Knowledge fuels change - Support energypedia!

For over 10 years, energypedia has been connecting energy experts around the world — helping them share knowledge, learn from each other, and accelerate the global energy transition.

Today, we ask for your support to keep this platform free and accessible to all.

Even a small contribution makes a big difference! If just 10–20% of our 60,000+ monthly visitors donated the equivalent of a cup of coffee — €5 — Energypedia would be fully funded for a whole year.

Is the knowledge you’ve gained through Energypedia this year worth €5 or more?

Your donation keeps the platform running, helps us create new knowledge products, and contributes directly to achieving SDG 7.

Thank you for your support, your donation, big or small, truly matters!

Difference between revisions of "Charcoal Production"

***** (***** | *****) |

***** (***** | *****) m |

||

| (119 intermediate revisions by 18 users not shown) | |||

| Line 1: | Line 1: | ||

| − | |||

| − | <br> | + | [[File:GIZ HERA Cooking Energy Compendium small.png|left|831px|GIZ HERA Cooking Energy Compendium|alt=GIZ HERA Cooking Energy Compendium small.png|link=GIZ HERA Cooking Energy Compendium]]<br/><br/><!-- |

| − | + | -->{{#ifeq: {{#show: {{PAGENAME}} |?Hera category}} | Cooking Energy System |'''[[GIZ HERA Cooking Energy Compendium#Cooking Energy Technologies and Practices|Cooking Energy System]]''' {{!}} | [[GIZ HERA Cooking Energy Compendium#Cooking Energy Technologies and Practices|Cooking Energy System]] {{!}} | }} <!-- | |

| − | + | -->{{#ifeq: {{#show: {{PAGENAME}} |?Hera category}} | Basics |'''[[GIZ HERA Cooking Energy Compendium#Basics about Cooking Energy|Basics]]''' {{!}} | [[GIZ HERA Cooking Energy Compendium#Basics about Cooking Energy|Basics]] {{!}} | }} <!-- | |

| − | + | -->{{#ifeq: {{#show: {{PAGENAME}} |?Hera category}} | Policy Advice |'''[[GIZ HERA Cooking Energy Compendium#Policy Advice on Cooking Energy|Policy Advice]]''' {{!}} | [[GIZ HERA Cooking Energy Compendium#Policy Advice on Cooking Energy|Policy Advice]] {{!}} | }} <!-- | |

| − | + | -->{{#ifeq: {{#show: {{PAGENAME}} |?Hera category}} | Planning |'''[[GIZ HERA Cooking Energy Compendium#Planning Cooking Energy Interventions|Planning]]''' {{!}} | [[GIZ HERA Cooking Energy Compendium#Planning Cooking Energy Interventions|Planning]] {{!}} | }} <!-- | |

| − | + | -->{{#ifeq: {{#show: {{PAGENAME}} |?Hera category}} | ICS Supply |'''[[GIZ HERA Cooking Energy Compendium#Designing and Implementing Improved Cookstoves .28ICS.29 Supply Interventions|Designing and Implementing ICS Supply]]''' {{!}} | [[GIZ HERA Cooking Energy Compendium#Designing and Implementing Improved Cookstoves .28ICS.29 Supply Interventions|Designing and Implementing ICS Supply]] {{!}} | }} <!-- | |

| − | + | -->{{#ifeq: {{#show: {{PAGENAME}} |?Hera category}} | Woodfuel Supply |'''[[GIZ HERA Cooking Energy Compendium#Designing and Implementing Woodfuel Supply Interventions|Designing and Implementing Woodfuel Supply]]''' {{!}} | [[GIZ HERA Cooking Energy Compendium#Designing and Implementing Woodfuel Supply Interventions|Designing and Implementing Woodfuel Supply]] {{!}} | }} <!-- | |

| − | {| | + | -->{{#ifeq: {{#show: {{PAGENAME}} |?Hera category}} | Climate Change |'''[[GIZ HERA Cooking Energy Compendium#Climate Change Related Issues|Climate Change]]''' | [[GIZ HERA Cooking Energy Compendium#Climate Change Related Issues|Climate Change]] {{!}} | }} <!-- |

| + | |||

| + | -->{{#ifeq: {{#show: {{PAGENAME}} |?Hera category}} | Extra |'''[[GIZ HERA Cooking Energy Compendium#Climate Change Related Issues|Extra]]''' | [[GIZ HERA Cooking Energy Compendium#Climate Change Related Issues|Extra]] }} | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | = Overview<br/> = | ||

| + | |||

| + | Charcoal is a prime source of energy in most African countries, and is a driving force in their economies. Worldwide charcoal production has increased, rising by an annual 3.7% from 1990 to reach 44 million tones in 2000 (see: [[:File:FAO 154-Forests and energy-2008.pdf|FAO (2008), Forests and Energy]] (pdf)) | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | = Challenges and Potentials to Sustainable Charcoal Production = | ||

| + | |||

| + | Surprisingly, policy makers pay little attention to the ways in which charcoal is produced and sold and whether wood used for charcoal burning is harvested in a sustainable fashion. Without coherent policies, almost all charcoal production, transportation, and distribution remains informal and unregulated – leading to inefficient and risky production methods. | ||

| + | |||

| + | <u>The common issues characterizing the charcoal production chain in many African countries comprise:</u> | ||

| + | |||

| + | #unregulated/illegal resources | ||

| + | #rampant and systemic corruption | ||

| + | #inefficient conversion technologies | ||

| + | #a perception that it is a poor man’s business | ||

| + | #considered ‘dirty’ and economically unattractive | ||

| + | #free access to wood resources, leading to deforestation and degradation | ||

| + | #the charcoal business is dominated by a few powerful individuals. | ||

| + | |||

| + | 'Lessons from eastern Africa's non-sustainable charcoal trade' can be found on the [http://www.worldagroforestry.org/our_products/publications website of the World Agroforestry Center in the publications section]. | ||

| + | |||

| + | Despite the growing scarcity of wood, charcoal generally remains underpriced by more than 20% to 50%, as only the opportunity cost of labour and capital required for charcoal production and transport are reflected. The production price for the raw material wood is often not reflected when wood is exploited from unsustainably managed wooded areas (e.g. open access areas). In addition, dues are ineffectively collected. Undervaluation translates into wasteful and inefficient production and consumption, and creates a formidable disincentive for forest management and tree growing (see box). A World Bank Publication from some years ago still correctly illustrates the problems of underpricing and provides methods for estimating adequate woodfuel stumpage values (see: [http://www-wds.worldbank.org/servlet/WDSContentServer/WDSP/IB/1989/09/01/000009265_3960928091844/Rendered/PDF/multi_page.pdf Fuelwood Stumpage. Financing Renewable Energy for the World’s Other Half]) | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | {| style="width: 100%" cellspacing="0" cellpadding="2" border="1" | ||

|- | |- | ||

| − | | bgcolor="#cccccc" | | + | | bgcolor="#cccccc" | '''Impacts of underpricing''' '''charcoal''' |

| − | '''Impacts of underpricing''' '''charcoal''' | + | <u>As long as charcoal is not sold at a real market price, investments in improved wood-to-charcoal production/conversion are economically not attractive:</u> |

| − | + | <br/> | |

| − | *Investment costs for improved kilns (metal chimneys etc.) do not pay off as long as wood remains a free resource. Despite training support, charcoal burners eventually abandon the improved technology. This is the main reason why the improved and highly efficient Casamance kiln has been disseminated | + | *Investment costs for improved kilns (metal chimneys etc.) do not pay off as long as wood remains a free resource. Despite training support, charcoal burners eventually abandon the improved technology. This is the main reason why the improved and highly efficient Casamance kiln has been disseminated for 20 years throughout Africa without success. |

| − | *Tree growing approaches stay ineffective, as planting and maintenance costs must be taken into account, when competing with open access resources. Significant subsidies (e.g. Madagascar: 200 to 300 €/ha) are necessary to provide enough incentive. This holds | + | *Tree growing approaches stay ineffective, as planting and maintenance costs must be taken into account, when competing with open access resources. Significant subsidies (e.g. Madagascar: 200 to 300 €/ha) are necessary to provide enough incentive. This also holds true for any investments in natural forest management. |

