Lighting Technologies

Overview

This article presents a short overview of the terms used to describe lighting technologies. A short overview of the terminology:

Luminous Intensity

Luminous intensity is a measure of the amount of light originated from the source, its light output, the unit of which is the candela (cd).

Luminance

Luminance is a measure of the brightness of a particular surface if considered as a large light source. A common unit of luminance is cd/m².

Luminous Flux

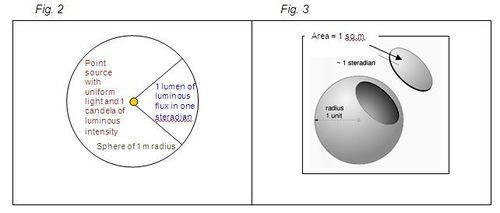

Luminous flux (or luminous power) is the quantity of light energy emitted in all directions. The unit of luminous flux is lumen (lm). One lumen is the luminous flux of the uniform point light source that has luminous intensity of 1 candela (cd) and is contained in one unit of spatial angle (or 1 steradian).

Steradian is the spatial angle that limits the surface area of the sphere equal to the square of the radius. If the radius of the sphere is 1 metre, which implies its area to be 4πr², then the luminous flux of the point light source of 1 candela is 4π lumens, as shown in Figures 2 & 3.

For instance, a light source can be emitting light with an intensity of one candela in all directions, or one candela in just a narrow beam (as in most LEDs). The intensity is the same but the total energy flux from the lamp, in lumens, is not the same. The output from a lamp is usually quoted in lumens, summed over all directions, together with the distribution diagram in candela.

Illuminance

Illumincance is a measure of the amount of light falling on a particular surface. Its unit is lux (lx), defined as equal to one lumen per metre squared (1 lm/m²). LUX meters are available in the market, which could be used by a lighting designer to measure the light falling on a given surface.

Repetitive Summary

- The intensity of a light source is measured in candelas;

- The total light flux in transit is measured in lumens (1 lumen = 1 candela X steradian);

- The amount of light received per unit of surface area is measured in lux (1 lux = 1 lumen/square meter).

Having considered the various aspects related to lighting terminology, it is important to get an impression about the typical lighting levels that are common in day to day life, as shown in Tab.1.

Tab.1: Typical lighting levels in day to day life

| Outdoor | Illuminance (lux) |

| Bright sun | 50,000 – 100,000 |

| Hazy day | 10,000 – 50,000 |

| Full moon | 0.05 - 0.2 |

| Indoor | Illuminance (lux) |

| Office or workshop | 200 - 300 |

| Reading Area | 300 - 500 |

| Class Room | 300 |

| Health Centres | Illuminance (lux) |

| Examination Area (Spot Light) | 500 |

| Surgery Room (Spot Light) | 2000 |

| Domestic Lighting | Illuminance (lux) |

| Living Room | 100 - 300 |

| Kitchen Working Area | 300 |

| Corridors | 50 - 100 |

| Good street light | 20 |

Lighting Technologies

Artificial light is produced by the user at the expense of some energy and it can be classified as

- flame-based lighting and

- electricity-based lighting.

Flame-based Lighting

Flame-bases lighting is related to the production of light from fire. Burning of carbon-based fuels such as wood, kerosene, vegetable oil, gas, wax, etc., to produce light is based on the principle of ‘incandescence’. Incandescent lamps in general and flame-based lighting in particular are not very energy-efficient, as most energy is lost in the form of waste heat. Furthermore flame-based lighting results in the production of unwanted pollutants, which can be harmful to health.

Electricity-based Lighting

Lamps that produce light, using electricity have now become the standard for modern lighting. Existing lamps can be categorized as detailed below.

