Difference between revisions of "Implications of natural refrigerants for cooling technologies"

***** (***** | *****) |

***** (***** | *****) |

||

| (11 intermediate revisions by 4 users not shown) | |||

| Line 2: | Line 2: | ||

= The Problem<br/> = | = The Problem<br/> = | ||

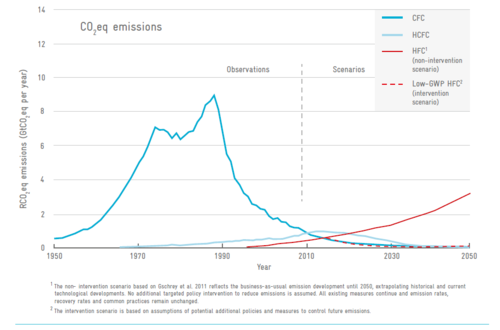

| − | [[File:Trends in CO2eq emission of CFCs, HCFCs and HFCs since 1950 and projected to 2050 (adapted from UNEP, 2011).PNG|thumb|right| | + | [[File:Trends in CO2eq emission of CFCs, HCFCs and HFCs since 1950 and projected to 2050 (adapted from UNEP, 2011).PNG|thumb|right|500px|Trends in CO2eq emission of CFCs, HCFCs and HFCs since 1950 and projected to 2050 (adapted from UNEP, 2011)]] Especially in developing countries and emerging economies, the refrigeration and air conditioning (RAC) sector is expanding and is expected to account for 13 % (GCI, 2014b) of global greenhouse gas (GHG) emissions by 2030. Since the Montreal Protocol (1989), HFCs have been widely used to substitute CFCs and HCFCs, but unfortunatelly their global warming potential (GWP) is 4,000 times higher than CO2. Thus, in the Kigali Amendment of 2016, 197 countries have committed to phase down HFCs, expecting to hinder 90 % of the temperature increase that would have been caused by HFCs. This increases the pressure on manufacturers to produce climate friendly RAC equipment.<br/> |

<br/> | <br/> | ||

| Line 8: | Line 8: | ||

<br/> | <br/> | ||

| − | |||

= Introducing Natural Refrigerants<br/> = | = Introducing Natural Refrigerants<br/> = | ||

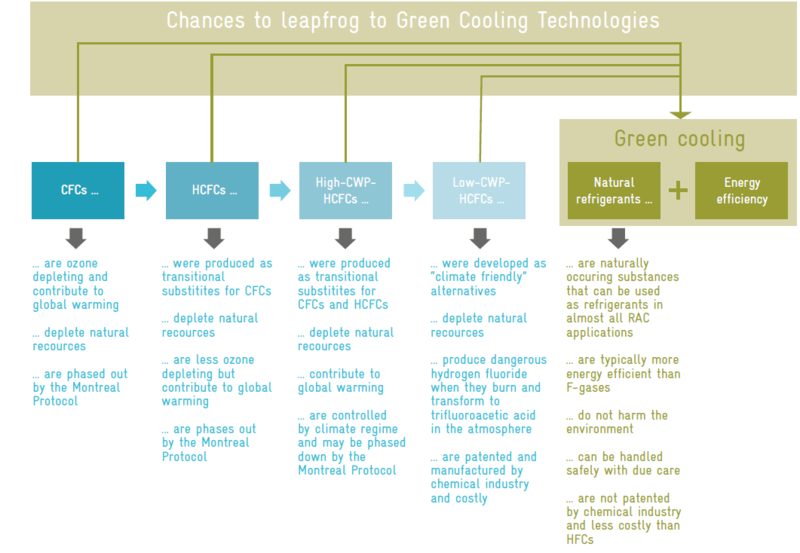

| − | This guide intends to provide arguments and guidance for changing from HFCs to natural refrigerants. These are less expensive than HFCs/HFOs, are commercially available for almost every application and system type and | + | This guide intends to provide arguments and guidance for changing from HFCs to natural refrigerants. These are less expensive than HFCs/HFOs, are commercially available for almost every application and system type and are constantly being developed to improve the safety and reduce their costs. In addition, they have negligible GWP and no ozone depleting potential (ODP). They are infinite and their extraction from the atmosphere does not damage the environment. [[File:Leapfrogging to green technologies (adapted from GIZ GCI, 2014).PNG|thumb|800px|Leapfrogging to green technologies (adapted from GIZ GCI, 2014)]]<br/><br/> |

