Difference between revisions of "Balloon Digester for Biogas Plants"

***** (***** | *****) m (→Overview) |

***** (***** | *****) m |

||

| (3 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| + | |||

= Overview<br/> = | = Overview<br/> = | ||

| Line 10: | Line 11: | ||

<br/>The table below gives a first comparison of the different types.<br/> | <br/>The table below gives a first comparison of the different types.<br/> | ||

| − | {| cellspacing="0" cellpadding="0" border="0" style="width:100% | + | {| cellspacing="0" cellpadding="0" border="0" style="width:100%" |

|- | |- | ||

| − | ! style="width: 126px | + | ! scope="col" style="width: 126px" | <p style="text-align: center">Factors</p> |

| − | ! style="width: 126px | + | ! scope="col" style="width: 126px" | <p style="text-align: center">Fixed dome</p> |

| − | ! style="width: 126px | + | ! scope="col" style="width: 126px" | <p style="text-align: center">Floating drum</p> |

| − | ! style="width: 126px | + | ! scope="col" style="width: 126px" | <p style="text-align: center">Tubular design</p> |

| − | ! style="width: 126px | + | ! scope="col" style="width: 126px" | <p style="text-align: center">Plastic containers</p> |

|- | |- | ||

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Gas storage</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Internal Gas storage up to 20 m³ (large)</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Internal Gas storage drum size (small)</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Internal eventually external plastic bags</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Internal Gas storage drum sizes (small)</p> |

|- | |- | ||

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Gas pressure</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Between 60 and 120 mbar</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Upto 20 mbar</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Low, around 2 mbar</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Low around 2mbar</p> |

|- | |- | ||

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Skills of contractor</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">High; masonry, plumbing</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">High; masonry, plumbing, welding</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Medium; plumbing</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Low; plumbing</p> |

|- | |- | ||

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Availability of Material</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">yes</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">yes</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">yes</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">yes</p> |

|- | |- | ||

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Durability</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Very high >20 years</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">High; drum is weakness</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Medium; Depending on chosen liner</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Medium</p> |

|- | |- | ||

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Agitation</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Self agitated by Biogas pressure</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Manual steering</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Not possible; plug flow type</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Evtl Manual steering</p> |

|- | |- | ||

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Sizing</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">6 to 124 m³ digester vol</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Up to 20 m³</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Combination possible</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Up to 6 m³ digester vol<br/></p> |

|- | |- | ||

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Methane emission</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">High</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Medium</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Low</p> |

| − | | style="width:126px" | <p style="text-align: center | + | | style="width:126px" | <p style="text-align: center">Medium<br/></p> |

|} | |} | ||

| + | <br/> | ||

= Balloon Plants = | = Balloon Plants = | ||

| − | A balloon plant consists of a heat-sealed plastic or rubber bag (balloon), combining digester and gas-holder. The gas is stored in the upper part of the balloon. The inlet and outlet are attached directly to the skin of the balloon. Gas pressure can be increased by placing weights on the balloon. If the gas pressure exceeds a limit that the balloon can withstand, it may damage the skin. Therefore, safety valves are required. If higher gas pressures are needed, a gas pump is required. Since the material has to be weather- and UV resistant, specially stabilized, reinforced plastic or synthetic <span data- | + | A balloon plant consists of a heat-sealed plastic or rubber bag (balloon), combining digester and gas-holder. The gas is stored in the upper part of the balloon. The inlet and outlet are attached directly to the skin of the balloon. Gas pressure can be increased by placing weights on the balloon. If the gas pressure exceeds a limit that the balloon can withstand, it may damage the skin. Therefore, safety valves are required. If higher gas pressures are needed, a gas pump is required. Since the material has to be weather- and UV resistant, specially stabilized, reinforced plastic or synthetic <span data-scaytid="10" data-scayt_word="caoutchouc">caoutchouc</span> is given preference. Other materials which have been used successfully include <span data-scaytid="11" data-scayt_word="RMP">RMP</span> (red mud plastic), <span data-scaytid="12" data-scayt_word="Trevira">Trevira</span> and butyl. The useful life-span does usually not exceed 2-5 years.<br/> |

| − | <br/>'''Advantages''': <br/> | + | <br/>'''Advantages''':<br/> |

| − | *Standardized prefabrication at low cost, <br/> | + | *Standardized prefabrication at low cost,<br/> |

| − | *low construction sophistication, <br/> | + | *low construction sophistication,<br/> |

| − | *ease of transportation, <br/> | + | *ease of transportation,<br/> |

| − | *shallow installation suitable for use in areas with a high groundwater table; <br/> | + | *shallow installation suitable for use in areas with a high groundwater table;<br/> |

| − | *high | + | *high temperature digesters in warm climates;<br/> |

| − | *uncomplicated cleaning, <br/> | + | *uncomplicated cleaning,<br/> |

| − | *emptying and maintenance; <br/> | + | *emptying and maintenance;<br/> |

*difficult substrates like water hyacinths can be used | *difficult substrates like water hyacinths can be used | ||

| − | Balloon | + | Balloon biogas plants are recommended, if local repair is or can be made possible and the cost advantage is substantial. |

<br/> | <br/> | ||

| − | '''Disadvantages''': <br/> | + | '''Disadvantages''':<br/> |

| − | *Low gas pressure may require gas pumps; <br/> | + | *Low gas pressure may require gas pumps;<br/> |

| − | *scum cannot be removed during operation; <br/> | + | *scum cannot be removed during operation;<br/> |