Incandescent Lamps

Incandescent lamps are based on the principle of incandescence, where a filament is heated to produce light, such as in standard tungsten filament lamps. Their energy efficiency is comparably low. For instance, when a typical 100 W incandescent lamp is lit, only about 10 W of energy is converted to visible light, the rest is converted to waste heat.An improved type, namely, the Halogen lamps are high pressure, incandescent lamps that consist of a tungsten filament inside a quartz envelope, which contains halogen gases such as iodine and bromine that allow filaments to work at higher temperatures and higher efficiencies. In halogen lamps, the quartz envelope is closer to the filament than the glass used in conventional light bulbs. Heating the filament to a high temperature causes the tungsten atoms to evaporate and combine with the halogen gas. These heavier molecules are then deposited back on the filament surface. This recycling process increases the life of the tungsten filament and enables the halogen lamp to produce more light per unit of energy. Consequently, halogen lamps are used in a variety of applications, including automobile headlights. Halogen lamps that work on both A.C. and D.C. power, ranging from 6 V to 230 V are available today. But usually, these lamps get very hot while in operation. They are sensitive to voltage fluctuations. Some studies indicate that their life expectancy is decreased to 50% by 5% overvoltage (e.g.: 0.6V on 12V) and by about 75% by 10% overvoltage.

Gas Discharge Lamps

Gas Discharge Lamps are based on a glowing gas in a glass enclosure. Examples for this type are sodium, mercury vapour and mercury tungsten (blended) lamps.In these lamps, the atoms or molecules of a gas inside a glass, quartz, or translucent ceramic tube, are ionized by an electric current sent through the gas or by a radio frequency or microwave field in proximity to the tube. This results in the generation of light - usually either visible or ultraviolet (UV). The colour depends on both the mixture of gasses and other materials inside the tube as well as the pressure and type and amount of the electric current or RF power (Radio-frequency power). There are a variety of gas discharge lamps, which are available in different forms, as explained further on.

Fluorescent Lamps

Fluorescent lamps are a special class of gas discharge lamps. Their functioning relies on the principle of fluorescence: Inside the glass tube is a partial vacuum and a small amount of mercury. An electric discharge in the tube causes the mercury atoms to emit light. The emitted light is in the ultraviolet range and is invisible, and also harmful to living organisms, so the tube is lined with a coating of a fluorescent (phosphoric) material, which absorbs the UVand re-emits visible light.They are sensitive to the ambient temperature around them. 1% loss in light output can be expected for every 2°F (1.1°C) above the optimum ambient temperature of 76°F (25°C), in most of the fluorescent lamps. But they are definitely more efficient than the incandescent lamps. Hum and flicker might be a problem in some cases. Frequent switching on and off will reduce the life of a fluorescent lamp.

Compact Fluorescent Lamps (CFLs)

A CFL can be seen as an advanced version of a fluorescent lamp. The salient features of it are: It consists of a gas-filled glass tube with two electrodes mounted in an end cap. It contains a low-pressure mix of argon gas, mercury vapour, and liquid mercury, and is coated on the inside with three different phosphorous substances. The electrodes provide a stream of electrons to the lamp and the ballast controls the current and voltage flowing into the assembly. The ballast, in general an electronic circuit, may be attached directly to the lamp, or may be remotely connected. CFLs are compact and are ideal for use in homes, work areas, schools, workshops, etc. They are more energy-efficient than incandescent light bulbs using between one third and one fifth of the energy. They are sensitive to the ambient temperatures, just like the standard fluorescent lamps.The life of a CFL is significantly shorter if it is used only for a few minutes at a time. Lab tests demonstrated that lifespan can be reduced down to 15% in the case of a 5 minute on/off cycle.

Low Pressure Sodium Lamps

A low pressure sodium lamp consists of a tube made of special sodium-resistant glass containing sodium and a neon-argon gas mixture. These lamps usually require 5 to 10 minutes to warm up. This light is basically monochromatic orange-yellow. This monochromatic light causes a dramatic lack of colour rendition: everything comes out in an orange-yellow version of black and white. Hence, low pressure sodium lamps are not suitable for use in homes, offices, workshops, etc. But they are widely used for street lighting purposes.Low pressure sodium lamps are the most energy efficient visible light sources in common use. These lamps have luminous efficacies as high as 180 lumens per Watt, whereas a typical incandescent lamp has around 12 lumens per Watt and a standard fluorescent lamp has around 45 lumens per Watt.

