Difference between revisions of "Nepal - Energy Efficiency in Industry"

***** (***** | *****) |

***** (***** | *****) |

||

| Line 41: | Line 41: | ||

<br/> | <br/> | ||

| + | |||

| Line 50: | Line 51: | ||

<br/> | <br/> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | [[File:Energy use in Nepalese Cement industry.PNG|thumb|left|200px|Energy use in cement industry in Nepal]]<br/> | + | === Energy Use === |

| + | <div>Main source of energy used in Cement factories is electricity and coal. Limestone-based units use coal for calcination. Clinker-based units use mainly electricity for grinding. Limestone-based cement plants is very energy-intensive with about 48% of energy cost on production value. In clinker-based units on 5% of the cost is due to energy.</div></div><div><span style="line-height: 20.400001525878906px;"></span><div><div>[[File:Energy use in Nepalese Cement industry.PNG|thumb|left|200px|Energy use in cement industry in Nepal]]<br/></div><div>[[File:Specific energy consumption in Nepalese brick sector.PNG|thumb|left|200px|Specific energy consumption in Nepalese cement sector]]</div></div><div> | ||

| + | === Energy Saving Potential === | ||

| + | <div>Saving potentials are estimated to be around 41% and 49%, respectively for limestone and clinker-based industry. In total Nepalese cement units could annually save about NPR 1.5 Billion by using energy-efficient technologies.</div></div> | ||

| + | [[File:Energy Saving tips for Cement industry.PNG|thumb|left|180px|Energy saving tips for cement industry]]<br/> | ||

| + | </div><div></div> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

== Cold Storage Sector<br/> == | == Cold Storage Sector<br/> == | ||

Revision as of 10:22, 13 May 2014

Overview

Although, Nepal has the second largest hydropower resources in the world, it is still suffering from high energy shortage since several years. This power crisis has resulted in scheduled power outages (called load shedding) up to 12 hours per day in the dry season when the run-off-the-river hydropower plant cannot meet the electricity demand.

Particularly, industry is suffering because they have to shut down during load shedding or to run costly fuel based backup systems. The import of petroleum product has increased sharply during the last decade resulting in a trade deficit with India.

However, energy is scarce and expensive it is often not used efficiently and wasted. This article gives an overview about energy saving potentials in eight energy-intensive sectors of Nepal, namely:

- Brick,

- Cement,

- Cold Storage,

- Food & Beverage,

- Hotel,

- Pulp & Paper,

- Soap, and

- Steel & Metal.[1]

Industrial Sectors

Brick Sector

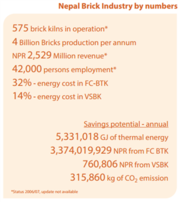

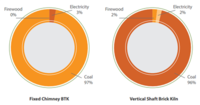

Sector highlightsBrick is a primary construction material in Nepal. Around 575 Brick kilns are in operations (Status 2006/2007) having a production capacity from 15,000 to 50,000 brick per day. Most of them operates only during dry season from December to June. Clay is the main raw material used in this industry and is available at very low cost. However, brick making is an energy and labour intensive industrial process. Hand moulding of green brick is mostly used. The predominant kiln technology in Nepal is the Fixed Chimney Bull Trench Kiln (FC-BTK). Apart from BTKs, Clamp Hoffmann and Vertical Shift Brick Kiln (VSBK) can be also found.

Energy Use

Energy Saving Potential

Cement Sector

Cement is a commonly used as a basic building material in the country. About 70% of the cement used in the construction sector is manufactured in Nepal. There are two types of cement factories, namely, limestone-based and clinker-based. Limestone-based industry use the raw material limestone, that is abundantly available in Nepal, and burn the clinker and process the clinker to cement. Clinker-based factories import the clinker from India and process it to cement. There are more than 60 cement industries in Nepal; most of them clinker-based. Few new large units have a production capacity between 900 to 1,000 tons per day are in pipeline.

Energy Use

Energy Saving Potential

Cold Storage Sector

Energy use

Energy saving potentials

Hotel Sector

Energy use

Energy saving potentials

Pulp and Paper Sector

Energy use

Energy saving potentials

Soap Sector

Energy use

Energy saving potentials

Steel and Metal Sector

Energy use

Energy saving potentials

Dairy Sector

Energy use

Energy saving potentials

References

- ↑ NEEP, 2012: Baseline Study of Selected Sector Industries to assess The Potentials for more Efficient use of Energy. Prepared by PACE Nepal for Nepal Energy Efficiency Programme (NEEP) of the Water and Energy Commission Secretariat (WECS), supported by German Development Cooperation GIZ. Retrieved from: http://wecs-neep.gov.np/downloadthis/120220_baseline_report.pdf