Difference between revisions of "Nepal - Energy Efficiency in Industry"

***** (***** | *****) |

***** (***** | *****) m (→Summary) |

||

| Line 165: | Line 165: | ||

<div>[[File:Energy use in Nepalese Dairy industry.PNG|thumb|left|300px|Energy use in Nepalese Dairy industry]][[File:Specific Energy Consumption of Dairy industry in Nepal.PNG|thumb|left|300px|Specific Energy Consumption of Dairy industry in Nepal]][[File:Energy Saving tips for Dairy industry.PNG|thumb|left|200px|Energy Saving tips for Dairy industry]]<br/></div></div> | <div>[[File:Energy use in Nepalese Dairy industry.PNG|thumb|left|300px|Energy use in Nepalese Dairy industry]][[File:Specific Energy Consumption of Dairy industry in Nepal.PNG|thumb|left|300px|Specific Energy Consumption of Dairy industry in Nepal]][[File:Energy Saving tips for Dairy industry.PNG|thumb|left|200px|Energy Saving tips for Dairy industry]]<br/></div></div> | ||

<br/> | <br/> | ||

| + | |||

= Summary = | = Summary = | ||

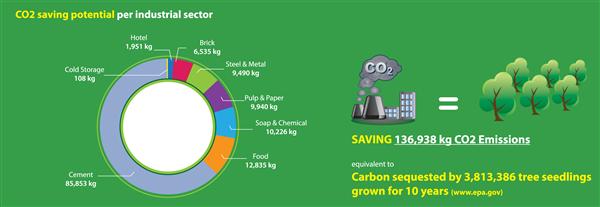

| − | Through energy efficiency Nepalese industries could save about 160,000 MWh hours electricity every year which is equivalent to the annual consumption fo 215,000 Nepalese households. On thermal energy the saving potential is about 8 Giga Joule which is equivalent to the import of 215 Billion litres of Diesel. Converted into carbon emission a total amount of 136 ton of CO2 could be mitigated which is the same amount of carbon requested by 4 billion tree seedlings | + | Through energy efficiency Nepalese industries could save about 160,000 MWh hours electricity every year which is equivalent to the annual consumption fo 215,000 Nepalese households. On thermal energy the saving potential is about 8 Giga Joule which is equivalent to the import of 215 Billion litres of Diesel. Converted into carbon emission a total amount of 136 ton of CO2 could be mitigated which is the same amount of carbon requested by 4 billion tree seedlings grown for 10 years. |

| + | |||

| + | [[File:Nepal - Electricity Saving Potentials per Industrial Sector.jpg|frame|left|180px|Nepal - Electricity Saving Potentials per Industrial Sector]]<br/> | ||

| − | [[File:Nepal - | + | [[File:Nepal - Thermal Saving Potentials per Industrial Sector.jpg|frame|left|180px|Nepal - Thermal Saving Potentials per Industrial Sector]]<br/> |

| − | [[File:Nepal - | + | [[File:Nepal - CO2 Saving Potentials per Industrial Sector.jpg|frame|left|180px|Nepal - CO2 Saving Potentials per Industrial Sector]]<br/> |

| − | |||

= References = | = References = | ||

Revision as of 05:47, 15 May 2014

Overview

Although, Nepal has the second largest hydropower resources in the world, it is still suffering from high energy shortage since several years. This power crisis has resulted in scheduled power outages (called load shedding) up to 12 hours per day in the dry season when the run-off-the-river hydropower plant cannot meet the electricity demand.

Particularly, industry is suffering because they have to shut down during load shedding or to run costly fuel based backup systems. The import of petroleum product has increased sharply during the last decade resulting in a trade deficit with India. However, energy is scarce and expensive it is often not used efficiently and wasted. This article gives an overview about energy saving potentials in eight energy-intensive sectors of Nepal.[1]

Industrial Sectors

Brick Sector

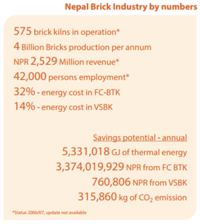

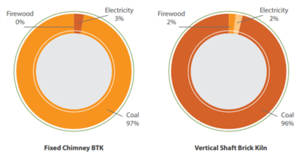

Sector highlightsBrick is a primary construction material in Nepal. Around 575 Brick kilns are in operations (Status 2006/2007) having a production capacity from 15,000 to 50,000 brick per day. Most of them operates only during dry season from December to June. Clay is the main raw material used in this industry and is available at very low cost. However, brick making is an energy and labour intensive industrial process. Hand moulding of green brick is mostly used. The predominant kiln technology in Nepal is the Fixed Chimney Bull Trench Kiln (FC-BTK). Apart from BTKs, Clamp Hoffmann and Vertical Shift Brick Kiln (VSBK) can be also found.