Light Emitting Diodes (LEDs)

Light Emitting Diodes (LEDs) are semiconductor devices similar to p-n junction diodes, specially engineered to emit visible light of a particular wavelength, giving out a specific colour.On supplying electrical power to an LED, electrons are made to “fall” from a high energy level to a low energy level inside the semiconductor material, releasing some energy, which is perceived as visible light.LEDs are usually monochromatic and are very energy-efficient and therefore used extensively as indicator lamps on many electronic devices. Red, green, and orange LEDs as indicator lamps are usually well known. They are usually operated with no more than 20 – 70 mW of electrical power and not adequate for lighting purposes. However, the development of bright white LEDs advanced rapidly in recent years and is achieving fast access to the market. In 1999, the first 1 W white LEDs came on the market. In 2002, first 5 W models were available.Parallel to this augmentation of the total power there has been also a dramatic increase in the luminous efficacies (see chapter 3.3) of LEDs during the past few years. Today the LEDs attain similar efficacy as CFLs and it is projected to increase further. In the last years, the price of bright white LEDs has fallen drastically and their availability increased considerably. Hence, LEDs are now used in many appliances like torches, bicycles and car lighting and are considered more and more for main stream lighting purposes.

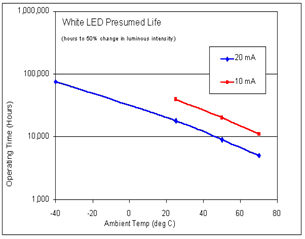

LEDs have a longer life than the incandescent lamps and all types of gas discharge lamps. As they are solid-state devices, theoretically they offer operating periods of 100,000 to 150,000 hours. But they are the same time sensitive to ambient temperatures what caused some problems in first projects on LEDs as lighting devices in the tropics. A study by Lumitex Inc., U.S.A, indicates a substantial fall in the life of an LED, at elevated ambient temperatures (Fig. 4). Hence, special care must be taken to house LEDs properly, to ensure expected life. Life here implies, the time taken for the light output to fall to its 50% value, when compared to its initial light output.

Fig. 4: Relation between ambient temperatures and LED life

LEDs due to their construction emit light only in one direction and hence are more effective in task based or focussed lighting such as in table lamps, torch lights, etc.More information on LED lighting is provided in the Lighting Africa Briefing Note: Light Emitting Diode (LED) Lighting Basics.

Synopsis of Efficiency and Costs of Various Lighting Technologies

Having analysed the various technical factors governing the lighting technologies, both flame-based as well as electricity-based ones, it is now worthwhile to have a brief synopsis focussing on efficiency and costs of all the lighting technologies in a single table, as shown in Tab. 3. Some details are discussed in the following paragraphs.

Power of the Lighting Device

In tab. 3, the 3rd column represents the power consumption of the lighting device. For flame based lighting systems, power of the device is calculated as shown here:

Power of the device (in Watts) =

Fuel consumption per second in litres or kgs X Energy Content of the fuel in Joules/litre or Joules/kg

The energy content of various fuels can be derived from tab. 2.

Tab. 2: Typical energy content of different fuels

| Fuel | Energy Content (MJ/kg) |

| Wax | 36.0 |

| Kerosene | 45 |

| LPG | 45 |

| Biogas | 27.7 |

| Propane | 42.5 |

| Butane | 43.3 |

| Natural gas | 46.4 |

| Dry Wood | 15 |

The fuel consumed by the lighting device in question per hour may be figured out by performing a test to find out the fuel consumed within 1 second.

The energy content of various fuels is the standard data provided by the research institutes, and may not be always available from the suppliers of fuels. Tab. 2 lists the typical values of the energy content of various fuels, expressed in mega joules per kg or litre (1 mega joule = 1000000 joules). If the fuel consumption is expressed in litres per second, then, the energy content should be expressed in joules per litre. If this is expressed in kg per second, the energy content of the fuel should be expressed in joules per kg.

Example: Power of the candle (as shown in Tab. 3)

The wax used = (0,0055 kg/hour), hence, wax used per second = 0,0055/3600 in kg.

The energy content of wax = 36 X 1000 000 joules.

Hence, the power consumption of the candle = (0,0055 /3600) X 36 X 1000 000 = 55 W

Example: Power of the kerosene lamp (as shown in Tab. 3)

The kerosene used = (0,03 lt/hour), hence, kerosene used per second = 0,03/3600 in kg.

The energy content of kerosene per litre = 36 X 1000 000 joules.

