rhythm of the piston action. Through pressure and friction forces inside the pressing tube, the material is strongly heated and cooling mechanisms might be considered. To produce briquettes with high density (up to 1.25 g/m3) the raw material eventually needs to be milled (less than 10 mm) and dried (<15% of water content) before briquetting. The capacity of piston presses depends both on the diameter of the die and the pretreatment of the raw material.

The capacity spectrum of piston presses range from only 25 up to 1800 kg/hr. Their typical specific energy use requires between 50 and 70 kWh/t.[5]

Figure 4.1: Piston Presses[6] |

Figure 4.2: Piston Presses[6] |

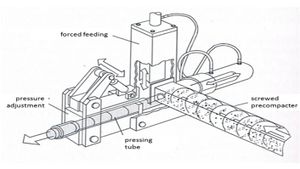

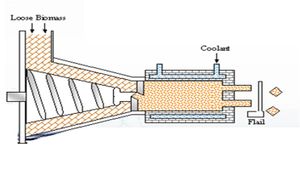

Screw Compaction or Extrusion

The aim of compaction using an extruder is to bring the smaller particles closer so that the forces acting between them become stronger, providing more strength the densified bulk material. During extrusion, the material moves from the feed port, with the help of a rotating screw, through the barrel and against a die, resulting in significant pressure gradient and friction due to biomass shearing. The combined effects of wall friction at the barrel, internal friction in the material, and high rotational speed of the screw, increase the temperature in the closed system and heat the biomass. This heated biomass is forced through the extrusion die to form the briquettes with the required shape. If the heat generated within the system is not sufficient for the material to reach a pseudo-plastic state for smooth extrusion, external heat might be added. In principle, screw presses reach slightly higher compaction but lower capacity (tons per hour) when compared to piston presses.

Figure 5.1: Screw Press[7] |

Figure 5.2:Screw Press[8] |

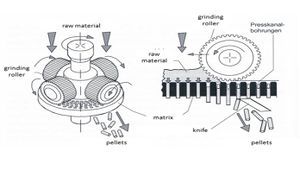

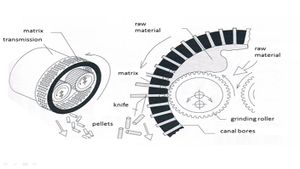

Pan Grinder Presses for Pelletizing

Pellets are the result of a process which is closely related to the briquetting processes described above. The main difference is that the dies have smaller diameters and each machine has a number of dies arranged as holes bored in a thick steel disk or ring. The material is forced into the dies by means of rollers moving over the surface on which the raw material is distributed. The pressure is built up by the compression of this layer of material as the roller moves perpendicular to the centerline of the dies. Thus the main force applied results in shear stresses in the material. The pellets will still be hot when leaving the dies, where they are cut to lengths normally about one or two times the diameter. Successful operation demands that a rather elaborate cooling system is arranged after the densification process.

There are two main types of pellet presses: flat and ring types. The flat die type has a circular perforated disk on which rollers rotate whereas the ring die press features a rotating perforated ring on which rollers press on the inner perimeter. The output of pellet presses range from about 200 kg/hr up to 8 ton/hr. Their specific energy consumption is reported to be around 1,5% of the energy content of the final peletts[6].

Figure 6.1: Pan Grinder[6] |

Figure 6.2: Pan Grinder[6] |

Manual

For sure the simplest way to produce small briquettes is hand-shaped briquettes: a slurry of biomass in water is left soaking for some days to enhance binding properties. The pulp is either squeezed by hand or pressed into a mould e.g. an ice-cube tray. Rearranged fibres assisted by a binder like paper pulp keep the briquette in shape during drying and use. A part of hand-shaped briquettes there are plenty of small manual briquetting machines which were developed by different producers and scientists all over the world. A very good overview on existing low cost briquetting machines, from perforated bottles to wooden lever presses, can be found in the manual “Micro-gasification: Cooking with gas from biomass” by Christa Roth (2011)[9]

Figure 7.1:Biomass Molds (Examples of low cost briquetting machines)[10] |

Figure 7.2: Biomass Presses (Examples of low cost briquetting machines)[11] |

However, it remains unclear, whether any manual densification process can ever be commercially viable even in circumstances where labour is very cheap. Considering their very low throughput, such techniques often require almost as much capital investment as the mechanical processes. The savings achieved are essentially a labour for electricity substitution rather than labour for capital.