<br/> | <br/> | ||

<br/> | <br/> | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | |||

= Aim of the Report<br/> = | = Aim of the Report<br/> = | ||

| − | The guide adresses in particular the | + | The guide adresses in particular the manufacturers of commercial and industrial equipment. The aim is to: |

*introduce international agreements and the regulatory landscape in key global regions, | *introduce international agreements and the regulatory landscape in key global regions, | ||

| − | * | + | *present available environmentally-friendly alternatives as direct replacement for HFCs and other chemical blends currently used in the refrigeration sector, |

*provide information on relevant technical and economic aspects of relevance when converting to environment-friendly alternatives, | *provide information on relevant technical and economic aspects of relevance when converting to environment-friendly alternatives, | ||

*provide practical application examples to showcase the technical feasibility of alternative technologies. | *provide practical application examples to showcase the technical feasibility of alternative technologies. | ||

| − | The recommendations intend to support manufacturers to be ahead of upcoming phase-out legislations and to shorten their learning curve. | + | The recommendations intend to support manufacturers to be ahead of upcoming phase-out legislations and to shorten their learning curve.<br/> |

| − | |||

| − | |||

| − | |||

| − | <br/> | ||

<br/> | <br/> | ||

| Line 40: | Line 39: | ||

The recommendations intend to support manufacturers to be ahead of upcoming phase-out legislations and to shorten their learning curve by providing relevant information obtained from experiences. The study includes 3 case studies, which allow an insight into the main technical and financial impacts of conversion to natural refrigerants, and briefly describes the conversion steps and challenges experienced by different refrigeration manufacturers from Bangladesh, Swaziland and South Africa. | The recommendations intend to support manufacturers to be ahead of upcoming phase-out legislations and to shorten their learning curve by providing relevant information obtained from experiences. The study includes 3 case studies, which allow an insight into the main technical and financial impacts of conversion to natural refrigerants, and briefly describes the conversion steps and challenges experienced by different refrigeration manufacturers from Bangladesh, Swaziland and South Africa. | ||

| − | + | The study also shows first technological attempts aiming a combined reduction of GWP by using renewable energies in addition to natural refrigerants. The Promethean Milk Cooler and the Sundanzer refrigerator have been implemented in regions with restricted access to energy, enabling a sustainable use of cooling technologies. | |

| − | [[File:Milk cooling system by Promethean.PNG|thumb|350px|Milk cooling system by Promethean (Source: Promethean)]]<br/> | + | [[File:Solar direct driven refrigerator.PNG|thumb|left|100px|Solar direct driven refrigerator (Source: Sundanzer)]][[File:Milk cooling system by Promethean.PNG|thumb|350px|Milk cooling system by Promethean (Source: Promethean)]]<br/> |

<br/> | <br/> | ||

| Line 50: | Line 49: | ||

<br/> | <br/> | ||

| + | <br/> | ||

| + | <br/> | ||

= Outlook<br/> = | = Outlook<br/> = | ||

| Line 58: | Line 59: | ||

However, to support their timely implementation, barriers that currently slow down the wide-scale introduction of natural refrigerants, such as funding, standards and regulations, and adequate training, need to be addressed and solved.<br/> | However, to support their timely implementation, barriers that currently slow down the wide-scale introduction of natural refrigerants, such as funding, standards and regulations, and adequate training, need to be addressed and solved.<br/> | ||

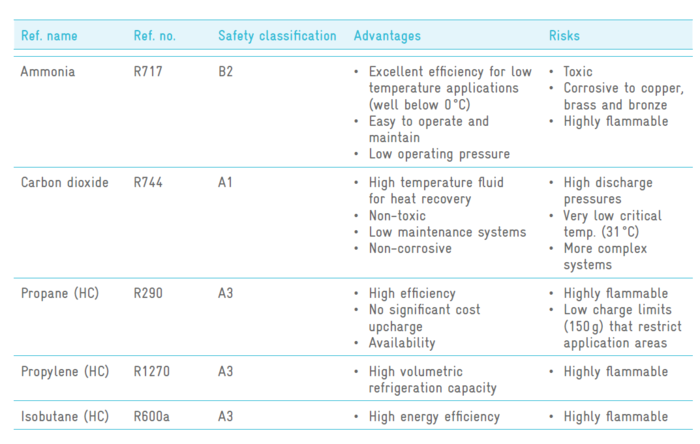

| − | + | Further challenges are mainly related to the properties of natural refrigerants, as shown in the table below besides their advantages. These aspects need to be taken into consideration when redesigning the refrigeration technologies and are currently being developed.<br/> | |

| − | + | <br/>[[File:Natural refrigerants classification and characteristics.PNG|thumb|left|700px|Natural refrigerants classification and characteristics (Source: international standards and industry’s best practice examples, own research and compilation by HEAT GmbH)]]<br/> | |

