Enhancing Production of Improved Cookstoves (ICS)

==> Back to Overview GIZ HERA Cooking Energy Compendium

Identification of potential ICS markets

The inception study informs the planning process about many aspects:

• Potential project locations

• Potential implementation partners

• Potential useful technologies

• Potential production and marketing concepts

• Political frame conditions for ICS production and marketing

The result of the inception study needs to be verified by important stakeholders, which is usually done in a national stakeholder workshop. As a result of this workshop, potential ICS markets can be described by aspects of:

• Type of customer

• Geographical intervention area

• Characteristics of required technology

• Potential options for production and marketing

Sometimes it is useful to prepare such business cases already upfront and discuss and rank these scenarios at the stakeholder workshop.

It is important to bear in mind that a cooking systems is more than just a financial consideration. It often requires a change of behavior which is difficult to achieve.

The core question is “Why should poor people spend their little cash for an ICS?”

• Financial issues: Investment cost, cost of usage, durability;

• Convenience issues: handling, intensity of attention to the fire, traditional meals, size and height, emissions of heat/light/smoke;

• Status issues: design, modernity, aspirational products;

• Access and vulnerability issues: Can we trust this new product? What does it mean to me if I buy it and than it does not work/I cannot access the fuel (e.g. supply shortage of imported parts or fuels)?

This question has to be answered through the perspective of the potential buyers to investigate if there is a business case. User group discussions or test sales can assist to verify the strength of an ICS market case.

The potential ICS markets can be ranked in various dimensions:

• Purchase power of customer groups;

• Size of the market;

• Access of potential customers to the market / Difficulty to reach customers;

• Likeliness to find a product that suits the demand of the potential customers (existing product or need for product development);

• Competition on the market through other players;

• possibility to scale up existing efforts.

Based on these (and other) criteria, the potential ICS markets can be prioritized. However, it needs to be verified if the “best market” is also relevant from the perspective of the underlying development goals.

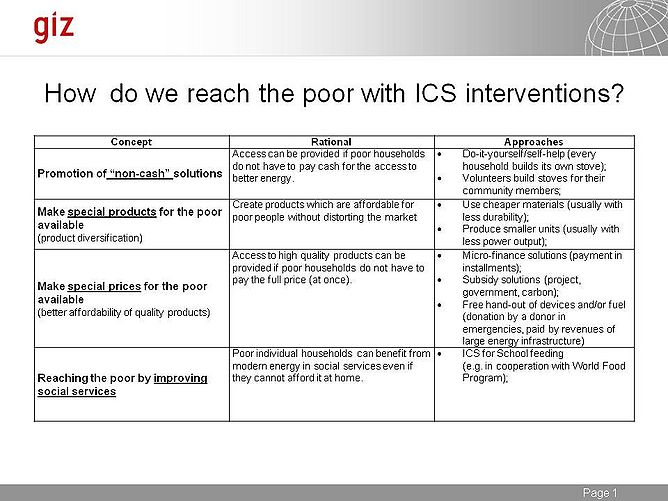

“How do we reach ‘the poor’ with our ICS interventions?”

Poverty reduction is the overarching goal of any development intervention. However, there can be huge difference between ‘directly addressing the needs of the poor’ and concepts where poverty reduction is an effect at the outer end of the result chain.

The first step is to agree who should be considered poor in the given environment. Usually there is a strata within “the poor” which can be instrumental in the process of identifying the right target group.

Generally, four concepts of how to address specifically very poor target groups can be distinguished:

1. Promotion of “non-cash” solutions

2. Make “special products” for the poor available

3. Make “special prices” for the poor available

4. Reaching the poor by improving social services

Each of these concepts has its specific rational and approaches.

At some stage there seems to be a trade-off between poverty orientation and sustainability. While “non-cash” self-help stoves and highly subsidized stoves may allow to reach fast many very poor people, the development of special products (to be sold at commercial rates) or the support through improved social services may result on the long run into more sustainable benefits for the poor.

Technology selection

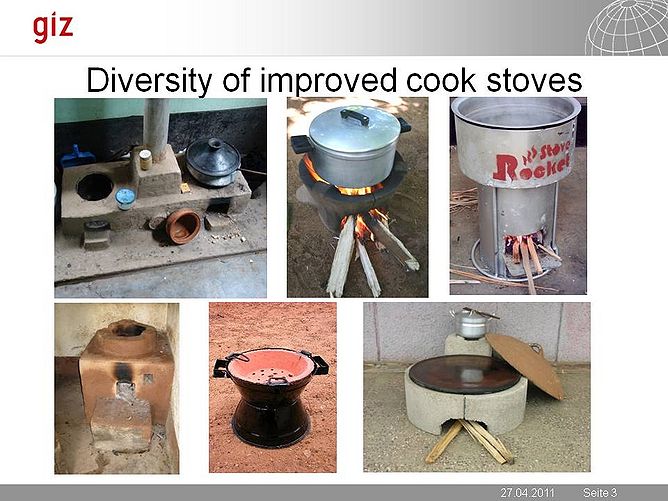

A wide range of improved cook stoves have been developed and disseminated in the past 30 years.