*Substitute fuels such as kerosene must be highly subsidized to be competitive, as is the case in a number of countries, such as Senegal and Chad. | *Substitute fuels such as kerosene must be highly subsidized to be competitive, as is the case in a number of countries, such as Senegal and Chad. | ||

|} | |} | ||

| − | + | <br/> | |

| − | + | Problems arise at all stages of the charcoal value chain, so a precise understanding of the charcoal value chain is necessary for shaping sound policy frameworks. It offers an opportunity to the various stakeholders to add knowledge, innovation, capital, and technology at each step or link in the value chain. Sound policy can provide checks and balances, creating more balance within and between the sectors, and supporting the intended overarching goals, such as the Millennium Development Goals (MDGs). | |

| − | + | Other papers highlighting the importance of adopting a value chain approach include: [[:file:Charcoal supply chains.pdf|Analysis of charcoal value chains - general considerations]]; and [http://commdev.org/policy-and-distributional-equity-natural-resource-commodity-markets-commodity-chain-analysis-policy Chain Concept Note for Reader.doc Policy and Distributional Equity in Natural Resource Commodity Markets: Commodity-Chain Analysis as a Policy Tool]. | |

| − | + | Furthermore, evidence-based analyses of the charcoal value chain provide the opportunity to demonstrate the regional added value of charcoal production and thus help to sensitise policy makers for a source of energy hitherto neglected & left to the informal sector. <u>Examples of study projects, geared towards a comprehensive assessment and analysis of the charcoal production chain, include:</u> | |

| − | |||

| − | |||

| − | |||

| − | + | <br/> | |

| − | + | *the supra-regional Chaposa project (1998-2002) investigating the charcoal potential for Southern Africa: -> [http://sei-international.org/mediamanager/documents/Publications/Climate/chaposa.pdf Charcoal Potential in Southern Africa CHAPOSA] | |

| + | *the National Charcoal Survey:Exploring the potential for a sustainable charcoal industry in Kenya (ESD 2005) | ||

| + | *the study initiated by the Forest Governance Learning Group (FGLG) for Malawi: [http://pubs.iied.org/13544IIED.html Charcoal - the reality: A study of charcoal consumption, trade and production in Malawi] | ||

| + | *a policy note prepared by Worldbank staff for decision makers in Tanzania summarizing the fundamental characteristics of charcoal use in the country and presenting policy options along the entire value chain of charcoal production and consumption (2010): [http://siteresources.worldbank.org/EXTCC/Resources/PolicyNote_Charcoal_TZ_08-09.pdf ENVIRONMENTAL CRISIS OR SUSTAINABLE DEVELOPMENT OPPORTUNITY? Transforming the charcoal sector in Tanzania] | ||

| − | + | <br/> | |

| − | + | <br/> | |

| − | {| | + | = Basics on Charcoal = |

| + | |||

| + | Charcoal is produced following several processes, artisanal and industrial. The best known industrial processes are slow pyrolysis and supra-carbonization.<br/> | ||

| + | |||

| + | During combustion, the wood will undergo 2 to 3 different chemical reactions: 2 for pyrolysis with endothermic and exothermic; we must add a third for supra-carbonization, that is, <span style="background-color: rgb(255, 255, 255)">endothermic</span> again. Because of this, charcoal has a higher fixed carbon content.<br/> | ||

| + | |||

| + | #Pyrolysis consists of heating wood or other substances, in the absence of oxygen, with external energy. <span style="background-color: rgb(255, 255, 255)">Pyrolysis is initiated by heating a pile of wood under controlled conditions in a closed space such as a charcoal kiln with a very limited supply of air triggering endothermic and exothermic reactions. The biomass produces, as a result of the pyrolysis process, a mixture of gas, liquid and charcoal.</span><br/> | ||

| + | #Supra-carbonisation ("MAGE" technology) does not require external energy, unlike pyrolysis, since it is the wood itself which serves as ignition for the furnaces and is done by the upper part; and with the help of high chimneys, this allows to control the process during the carbonization phase. As the fresh air intake is located below the furnaces, the carbonization front goes downhill because the air at the top of the furnaces is consumed first. The combustion phase is followed by a carbonizer, in order to avoid the total ignition of the wood inside the oven, as well as the evaporation of the water present in the raw material (up to 100 ° C). The energy required for this step comes from the partial combustion of the wood, giving CO, CO2, acetic acid and methanol (up to 270 ° C). Then, the exothermic decomposition of the wood begins, between 270 and 300 ° C, causing an increase in the temperature inside the furnace up to 400 ° C, with the production of charcoal, plant tar and pyroligneous extracts. At this stage, the charcoal still contains a large amount of volatile compounds (about 30%), with a fixed carbon content of 60 to 65%. At + 800 ° C, the fixed carbon content reaches 82 to 84% for 3 to 7% of volatile compounds.<br/> | ||

| + | |||

| + | Charcoal is first of all characterized by its density which can vary between 0.2 and 0.6 t/m<sup>3</sup> depending on the density of wood used as raw material. Charcoal produced from hardwood is heavy and strong, whereas produced from softwood is soft and light. The coefficient of transformation is about half (example: eucalyptus with a density of about 0.6 gives charcoal with a density of around 0.25 to 0.35).<br/>The bulk density of charcoal does not only depend on the apparent density but also on the size distribution, and is in the range of 180 - 220 kg/m<sup>3</sup>.<br/>Charcoal has a relatively low moisture content of around 3 to 10%. The gross calorific value of charcoal is linked to the amount of fixed carbon and depends strongly on the carbonization temperature varying from 27 to 33 MJ/kg. Low carbonization temperatures give a higher yield of charcoal but this charcoal is low grade, is corrosive due to its content of acidic tars, and does not burn with a clean smoke-free flame. Good commercial charcoal should have a fixed carbon content of about 75% and a final carbonization temperature of around 500°C.<br/> | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | = Technological Aspects = | ||

| + | |||

| + | For conversion of wood into charcoal people use "kilns". The most common types of traditional kilns are earth pit or mound kilns with efficiencies ranging between 8% and 12 % (Table 7). Because parameters like the humidity of the wood used, kiln size, and process control, play an important role, the relative gain of an improved technology ranges between 5% to 50%. | ||

| + | |||

| + | See: [http://www.fao.org/docrep/X5555E/X5555E00.htm www.fao.org, Industrial charcoal making] | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | {| style="width: 100%" cellspacing="1" cellpadding="1" border="1" | ||

|- | |- | ||

| colspan="3" | '''Table 7: Efficiencies of various types of kiln''' | | colspan="3" | '''Table 7: Efficiencies of various types of kiln''' | ||

|- | |- | ||

| − | | <br> | + | | <br/> |

| − | | Production of 1 kg of charcoal from | + | | Production of 1 kg of charcoal from |

| Kiln efficiency | | Kiln efficiency | ||

|- | |- | ||

| − | | Traditional Kilns | + | | Traditional Kilns |

| − | | 8- 12 kg wood | + | | 8- 12 kg wood |

| 8 – 12% | | 8 – 12% | ||

|- | |- | ||

| − | | Improved traditional kilns | + | | Improved traditional kilns |

| − | | 6 – 8 kg wood | + | | 6 – 8 kg wood |

| 12 - 17% | | 12 - 17% | ||

|- | |- | ||

| − | | Industrial production technologies | + | | Industrial production technologies |

| − | | 5 – 7 kg wood | + | | 5 – 7 kg wood |

| 20 – 14% | | 20 – 14% | ||

|- | |- | ||

| − | | New high-yield, low-emission systems | + | | New high-yield, low-emission systems |

| − | | 3 – 4 Kg wood | + | | 3 – 4 Kg wood |

| 25 - 33% | | 25 - 33% | ||

|} | |} | ||

| − | Part of the energy losses during charcoal making are compensated for during end use, as charcoal stoves have higher efficiencies than wood stoves (30% - charcoal stoves versus 10%-15% untended open fire or tripod).The following table gives information on the amount of energy loss in % when introducing improved kilns and/or improved stoves in comparison to the usage of firewood | + | Part of the energy losses during charcoal making are compensated for during end use, as charcoal stoves have higher efficiencies than wood stoves (30% - charcoal stoves versus 10%-15% untended open fire or tripod).The following table gives information on the amount of energy loss in % when introducing improved kilns and/or improved stoves in comparison to the usage of firewood. For example, if one converts wood to charcoal using a traditional kiln (with efficiency of 8%) and then burns that charcoal on a traditional stove (with efficiency of 20%), there is a resulting energy loss of 73%. |

| + | |||

| + | <br/> | ||

| − | {| | + | {| style="width: 100%" cellspacing="1" cellpadding="1" border="1" |

|- | |- | ||

| − | | colspan="6" | '''Table 8: Energy | + | | colspan="6" | '''Table 8: Energy Losses Converting Woodfuel to Charcoal (using various stoves)''' |

|- | |- | ||

| − | | <br> | + | | <br/> |

| − | | <br> | + | | <br/> |

| − | | colspan=" | + | | colspan="2" | '''<span style="color: rgb(0, 0, 255)">Traditional</span>''' |

| − | + | '''Stove 1 Stove 2''' | |

| − | + | ||

| − | + | | colspan="2" bgcolor="#99ccff" | '''Improved''' | |

| − | + | '''Stove 1 Stove''' | |

| − | | bgcolor="#99ccff | + | |

|- | |- | ||

| − | | <br> | + | | <br/> |

| − | | < | + | | '''Efficiency''' |

| − | + | | '''<span style="color: rgb(255, 0, 0)">20%</span>'''<span style="color: rgb(255, 0, 0)"></span><br/> | |