Energy use

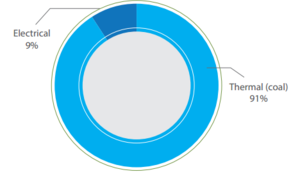

Coal is the main energy source used in the brick kilns in Nepal and is mostly imported from India. Small amount of sawdust, fire wood and bagasse are sometimes also used as fuel. The energy cost on product value is 32% for FC-BTK and 14% for VSBK.

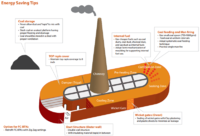

Energy Saving Potential

Thermal energy savings in Nepal’s brick sector is estimated to be 34% for the FC-BTK kiln technology and 4% for VSBK. It is estimated that brick kiln owners could save a total amount of NPR 3.45 Million every year by implementing energy efficiency measures.

Cement Sector

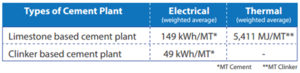

Cement is a commonly used as a basic building material in the country. About 70% of the cement used in the construction sector is manufactured in Nepal. There are two types of cement factories, namely, limestone-based and clinker-based. Limestone-based industry use the raw material limestone, that is abundantly available in Nepal, and burn the clinker and process the clinker to cement. Clinker-based factories import the clinker from India and process it to cement. There are more than 60 cement industries in Nepal; most of them clinker-based. Few new large units have a production capacity between 900 to 1,000 tons per day are in pipeline.

Energy Use

Main source of energy used in Cement factories is electricity and coal. Limestone-based units use coal for calcination. Clinker-based units use mainly electricity for grinding. Limestone-based cement plants is very energy-intensive with about 48% of energy cost on production value. In clinker-based units on 5% of the cost is due to energy.

Energy Saving Potential

Saving potentials are estimated to be around 41% and 49%, respectively for limestone and clinker-based industry. In total Nepalese cement units could annually save about NPR 1.5 Billion by using energy-efficient technologies.

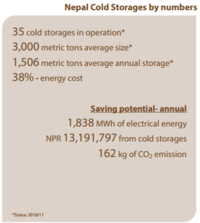

Cold Storage Sector

Sector highlights

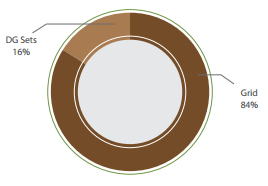

Cold storage units in Nepal are mainly used to store agriculture products such as potatoes, fruits, etc. Few of them store also meat items. There are about 35 cold storage units running in the country with an average size of 3,000 metric tons. The electricity price for cold storage is subsidized by 50%.Energy Use

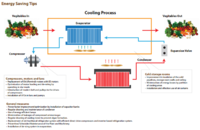

Cold storage units use only electricity that is provided by Nepal Electricity Authority (NEA). During power outage (load shedding) power is supplied through Diesel based backup systems. Electricity is mainly consumed for the cooling process. Energy cost on product value in cold storage sector is estimated to be 38%.

Energy Saving Potential

Energy Saving potentials are around 20% which is equivalent to 1,800 Megawatt hours annually. By going energy-efficient cold storage units could save about NPR 13 Million on energy cost every year.

Hotel Sector

Sector highlights

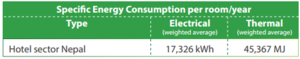

Energy Use

Hotels in Nepal use electricity as well as thermal energy in form of diesel, and LPG. Major energy is consumed for refrigeration, air conditioning, lighting, steam and hot water and cooking. Increased hours of scheduled power outage (called load shedding) has increased the energy costs in hotels due to the fact that they have to run diesel-based backup systems. Small and no-star hotels are unable to provide air conditioning service during power outage resulting in lower occupancy. Main source of energy is still electricity followed by diesel, and LPG.

Energy Saving Potential

About 8% of product value is spend on energy in hotels. Saving potentials are estimated to be 39% whereas 65% for electrical and 16% for thermal energy. In total the hotel sector could save a total amount of NPR 360 Million every year by implementing energy efficiency measures.

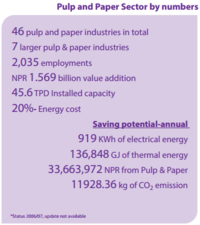

Pulp and Paper Sector

Sector highlights

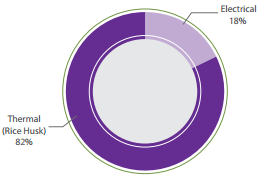

Almost four decade ago paper industry was established in Nepal. The number of pulp and paper units amount to about 46 providing around 2,000 jobs (CBS, 2007). The average installed capacity is about 45 tons per day whereas the average production is 22 tons per day. Nepal’s paper units are producing two types of product: 1.Bleached writing/printing paper & newsprint paper; 2.Unbleached craft paper. For paper making 63% non-wood pulp and 37% scrapped papers is used as raw material.Energy Use

In pulp and paper plants electricity is used for lighting. Thermal energy is used for boilers to generate steam. Many units have already switch to rise husk boiler.

Energy Saving Potential

The energy cost is estimated at 20% of product value. Energy saving potential in pulp and paper industry is 2% on electrical and 8% on thermal side. A total amount of NPR 33 Million on energy cost could be saved by this sector through energy efficiency measures.

