Difference between revisions of "Enhancing Production of Improved Cookstoves (ICS)"

***** (***** | *****) |

***** (***** | *****) |

||

| Line 61: | Line 61: | ||

| | ||

| − | + | Scaling-up can be done in two dimensions: | |

<br> | <br> | ||

| − | + | '''1. Increasing the number of small scale supply-demand systems<br>'''In this case the concept of “local production for local markets based on local resources and local skills” is maintained. It is a concept which provides a close link between producers and users and is relatively robust against external shocks. For scaling-up this concept, a large effort in capacity building for many artisans is required. There are good examples for this approach: the “training of trainers” concept in Kenya and Uganda. | |

| − | Another Approach is the “mainstreaming concept” of the Program for Biomass Energy Conservation (ProBEC) in Malawi. It is based on the assessment that supporting a nation-wide dissemination is too large a task to be accomplished by a single project team. Strong and organised partners are needed, who know both the country and its people very well, allowing the project to act as a facilitator. Involvement with other organisations, such as NGOs, the private sector, or governmental bodies, is a precondition for achieving sustainable access to household energy for large numbers of people. These already existing partners can be found in many sectors which are related to cooking energy. The next figure illustrates fields and sectors where cooking energy could be incorporated into the activities of sectors other than energy. <br> | + | Another Approach is the “mainstreaming concept” of the Program for Biomass Energy Conservation (ProBEC) in Malawi. It is based on the assessment that supporting a nation-wide dissemination is too large a task to be accomplished by a single project team. Strong and organised partners are needed, who know both the country and its people very well, allowing the project to act as a facilitator. Involvement with other organisations, such as NGOs, the private sector, or governmental bodies, is a precondition for achieving sustainable access to household energy for large numbers of people. These already existing partners can be found in many sectors which are related to cooking energy. The next figure illustrates fields and sectors where cooking energy could be incorporated into the activities of sectors other than energy.<br> |

| − | |||

| − | | ||

[[Image:Cooking is Central.png|Health, forestry and food are all linked to household energy. Source: GTZ ProBEC.]]<br> | [[Image:Cooking is Central.png|Health, forestry and food are all linked to household energy. Source: GTZ ProBEC.]]<br> | ||

| Line 77: | Line 75: | ||

[http://energypedia.info/index.php/File:Jetzt.JPG energypedia.info/index.php/File:Jetzt.JPG] | [http://energypedia.info/index.php/File:Jetzt.JPG energypedia.info/index.php/File:Jetzt.JPG] | ||

| − | <br> | + | <br>'''2. Increasing productivity of production systems<br>''' |

Another way of increasing the production is the transformation of the existing production system to increase the productivity per producer. This can be based on the introduction of improved tooling (e.g. in Senegal the introduction of flanging, bending and rounding machines for metal works) of local artisans or the establishment of semi-industrial production centers (e.g. introduction of an extruder machine for the production of ceramic liners in Ethiopia). | Another way of increasing the production is the transformation of the existing production system to increase the productivity per producer. This can be based on the introduction of improved tooling (e.g. in Senegal the introduction of flanging, bending and rounding machines for metal works) of local artisans or the establishment of semi-industrial production centers (e.g. introduction of an extruder machine for the production of ceramic liners in Ethiopia). | ||

| − | The | + | The investment into machinery has various dimensions:<br>• The investment has to be financed: There might be need to support the producers through micro-finance instruments (link zum entsprechenden Kapitel des Kompendiums einbauen) to facilitate the investment.<br>• The investment must be viable: The additional costs of the investment must be overcompensated by additional income through cheaper production and increase of sales. A business case study for such an investment should be produced before the investment is executed.<br>• Staff qualification: new machines require new skills and knowledge. Existing staff has to be trained or better staff has to be recruited to operate the new machines properly.<br>• The investment can increase the vulnerability of the production: If new machines depend on the availability of electricity or the presence of a specific (qualified) staff member, the production might be more vulnerable for forced interruptions. The risks of such vulnerabilities should be assessed upfront. |

| − | [[Category:Cooking]] [[Category:Cooking_Energy_Compendium]] | + | <br>[[Category:Cooking]] [[Category:Cooking_Energy_Compendium]] |

Revision as of 09:26, 8 August 2011

==> Back to Overview GIZ HERA Cooking Energy Compendium

Product development

In the planning process, the targeted market segment for the promotion of ICS has been identified. Sometimes existing improved stoves can be further promoted by investing into scaling-up interventions. However, often there is no ready-made improved cook stove model available that adheres 100% to the specific requirements of this market. Adaptation or even the development of a new product is required to find the best balance between the needs of the targeted customers, the needs of the producers and the frame conditions of the production chain.