Hence, the power consumption of the kerosene lamp = (0,03 /3600) X 36 X 1000 000 = 300 W

| Type of Lamps | 'Power'Consumption (W) | Luminous Flux (lm) | 'Efficacy'Lm/W | 'Life'(h) | 'Typical Unit[1]Price'(US $) | 'Annual Lamp/ Unit Costs'(1825 hrs/yr) (US $) (A) |

'Annual Maintenance Costs'(US $) (B) | Annual Energy Costs'(US $)'(C) | Annual Operating Costs'(US $)'(A+B+C) | Annual Operating Costs (US $) (A+B+C)(Renewable Electricity[2]) |

| Candle | 55 - 72 | 1 - 16(10) | 0.02 – 0.22 | 1 | 0,15 | 273,8 | 0 | 0 | 273,25 | 273,25 |

| Kerosene/Oil(Wick:2.7 mm thick and 95 mm of inside diameter) | 200 – 488(300) | 10 –100(50) | 0.05 – 0.21 | 5,500[3] | 6,0 | 1,99 | 8 ($0.5 X 12 = wick + $1 X 2 = glass) |

21,9 (0.03 ltr /hr @ $0.40 / ltr) |

31,89 | 31,89 |

| Liquified Petroleum Gas (LPG) | 350 - 425 | 330 – 1000(750) | 0.94 – 2.35 | 7,500[4] | 20,0 | 4,867 | 8($0.5 X 12 = mantle+ $1 X 2 = glass) | 27,375(30 gm /hr @ $0.50 / kg) | 40,242 | 40,242 |

| Incande-scent | 100 | 1200 | 12 | 1,200 | 1,5 | 2,28 | 0 | 12,78 ( $0,07/ kWh) |

15,06 | 40,62 ( $0,21/ kWh) |

| Halogen | 25 | 500 | 20 | 2,000 | 6,5 | 5,931 | 0 | 3,194 ( $0,07/ kWh) |

9,125 | 15,513 ( $0,21/ kWh) |

| Floures-cent(Ballast)26 mm tube diameter | 18 | 750 | 45 | 8,000 | 17,0 | 3,878 | 0 | 2,30 ( $0,07/ kWh) |

6,178 | 10,778 ( $0,21/ kWh) |

| Compact Floures-cent | 5 | 280 | 56 | 9,000 | 8 | 1,622 | 0 | 0,638 ( $0,07/ kWh) |

2,26 | 3,536 ( $0,21/ kWh) |

| LED (5mm)(WhiteUltra bright) | 1 | 20 | 20 | 20,000[5] | 10 - 15(12.5) | 1,14 | 0 | 0,128 ( $0,07/ kWh) |

1,268 | 1,524 ( $0,21/ kWh) |

----

Luminous Performance or Efficacy

Luminous Performance is a measure of the efficiency of a device in converting electrical power to visible light and is measured in lumens/watt or lux/watt. As mentioned earlier, the low pressure sodium lamps have the highest luminous efficacy, followed by LEDs, fluorescents, and incandescents. Table 4 gives a comparative view of different lighting technologies.

Flame-based lighting has the worst luminous efficacy. A typical kerosene lamp with wick has a luminous efficacy of 0.1 lm/W and it is about 0.11 lm/W for a typical wax based candle. Kerosene pressure lamps might offer 1 to 2 lm/W and LPG (liquefied petroleum gas) lamps are a little better with about 1 to 2.5 lm/W, followed by biogas lamps that offer 0.5 to 0.9 lm/W. Also flame based lighting results in many other ill effects, causing indoor air pollution. Typical luminous efficacies for various lighting options are cited in Tab. 3.

Life of a Device

Life of a device is another important parameter to consider, while deciding on lighting technologies. Life of a lighting device is the number of total operating hours that the device can function satisfactorily. A wax candle of the type mentioned in Tab. 3 might last for an hour, while a typical kerosene lamp, shown in Tab. 3 might last for 5500 hours. Assuming the device to be used for 5 hours a day, this amounts to (5500/5 = 1100 days) or about 3 years of satisfactory operation of the kerosene/hurricane lamp.

Typical Unit Price

Usually, a lighting device is a unit complete with necessary accessories. While specifying lamp prices, it is better to consider unit prices rather than just the lamp prices. For instance, a kerosene lamp may have the frame, a glass chimney, a wick, etc. whereas an incandescent lamp may have a lamp holder. Fluorescent lamps use a frame, a starter, a ballast, besides the lamp. A CFL may have a ballast and a holder. An LED light system typically has a circuit board with some electronic components, besides the LED or LEDs.

