Cold Storage of Agricultural Products

Introduction

Roughly 30% of food that is consumed in developing countries is perishable[1]. Cold storage facilities are crucial to minimize post-harvest losses; however, losses occur at every step in the post harvest cycle, and therefore cold storages cannot be considered as independent solutions to prevent post harvest spoilage but as one component that needs to be integrated in a cold chain network from the point of harvest to the point of purchase by the end consumer[1]

The different stages in the post-harvest cycle can be summarized as:

- harvest

- precooling

- transportation & packaging

- cold storage

- display at the market

During these different stages, not only temperature control, but also proper and minimal handling of produce including handling, cleaning, sorting and adequate packing is crucial[1].

Additionally, socioeconomic factors add to the post harvest loss issue: the lack of marketing systems, transportation facilities and market information are key hindering factors. Also, government regulation, often intended to keep prices low for consumers or to ensure a certain minimum price for farmers, can be counterproductive regarding incentivizing the production of high quality produce. Often, simply the required equipment, such as harvesting tools, containers, cleaning, packing and cooling equipment are not available. Furthermore, the knowledge on post harvest handling and marketing of farmers and other actors handling the produce, for example during transport, is generally very limited leading to suboptimal treatment of the produce[2].

Harvest, handling and transport

Adequate and proper harvesting and handling of fresh produce are crucial preconditions for long storage and shelf lives of fruit and vegetables[3]. Considering the harvesting and subsequent handling stage of produce, the thumb rule of, the less the better should be followed, in order to minimize chances of mechanical injuries of produce[4]. Once damaged, shelf life is considerably compromised.

Harvesting principles:

For harvest procedures the subsequent points are important to consider:

- choosing the correct harvest time refers to both the ripeness and maturity of the produce as well as the right time of the day. Optimal harvest times for most produce is either early morning hours or the evening when temperatures are lower[5]

- harvesting of delicate, high value produce is best done manually (especially when labor costs are low and fuel costs are high[4]

- do not place produce on the ground directly, but use harvesting mats or containers/baskets instead[6]

Considering the handling of harvested produce, the following points are important:

Handling:

- before being put into storage, produce should be sorted and graded with regards to quality (only high quality produce should enter the storage facility)[4]

- produce needs to be cleaned (with clean water in order to avoid the spread of molds and fungi) before being put into storage containers and entering the storage rooms. Dirt bears the potential of introducing pests into the storage facility[6]

- time span between harvest and the placement into storage needs to be kept as short as possible[4]

Transport:

For the transport of fresh produce, the following points need to be considered:

- trucks, carts, etc. should not be overloaded to avoid damage[4]

- use high quality packaging that will withstand the transport[4]

Temperature Control - Cold Storage

Fresh food products are characterized by their perishability, and levels of vulnerability to pests and spoilage; however, in general the control of temperature and relative humidity and the prevention of damage can increase shelflife, especially of fresh vegetables and fruits, tremendously. Biological deterioration, caused by respiration rate, ethylene production, mechanical injuries, water stress, physiological disorders and pathological breakdown, leads to decay, loss in nutritive value, and changes in color, texture and flavor. Factors influencing the rate of deterioration are temperature, the level of relative humidity, air velocity, atmospheric composition, i.e. concentration of oxygen, carbon dioxide and ethylene, as well as sanitation[2].

Molding, pests and other spoilage reasons which lead to quality deterioration, such as loss of water, thrive under warm and humid conditions – conditions which can be commonly found in India. Most factors causing product deterioration can be addressed through temperature control, i.e. cooling. A reduction in temperature lowers rates of physiological change (respiration, ethylene production, and enzymatic processes) and slows down the growth of microorganisms (bacteria and fungi). Produce after the point of harvest is still ‘alive’ meaning that processes of the metabolism, such as respiration, as well as the activity of microorganisms remain ongoing leading to product deterioration[7]. In order to lower respiration rates, delay ripening and to reduce water loss temperature needs to be controlled, either by avoiding the exposure of heat or by creating cooling conditions thereby increasing a product’s shelf life. Adequate storage facilities can, to a certain extent, control factors such as temperature, relative humidity and air velocity, increasing product quality, shelf-life and value[8].