| − | | <span style="color: | + | | <span style="color: rgb(255, 0, 0)">'''24%'''</span> |

| − | | bgcolor="#99ccff" | <span style="color: | + | | bgcolor="#99ccff" | <span style="color: rgb(255, 0, 0)">'''30%'''</span> |

| − | | bgcolor="#99ccff" | <span style="color: | + | | bgcolor="#99ccff" | <span style="color: rgb(255, 0, 0)">'''35%'''</span> |

|- | |- | ||

| − | | <span style="color: | + | | <span style="color: rgb(0, 0, 255)">'''Traditional Kiln'''</span>'''<span style="color: rgb(0, 0, 255)">1</span>''' |

| − | | <span style="color: | + | | <span style="color: rgb(255, 0, 0)">'''8%'''</span> |

| − | | <span style="color: | + | | <span style="color: rgb(0, 0, 255)">73%</span> |

| − | | <span style="color: | + | | <span style="color: rgb(0, 0, 255)">68%</span> |

| − | | bgcolor="#99ccff" | 60% | + | | bgcolor="#99ccff" | 60% |

| bgcolor="#99ccff" | 53% | | bgcolor="#99ccff" | 53% | ||

|- | |- | ||

| − | | < | + | | <span style="color: rgb(0, 0, 255)">'''Traditional Kiln 2'''</span> |

| − | | <span style="color: | + | | <span style="color: rgb(255, 0, 0)">'''12%'''</span> |

| − | | <span style="color: | + | | <span style="color: rgb(0, 0, 255)">60%</span> |

| − | | <span style="color: | + | | <span style="color: rgb(0, 0, 255)">52%</span> |

| − | | bgcolor="#99ccff" | 40% | + | | bgcolor="#99ccff" | 40% |

| bgcolor="#99ccff" | 30% | | bgcolor="#99ccff" | 30% | ||

|- | |- | ||

| − | | bgcolor="#99ccff" | '''Improved''' ''' | + | | bgcolor="#99ccff" | '''Improved''' '''Kiln 1''' |

| − | | bgcolor="#99ccff" | <span style="color: | + | | bgcolor="#99ccff" | <span style="color: rgb(255, 0, 0)">'''14%'''</span> |

| − | | bgcolor="#99ccff" | 53% | + | | bgcolor="#99ccff" | 53% |

| − | | bgcolor="#99ccff" | 44% | + | | bgcolor="#99ccff" | 44% |

| − | | bgcolor="#99ccff" | 30% | + | | bgcolor="#99ccff" | 30% |

| bgcolor="#99ccff" | 18% | | bgcolor="#99ccff" | 18% | ||

|- | |- | ||

| − | | bgcolor="#99ccff" | | + | | bgcolor="#99ccff" | '''Improved Kiln 2''' |

| − | | bgcolor="#99ccff" | <span style="color: | + | | bgcolor="#99ccff" | <span style="color: rgb(255, 0, 0)">'''18%'''</span> |

| − | | bgcolor="#99ccff" | 40% | + | | bgcolor="#99ccff" | 40% |

| − | | bgcolor="#99ccff" | 28% | + | | bgcolor="#99ccff" | 28% |

| − | | bgcolor="#99ccff" | 10% | + | | bgcolor="#99ccff" | 10% |

| bgcolor="#99ccff" | -5% | | bgcolor="#99ccff" | -5% | ||

|} | |} | ||

| − | <br> | + | == <br/>Publications<br/> == |

| + | |||

| + | *[http://rael.berkeley.edu/sites/default/files/very-old-site/OA5.1.pdf Impacts of Greenhouse Gas and Particulate Emissions from Woodfuel Production and End-Use in Sub-Saharan Africa]<u><span style="line-height: 115%"></span></u> | ||

| + | |||

| + | == Traditional Kilns == | ||

| + | |||

| + | === Earth Pit Kilns === | ||

| + | |||

| + | Earth pit kilns are the traditional way of making charcoal in many parts of the world and may represent the simplest technology for charcoal production. In brief, the process of using an earth pit kiln begins by stacking wood in a pit, sealing it with a layer of grass and soil and starting carbonization by igniting the wood at one end. Earth pit kilns are typically large and large pieces of wood can be used. But can these kilns can also be built in small size and can thus, be suitable for families and even individuals. | ||

| + | |||

| + | Pit kilns are labor intensive since a pit must be dug into the ground. Ventilation may also be difficult to control and often carbonization is incomplete, producing only low quality charcoal. To improve efficiency, pit kilns can be equipped with a chimney which allows the use of biomass other than wood, such as coconut shells. | ||

| + | |||

| + | === Earth Mound Kiln === | ||

| + | |||

| + | This is also a common kiln used for charcoal production. It can be constructed from locally available material. In brief, wood is collected and stacked in the polygonal shape of kiln. The wood is then covered with a layer of grass and the construction is sealed with soil. A small opening allows the control and monitoring of the process. When the kiln has been lit, it requires continuous attention for 3 to 15 days depending on the size. After the kiln has cooled down charcoal can be harvested. The main advantage of this type of kiln is that it can be constructed easily without cost at the harvest site. | ||

| + | |||

| + | Downsides are that carbonization takes rather long and the process requires continuous attention. In addition, charcoal quality is rather low and efficiency is only between 8 and 15 %. Therefore charcoal production using traditional kilns is associated with high consumption of wood. Nonetheless, earth mound kilns are typically more efficient than earth pit kilns. | ||

| + | |||

| + | == Improved Kilns == | ||

| + | |||

| + | === Casamance Kiln === | ||

| + | |||

| + | [[File:Meule casamancaise.jpeg.JPG|right|340px|Meule casamancaise.jpeg.JPG|alt=Meule casamancaise.jpeg.JPG]]The Casamance kiln was developed in Senegal and is an earth mound kiln equipped with a chimney. This chimney, which can be made of oil drums, allows a better control of air flow. In addition, the hot flues do not escape completely but are partly redirected into the kiln, which enhances pyrolysis. Due to this reverse draft carbonization is faster than traditional kilns. and more uniform giving a higher quality of charcoal and efficiency up to 30 %. Comparative tests of the casamance kiln and traditional mound kilns confirmed the advantages in terms of efficiency and shorter carbonization times due to the enhanced hot flue circulation (see [[:file:Meule casamancaise PERACOD Mundhenk.pdf|Meule casamancaise PERACOD Mundhenk (pdf]]))<br/>Disadvantages of this kiln type are that it requires some capital investment for the chimney and it is more difficult to construct.<br/> | ||

| + | |||

| + | === Brick Kiln === | ||

| + | |||

| + | The brick kiln is stationary, unlike the Casamance or traditional kilns. They have an efficiency of up to 30 % and are suitable for semi-industrial production of charcoal. One type is the truncated pyramid kiln, which is used in Chad mainly in the informal sectors. However, it has a lower efficiency than other brick kilns. The most notable type is the Argentine half orange Kiln, which has been adopted by the Malawi Charcoal Project. It is made entirely out of brick and mud as mortar. Loading and unloading is performed through two opposite doors, which are sealed before the kiln is ignited. The carbonisation cycle is much quicker and allows harvesting of charcoal after 13 – 14 days. Using a kiln of about 6 m diameter, up to 15 t of high quality charcoal can be produced per month. However, as brick kilns are stationary once built, they can only be used in areas with an easy supply of wood. Furthermore, the wood has to be cut with some precision and water supply is required for preparation of mortar. Kilns can also be produced using concrete instead of bricks; however, as their construction is very cost-intensive they have not succeeded in Africa. | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | === Steel Kiln === | ||

| + | |||

| + | Many different types of steel kilns have been developed which are considered as one basis of modern charcoal production. They are capable to carbonize even poor quality wood and can easily be transported when necessary. However, as the annual output of a typical demountable steel kiln is about 100 – 150 t, they are not suitable for high-volume production. Furthermore, the investment costs may be as high as 1,000 US$, which limits the use of steel kilns considerably. Nevertheless, since efficiency is high (27 – 35 %) and carbonization is quick (16 to 24 hours after ignition), steel kilns have been promoted as community kilns in Kenya. There are also steel [[File:Engery Uhuru (Freedom) - The Green Cap Kiln.PNG|thumb|right|325px|Energy Uhuru (Freedom)]]drum kilns on the market - designed by Dr. M. Kinyanjui to facilitate access to sustianably made charcoal, (using twigs, branches, maize cobs, coconuts etc. for feedstock) these kilns are low cost, portable and easy to use. They can also have a wood oil trap installed to condense some of the smoke into wood tar/oil for home use. They come in two sizes - domestic for 40$ and business for 130$.<br/>Marketing materials promoting these kilns. | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | A '''"Box-Kiln"''' has been developed by Dr.Chris ADAM in 2019. This kiln works as an improvment to the round steel kilns (MARK II) . For more information search this "Box-Kiln" via Youtube. | ||