As a lighting device is a total unit composing of these various components, it is always necessary to find out the total unit price. The prices are expressed in U.S. dollars for ease of use, as a standard unit of currency, in this document.

Annual Operating Costs

To take a sensible decision on choosing an appropriate lighting technology for a given situation, one of the most important criteria is the annual operating costs, which is the total amount of money one has to spend in one year to have the said benefits of lighting. The cost analysis is explained in the following chapter, in detail.

SCOPE – A Layman’s Approachfor Appropriate Lighting Design

Designing a lighting system appears complex and hence, it is better to have a systematic approach to arrive at a fair conclusion. Here, a simple practical approach to designing an optimum lighting system for a given setting is explained by five successive steps, namely, SCOPE. This approach might be adopted by any ordinary lighting designer aiming to provide adequate lighting for locations such as a house, health centre, school, streets, etc. The following paragraphs explain the approach in detail.

- Specify the need

- Consider the lighting options

- Opt for an ideal lamp type

- Preview the costs involved

- End up deciding on an appropriate technology

Specify the Need

Firstly, it is important to specify the amount of light required. The lighting designer may consider the application – intended lighting area and decide on how much light is required for that situation. Tab.1 would assist in specifying the required amount of light in lux.

Consider the Lighting Options

In general, electricity-based lighting is the better option compared to flame-based lighting. But it is always possible to check on how much one has to spend in both of the cases, flame-based as well as electricity-based lighting options.

As discussed earlier in this document, lamps of different types have their respective luminous efficacies. Some of them are shown in Table. 4

To achieve the 300 lux required by the user, one may consider the following options for electricity-based lighting:

Incandescent Lamp:

Required light = 300 lux

Lamp’s Power = 100 W

Luminous efficacy of the lamp (from the Tab.4) = 12 lumens/Watt

Hence, the light output from the lamp =

Luminous efficacy X Lamp’s Power =

12 X 100 = 1200 lumens.

For instance, if the lamp is fixed on the roof or wall at a distance of about 2 metres from the surface to be illuminated, then, the total light falling on the surface to be illuminated is given by:

Light output from the lamp at source /

Square of the distance between the light source and the surface to be illuminated

Tab. 4: Luminous Efficacies of different lighting options

| Type of Lamp | Luminous Efficacy (lm/W) |

| Flame Based Lamps | |

| Kerosene Lantern | 0.05 – 0.21 |

| Kerosene Pressure Lamp | 0.39 – 1.60 |

| Candle (Wax) | 0.02 – 0.22 |

| Gas Lamp (LPG) | 0.94 – 2.35 |

| Biogas Lamp | 0.48 – 0.94 |

| Electricity Based Lamps | |

| Incandescent Lamp (100 W) | 12 - 15 |

| Halogen Lamp (25 W) | 20 - 30 |

| Fluorescent Tube (13 W) | 45 - 60 |

| Fluorescent Lamp | 56 - 60 |

| Compact Fluorescent Lamp | 50 - 90 |

| Metal Halide | 80 - 120 |

| High Pressure Sodium | 80 - 130 |

| Low Pressure Sodium | 90 - 220 |

| Light Emitting Diode Lamps | 25 - 150 |

In the above case, the total light falling on the surface to be illuminated would now be: 1200/2 sq.m = 1200/4 = 300 lumens. But these 300 lumens can be made to be concentrated on an area of 1 sq.m or more area. Luminaires (light concentrators) concentrate the light emitted by a lamp in the required direction. If a luminaire is used the light is distributed uniformly in the spectrum specified by the manufacturer. If - for instance - the area of the room is about 10 sq.m, then - without a luminaire - the amount of light falling on the surface to be illuminated in the current example would be: 300/10 = 30 lux.

As discussed, an incandescent lamp is the most inefficient of the electricity based lamp types, it may not be necessary to use a 100 W incandescent lamp with a luminaire to achieve the 300 lux mentioned in the current example.

It is indeed possible to consider various options to achieve the same results.