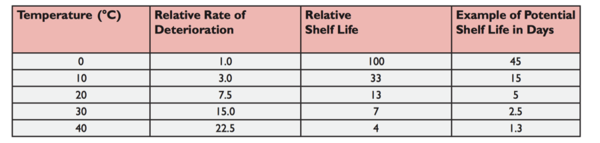

The table below demonstrates the effect of temperate control on shelf life of fresh produce. Temperature reduction, even if kept above the level of optimum storage conditions, can yield tremendous extensions of storage life. Accordingly, any form of cooling, such as moving produce to a shaded and ventilated area or choosing harvest hours in the early morning or evening, is beneficial[9].

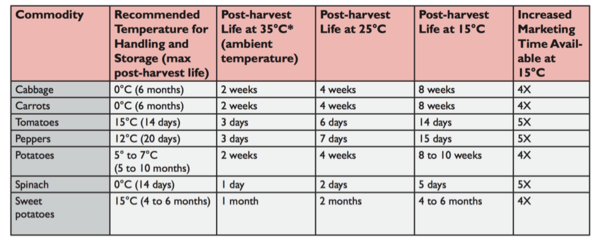

After produce has been pre-cooled, it needs to be transported and put into a cold storage facility where, in order to maximize shelf-life and quality, it should be stored at its optimum storage temperature which varies according to different items making the storage of several items in one facility problematic if multiple storage chambers are not available. Storage and shelf life depends on intrinsic characteristic of items stored as well as the storage conditions.

In general, the optimum storage temperature is as low as possible but still above the level of chilling sensitivity of the respective crop. Another important factor affecting shelf-life of fresh produce is the level of relative humidity, impacting water loss, decay, physiological disorders, and the uniformity of ripening. Relative humidity levels should be high and saturated for most types of produce[7]. Finally, ethylene also impacts shelf life: whilst some items are ethylene producers after harvest, other crops are sensitive to ethylene exposure[10]. Subsequntly, if produce cannot be stored separately, their requirements regarding temperature, relative humidity and ethylene production/exposure need to be considered.

According to the Postharvest Centre of California[11], for the sake of short-term storage or transport, three groups of produce can be kept together:

1. most leafy vegetables, cole crops, fruits and berries from temperate climates

- 0°-2°C, 90%-98% relative humidity

2. citrus fruits, most tropical fruits, many fruit-type vegetables

- 7°-10°C, 85%-95% relative humidity

3. root-type vegetables, winter squashes, most tropical fruits and melons

- 13°-18°C, 85%-95% relative humidity

More detailed information on optimum storage conditions for specific items can be found here.

In the Indian context, the Indian National Board for Horticulture has divided produce into 7 categories according to optimum storage temperature and relative humidity. The categories can be found here.

Cold Storage Technologies for Small-scale Production

Cooling and cold storage are very energy intensive and expensive undertakings that require reliable electricity supply. This precondition is often not given and capital and running costs for farmers in developing countries are generally too high. Hence, unbroken cold chains and the use of appropriate cold storage facilities are generally not accessible for small-scale farmers[1] [12].

Below, several low technology options are being presented that can operate in electricity scarce regions and are feasible for small-scale farming operations:

| Technology | Description | Temperature provided | Fuel |

| passive/evapaorative cooler[1][13] | works in naturally dry areas without the input of energy | 10-25°C |

|

| absorption refrigerator[1] | heat-driven technology | below 10°C |

|

| refrigerators[1] | electricity-driven and therefore dependent on reliable electricity supply | 0°C |

|

There are multiple factors to consider in the technology and site selection of a cold storage facility:

- Location: the location chosen should be easily accessible and close to market hubs and/or produce collection points[9]

- Electricity: the access to and the supply of electricity to the cold storage facility should be given. Electricity supply has an impact on the size and equipment feasible of the cold storage[9]

- Drainage and waste disposal: good drainage options and waste management equipment needs to be readily available[14]

- Water: supply of water is important for matter of sanitation. Also the removal of wastewater generated has to be given[9]

- Economic viability: the value generated though cold storage needs to justify investment and running costs[9]

In general, choosing an appropriate cold storage technology depends on the temperatures and level of reliability required, resources available – including skilled labor, capital, electricity and water supply[13]

Cold Storage Management

Temperature control can have huge benefits for the improvement of shelf-life and product; however, benefits will only realize if the cold storage is managed properly with regards to temperature, relative humidity levels, air circulation, adequate space between storage bins, trays and containers, the mixing of compatible produce, as well as the management of product in and outflow which should follow the ‘First In, First Out’ principle[9].

The following points should therefore be considered:

Temperature management

According to information of the FAO[9], cold storage facilities should be cooled to the storage temperature required at least three days before produce is being entered.