| + | [[File:Box-Kiln m Vida 2021 sml.jpg|thumb|"Box-Kiln" Ghana 2021 (giz project)|alt=]] | ||

| + | |||

| + | <br /> | ||

| + | |||

| + | === Adam Retort === | ||

| + | |||

| + | [[File:Adam retort.jpg|thumb|right|200px|Adam retort]]The retort kiln is one of the most efficient means of producing good quality charcoal. The kiln returns the wood gases from the carbonisation chamber back to the external fire-box, burns the volatile a higher proportion of the tar components almost completely and uses the heat for the carbonisation process. The Improved Charcoal Production System (ICPS), also called "adam-retort", may be presented as a modern example of retort technology. Efficiency can be as high as 35 % and noxious emission can be reduced by 70 %. In addition, the production cycle is completed within 12 hours or 24 to 30 hours included cooling. The retort kiln is suitable for rural and semi-industrial charcoal production. Volume of wood chamber is about 3m³ and ~250kg or more of charcoal can produced per batch. Wood chamber can be loaded with about 1 ton of wet wood or ~750kg of ofen dry wood. (www.biocoal.org)<br/> | ||

| − | < | + | [[File:Adam retort India Puja initiation 2014 small.jpg|right|207px|alt=Adam retort India Puja initiation 2014 small.jpg]]<br/>Disadvantges include that it’s a stationary kiln, investment costs exceed 1,200 US$ and special skills are required for construction and operation. Nevertheless, the Adam-retort has been introduced in several countries (Senegal, Tanzania, Mali, Angola, Madagascar, Peru, Costa Rica, Mexico, India, Cambodia, etc.) on a pilot basis. Currently, the method is being further refined for up-scaling. A construction manual with drawings is available on a license basis by dr.Chris ADAM.<br/>(Photo up: Madagascar, Photo down: "Puja initiation" of a retort in South India/Kumta, 2014)<br/> |

| − | = | + | <br/>[[File:Trice adam-retort kiln at Ghana.jpg|right|200px|alt=Trice adam-retort kiln at Ghana.jpg]]A unit of 3 adam-retort kilns (trice-retort) was built by www.ghana-resorts.com in Ghana to carbonize bamboo. Baskets are used to load and unload the bamboo biomass from the wood chamber. |

| − | < | + | <br/> |

| − | + | <br/> | |

| − | + | == The "mobile adam-retort" == | |

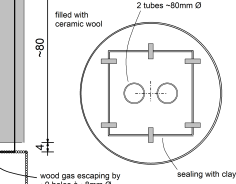

| − | = | + | [[File:Mobile Adam Retort Testrun Trailer Small.JPG|thumb|right|200px|alt=Mobile Adam Retort Testrun Trailer Small.JPG]]This lately developed '''mobile retort''' by Dr.Chris ADAM is available since 2015 and its design is based on 2 oil drums. These oil drums are replacable. |

| − | + | The mobile retort burns most of the smoke and works with high efficiency of about 30% referring to the dry mass of the wood. About 140kg of wet wood (corresponding to about 120kg of wood without water) can be loaded and about 35kg of charcoal (high temperature burnt) can be harvested. This mobile retort is not yet smoke free and some modifications will be done in 2022.<br/> | |

| − | == | + | == Unit to carbonize coffee husks to make briquetts == |

| + | <br />In 2022 CARiTAS-SUISSE is lancing a briquetting project in Ethiopia. The briquettes are made from carbonized coffee husks. 3 differnt carbonizing units are currently be developed and tested. All units are low-cost systems and they have been designed by Dr.Chris ADAM (www.biocoal.org) : | ||

| − | + | '''Carbonizer-1''' (drum open pit carbonizer) The unit works by adding the coffee husks continously into a barrel (oil drum). <gallery> | |

| + | File:Carbonizer-1 zen.png | ||

| + | </gallery>'''Carbonizer-2''' (drum rotary retort carbonizer) The unit works by adding the coffee husks by batch into a turning barrel | ||

| + | [[File:Carbonizer-2 zen .png|none|thumb]] | ||

| − | + | '''Carbonizer-3''' (drum retort carbonizer) The unit works by adding the coffee husks by batch into a barrel | |

| + | [[File:Carbonizer-3 zen .png|none|thumb]] | ||

| − | = | + | = Industrial Process = |

| − | + | == <span class="mw-headline" style="font-family: -webkit-standard"><span style="font-size: 13pt; font-family: Arial">The supra-carbonization technology "MAGE"</span></span><br/> == | |

| − | = | + | [[File:Fours MAGE.jpg|thumb|left|180px|alt=Fours MAGE.jpg]]The innovative character of the "MAGE" supra-carbonization process ([https://www.blukarb.com/english/ https://www.blukarb.com/english/]) is based on the use of vertical cylindrical metal furnaces, intended for the carbonization of wood at temperatures of around 800 °C, to reach a fixed carbon content in charcoal between 82 and 84%, higher than the standard NF EN 1860-2 June 2005. |

| − | + | '''The production process does not contaminate soil or air. All gases from carbonization are destroyed by a flare.''' | |

| − | + | The "MAGE" technology was developed in the early 80's by Jacques & Jean-Pascal MAGE, then patented in the United States in 1989. It was then marketed in Argentina and Chile by Blu Karb. | |

| − | + | *These furnaces industrially produce renewable energy, namely a charcoal whose fixed carbon content is > 82% because the technology makes it possible to control the carbonization temperature at the heart of the furnace; | |

| + | *"MAGE" technology requires 30% less wood than traditional methods to obtain the same amount of charcoal, and kilns make it possible to recover industrial and forest wood waste; | ||

| + | *This technology, unlike pyrolysis for example, does not need external energy input to cook the wood; | ||

| + | *The furnace is filled with pre-cut woods chips in 10*5*5 cm, which avoids breaking the pieces of charcoal after charring, increasing productivity by +30%; | ||

| + | *The wood is inflamed from the top and it will ignite to the bottom thanks to the air circulation; the air vents located under the furnace are then closed once all the wood is on fire ; | ||

| + | *A complete carbonization cycle lasts between 20 and 24 hours, depending on the moisture content of the wood; | ||

| + | *Carbonization is broken down into 3 phases: endothermy, then exothermic and finally again endothermy; | ||

| + | *Furnaces work 10 years and are 100% recyclable; | ||

| + | *The fixed carbon quality obtained preserves the health of consumers (colorectal cancer); | ||

| + | *A factory of 10 furnaces can be installed on a site of only 10,764 sq m; it generates about 40,000 carbon credits over the year; | ||

| − | + | The volume of the furnace is about 16m³ of wood and at least 1,500 KGs of charcoal are produced per carbonization cycle, for 1 oven : 36,000 KGs for 24 carbonizations per month.<ref>Blu Karb https://www.blukarb.com</ref> | |

| − | + | <br/> | |

| − | + | <br/> | |

| − | = | + | = Charcoal Briquetting = |

| − | + | [[File:Briquetting process.jpg|right|215px|Briquetting process.jpg|alt=Briquetting process.jpg]] | |

| − | < | + | A briquette is a block of flammable matter used as fuel to start and maintain a fire. Residues from agriculture and forestry e.g. bagasse, coffee husks, saw-dust, and coconut husks are a valuable source of raw material and can be used for producing briquettes.The briquetting process entails many steps. After collection, the wood or agro-industrial waste is dried before it is converted to charcoal in a charring kiln. The carbonised biomass is then mixed with water and locally-available binders such as starch, gum arabic, molasses, clay and others. Finally, the mixture (powdered charcoal + binder mixture) is pressed into briquettes. Piston and screw presses are the most widely used technologies where as in the developed countries roll presses are more common. The production capacity of screw presses is around 40 to 70 kg per hour. After a subsequent drying step, the briquettes will develop the required strength and stability. Forest and agricultural waste charcoal briquettes, with about 20% of clay, produce about 12 MJ/kg depending on the composition of charcoal. |

| + | |||

| + | Further information on biomass charcoal briquetting for energy based income generation in rural areas can be found in the booklet [http://www.amm-mcrc.org/publications/BiomassCharcoalBriquetting_English.pdf Biomass Charcoal Briquetting].<br/>The GIZ Program to promote rural electrification and a sustainable supply of domestic fuel (PERACOD) in Senegal documented their experience at the [http://www.peracod.sn/?lang=en Peracod website]. | ||

| + | |||

| + | More information about production and marketing of briquettes can also be found [[Biomass Briquettes – Production and Marketing|here]] on energypedia.<br/> | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | = Transport and Marketing = | ||