Calculation of Luminous Efficacy of an electricity based lighting device

If the power of luminous intensity of a lamp only is provided in candela (say for example, Φ cd), which is usually the case with most of the LED lamps, then, the following formula is applicable:

Light output in lumens: Luminous Intensity in candela X 4π ; (π ~ 3.14)

But it is important to note that the said amount of light output in lumens would be confined to the dispersion region specified for a lamp type. If it is an incandescent lamp, the total light output is equally distributed around the bulb (360° dispersion angle). In the case of fluorescents it might be a 180° dispersion angle. Whereas in the case of LED lamps, the light output might be confined to a very narrow beam of a dispersion angles ranging from 5°;to 180°. It can be seen from this that it is not possible to compare the overall lighting effect from lamps of different characteristics. If, for instance, an LED lamp provides light output in a narrow beam of 30° dispersion angle, then one may have to arrange about 6 LEDs in different positions to achieve 180° of total dispersion angle. But it is also possible to buy LEDs of 180° dispersion angle, where the light output is equally distributed around the lamp.

It must be noted here that all the luminous flux in lumens and the luminous intenstiy in candela disscussed here holds good for a (lamp to lighting area) distance of one metre. If the distance is different from this, it is possible to calculate the light output at the given position, using the following formula:

Light Intensity at source: Φ (cd)

Light intensity at a distance of ‘d’ metres away from the light source = Φ/d2(cd)

Calculation of Luminous Efficacy of a flame based lighting device

If the luminous efficacies are not specified by the manufacturer, which is usually the case with flame based lighting options, it might be possible to use the following procedure to find out the same:

[Also, it is possible to use the values from Table.3: (Energy content of a fuel in kWh = Energy content of the fuel in MJ / 3.6).]

Hence, the Power consumption/hour (in kilowatts or kW). = Energy content in kWh X δ

The amount of light output may be found out by using a standard LUX meter at the intended spot or area. Now, the luminous efficacy may be found out as shown here:

Luminous Efficacy (lm/W) =

Measured Illumination in Lux / Power consumption of the lamp in Watts

LUX meter can also be utilised to measure the illumination on a specified area from electricity based light sources, and thus calculate their luminous efficacies, using the same formula shown above.

To have a more generalised approach to obtain the required lighting levels, one may consider the following approach. (The letters in perenthesis are symbols):

(a) Power of the Lamp (S) in Watts

(b) Luminous efficacy (T) in lm/W

(c) Light flux or light output from the lamp = S X T in lumens

(d) Total surface area on which the light is falling is say, U sq.m,

(e) Light illumination on a given surface at 1 metre from the source = S X T/ U in lux.

(f)Light illumination on a given surface at ‘d’ metres from the source = (S X T)/(d²)(U) in lux.

Opt for an Ideal Lamp Type

Based on the procedures mentioned in the preceding paragraphs, it is easier to decide on a lamp type for a given situation. However, it should be noted that some lamps are best suited for certain applications.As a rule, fluorescents might be ideal for use in homes, work areas while Halogen lamps and LED based lamps might be ideal for focussed, task based lighting. Low pressure sodium lamps may be considered for parking areas. It is better to avoid the incandescent lamps as much as possible. It is also important to look at the availability of the lamp types in the market, for easy replacement.

Comparison of CFLs and LEDs

Both technologies are quite new, have similar efficacy and hence are the most important lighting technologies for projects that provide modern lighting services to the poor. Therefore the main differences are to be described.

Their efficacy (input of electrical power / light output) is similar.

LEDs are generally available as smaller units with less power. Typical characteristic values of CFLs are 5 to 11 W. Typical LEDs have 1- 5 W. Therefore – today - LEDs qualify for smaller application units.

In contrast to CFLs the LEDs emit light only in one direction and hence are more effective in task based or focussed lighting such as in table lamps, torch lights, etc.

For instance, a 0.3 W LED that delivers a luminous flux of only 10 lumens, which is only about 3.5% of the 280 lumens, delivered by a 5 W CFL, can offer double the illuminance (in lux) on a table or a book, when compared to the 5 W CFL.

CFLs are not suitable for use with frequently switching on and off.

The lower power requirements, higher durability and rapid advancements, are projected to offer competitive long-term operating costs, making LED technology more attractive for lighting solutions in the developing world.