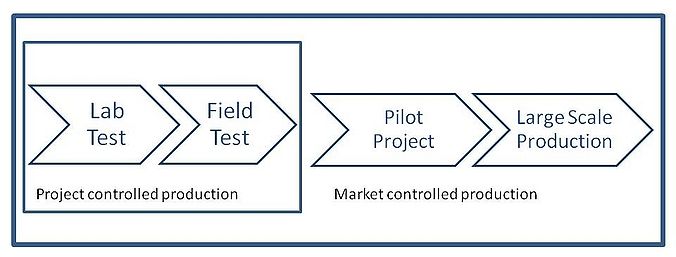

In the phase of product-development or –adaptation, the production of the ICS is controlled by “the project”. Once the ICS is ready for field testing and market introduction, the control of the production is gradually handed over to the market forces. This transition is very difficult and many projects failed due to the incompatibility between the project- and the market controlled production systems.

Prototypes of new stoves are usually produced in a lab-controlled environment with close collaboration between craftsmen, researchers and stove users. Once the prototype fulfills the required standards, it has to be field tested at a larger scale to verify if the stove performs well enough if ordinary households are using it. In reality, there might be alterations between phases of lab testing and field testing. In this period, production is controlled by the project. Market forces do not yet play a role.

The development of an ICS is actually never completed. Even after 10 years of promotion, new materials or design features may come up. Researchers and technicians tend to request for long product development phases, whereas project managers tend to push for early piloting. There is no golden rule to identify when a stove is ready for the market.

But there are some general requirements:

• The stove must be safe enough to be used in households without doing harm to the user;

• The stove must perform well enough to satisfy both the potential user as well as the project indicators for “improved cook stoves”;

• The stove must be convenient and appealing enough to convince the target group to buy and use it;

• The stove must be easy to produce (simple tooling and available materials) if the product is targeting a poor population group;

• The cost of stove production (including material cost) must be low enough to allow a retail price which satisfies both the target group (affordability) as well as the producer (profit margin per stove and turn over).

At some stage of the development process there is need to interrupt the change processes for at least a year to allow a field based learning on a constant stove model. Otherwise it is difficult to identify which variation of the stove model is related to which feedback or observation. While an early release to the public bears the risk of a public failure (image problem), a prolonged research period increases the cost of development and delays the results of dissemination.

Piloting of ICS production

Once the field test confirms the satisfaction of the target group with the product, the ICS will be produced for the selected market. As there is still the danger of “teething problems” in the first few years, it is a common practice to start with a geographically restricted pilot project. This will allow a close follow-up or producers and users through “the project” to ensure that the stoves are properly produced and appropriately used. If problems with the design or the materials are arising, there is still the possibility to correct the faults before large segments of the targeted market are already dissatisfied with the product.

The initial step from “prototyping” to “piloting production” is very crucial and difficult. On the one hand:

• we are not yet sure of the product (teething problems);

• we are not yet sure of the market (new product);

• we are not yet sure of the market case (production costs vs. sales price);

• we are not yet sure of the marketing system.

Because of these uncertainties, many projects feel the need to protect the initial producers against the risks of entering this new production business. This “protection” can take the form of…

• providing producers required tools;

• providing producers required production materials;

• providing producers grants or loans;

• giving producers large production contracts (= project buys all the stoves of them);

• employ the producers (=time-based contracts);

While these interventions are useful to get the production going, there are also huge risks for the long term sustainability attached to these approaches.

• The initial producers may consider themselves as “employees of the program” and therefore the program will have to provide a market for the stove/ has to market the stoves for them;

• These “special conditions” for the early producers cannot be maintained on the long run, if sustainable supply-demand systems are the envisaged goal of the intervention. Hence producers who will be trained later will not benefit in the same way as the initial producers. But the knowledge about the initial conditions will spread fast, leading to constant jealousy between old and new producers and demands for support by the “disadvantaged” producers;

• If the risk to produce for the market is buffered by the project, there is little motivation for the producers to develop a cost-efficient production concept. The initial price for the stove will always be high as there is no incentive to produce many stoves in short time. As a remedy, projects tend to subsidies the initial price for the customer to still find a market for the stove. Once this system of a high workshop-gate price on the side of the producers and a project-based subsidized low customer price is established, it will be highly difficult to exit this scenario without severe fractions. If the stove price increases up to the real price after the removal of the subsidy, the customers will complain that they are used to have a cheaper stove. Or the workshop-gate price is pushed lower, than the producers may lose interest. Unless there is a clear element of economy of scale which will result in a natural reduction of production costs over a short time, there is no easy exit of this system.

In many countries, there are artisans who worked already with former “stove projects”. New interventions often have also to combat expectations which are generated from these past experiences. It requires time, good knowledge of the local stove project history and strong standing to establish a different system. The selection of the location and the initial producers is something which should be done based on thorough planning.