| + | |||

| + | The trade of charcoal in many African countries is primarily informal and it is characterized by a high turnover rate. There is no significant warehousing. All stocks produced are promptly consumed. Abundant evidence of the charcoal trade is visible throughout the cities and surrounding regions. Roads are lined with charcoal bags for sale in the center of the cities, both on the city outskirts and in the proximity of the production areas.<br/>Charcoal trading is a key segment in the supply/demand chain, and the dealers are the key actors in this regard. Often transporters function as middlemen and wholesalers.<br/>Lorries and pickups are the most popular kind of motorized transport due to their carrying capacity. Charcoal is not a heavy commodity but it is bulky. Bicycles are the most common non-motorised form of transport. Some carry up to five bags of charcoal. Furthermore, the use of donkey carts is a notable form of transportation. Human transport is also used, but only for short distances and especially in areas inaccessible by other forms of transport.<br/>Transport costs are a critical component not only of urban woodfuel prices but of the area from which woodfuels can be supplied at competitive prices.<br/>Profits are usually concentrated in the hands of a few intermediaries, engaged as transport agents or wholesalers. Instead of equitable revenue-sharing along the entire value chain, revenue circulates in a loop between traders and consumers reaping off up to 80% of the value chain profits. Marginal profits (20-30%) go to the charcoal producers– and virtually none to those communities, whose forest areas are being depleted in the process. | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | = Social, Economic and Environmental Impacts = | ||

| + | |||

| + | [[Cooking with Charcoal|Charcoal consumption]] is a very controversial issue, as the transformation process from wood to charcoal results in considerable energy loss, requiring significantly more forest resources to produce the same amount of energy. This has led to many countries such as Kenya, Tanzania, Gambia etc, to impose bans on charcoal. However these bans have had little success and charcoal use continues to increase with the pressures of growing urbanisation. Charcoal burns more cleanly than wood or dried biomass, producing higher temperatures and it is cheaper to transport and store. For these reasons, interest in charcoal as a fuel is reviving, and steps need to be taken to promote improved charcoal-making technologies and thus reduce the amount of raw biomass required. | ||

| + | |||

| + | Charcoal production is a labour-intensive process, employing a large number of people at different phases of the process and distribution. It is estimated that charcoal production generates between 200-350 person days of employment per Terajoule of energy, compared to 10 person days per Terajoule for kerosene. Sustainable production of wood-based fuels (particularly charcoal) can support rural development through decentralised processing & production, short transport distances with low risks, locally available and renewable resources, and potential for short-term efficiency improvements (improved stoves, kilns etc). It can yield a health-dividend, due to reduced levels of smoke, cleaner combustion, and easy handling. To be environmentally beneficial, highly efficient kilns and renewably-sourced fuels are required. | ||

| + | |||

| + | To this end, woodfuel policies need to be designed within the context of a sustainable (rural) development approach, and principles of local control and participation adhered to in the planning process. Comparative advantages of locally produced/managed energy sources must be fully exploited to stimulate regional economic growth. Further ways to shape charcoal policies are described in the following paper: "[[:file:Shaping charcoal policies.pdf|Shaping charcoal policies: context, process, and instruments as exemplified by country cases]]". | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | = Further Information = | ||

| + | |||

| + | {| cellspacing="1" cellpadding="1" border="1" | ||

| + | |- | ||

| + | | [[Charcoal Cookstoves|Charcoal Cookstoves]], article on energypedia | ||

| + | | | ||

| + | |- | ||

| + | | [[Cooking with Charcoal|Cooking with Charcoal]], article on energypedia | ||

| + | | | ||

| + | |- | ||

| + | | The Alternative Charcoal Tool: gives small and medium enterprises, policy makers as well as NGOs in developing countries insight in the potential of charcoal production from alternative feedstocks on a regional or country level. Examples are charcoal dust, harvest residues like cotton stalks, processing residues and invasive species | ||

| + | | | ||

| + | *[[Alternative Charcoal Tool (ACT)|Alternative Charcoal Tool (ACT)]]<br/> | ||

| − | + | |- | |

| + | | Production of fuel briquettes from charcoal waste in Diego, Madagascar by Matthew Owen commissioned by ECO-Consulting Group<br/> | ||

| + | | | ||

| + | *[[:File:Production of Fuel Briquettes from Charcoal Waste in Madagascar.pdf|Viability Assessment - Production of fuel briquettes from charcoal waste in Diego, Madagascar]]<br/> | ||

| − | - | + | |- |

| + | | Manual for Charcoal Production in Earth Kilns in Zambia | ||

| + | | | ||

| + | *[http://www.mewd.gov.zm/index2.php?option=com_docman&task=doc_view&gid=3&Itemid=63 Manual] | ||

| − | + | |- | |

| + | | Review of Technologies for the Production and Use of Charcoal | ||

| + | | | ||

| + | *[http://rael.berkeley.edu/files/2005/Kammen-Lew-Charcoal-2005.pdf rael.berkeley.edu] | ||

| + | |- | ||

| + | | Overview on charcoal in Africa-Importance, Problems and Possible Solution Strategies | ||

| + | | | ||

| + | *[[:file:Charcoal-in-africa-gtz 2008-eng.pdf|Charcoal in africa]]<br/> | ||

| + | |- | ||

| + | | Founded in 2009, the Charcoal Project is supported by a global network of volunteer specialists that include scientists, conservationists, marketing, web, social development, and business experts. Their mission is to promote, facilitate, and advocate for the widespread adoption of clean burning technologies, sustainable fuel alternatives, and policies that support energy-poverty alleviation for those who depend on biomass as their primary fuel around the world.<br/> | ||

| + | | | ||

| + | *[http://www.charcoalproject.org/ www.charcoalproject.org] | ||

| − | |||

|- | |- | ||

| + | | The FAO supported project in Croatia to enhance the development of a sustainable charcoal industry provides several useful reports on the ecological and economical impacts of charcoaling<br/> | ||

| | | | ||

| − | < | + | *[ftp://ftp.fao.org/DOCREP/fao/012/i1107e/i1107e01.pdf Wisdom Croatia]<br/> |

| + | |- | ||

| + | | A short film (40 minutes) called '''[http://vimeo.com/25721658 MAKALA (Modern Charcoal Production)]''' about the IFDC's project SEW. In order to preserve one of the world's heritages, the Virungu National Park in the Democratic Republic of Congo, the project aims to professionalize the fuel sector by training charcoalers with modern carbonization techniques. Men and women are trained in a peer to peer approach and obtain certificates. The training in summary comprises of the right approach for drying wood, stacking it correctly, building an effective kiln and monitoring the kiln to ensure the maximum amount and high quality charcoal. | ||

| | | | ||

| − | [http:// | + | *[http://vimeo.com/25721658 vimeo.com] |

|- | |- | ||

| − | | | + | | Acacia trees can be grown to produce charcoal, a main fuel in Kenya. This publication by Practical Action Consulting prepared for PISCES shares information on different acacia species, and gives helpful advice during all stages of production up to methods of processing the wood into charcoal. |

| | | | ||

| − | + | *[http://practicalaction.org/media/preview/31871 Pocketbook] | |

|- | |- | ||

| + | | The Kenyan ministries recently formulated policy and legislation to help grow the charcoal industry. This handbook, by Practical Action Consulting East Africa for PISCES, aims to clarify these new developments for the key players in the charcoal value chain. It also provides the forms necessary for those different actors to ensure legality of the processes. | ||

| | | | ||

| − | + | *[http://r4d.dfid.gov.uk/Output/189258/ Kenya Charcoal Policy Handbook.pdf Kenya Charcoal Policy Handbook] | |

| − | |||

|- | |- | ||

| − | | | + | | This is a further simplified and abridged version of The Kenya Charcoal Policy Handbook (above), especially focused on informing producers, transporters and vendors about the current legislation as well as how to apply for licenses. |

| − | | [http:// | + | | |

| + | *[http://r4d.dfid.gov.uk/Output/192184/ Charcoal Pocketbook] | ||

| + | |||

|- | |- | ||

| − | | | + | | 8 minutes video on "Introducing a Sustainable Charcoal in Cambodia" by GERES. The video illustrates the GERES activities in respect to sustainable forest management, improved charcoal production with the installation and operation of the Yoshimura kiln and the efficient use of charcoal with improved stoves. |

| − | | <br> | + | | |

| + | *[http://www.youtube.com/watch?v=1ftiqCA6mVg&feature=c4-overview&playnext=1&list=TLWfy3GUvuW6k www.youtube.com]<br/> | ||

| + | |||

|- | |- | ||

| − | | | + | | More information on the "adam-retort" under:<br/>For a short video of 3 min. use search funktion under www.youtube.com and "adam-retort".<br/>Report on a retort charcoal project in Kenya (2005): |