Preview the Costs Involved

Having considered various selection criteria for different technologies, it is important to have a preview of the costs involved in considering a specific option. It would be of advantage to calculate the total operating costs for one full year, for each lighting option, which would reflect the cost of the lamp, cost of energy, cost of labour and maintenance, as shown in Tab. 5 (see attached excel calculation sheet).Tab. 5 serves as a guide with some typical lighting options, based on realistic values of the various specifications. The ultimate aim of Tab. 5 is to compute the annual operating costs of a lamp type.

Total Annual Operating Costs =

Lamp/Unit Costs / Year +

Maintenance Costs / Year +

Electricity/Energy Costs/ Year

- Lamp/Unit costs / Year: This is the amount spent on lamp units per year. Depending on the life of a lamp/Unit, the costs differ from lamp type to type. (Tab.5, No.12)

- Maintenance costs / Year: It is the amount spent on the lamp/unit, excluding the energy costs. In case of flame based lighting, this would mean the amount spent on wicks, glass cover, etc. In case of electricity based lighting, this might mean the lamp replacement cost, etc. (Tab.5, No.13)

- Electricity/Energy costs/ Year: It is the amount spent on energy consumed by the lighting device/unit in consideration in a year. (Tab.5, No.14)

To compute these three major components (a, b & c) that constitute the total operating costs per year, the following data has to be obtained from reliable sources for the lighting options considered:

For flame based as well as electricity based lighting options:

1.'Lamp/Unit Cost = (A) ($)

2.'Lamp Life in hours = (B)

3.'Lamp Operating hours/day = (C)

4.'Lamp Maintenance Cost/Year = (D) ($)

5.'Total Number of Lamps used = (E)

Only for Flame based lighting options:

6.'Average Fuel Cost /kg = (I) ($)

7.'Fuel Consumption/ hour/lamp = (J) kg

Only for Electricity based lighting options:

8.'Lamp Power = (F) Watts

9.'Average Electricity Cost /kWh = (G) ($)

Once these values are entered into their respective columns in Table.5, then, the total annual operating costs of a lamp type are computed automatically.

10.''Lamp/Unit Costs / Year (P)= (A X C X 365 X E)/ (B)

11. 'Lamp Maintenance Cost/ Year (Q) ($):

For instance, the kerosene lamp considered consumes one wick every month. Assuming the cost of a wick to be $ 0.50, the total amount spent on wicks in a year would be ($ 0.50 X 12 = $ 6). Also, assuming the cost of the glass cover to be $ 1, when the glass cover is to be replaced once in 6 months, then the total annual maintenance costs would be ($ 6 + $ 2 = $ 8). In the case of electricity based lighting options, some lamp replacement costs might apply, if the lamps are to be replaced in a public building, where an electrician is employed.

12. 'Electricity/Energy Costs/ Year

Energy costs are the most important recurring costs, which would increase with increasing load or with increasing power of the lamp in consideration.

For Flame based lighting systems,

Total Energy Cost / Year in ($) (J) =

(I X J X C X E X 365)

[(J) = (average fuel cost/kg X Fuel consumption/hour/lamp X Lamp operating hours per day X number of lamps used X 365 days) ].

For Electricity based lighting systems,

Total Electricity Cost / Year in ($) (H) =

(F X C X G X E X 365)/1000

[ (H) = (Lamp power in watts X lamp operating hours/day X Average electricity cost/kWh X Total number of lamps used X 365 days)/ 1000].

Some examples are shown in Tab. 5

Summary: End Up Deciding on an Appropriate Lighting Method

To summarise the steps explained in the previous sections:

- define the need.

- check what lighting options may or may not be considered looking at the light output and the general characteristics of the lamp in consideration, as well as the intended application, making sure that the lamp unit is affordable and spare parts are available in the local market/vicinity, for the initial investment.

- calculate the total operating costs of the lamp/unit per year, for the lamp type in consideration.

- calculate how much light output can be expected and how much would it cost the user.

- select the most suitable lamp type (if a gas lamp appears economical to a comparable electric lamp option, it would be good to choose the electric lamp, as there is no air pollution associated with the latter).

After deciding on the lamp type it would be helpful to list the parameters with the data obtained, as shown here:

- Amount of light considered

- Target Application area

- Source of Energy considered

- Lamp type considered

- Price/kWh of electricity or Price/litre or kg of fuel considered

- Price of lighting obtained/Operating costs per one year.

- Initial investment required for the lighting option.

Further Information