Chilling injury

Some produce, especially of tropical origin, is sensitive to chilling, which means that it will incur physiological damages if stored at a certain time period below a certain temperature but above their freezing points. In general, the longer the time period that produce is exposed to temperature below their level of chilling sensitivity and the lower the temperature, the faster damages will occur. It should also be noted that effects can be of a cumulative nature, i.e. the time periods of storage below the level of chilling sensitivity add up even if produce is stored at optimal conditions in between. Several factors, such as the level of maturity and level of ripeness at the point of harvest can affect chilling sensitivity[9].

Common visual symptoms:[9]

- Surface lesions (pitting, large sunken areas and discoloration)

- Water soaking (disruption of cell structure and accompanying release of substrate favors the growth of microorganisms)

- Internal discoloration of the pulp

- Failure to ripen in the expected pattern

- Accelerated rate of senescence

- Increased susceptibility to decay

- Compositional changes

Freezing injury

Below 0°C all type of produce freezes due to dissolved soluble solids which are present in cell saps. Often, damages incurred through freezing only become visible once the produce is returned to temperatures above 0°C[9].

Symptoms:[9]

- Waterlogging

- Glassy areas in the flesh

Storage mix

Different produce has different storage demands with regards to factors, such as optimum temperature, level of relative humidity, levels of ethylene production and sensitivity, and chilling sensitivity. Hence, the storage of single commodities is less complex than the storage of multiple commodities; however, the latter can still be the more viable option depending on external circumstances. Besides damages due to mismatches in temperature, also odors can be transmitted and ripening and decay can be affected through the exposure to ethylene, which can result in changes in color, flavor and texture. Further, only high quality produce should be ‘allowed’ in the cold storage and produce should be sorted accordingly[9]

Examples of odor transfers which should be avoided:

- apples/pears with celery, cabbage, carrots, potatoes or onions

- celery with onions or carrots

- citrus with strongly scented vegetables

- pears/apples with potatoes à former acquire unpleasant taste

- green pepper will taint pineapples

- onions, nuts, citrus, potatoes should be stored separately

Examples of ethylene producing and ethylene sensitive products:

- Ethylene producing: e.g. apples, avocado, bananas, pears, peaches, plums, tomatoes

- Ethylene sensitive produce: e.g. lettuce, cucumbers, carrots, potatoes, sweet potatoes

Stacking

Adequate airflow and the even distribution of cold air need to be ensured[9]. It is important to note that air always takes the path where resistance is lowest, and hence partly or unevenly filled storage facilities will have poor cooling rates[3]. The following points should be considered:

- A gap of at least 8 cm between walls and the floor, and the stacks of produce should be kept in order to ensure air flow

- Well-ventilated storage boxes/containers/crates will improve cooling speed, such as PVC crates or ventilated boxes made of cardboard[3]

- adequate space in between storage pallets should be about 4-6 inches[3]

Operation and maintenance

Cold storage is a very costly and energy intensive undertaking and therefore the door to the cold storage should be opened as few times as possible and that also in the early morning or evening hours[6]. Also the usage of lighting and fans should be kept at a minimum[4]. Further points should further be considered:

- Logbook: operators should keep track of incoming and outgoing, as well as produced stored, including anticipated arrival time, quantity, quality, anticipated storage time, storage conditions required, sales price on day stored, actual sales price, energy consumed, etc. of new produce[9] [6].

- Inventory: an up-to-date inventory should be kept including information about location within cold storage, type, quantity and harvest date of produce, use of pre-cooling method, date produce entered the facility, etc.

- Loading: in general, loading rates should be 4-5% of total capacity. The cold storage should be divided in areas for short-term and longer-term storage space [3] [6]

Hygiene

In order to prevent pathogen built-up within the facility, strict hygiene measures are pivotal. All hygiene measures have to take necessary safety measures for staff into consideration.

- Clean thoroughly at the end of each season: wash walls and floor with sanitizers, such as hypochlorite solution[9]

- Use of ozone generators to prevent molds and fungi[9]

- Regular ventilation to avoid built-up of ethylene, carbon dioxide and odors[9]

Further Information

- Importance of Cold Storage

- Small-scale Cold Storage For Fruit and Vegetables in India

- Pre-cooling of Agricultural Products

- Powering agriculture portal on energypedia

References

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 1.6 GIZ-HERA (2011) Modern Energy Services for Modern Agriculture – A Review of Smallholder Farming in Developing Countries. Available from: http://www.water-energy-food.org/documents/giz/energy-services-for-modern-agriculture.pdf