| − | | [http:// | + | | |

| + | *[http://biocoal.org/3.html biocoal.org]<br/> | ||

| + | *[http://www.mediafire.com/view/ru17by2a0qn70d0/L-Report-PUBLISH-ADAM_05_MM.pdf www.mediafire.com]<br/> | ||

| + | |||

|} | |} | ||

| − | [[Category: | + | <br/> |

| + | |||

| + | <br/> | ||

| + | |||

| + | = References = | ||

| + | |||

| + | This article was originally published by [http://www.giz.de/fachexpertise/html/2769.html GIZ HERA]. It is basically based on experiences, lessons learned and information gathered by GIZ cook stove projects. You can find more information about the authors and experts of the original “Cooking Energy Compendium” in the [[Imprint - GIZ HERA Cooking Energy Compendium|Imprint]].<br/><references /> | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | [[Charcoal Production#Challenges and Potentials to Sustainable Charcoal Production|Top of the page]] | ||

| + | |||

| + | [[GIZ HERA Cooking Energy Compendium|--> Back to Overview GIZ HERA Cooking Energy Compendium]]<br/> | ||

| + | |||

| + | {{#set: Hera category=Woodfuel Supply}} | ||

| + | |||

| + | [[Category:Cooking_Energy_Compendium_(GIZ_HERA)]] | ||

| + | [[Category:Briquettes]] | ||

| + | [[Category:Impacts]] | ||

| + | [[Category:Charcoal]] | ||

| + | [[Category:Woodfuel]] | ||

| + | [[Category:Energy_Efficiency]] | ||

| + | [[Category:Cooking_Energy]] | ||

Latest revision as of 06:46, 30 March 2022

Cooking Energy System | Basics | Policy Advice | Planning | Designing and Implementing ICS Supply | Designing and Implementing Woodfuel Supply | Climate Change | Extra

Overview

Charcoal is a prime source of energy in most African countries, and is a driving force in their economies. Worldwide charcoal production has increased, rising by an annual 3.7% from 1990 to reach 44 million tones in 2000 (see: FAO (2008), Forests and Energy (pdf))

Challenges and Potentials to Sustainable Charcoal Production

Surprisingly, policy makers pay little attention to the ways in which charcoal is produced and sold and whether wood used for charcoal burning is harvested in a sustainable fashion. Without coherent policies, almost all charcoal production, transportation, and distribution remains informal and unregulated – leading to inefficient and risky production methods.

The common issues characterizing the charcoal production chain in many African countries comprise:

- unregulated/illegal resources

- rampant and systemic corruption

- inefficient conversion technologies

- a perception that it is a poor man’s business

- considered ‘dirty’ and economically unattractive

- free access to wood resources, leading to deforestation and degradation

- the charcoal business is dominated by a few powerful individuals.

'Lessons from eastern Africa's non-sustainable charcoal trade' can be found on the website of the World Agroforestry Center in the publications section.

Despite the growing scarcity of wood, charcoal generally remains underpriced by more than 20% to 50%, as only the opportunity cost of labour and capital required for charcoal production and transport are reflected. The production price for the raw material wood is often not reflected when wood is exploited from unsustainably managed wooded areas (e.g. open access areas). In addition, dues are ineffectively collected. Undervaluation translates into wasteful and inefficient production and consumption, and creates a formidable disincentive for forest management and tree growing (see box). A World Bank Publication from some years ago still correctly illustrates the problems of underpricing and provides methods for estimating adequate woodfuel stumpage values (see: Fuelwood Stumpage. Financing Renewable Energy for the World’s Other Half)

| Impacts of underpricing charcoal

As long as charcoal is not sold at a real market price, investments in improved wood-to-charcoal production/conversion are economically not attractive:

|

Problems arise at all stages of the charcoal value chain, so a precise understanding of the charcoal value chain is necessary for shaping sound policy frameworks. It offers an opportunity to the various stakeholders to add knowledge, innovation, capital, and technology at each step or link in the value chain. Sound policy can provide checks and balances, creating more balance within and between the sectors, and supporting the intended overarching goals, such as the Millennium Development Goals (MDGs).

Other papers highlighting the importance of adopting a value chain approach include: Analysis of charcoal value chains - general considerations; and Chain Concept Note for Reader.doc Policy and Distributional Equity in Natural Resource Commodity Markets: Commodity-Chain Analysis as a Policy Tool.

Furthermore, evidence-based analyses of the charcoal value chain provide the opportunity to demonstrate the regional added value of charcoal production and thus help to sensitise policy makers for a source of energy hitherto neglected & left to the informal sector. Examples of study projects, geared towards a comprehensive assessment and analysis of the charcoal production chain, include:

- the supra-regional Chaposa project (1998-2002) investigating the charcoal potential for Southern Africa: -> Charcoal Potential in Southern Africa CHAPOSA

- the National Charcoal Survey:Exploring the potential for a sustainable charcoal industry in Kenya (ESD 2005)

- the study initiated by the Forest Governance Learning Group (FGLG) for Malawi: Charcoal - the reality: A study of charcoal consumption, trade and production in Malawi

- a policy note prepared by Worldbank staff for decision makers in Tanzania summarizing the fundamental characteristics of charcoal use in the country and presenting policy options along the entire value chain of charcoal production and consumption (2010): ENVIRONMENTAL CRISIS OR SUSTAINABLE DEVELOPMENT OPPORTUNITY? Transforming the charcoal sector in Tanzania

Basics on Charcoal

Charcoal is produced following several processes, artisanal and industrial. The best known industrial processes are slow pyrolysis and supra-carbonization.

During combustion, the wood will undergo 2 to 3 different chemical reactions: 2 for pyrolysis with endothermic and exothermic; we must add a third for supra-carbonization, that is, endothermic again. Because of this, charcoal has a higher fixed carbon content.

- Pyrolysis consists of heating wood or other substances, in the absence of oxygen, with external energy. Pyrolysis is initiated by heating a pile of wood under controlled conditions in a closed space such as a charcoal kiln with a very limited supply of air triggering endothermic and exothermic reactions. The biomass produces, as a result of the pyrolysis process, a mixture of gas, liquid and charcoal.

- Supra-carbonisation ("MAGE" technology) does not require external energy, unlike pyrolysis, since it is the wood itself which serves as ignition for the furnaces and is done by the upper part; and with the help of high chimneys, this allows to control the process during the carbonization phase. As the fresh air intake is located below the furnaces, the carbonization front goes downhill because the air at the top of the furnaces is consumed first. The combustion phase is followed by a carbonizer, in order to avoid the total ignition of the wood inside the oven, as well as the evaporation of the water present in the raw material (up to 100 ° C). The energy required for this step comes from the partial combustion of the wood, giving CO, CO2, acetic acid and methanol (up to 270 ° C). Then, the exothermic decomposition of the wood begins, between 270 and 300 ° C, causing an increase in the temperature inside the furnace up to 400 ° C, with the production of charcoal, plant tar and pyroligneous extracts. At this stage, the charcoal still contains a large amount of volatile compounds (about 30%), with a fixed carbon content of 60 to 65%. At + 800 ° C, the fixed carbon content reaches 82 to 84% for 3 to 7% of volatile compounds.

Charcoal is first of all characterized by its density which can vary between 0.2 and 0.6 t/m3 depending on the density of wood used as raw material. Charcoal produced from hardwood is heavy and strong, whereas produced from softwood is soft and light. The coefficient of transformation is about half (example: eucalyptus with a density of about 0.6 gives charcoal with a density of around 0.25 to 0.35).

The bulk density of charcoal does not only depend on the apparent density but also on the size distribution, and is in the range of 180 - 220 kg/m3.

Charcoal has a relatively low moisture content of around 3 to 10%. The gross calorific value of charcoal is linked to the amount of fixed carbon and depends strongly on the carbonization temperature varying from 27 to 33 MJ/kg. Low carbonization temperatures give a higher yield of charcoal but this charcoal is low grade, is corrosive due to its content of acidic tars, and does not burn with a clean smoke-free flame. Good commercial charcoal should have a fixed carbon content of about 75% and a final carbonization temperature of around 500°C.

Technological Aspects

For conversion of wood into charcoal people use "kilns". The most common types of traditional kilns are earth pit or mound kilns with efficiencies ranging between 8% and 12 % (Table 7). Because parameters like the humidity of the wood used, kiln size, and process control, play an important role, the relative gain of an improved technology ranges between 5% to 50%.

