Difference between revisions of "Control Equipment - Hydropower"

***** (***** | *****) |

***** (***** | *****) m |

||

| Line 1: | Line 1: | ||

| − | == Controller: <br> | + | == Controller: <br> == |

<!--[if gte mso 9]><xml> | <!--[if gte mso 9]><xml> | ||

| Line 6: | Line 6: | ||

<o:shapelayout v:ext="edit"> | <o:shapelayout v:ext="edit"> | ||

<o:idmap v:ext="edit" data="1"/> | <o:idmap v:ext="edit" data="1"/> | ||

| − | </o:shapelayout></xml><![endif]--> <!--StartFragment--> | + | </o:shapelayout></xml><![endif]--><!--StartFragment--> |

| − | <span id="1274973221030S" style="display: none | + | <span id="1274973221030S" style="display: none"> </span> |

=== <!--[if gte vml 1]><v:shapetype id="_x0000_t75" coordsize="21600,21600" | === <!--[if gte vml 1]><v:shapetype id="_x0000_t75" coordsize="21600,21600" | ||

| Line 36: | Line 36: | ||

o:title="CIMG1955" cropleft="11224f" cropright="15384f"/> | o:title="CIMG1955" cropleft="11224f" cropright="15384f"/> | ||

<w:wrap type="square"/> | <w:wrap type="square"/> | ||

| − | </v:shape><![endif]--><!--[if !vml]--><!--[endif]--><span lang="DE" style="font-size: 11pt; font-family: | + | </v:shape><![endif]--><!--[if !vml]--><!--[endif]--><span lang="DE" style="font-size: 11pt; color: black; font-family: tahoma">Function principles:</span><span lang="DE" style="font-size: 11pt; color: black; font-family: tahoma">[[Image:Mhp-scheme.jpg|right|558x386px|Elements of a Micro Hydro Power Scheme]]</span> === |

| − | Load- or Flow- controller ensure that the power output does not exceed the power demand (e.g. 230V, 50 Hz). <br> If flow of water in a MHP-station is constant the energy output of a turbine/generator is constant as well. Power demand is usually fluctuating over the time (e.g. day/night). If supply is higher than demand, excess energy must be diverted, dumped. alternatively the water flow can be reduced which results in less power output. <br> In case of more power demand than supply the controller cuts of the of demand line. <br> Load controller are placed between generator output and the consumer line.<!--EndFragment--> <span lang="DE" style="font-size: 11pt; font-family: | + | Load- or Flow- controller ensure that the power output does not exceed the power demand (e.g. 230V, 50 Hz). <br>If flow of water in a MHP-station is constant the energy output of a turbine/generator is constant as well. Power demand is usually fluctuating over the time (e.g. day/night). If supply is higher than demand, excess energy must be diverted, dumped. alternatively the water flow can be reduced which results in less power output. <br>In case of more power demand than supply the controller cuts of the of demand line. <br>Load controller are placed between generator output and the consumer line.<!--EndFragment--> <span lang="DE" style="font-size: 11pt; color: black; font-family: tahoma" /> |

| − | |||

| − | <br> | + | <br> |

| − | <br> | + | <br> |

| − | <br> | + | <br> |

| − | <br> | + | <br> |

<!--[if gte mso 9]><xml> | <!--[if gte mso 9]><xml> | ||

| Line 54: | Line 53: | ||

<o:shapelayout v:ext="edit"> | <o:shapelayout v:ext="edit"> | ||

<o:idmap v:ext="edit" data="1"/> | <o:idmap v:ext="edit" data="1"/> | ||

| − | </o:shapelayout></xml><![endif]--> <!--StartFragment--> | + | </o:shapelayout></xml><![endif]--><!--StartFragment--> |

| − | === <span lang="DE" style="font-size: 11pt; font-family: | + | === <span lang="DE" style="font-size: 11pt; color: black; font-family: tahoma">Controller Types</span> === |

==== Load controller: ==== | ==== Load controller: ==== | ||

| − | [[Image:Controler.jpg|right| | + | [[Image:Controler.jpg|right|349x141px|Controler.jpg]] |

Electronic circuit, which keeps output power constant in Frequency- and Voltage- parameters. | Electronic circuit, which keeps output power constant in Frequency- and Voltage- parameters. | ||

| Line 76: | Line 75: | ||

Nowadays flow control is done mostly via electronics (which steer a valve) | Nowadays flow control is done mostly via electronics (which steer a valve) | ||

| − | [[Image:Flow-control.jpg|left|650x264px|principle flow control]] | + | [[Image:Flow-control.jpg|left|650x264px|principle flow control]] |

| + | |||

| + | [[Category:Hydro]] | ||

Revision as of 11:04, 16 June 2010

Controller:

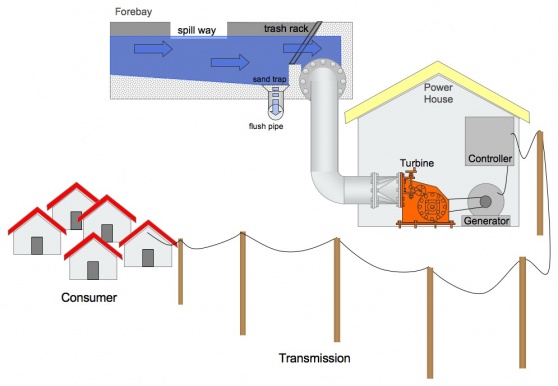

Function principles:

Load- or Flow- controller ensure that the power output does not exceed the power demand (e.g. 230V, 50 Hz).

If flow of water in a MHP-station is constant the energy output of a turbine/generator is constant as well. Power demand is usually fluctuating over the time (e.g. day/night). If supply is higher than demand, excess energy must be diverted, dumped. alternatively the water flow can be reduced which results in less power output.

In case of more power demand than supply the controller cuts of the of demand line.

Load controller are placed between generator output and the consumer line.

Controller Types

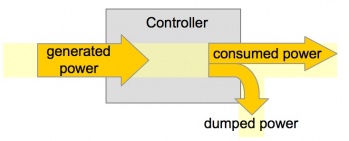

Load controller:

Electronic circuit, which keeps output power constant in Frequency- and Voltage- parameters.

Fluctuating energy demand requires a mechanism which either regulates the water input into the turbine (= flow control) or by diverting excess energy from the consumer connection (= ballast load).

Ballast load

usually electrical heaters in water or air. If energy demand is temporarily low the excess energy is converted into heat.

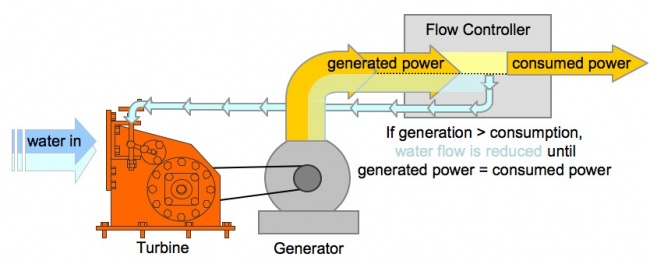

Flow control

regulates the amount of water into the turbine in order to match power output and power demand.

Nowadays flow control is done mostly via electronics (which steer a valve)