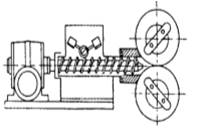

Roller Presses

Densification of biomass using roller presses works on the principle of pressure and agglomeration, where pressure is applied between two counter-rotating rolls. Ground biomass, when forced through the gap between the two rollers, is pressed into a die, or small pockets, forming the densified product. Roller presses are considered the world standard technology to produce ovoid (pillow-shaped) charcoal briquettes from a variety of biomass types. In a roller press, a mixture of charcoal and binder is fed to the tangential pockets of two rollers to produce briquettes. The smooth production of charcoal briquettes using this technology requires high-quality rollers with smooth surfaces on which the briquettes are shaped. The type of roller determines the shape of the briquettes. Currently, roll presses available in developed countries have production capacities of 1 t/hr and more. The 1 tonne/hr capacity press with controlled feeding device costs about $ 320,000. Much cheaper roller-type charcoal briquetting machines can be sourced in India and China: Seboka (2009) indicates that a roller press with a capacity of 1.5 tonne/hr costing $ 19,000 can be found in India[12].

Agglomeration

Agglomeration is a method of increasing particle size by gluing powder particles together. Usually the equipment consists of a rotating volume that is filled with balls of varying sizes and fed with powder and often a binder. The rotation of the agglomerator results in centrifugal, gravitational and frictional forces from the smooth rolling balls. These forces, together with inertial forces, press the balls against the powder, helping them to stick together and grow. NL Agency[13] reports applied agglomeration technology in small-scale briquetting processes in several developing countries. The charcoal is milled to powder, binders are added, the components are mixed together, and the mix is then agglomerated. Agglomerated charcoal briquettes are produced using a motor-driven agglomerator, the typical nominal capacity of which is 25-50 kg/hour. Agglomerated charcoal briquettes are spherical and typically have diameters between 20-30 mm. The briquettes can be used for household cooking as well as for fuelling industrial furnaces. Agglomerated briquettes are said to be stronger than most other briquette types (Reference numbered as "5". It is missing and does not match order).

Figure 12: Small-scale agglomerator[14]

|

|

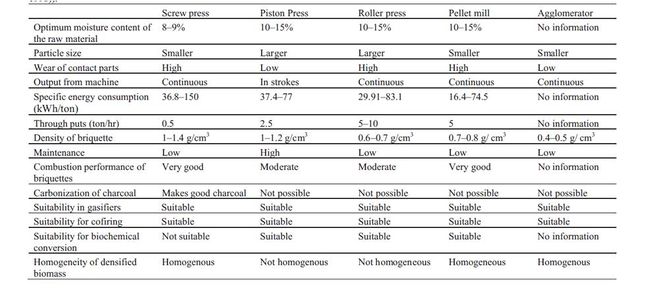

As seen above, there are different technologies to produce densified biomass briquettes. The following table 1 summarizes their main characteristics.

For the right choice of an adapted machine, two main issues should be considered:

- Quantity and quality of the raw material

- Market availability of briquetting machines and spare parts

Table 1: Comparison of different densification equipments[15]:

Problems arise often if the die has not been shaped correctly or if the feeding mechanism has not been sized for the material to be used. It is normal for machines made in Europe or North America to be designed to operate on wood wastes. The use of agroresidues normally de-rates the throughput and may require some modification to the feeder. Therefore, when searching for briquetting machines, best is finding machines which are already running with similar raw material and under similar conditions.

Further information:

- Bhattacharya, S.C.: biomass energy and densification: A Global Review with Emphasis on Developing Countries; Energy Program, Asian Institute of Technology; Thailand gives an overview on different technologies used for briquetting in many countries in Asia, South America and Africa.

- When searching for “briquetting” in the internet a huge number of producers will appear. ► A list of mainly European briquetting machines sellers.

Auxiliary Equipment

Only in few cases will the briquetting press be the only equipment needed to set up a briquetting plant. From the starting point, the complexity of briquetting plants increases up to the fully automated woodwaste briquetting plants in which the raw material is fed by a tractor into a hopper from where it is crushed, screened, stored, dryed, stored again, fed into the presses and transported to the product storage in fully automatic process, supervised by a couple of operators.

Without going into details, the following text is a brief listing of a few common types of necessary auxiliary equipments and their applications which might have to be considered as also important economical factors:

- Storage (rainy seasons, both the raw material and the product)

- Handling (conveyors, elevators etc.)