See: www.fao.org, Industrial charcoal making

| Table 7: Efficiencies of various types of kiln | ||

| Production of 1 kg of charcoal from | Kiln efficiency | |

| Traditional Kilns | 8- 12 kg wood | 8 – 12% |

| Improved traditional kilns | 6 – 8 kg wood | 12 - 17% |

| Industrial production technologies | 5 – 7 kg wood | 20 – 14% |

| New high-yield, low-emission systems | 3 – 4 Kg wood | 25 - 33% |

Part of the energy losses during charcoal making are compensated for during end use, as charcoal stoves have higher efficiencies than wood stoves (30% - charcoal stoves versus 10%-15% untended open fire or tripod).The following table gives information on the amount of energy loss in % when introducing improved kilns and/or improved stoves in comparison to the usage of firewood. For example, if one converts wood to charcoal using a traditional kiln (with efficiency of 8%) and then burns that charcoal on a traditional stove (with efficiency of 20%), there is a resulting energy loss of 73%.

| Table 8: Energy Losses Converting Woodfuel to Charcoal (using various stoves) | |||||

| Traditional

Stove 1 Stove 2 |

Improved

Stove 1 Stove | ||||

| Efficiency | 20% |

24% | 30% | 35% | |

| Traditional Kiln1 | 8% | 73% | 68% | 60% | 53% |

| Traditional Kiln 2 | 12% | 60% | 52% | 40% | 30% |

| Improved Kiln 1 | 14% | 53% | 44% | 30% | 18% |

| Improved Kiln 2 | 18% | 40% | 28% | 10% | -5% |

Publications

Traditional Kilns

Earth Pit Kilns

Earth pit kilns are the traditional way of making charcoal in many parts of the world and may represent the simplest technology for charcoal production. In brief, the process of using an earth pit kiln begins by stacking wood in a pit, sealing it with a layer of grass and soil and starting carbonization by igniting the wood at one end. Earth pit kilns are typically large and large pieces of wood can be used. But can these kilns can also be built in small size and can thus, be suitable for families and even individuals.

Pit kilns are labor intensive since a pit must be dug into the ground. Ventilation may also be difficult to control and often carbonization is incomplete, producing only low quality charcoal. To improve efficiency, pit kilns can be equipped with a chimney which allows the use of biomass other than wood, such as coconut shells.

Earth Mound Kiln

This is also a common kiln used for charcoal production. It can be constructed from locally available material. In brief, wood is collected and stacked in the polygonal shape of kiln. The wood is then covered with a layer of grass and the construction is sealed with soil. A small opening allows the control and monitoring of the process. When the kiln has been lit, it requires continuous attention for 3 to 15 days depending on the size. After the kiln has cooled down charcoal can be harvested. The main advantage of this type of kiln is that it can be constructed easily without cost at the harvest site.

Downsides are that carbonization takes rather long and the process requires continuous attention. In addition, charcoal quality is rather low and efficiency is only between 8 and 15 %. Therefore charcoal production using traditional kilns is associated with high consumption of wood. Nonetheless, earth mound kilns are typically more efficient than earth pit kilns.

Improved Kilns

Casamance Kiln

The Casamance kiln was developed in Senegal and is an earth mound kiln equipped with a chimney. This chimney, which can be made of oil drums, allows a better control of air flow. In addition, the hot flues do not escape completely but are partly redirected into the kiln, which enhances pyrolysis. Due to this reverse draft carbonization is faster than traditional kilns. and more uniform giving a higher quality of charcoal and efficiency up to 30 %. Comparative tests of the casamance kiln and traditional mound kilns confirmed the advantages in terms of efficiency and shorter carbonization times due to the enhanced hot flue circulation (see Meule casamancaise PERACOD Mundhenk (pdf))

Disadvantages of this kiln type are that it requires some capital investment for the chimney and it is more difficult to construct.

Brick Kiln

The brick kiln is stationary, unlike the Casamance or traditional kilns. They have an efficiency of up to 30 % and are suitable for semi-industrial production of charcoal. One type is the truncated pyramid kiln, which is used in Chad mainly in the informal sectors. However, it has a lower efficiency than other brick kilns. The most notable type is the Argentine half orange Kiln, which has been adopted by the Malawi Charcoal Project. It is made entirely out of brick and mud as mortar. Loading and unloading is performed through two opposite doors, which are sealed before the kiln is ignited. The carbonisation cycle is much quicker and allows harvesting of charcoal after 13 – 14 days. Using a kiln of about 6 m diameter, up to 15 t of high quality charcoal can be produced per month. However, as brick kilns are stationary once built, they can only be used in areas with an easy supply of wood. Furthermore, the wood has to be cut with some precision and water supply is required for preparation of mortar. Kilns can also be produced using concrete instead of bricks; however, as their construction is very cost-intensive they have not succeeded in Africa.

Steel Kiln

Many different types of steel kilns have been developed which are considered as one basis of modern charcoal production. They are capable to carbonize even poor quality wood and can easily be transported when necessary. However, as the annual output of a typical demountable steel kiln is about 100 – 150 t, they are not suitable for high-volume production. Furthermore, the investment costs may be as high as 1,000 US$, which limits the use of steel kilns considerably. Nevertheless, since efficiency is high (27 – 35 %) and carbonization is quick (16 to 24 hours after ignition), steel kilns have been promoted as community kilns in Kenya. There are also steel

drum kilns on the market - designed by Dr. M. Kinyanjui to facilitate access to sustianably made charcoal, (using twigs, branches, maize cobs, coconuts etc. for feedstock) these kilns are low cost, portable and easy to use. They can also have a wood oil trap installed to condense some of the smoke into wood tar/oil for home use. They come in two sizes - domestic for 40$ and business for 130$.

Marketing materials promoting these kilns.

A "Box-Kiln" has been developed by Dr.Chris ADAM in 2019. This kiln works as an improvment to the round steel kilns (MARK II) . For more information search this "Box-Kiln" via Youtube.

Adam Retort

The retort kiln is one of the most efficient means of producing good quality charcoal. The kiln returns the wood gases from the carbonisation chamber back to the external fire-box, burns the volatile a higher proportion of the tar components almost completely and uses the heat for the carbonisation process. The Improved Charcoal Production System (ICPS), also called "adam-retort", may be presented as a modern example of retort technology. Efficiency can be as high as 35 % and noxious emission can be reduced by 70 %. In addition, the production cycle is completed within 12 hours or 24 to 30 hours included cooling. The retort kiln is suitable for rural and semi-industrial charcoal production. Volume of wood chamber is about 3m³ and ~250kg or more of charcoal can produced per batch. Wood chamber can be loaded with about 1 ton of wet wood or ~750kg of ofen dry wood. (www.biocoal.org)

Disadvantges include that it’s a stationary kiln, investment costs exceed 1,200 US$ and special skills are required for construction and operation. Nevertheless, the Adam-retort has been introduced in several countries (Senegal, Tanzania, Mali, Angola, Madagascar, Peru, Costa Rica, Mexico, India, Cambodia, etc.) on a pilot basis. Currently, the method is being further refined for up-scaling. A construction manual with drawings is available on a license basis by dr.Chris ADAM.

(Photo up: Madagascar, Photo down: "Puja initiation" of a retort in South India/Kumta, 2014)

A unit of 3 adam-retort kilns (trice-retort) was built by www.ghana-resorts.com in Ghana to carbonize bamboo. Baskets are used to load and unload the bamboo biomass from the wood chamber.

The "mobile adam-retort"

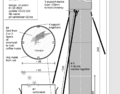

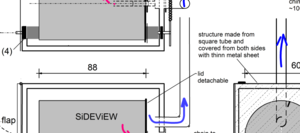

This lately developed mobile retort by Dr.Chris ADAM is available since 2015 and its design is based on 2 oil drums. These oil drums are replacable.

The mobile retort burns most of the smoke and works with high efficiency of about 30% referring to the dry mass of the wood. About 140kg of wet wood (corresponding to about 120kg of wood without water) can be loaded and about 35kg of charcoal (high temperature burnt) can be harvested. This mobile retort is not yet smoke free and some modifications will be done in 2022.

Unit to carbonize coffee husks to make briquetts

In 2022 CARiTAS-SUISSE is lancing a briquetting project in Ethiopia. The briquettes are made from carbonized coffee husks. 3 differnt carbonizing units are currently be developed and tested. All units are low-cost systems and they have been designed by Dr.Chris ADAM (www.biocoal.org) :

Carbonizer-1 (drum open pit carbonizer) The unit works by adding the coffee husks continously into a barrel (oil drum).

Carbonizer-2 (drum rotary retort carbonizer) The unit works by adding the coffee husks by batch into a turning barrel

Carbonizer-3 (drum retort carbonizer) The unit works by adding the coffee husks by batch into a barrel

Industrial Process

The supra-carbonization technology "MAGE"

The innovative character of the "MAGE" supra-carbonization process (https://www.blukarb.com/english/) is based on the use of vertical cylindrical metal furnaces, intended for the carbonization of wood at temperatures of around 800 °C, to reach a fixed carbon content in charcoal between 82 and 84%, higher than the standard NF EN 1860-2 June 2005.