It is not possible to suggest “the best way” on how to initiate the ICS production as it is highly circumstantial. However, here are some ideas which have worked in the past:

• At the end of the prototype-development phase, test-sales can be done to assess what would people pay for the stove. They can also generate orders for stoves.

• Based on this concrete demand, artisans with an already established workshop and business can be asked if they are interested to satisfy this documented demand if trained by the program. It is assumed that these producers have all tools and labor required to manufacture the stoves. The project may give a warranty that the investment into the materials for the stoves will be covered in case the stoves actually are not sold despite the orders of the customers.

• Once these first stoves are produced and sold, the initial producers are invited to participate in awareness and marketing activities to establish their own links to potential target groups and understand how to find markets for their new product.

• They are continuously supported through quality control and additional awareness campaigns. Feedback rounds with early customers may assist to create a better understanding of the perception of the customers.

There are some lessons from previous interventions to be shared:

• Do not pay artisans for attending a training workshop on stove production.

Some projects pay artisans for attending training courses as “they cannot afford to lose a working days income by attending a training course without pay”. But if you pay for participation, people will attend for the money (as a job) and you do not get the interested people. At least their time should be their contribution into a better future. You can buffer the “income-argument” by providing food and by designing half-day trainings close to the homes or work-places of the participants. Hence they can still work half time in their work-shops and still earn a little money.

• Do not provide free tooling and free materials to kick-start production:

Access to tools and materials for the production of the new product might be a bottleneck for the newly trained producers. Hence it is tempting to provide them with all tools necessary and the materials required for the first number of stoves with the idea that they can afford to purchase the next materials from the income of the first stoves.

In some cases this works out fine. But sometimes this attracts the wrong participants who are using the provided inputs to produce any type of other product and afterwards claim that they have to be given another material for the stoves. To avoid this kind of frustration, another option is to provide tools and inputs on a cost sharing arrangement, and the part to be paid by the artisan can be pre-financed by a micro-credit organization. This goes along with the support of the project to connect the artisans with their first customers. By doing so, there is a strong motivation to produce stoves is generated.

Scaling-up of ICS production capacities

Once an initial ICS production is established and the market case has been proven by an increasing demand, there is need to scale-up the production to satisfy larger customer groups.

It is important to consider the coordinated growth of both production and demand, as

• demand without products is frustrating the customers and

• production without markets ruins the producers.

Scaling-up can be done in two dimensions:

1. Increasing the number of small scale supply-demand systems

In this case the concept of “local production for local markets based on local resources and local skills” is maintained. It is a concept which provides a close link between producers and users and is relatively robust against external shocks. For scaling-up this concept, a large effort in capacity building for many artisans is required. There are good examples for this approach: the “training of trainers” concept in Kenya and Uganda.

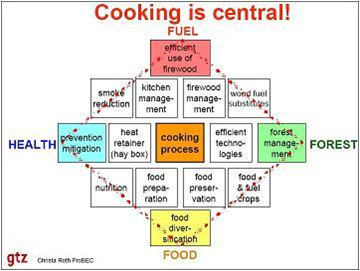

Another Approach is the “mainstreaming concept” of the Program for Biomass Energy Conservation (ProBEC) in Malawi. It is based on the assessment that supporting a nation-wide dissemination is too large a task to be accomplished by a single project team. Strong and organised partners are needed, who know both the country and its people very well, allowing the project to act as a facilitator. Involvement with other organisations, such as NGOs, the private sector, or governmental bodies, is a precondition for achieving sustainable access to household energy for large numbers of people. These already existing partners can be found in many sectors which are related to cooking energy. The next figure illustrates fields and sectors where cooking energy could be incorporated into the activities of sectors other than energy.

Health, forestry and food are all linked to household energy. Source: GTZ ProBEC.

energypedia.info/index.php/File:Jetzt.JPG

2. Increasing productivity of production systems

Another way of increasing the production is the transformation of the existing production system to increase the productivity per producer. This can be based on the introduction of improved tooling (e.g. in Senegal the introduction of flanging, bending and rounding machines for metal works) of local artisans or the establishment of semi-industrial production centers (e.g. introduction of an extruder machine for the production of ceramic liners in Ethiopia).

The investment into machinery has various dimensions:

• The investment has to be financed: There might be need to support the producers through micro-finance instruments (link zum entsprechenden Kapitel des Kompendiums einbauen) to facilitate the investment.

• The investment must be viable: The additional costs of the investment must be overcompensated by additional income through cheaper production and increase of sales. A business case study for such an investment should be produced before the investment is executed.

• Staff qualification: new machines require new skills and knowledge. Existing staff has to be trained or better staff has to be recruited to operate the new machines properly.

• The investment can increase the vulnerability of the production: If new machines depend on the availability of electricity or the presence of a specific (qualified) staff member, the production might be more vulnerable for forced interruptions. The risks of such vulnerabilities should be assessed upfront.