- Comminution (chipper, hammer mill, conditioner, mixing with binder)

- Classification (separation, cleaning)

- Drying

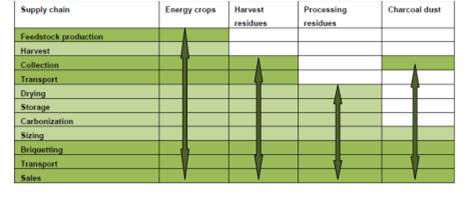

To demonstrate the necessary steps for charcoal briquetting of different raw materials, NL Agency (2013) created table 2 below. Charcoal dust has the shortest supply chain, only a collection and briquetting step is needed to produce charcoal briquettes. On the contrary, the charcoal production chain based on the growing of dedicated energy crops involves a considerable number of steps. Each step in the supply chain represents efforts, money and possible complications, and this indicator shows that charcoal dust and processing residues have a logistic advantage over other types of feedstocks.

Table 2: Charcoal production chain of selected feedstocks[14]:

Costs

The financial costs of briquetting are very dependent upon the nature of the project, in particular upon the raw material used and the plant location. They depend upon a number of operating costs, including labour, maintenance, power, raw material cost and transport etc. as well as of capital cost component. Whether or not briquetting is economic in any given location will depend critically upon how these unit costs relate to the price of the likely substitute fuels.

Capital Costs

The capital costs of a plant are not always easy to establish on a consistent basis. In different circumstances there may be different conventions about what is included in capital cost: for example, do spare parts count for capital costs or operational cost? Is the plant a stand-alone operation or is it part of an existing agro plant and maybe existing buildings can be used?

Probably, one of the biggest variations in plant capital costs, however, comes from the raw material to be used and the form in which it is collected. The nature of the raw material, especially the density, influences significantly the output rate of briquetting machines. Most agro-residues will cause lower outputs than wood residues for the same briquetting machine what will influence the unit capital costs. In addition, the form of the initial feed may require pretreatment efforts before it is fed to the briquetter as such. Some wastes, for example sawdust, often need to be dried to reduce their moisture to 15%, others like cotton stalks might be chipped or shredder before briquetting. Thirdly, there is a very big difference between field-residues and factory-residues if the cost of the equipment to collect the residue is included in the initial capital cost.

Another important aspect of capital costs are the engineering and design standards of the plant. For example, it is likely that in a plant where little or no use is made of mechanical handling, there will be a need to have spacious buildings to avoid problems of dust and dangerous overcrowding. Briquetting machines which are squeezed into residue-producing plants to utilize existing buildings may naturally have lower capital costs than briquetting plants with firm floors, proper electrical fittings etc.

Apart of these direct production capital costs, in many countries additional costs have to be considered and can range widely from country to country. For example credit costs or custom duties on imported machines.

Operating Costs

The first obvious operating cost is the price to be paid for the raw material. This costs are very project and site-specific. The raw material might have a specific price when its use is competing with alternative uses. However, even if the residue is free, it is common for a transport cost to be incurred in bringing the residue to the briquetting plant. In the case of briquetting plants sited at the residue production point this is avoided but for other situations the transport cost may be a significant part of operational costs. These transport costs may be added into general labour costs if full time drivers are employed but certainly a more common situation is to hire appropriate transport for a given period of collecting the raw material.

The labour costs of a briquetting plant are in general very dependent upon plant design: are there any significant residue collection activities; the wage rate of various categories of labour employed (collecting, loading, maintenance, supervision etc.); and the extent to which the unit is integrated with a larger factory which can supply some labour needs on a part-time basis and cover administration costs. However, S. Eriksson and M. Prior[8] results that despite the wide variations in labour costs, briquetting as such is not labour intensive relative to the unit capital costs and the cost of maintenance, power and other consumables. Labour costs seldom exceed 15% of the total and are usually much less.

Maintenance costs can be a significant element of briquette production costs and one that is often underestimated in planning plants. Especially when briquetting machines are working on abrasive materials, such as rice-husks or charcoal, the maintenance cost can be quite high particularly for pan grinder for pelletizing, screw presses and piston presses. It is a factor which may place a continuing reliance on imported spare-parts or in the need to employ virtually an operative on building up spare parts.

Except of manual driven briquetting machines, all other types of briquetting machines require a certain power supply. There is no reason why plants in remote areas should not use diesel generators or use direct drive from diesel or steam engines. But in most cases the briquetting machines are connected to the main electrical power supply: depending on the size and output rate of the machine whether single phase 220V or 3 phases 400V supply is necessary. The specific requirements and consumption of each machine has to be considered in an early state of planning and to be adapted to local circumstances.