<br/><br/><br/> | <br/><br/><br/> | ||

| Line 68: | Line 69: | ||

<br/> | <br/> | ||

| + | <br/> | ||

| + | |||

| + | <br/> | ||

= Publication<br/> = | = Publication<br/> = | ||

| − | + | [[File:Implications of natural refrigerants for cooling technologies.pdf|thumb|left|180px|Implications of natural refrigerants for cooling technologies]]<br/> | |

| + | |||

| + | <br/> | ||

| + | |||

| + | <br/><br/> | ||

<br/> | <br/> | ||

| Line 92: | Line 100: | ||

<br/> | <br/> | ||

| + | |||

| + | [[Category:Climate_Change]] | ||

| + | [[Category:Cooling]] | ||

| + | [[Category:Powering_Agriculture]] | ||

Latest revision as of 16:44, 14 July 2019

The Problem

Especially in developing countries and emerging economies, the refrigeration and air conditioning (RAC) sector is expanding and is expected to account for 13 % (GCI, 2014b) of global greenhouse gas (GHG) emissions by 2030. Since the Montreal Protocol (1989), HFCs have been widely used to substitute CFCs and HCFCs, but unfortunatelly their global warming potential (GWP) is 4,000 times higher than CO2. Thus, in the Kigali Amendment of 2016, 197 countries have committed to phase down HFCs, expecting to hinder 90 % of the temperature increase that would have been caused by HFCs. This increases the pressure on manufacturers to produce climate friendly RAC equipment.

Introducing Natural Refrigerants

This guide intends to provide arguments and guidance for changing from HFCs to natural refrigerants. These are less expensive than HFCs/HFOs, are commercially available for almost every application and system type and are constantly being developed to improve the safety and reduce their costs. In addition, they have negligible GWP and no ozone depleting potential (ODP). They are infinite and their extraction from the atmosphere does not damage the environment.

Aim of the Report

The guide adresses in particular the manufacturers of commercial and industrial equipment. The aim is to:

- introduce international agreements and the regulatory landscape in key global regions,

- present available environmentally-friendly alternatives as direct replacement for HFCs and other chemical blends currently used in the refrigeration sector,

- provide information on relevant technical and economic aspects of relevance when converting to environment-friendly alternatives,

- provide practical application examples to showcase the technical feasibility of alternative technologies.

The recommendations intend to support manufacturers to be ahead of upcoming phase-out legislations and to shorten their learning curve.

Case Studies & Potential Systems for Conversion

The recommendations intend to support manufacturers to be ahead of upcoming phase-out legislations and to shorten their learning curve by providing relevant information obtained from experiences. The study includes 3 case studies, which allow an insight into the main technical and financial impacts of conversion to natural refrigerants, and briefly describes the conversion steps and challenges experienced by different refrigeration manufacturers from Bangladesh, Swaziland and South Africa.

The study also shows first technological attempts aiming a combined reduction of GWP by using renewable energies in addition to natural refrigerants. The Promethean Milk Cooler and the Sundanzer refrigerator have been implemented in regions with restricted access to energy, enabling a sustainable use of cooling technologies.

Outlook

Natural refrigerants pose a future-proof solution due to their very good environmental and technical performance. The fast development of F-gas regulations around the world and the price development of synthetic refrigerants makes an early conversion to natural refrigeratns the safest opportunity to avoid a drawback in the market.

However, to support their timely implementation, barriers that currently slow down the wide-scale introduction of natural refrigerants, such as funding, standards and regulations, and adequate training, need to be addressed and solved.

Further challenges are mainly related to the properties of natural refrigerants, as shown in the table below besides their advantages. These aspects need to be taken into consideration when redesigning the refrigeration technologies and are currently being developed.

Publication

References

GIZ GCI (2014a). Green Cooling technologies – market trends in selected refrigeration and air conditioning sub-sectors. Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH.

Green Cooling Initiative (2014b). Country data map – http://www.green-cooling-initiative.org/country-data/ (accessed on 10 July 2018)

UNEP (2011). HFCs: A Critical Link in Protecting Climate and the Ozone Layer. United Nations Environment Programme (UNEP), 36 pp.