- ↑ 2.0 2.1 Kader, A. A. (2005) Increasing Food Availability by Reducing Postharvest Losses of Fresh Produce. In: Mencarelli, F. and Tonutti, P. (eds.). V International Postharvest Symposium. Verona, Italy

- ↑ 3.0 3.1 3.2 3.3 3.4 National Horticulture Board (2010) Cold Storage for Fresh Horticulture Produce Requiring Pre-cooling before Storage. Haryana: Cold Chain Development Centre National Horticulture Board

- ↑ 4.0 4.1 4.2 4.3 4.4 4.5 4.6 USAID (2009) Empowering Agriculture – Energy Options for Horticulture. [Online] Available from: http://ucce.ucdavis.edu/files/datastore/234-1386.pdf Cite error: Invalid

<ref>tag; name "USAID, 2009" defined multiple times with different content Cite error: Invalid<ref>tag; name "USAID, 2009" defined multiple times with different content Cite error: Invalid<ref>tag; name "USAID, 2009" defined multiple times with different content Cite error: Invalid<ref>tag; name "USAID, 2009" defined multiple times with different content Cite error: Invalid<ref>tag; name "USAID, 2009" defined multiple times with different content Cite error: Invalid<ref>tag; name "USAID, 2009" defined multiple times with different content - ↑ Thompson, J. F. (n.d.) Pre-cooling and Storage Facilities. [Online] Available from: http://www.ba.ars.usda.gov/hb66/precooling.pdf

- ↑ 6.0 6.1 6.2 6.3 6.4 SUSTAIN (n.d.) Operational Manual for Cold Storage

- ↑ 7.0 7.1 FAO (2004) Manual for the preparation and sale of fruits and vegetables – From field to markets, Rome: FAO, Available from: http://www.fao.org/docrep/008/y4893e/y4893e00.HTM

- ↑ Worldbank (2011) Case study: Waste to Wealth by Incubating Mini Cold Storage Technology Ventures in India [Online] Available from: http://siteresources.worldbank.org/INTARD/Resources/335807-1338987609349/IndiaCaseStudy.pdf [accessed: 17th August 2014]

- ↑ 9.00 9.01 9.02 9.03 9.04 9.05 9.06 9.07 9.08 9.09 9.10 9.11 9.12 9.13 9.14 9.15 9.16 FAO (2009) Horticultural Chain Management for Countries of Asia and the Pacific Region. [Online] Available from: http://www.fao.org/3/a-i0782e/ Cite error: Invalid

<ref>tag; name "FAO, 2009" defined multiple times with different content Cite error: Invalid<ref>tag; name "FAO, 2009" defined multiple times with different content Cite error: Invalid<ref>tag; name "FAO, 2009" defined multiple times with different content Cite error: Invalid<ref>tag; name "FAO, 2009" defined multiple times with different content Cite error: Invalid<ref>tag; name "FAO, 2009" defined multiple times with different content Cite error: Invalid<ref>tag; name "FAO, 2009" defined multiple times with different content Cite error: Invalid<ref>tag; name "FAO, 2009" defined multiple times with different content Cite error: Invalid<ref>tag; name "FAO, 2009" defined multiple times with different content Cite error: Invalid<ref>tag; name "FAO, 2009" defined multiple times with different content Cite error: Invalid<ref>tag; name "FAO, 2009" defined multiple times with different content Cite error: Invalid<ref>tag; name "FAO, 2009" defined multiple times with different content Cite error: Invalid<ref>tag; name "FAO, 2009" defined multiple times with different content Cite error: Invalid<ref>tag; name "FAO, 2009" defined multiple times with different content Cite error: Invalid<ref>tag; name "FAO, 2009" defined multiple times with different content Cite error: Invalid<ref>tag; name "FAO, 2009" defined multiple times with different content - ↑ University of California (2011) Compatibility Chart for Short-term Transport or Storage. Accessible from: http://postharvest.ucdavis.edu/produce_information/CompatibilityChart/

- ↑ University of California (2012) Produce Facts in English. Available from: http://postharvest.ucdavis.edu/producefacts/

- ↑ Practical Action (2003) Evaporative Cooling, Available from: http://practicalaction.org/evaporative-cooling-1

- ↑ 13.0 13.1 Practical Action (2010) Refrigeration Developing Countries. [Online] Available from: http://practicalaction.org/refrigeration-in-developing-countries-1

- ↑ Bank of India (n.d.) Cold Storage. [Online] Available from: http://www.bankofindia.co.in/english/coldstorage.aspx