*the plastic balloon has a relatively short useful life-span and is susceptible to mechanical damage and usually not available locally. In addition, local craftsmen are rarely in a position to repair a damaged balloon. There is only little scope for the creation of local employment and, therefore, limited self-help potential. | *the plastic balloon has a relatively short useful life-span and is susceptible to mechanical damage and usually not available locally. In addition, local craftsmen are rarely in a position to repair a damaged balloon. There is only little scope for the creation of local employment and, therefore, limited self-help potential. | ||

| + | |||

<br/> | <br/> | ||

'''Variations:''' A variation of the balloon plant is the channel-type digester, which is usually covered with plastic sheeting and a sunshade (fig.1-E). Balloon plants can be recommended wherever the balloon skin is not likely to be damaged and where the temperature is even and high.<br/> | '''Variations:''' A variation of the balloon plant is the channel-type digester, which is usually covered with plastic sheeting and a sunshade (fig.1-E). Balloon plants can be recommended wherever the balloon skin is not likely to be damaged and where the temperature is even and high.<br/> | ||

| − | {| cellpadding="10" border="0 | + | {| cellpadding="10" border="0" style="width: 100%" class="IMGright FCK__ShowTableBorders" |

|- | |- | ||

| | | | ||

| Line 107: | Line 110: | ||

[[#toc|►Go to Top]]<br/> | [[#toc|►Go to Top]]<br/> | ||

| + | |||

| + | = Further Information = | ||

| + | |||

| + | *[[Portal:Biogas|Biogas portal on energypedia]] | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | = References = | ||

| + | |||

| + | *GTZ: [[:File:Biogas gate volume 2.pdf|Biogas Digest Volume II: Biogas - Application and Product Development]] | ||

| + | |||

| + | *This article is a continuation of the article, '''[[Types of Biogas Digesters and Plants|Types of Biogas Digesters and Plants]]'''. For questions regarding the article, please contact the authors of the article, '''[[Types of Biogas Digesters and Plants|Types of Biogas Digesters and Plants]].''' | ||

| + | |||

| + | <br/><references /><br/> | ||

| + | |||

| + | [[Category:Biogas]] | ||

Latest revision as of 12:57, 25 January 2016

Overview

There are different types of small scale biogas digesters. Some of the biogas digesters are summarized below:

The table below gives a first comparison of the different types.

Factors |

Fixed dome |

Floating drum |

Tubular design |

Plastic containers |

|---|---|---|---|---|

Gas storage |

Internal Gas storage up to 20 m³ (large) |

Internal Gas storage drum size (small) |

Internal eventually external plastic bags |

Internal Gas storage drum sizes (small) |

Gas pressure |

Between 60 and 120 mbar |

Upto 20 mbar |

Low, around 2 mbar |

Low around 2mbar |

Skills of contractor |

High; masonry, plumbing |

High; masonry, plumbing, welding |

Medium; plumbing |

Low; plumbing |

Availability of Material |

yes |

yes |

yes |

yes |

Durability |

Very high >20 years |

High; drum is weakness |

Medium; Depending on chosen liner |

Medium |

Agitation |

Self agitated by Biogas pressure |

Manual steering |

Not possible; plug flow type |

Evtl Manual steering |

Sizing |

6 to 124 m³ digester vol |

Up to 20 m³ |

Combination possible |

Up to 6 m³ digester vol |

Methane emission |

High |

Medium |

Low |

Medium |

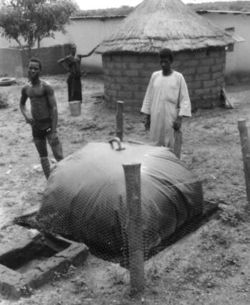

Balloon Plants

A balloon plant consists of a heat-sealed plastic or rubber bag (balloon), combining digester and gas-holder. The gas is stored in the upper part of the balloon. The inlet and outlet are attached directly to the skin of the balloon. Gas pressure can be increased by placing weights on the balloon. If the gas pressure exceeds a limit that the balloon can withstand, it may damage the skin. Therefore, safety valves are required. If higher gas pressures are needed, a gas pump is required. Since the material has to be weather- and UV resistant, specially stabilized, reinforced plastic or synthetic caoutchouc is given preference. Other materials which have been used successfully include RMP (red mud plastic), Trevira and butyl. The useful life-span does usually not exceed 2-5 years.

Advantages:

- Standardized prefabrication at low cost,

- low construction sophistication,

- ease of transportation,

- shallow installation suitable for use in areas with a high groundwater table;

- high temperature digesters in warm climates;

- uncomplicated cleaning,

- emptying and maintenance;

- difficult substrates like water hyacinths can be used

Balloon biogas plants are recommended, if local repair is or can be made possible and the cost advantage is substantial.

Disadvantages:

- Low gas pressure may require gas pumps;

- scum cannot be removed during operation;

- the plastic balloon has a relatively short useful life-span and is susceptible to mechanical damage and usually not available locally. In addition, local craftsmen are rarely in a position to repair a damaged balloon. There is only little scope for the creation of local employment and, therefore, limited self-help potential.

Variations: A variation of the balloon plant is the channel-type digester, which is usually covered with plastic sheeting and a sunshade (fig.1-E). Balloon plants can be recommended wherever the balloon skin is not likely to be damaged and where the temperature is even and high.

Further Information

References

- This article is a continuation of the article, Types of Biogas Digesters and Plants. For questions regarding the article, please contact the authors of the article, Types of Biogas Digesters and Plants.