The production process does not contaminate soil or air. All gases from carbonization are destroyed by a flare.

The "MAGE" technology was developed in the early 80's by Jacques & Jean-Pascal MAGE, then patented in the United States in 1989. It was then marketed in Argentina and Chile by Blu Karb.

- These furnaces industrially produce renewable energy, namely a charcoal whose fixed carbon content is > 82% because the technology makes it possible to control the carbonization temperature at the heart of the furnace;

- "MAGE" technology requires 30% less wood than traditional methods to obtain the same amount of charcoal, and kilns make it possible to recover industrial and forest wood waste;

- This technology, unlike pyrolysis for example, does not need external energy input to cook the wood;

- The furnace is filled with pre-cut woods chips in 10*5*5 cm, which avoids breaking the pieces of charcoal after charring, increasing productivity by +30%;

- The wood is inflamed from the top and it will ignite to the bottom thanks to the air circulation; the air vents located under the furnace are then closed once all the wood is on fire ;

- A complete carbonization cycle lasts between 20 and 24 hours, depending on the moisture content of the wood;

- Carbonization is broken down into 3 phases: endothermy, then exothermic and finally again endothermy;

- Furnaces work 10 years and are 100% recyclable;

- The fixed carbon quality obtained preserves the health of consumers (colorectal cancer);

- A factory of 10 furnaces can be installed on a site of only 10,764 sq m; it generates about 40,000 carbon credits over the year;

The volume of the furnace is about 16m³ of wood and at least 1,500 KGs of charcoal are produced per carbonization cycle, for 1 oven : 36,000 KGs for 24 carbonizations per month.[1]

Charcoal Briquetting

A briquette is a block of flammable matter used as fuel to start and maintain a fire. Residues from agriculture and forestry e.g. bagasse, coffee husks, saw-dust, and coconut husks are a valuable source of raw material and can be used for producing briquettes.The briquetting process entails many steps. After collection, the wood or agro-industrial waste is dried before it is converted to charcoal in a charring kiln. The carbonised biomass is then mixed with water and locally-available binders such as starch, gum arabic, molasses, clay and others. Finally, the mixture (powdered charcoal + binder mixture) is pressed into briquettes. Piston and screw presses are the most widely used technologies where as in the developed countries roll presses are more common. The production capacity of screw presses is around 40 to 70 kg per hour. After a subsequent drying step, the briquettes will develop the required strength and stability. Forest and agricultural waste charcoal briquettes, with about 20% of clay, produce about 12 MJ/kg depending on the composition of charcoal.

Further information on biomass charcoal briquetting for energy based income generation in rural areas can be found in the booklet Biomass Charcoal Briquetting.

The GIZ Program to promote rural electrification and a sustainable supply of domestic fuel (PERACOD) in Senegal documented their experience at the Peracod website.

More information about production and marketing of briquettes can also be found here on energypedia.

Transport and Marketing

The trade of charcoal in many African countries is primarily informal and it is characterized by a high turnover rate. There is no significant warehousing. All stocks produced are promptly consumed. Abundant evidence of the charcoal trade is visible throughout the cities and surrounding regions. Roads are lined with charcoal bags for sale in the center of the cities, both on the city outskirts and in the proximity of the production areas.

Charcoal trading is a key segment in the supply/demand chain, and the dealers are the key actors in this regard. Often transporters function as middlemen and wholesalers.

Lorries and pickups are the most popular kind of motorized transport due to their carrying capacity. Charcoal is not a heavy commodity but it is bulky. Bicycles are the most common non-motorised form of transport. Some carry up to five bags of charcoal. Furthermore, the use of donkey carts is a notable form of transportation. Human transport is also used, but only for short distances and especially in areas inaccessible by other forms of transport.

Transport costs are a critical component not only of urban woodfuel prices but of the area from which woodfuels can be supplied at competitive prices.

Profits are usually concentrated in the hands of a few intermediaries, engaged as transport agents or wholesalers. Instead of equitable revenue-sharing along the entire value chain, revenue circulates in a loop between traders and consumers reaping off up to 80% of the value chain profits. Marginal profits (20-30%) go to the charcoal producers– and virtually none to those communities, whose forest areas are being depleted in the process.

Social, Economic and Environmental Impacts

Charcoal consumption is a very controversial issue, as the transformation process from wood to charcoal results in considerable energy loss, requiring significantly more forest resources to produce the same amount of energy. This has led to many countries such as Kenya, Tanzania, Gambia etc, to impose bans on charcoal. However these bans have had little success and charcoal use continues to increase with the pressures of growing urbanisation. Charcoal burns more cleanly than wood or dried biomass, producing higher temperatures and it is cheaper to transport and store. For these reasons, interest in charcoal as a fuel is reviving, and steps need to be taken to promote improved charcoal-making technologies and thus reduce the amount of raw biomass required.

Charcoal production is a labour-intensive process, employing a large number of people at different phases of the process and distribution. It is estimated that charcoal production generates between 200-350 person days of employment per Terajoule of energy, compared to 10 person days per Terajoule for kerosene. Sustainable production of wood-based fuels (particularly charcoal) can support rural development through decentralised processing & production, short transport distances with low risks, locally available and renewable resources, and potential for short-term efficiency improvements (improved stoves, kilns etc). It can yield a health-dividend, due to reduced levels of smoke, cleaner combustion, and easy handling. To be environmentally beneficial, highly efficient kilns and renewably-sourced fuels are required.

To this end, woodfuel policies need to be designed within the context of a sustainable (rural) development approach, and principles of local control and participation adhered to in the planning process. Comparative advantages of locally produced/managed energy sources must be fully exploited to stimulate regional economic growth. Further ways to shape charcoal policies are described in the following paper: "Shaping charcoal policies: context, process, and instruments as exemplified by country cases".

Further Information

| Charcoal Cookstoves, article on energypedia | |

| Cooking with Charcoal, article on energypedia | |

| The Alternative Charcoal Tool: gives small and medium enterprises, policy makers as well as NGOs in developing countries insight in the potential of charcoal production from alternative feedstocks on a regional or country level. Examples are charcoal dust, harvest residues like cotton stalks, processing residues and invasive species | |

| Production of fuel briquettes from charcoal waste in Diego, Madagascar by Matthew Owen commissioned by ECO-Consulting Group |

|

| Manual for Charcoal Production in Earth Kilns in Zambia | |

| Review of Technologies for the Production and Use of Charcoal | |

| Overview on charcoal in Africa-Importance, Problems and Possible Solution Strategies | |

| Founded in 2009, the Charcoal Project is supported by a global network of volunteer specialists that include scientists, conservationists, marketing, web, social development, and business experts. Their mission is to promote, facilitate, and advocate for the widespread adoption of clean burning technologies, sustainable fuel alternatives, and policies that support energy-poverty alleviation for those who depend on biomass as their primary fuel around the world. |

|

| The FAO supported project in Croatia to enhance the development of a sustainable charcoal industry provides several useful reports on the ecological and economical impacts of charcoaling |

|

| A short film (40 minutes) called MAKALA (Modern Charcoal Production) about the IFDC's project SEW. In order to preserve one of the world's heritages, the Virungu National Park in the Democratic Republic of Congo, the project aims to professionalize the fuel sector by training charcoalers with modern carbonization techniques. Men and women are trained in a peer to peer approach and obtain certificates. The training in summary comprises of the right approach for drying wood, stacking it correctly, building an effective kiln and monitoring the kiln to ensure the maximum amount and high quality charcoal. | |

| Acacia trees can be grown to produce charcoal, a main fuel in Kenya. This publication by Practical Action Consulting prepared for PISCES shares information on different acacia species, and gives helpful advice during all stages of production up to methods of processing the wood into charcoal. | |

| The Kenyan ministries recently formulated policy and legislation to help grow the charcoal industry. This handbook, by Practical Action Consulting East Africa for PISCES, aims to clarify these new developments for the key players in the charcoal value chain. It also provides the forms necessary for those different actors to ensure legality of the processes. | |

| This is a further simplified and abridged version of The Kenya Charcoal Policy Handbook (above), especially focused on informing producers, transporters and vendors about the current legislation as well as how to apply for licenses. | |

| 8 minutes video on "Introducing a Sustainable Charcoal in Cambodia" by GERES. The video illustrates the GERES activities in respect to sustainable forest management, improved charcoal production with the installation and operation of the Yoshimura kiln and the efficient use of charcoal with improved stoves. | |

| More information on the "adam-retort" under: For a short video of 3 min. use search funktion under www.youtube.com and "adam-retort". Report on a retort charcoal project in Kenya (2005): |

References

This article was originally published by GIZ HERA. It is basically based on experiences, lessons learned and information gathered by GIZ cook stove projects. You can find more information about the authors and experts of the original “Cooking Energy Compendium” in the Imprint.

- ↑ Blu Karb https://www.blukarb.com