Soap Sector

Sector highlights

Soap and chemical industry in Nepal produces mainly laundry soap; around 15% of the units manufacture also toilet soap. A total of 31 industries employs around 1,700 peoples with value addition of NPR 1.35 Billion (CBS, 2006/2007). The average soap production amounts to 15 tons per day.Energy Use

Soap and chemical industries consumers both electrical as well as thermal energy. Mainly rice husk, is used as source of thermal energy for boilers. Electrical energy is used for drives, compressed air generation, refrigeration and lighting.

Energy Saving Potential

The energy cost on product value is 5% for the soap and chemical industries. Energy saving potential for electrical and thermal are estimated to be 10% and 39% respectively. Energy efficiency could lead to annual savings of abound NPR 42 Million.

Steel and Metal Sector

Sector highlights

Steel and metal Industry in Nepal can be differentiated into three diffeerent classes namely: 1 basic iron and steel, 2. structural metal products, and 3. forging pressing and stamping of metal. However, this study only covers the first class basic iron and steel in general and re-rolling mills in particular.Nepal iron and steel industry is one of the top export earnings of Nepal with a growth rate of 1.2% (status 2011). Iron rod, steel rod, stainless steel, cast iron pipe, tin sheet are some of the export items of this industry. A total of 17 steel rolling mill units account for the employment of about 2,400 peoples (CBS, 2006/2007) and contributes with a value addition of NPR 1.9 Billion. The average production is about 113 tons per day.

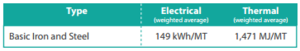

Energy Use

Main sources of energy used in the Iron and Steel industries in Nepal are furnace oil, electricity and coal. Coal is mainly used in the re-heating furnace for billet heating. Furnace oil or diesel is used in place of coal by some industries. Steel rolling mills also uses electricity from the grid. However, all units have diesel generator backup for power supply during load shedding hours when normal production has to stop.

Energy Saving Potential

Energy cost on product values is about 3% and energy saving potential are estimated to be 6% on electricity and 23% on thermal side. Steel rolling mills could save around NPR 283 Million every year by going energy-efficient.

Dairy Sector

Sector highlights

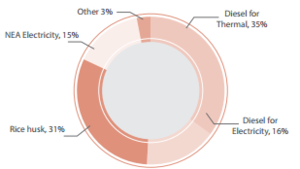

Dairy is an important and growing food industry in the country. In 2006/2007 a total number of 30 dairy units were registered generating employment for around 2,000 people. The average production of milk and milk products over one year was estimated at 1.45 million tons (Economic survey, 2010/11). Nepalese Dairy Industries are producing standard milk as well as other milk products like yoghurt, ice-cream, cheese and butter.Energy Use

There are three major process steps for milk and milk products, namely chilling of raw milk for intermediate storage, heating of milk (Pasteurization or boiling) and, fi¬nally, cooling for storage and distribution. Industries use significant amount of electrical as well as thermal energy for operating the motors and drives as well as for compressors of chilling units. Main source of electricity is the national grid, whereas diesel generators are used during power outage. Thermal energy is required for the operation of boilers that generate steam for the pasteurization of milk and other processes. Rice husk and diesel is used for boiler operation. Small amounts of other fuels such as furnace oil, kerosene and coal are also used.

Energy Saving Potential

The energy cost on product value in dairy industry is estimated to be around 5%. Energy saving potential for the sector is about 6% on electrical side and 14% on thermal side. The sector could saving a total amount of NPR 257 Million annually by implementing energy efficiency measures.

Summary

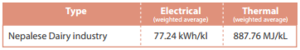

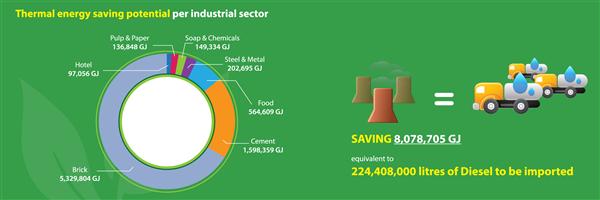

Through energy efficiency Nepalese industries could save about 160,000 MWh hours electricity every year which is equivalent to the annual consumption fo 215,000 Nepalese households. On thermal energy the saving potential is about 8 Giga Joule which is equivalent to the import of 215 Billion litres of Diesel. Converted into carbon emission a total amount of 136 ton of CO2 could be mitigated which is the same amount of carbon requested by 4 billion tree seedlings grown for 10 years.

References

- ↑ NEEP, 2012: Baseline Study of Selected Sector Industries to assess The Potentials for more Efficient use of Energy. Prepared by PACE Nepal for Nepal Energy Efficiency Programme (NEEP) of the Water and Energy Commission Secretariat (WECS), supported by German Development Cooperation GIZ. Retrieved from: http://wecs-neep.gov.np/downloadthis/120220_baseline_report.pdf