Other costs which might have to be considered when operating a briquetting plant are: taxes, insurance, consumables such as lubricating oil, packaging etc.

|

Box: Comparison between pelleting and briquetting[4] Briquette processing is more efficient than pelleting because the biomass materials do not necessarily have to be preprocessed or uniformly ground up, which results in less preparation. Another advantage of briquetting is it can be set onsite. Briquetting waste byproducts and reusing them onsite for energy rather than transporting them to another location or to a landfill can save on disposal costs. Briquetting generally use less horsepower. From the investment point of view, the purchase capital and maintenance costs to make briquettes are less than for pellets. If transportation is one of the main criteria, pellets are more advantageous because there are more pounds per foot than briquettes. This is especially true if the briquettes are larger because it allows for more air between them when they are stacked. |

To keep in mind!

|

Further Information

- Alternative Charcoal Tool (ACT)

- Biomass Briquettes – Production and Marketing

- Biomass Briquettes - Marketing

- Biomass portal on energypedia

- The Charcoal Project

- Harvest Fuel Initiative

References

- ↑ Advertising slogan of the briquetting company Di piu; www.di-piu.com

- ↑ The original German version: Kaltschmitt, M.; Hartmann, H. und Hofbauer, H. (2009): Energie aus Biomasse. Grundlagen, Techniken und Verfahren; Springer-Verlag Berlin Heidelberg 2001, 2009, korrigierter Nachdruck 2009

- ↑ Picture : Grover, S.D. and Mishra S.K. (1996): Biomass Briqetting: Technology and Practices; FAO Regional Wood Energy Development Programme in Asia, Bangkok, Thailand (1996)

- ↑ 4.0 4.1 Picture : Jaya Shankar Tumuluru et al. (2010): A Review on Biomass Densification Technologies for Energy Application; Idaho national laboratory; 2010 Cite error: Invalid

<ref>tag; name "Jaya 2010" defined multiple times with different content - ↑ Kaltschmitt, M.; Hartmann, H. und Hofbauer, H. (2009): Energie aus Biomasse. Grundlagen, Techniken und Verfahren; Springer-Verlag Berlin Heidelberg 2001, 2009, korrigierter Nachdruck 2009

- ↑ 6.0 6.1 6.2 6.3 6.4 Picture: The original German version: Kaltschmitt, M.; Hartmann, H. and Hofbauer, H. (2009): Energie aus Biomasse. Grundlagen, Techniken und Verfahren; Springer-Verlag Berlin Heidelberg 2001, 2009, korrigierter Nachdruck 2009 Cite error: Invalid

<ref>tag; name "Kaltschmitt 2009" defined multiple times with different content Cite error: Invalid<ref>tag; name "Kaltschmitt 2009" defined multiple times with different content Cite error: Invalid<ref>tag; name "Kaltschmitt 2009" defined multiple times with different content - ↑ Picture : http://www.soi.wide.ad.jp/class/20070041/slides/03/index_12.html

- ↑ 8.0 8.1 8.2 Picture: Eriksson, S. and Prior, M. (1990): The briquetting of agricultural wastes for fuel, FAO Environment and Energy Paper 11, FAO of the UN, Rome, 1990 Cite error: Invalid

<ref>tag; name "Eriksson 1990" defined multiple times with different content Cite error: Invalid<ref>tag; name "Eriksson 1990" defined multiple times with different content - ↑ https://energypedia.info/wiki/File:Micro_Gasification_Cooking_with_gas_from_biomass.pdf

- ↑ Pictures: http://home.fuse.net/engineering/

- ↑ Pictures: http://home.fuse.net/engineering/

- ↑ Seboka, Y. (2009): Charcoal Production: Opportunities and Barriers for Improving Efficiency and Sustainability. In: Bio-carbon Opportunities in Eastern & Southern Africa, UNDP, 2009

- ↑ NL Agency (2013): Charcoal Production from Alternative Feedstocks; final version 2013

- ↑ 14.0 14.1 Picture: NL Agency (2013): Charcoal Production from Alternative Feedstocks; final version 2013 Cite error: Invalid

<ref>tag; name "NL 2013" defined multiple times with different content - ↑ Jaya Shankar Tumuluru et al. (2010): A Review on Biomass Densification Technologies for Energy Application; Idaho national laboratory; 2010

This article is part of the Biomass Briquettes - Production and Marketing and belongs to the GIZ HERA Cooking Energy Compendium.