They differ in many aspects:

- Fuel: firewood, charcoal, other non-tree solid biomass, liquid biomass, gas from biomass, non-biomass fuels;

- Mobility: portable or fixed stoves

- Flames: one flame stove or multiple flame stove

- Pots: (a) ‘one pot only at a time’ or ‘multiple pots used at the same time’; (b) only usable for a specific pot (sunken pot concept) or usable for a variety of pot sizes and shapes;

- Material: (a) mud, fired clay, bricks, cement/concrete, metal, isolation materials (vermiculite, ceramic wool, refractory bricks, air…) (b) one material or material mix;

- Chimney: smoke reduction (without chimney) or smoke extraction (with chimney);

- Dimension: Tea preparation stove (for app. 1-2l), household size stove (for app. 3-15l), restaurant size (for app. 15-50l), large institutional stove (for app. 50-300l)

All these differences impact on the perception of the “convenience of use” by potential user groups.

An overview on ICS examples is given in chapter “cooking energy technologies and practices”.

There is no standard procedure to identify which technology option might be most successful on the market. On the one hand it has often been observed that “evolution” of existing baseline technologies is more acceptable and feasible than “revolution” (e.g. bringing in a completely new stove and fuel concept). On the other hand, the establishment of a commercial supply chain might be more feasible with a “modern/strange” product (e.g. a portable metal stove) rather than with a modification of an existing self-help product (e.g. an improve mud stove), if there is already a long tradition of local non-cash stove building.

Many interventions resorted into offering a range of stoves to the target groups and let them have the choice according to their needs, capabilities and preferences. Sometimes you start with one or two products and then, after realizing additional market opportunities, additional products are taken on board.

In the selection of technologies, the needs and perception of both potential customers and users on the one hand and potential producers and traders on the other hand have to be taken into consideration.

- A stove which works well and is very cheap, but which will not give the producer any profit, will not be produced for sale.

- A high-end efficient, durable and beautiful stove which is highly profitable for the producer will not be effective if the target group is not prepared to spend so much money for its purchase.

Both sides should be involved in the selection process of the technology.

New technologies often have to be adapted to the local requirements. It is important to reserve time and resources for several loops between producers and users of a new ICS to make sure that the stove model is well accepted and matured before the actual market introduction. Although this sounds trivial, in the reality there are tremendous time pressures which suggest taking some short cuts. However, this might be the wrong place to cut corners.

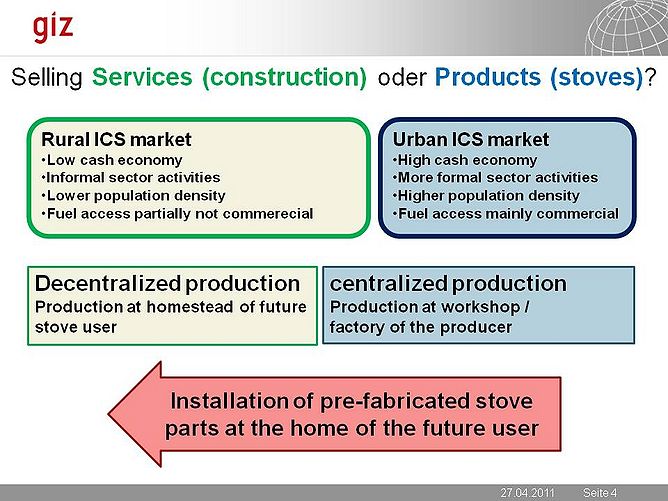

The links between technology selection and design of the intervention

Selecting a stove technology is much more than just a technical decision. It has huge impacts on the overall design of the intervention. One of the chore questions is related to the portability of the stove. In generalizing terms, one could distinguish between the needs of the rural and urban ICS markets as below. There are, however, also a number of examples of rural areas with portable stoves. This holds particularly true in areas where cooking is done outside. Hence this is just a generalization to demonstrate the links between technology selection and the design of the intervention. It does not cover all cases.

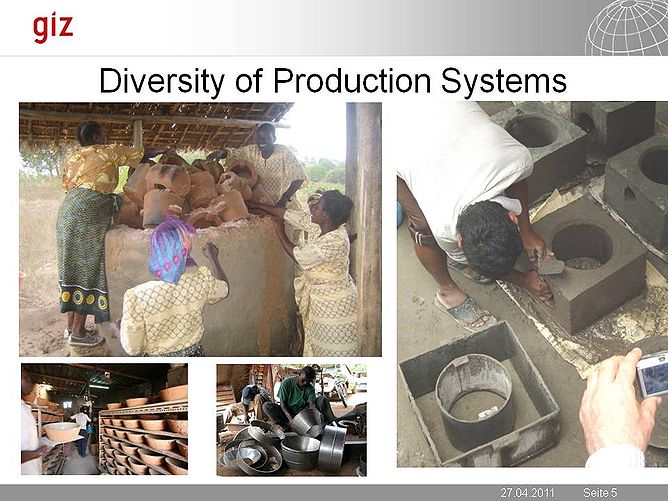

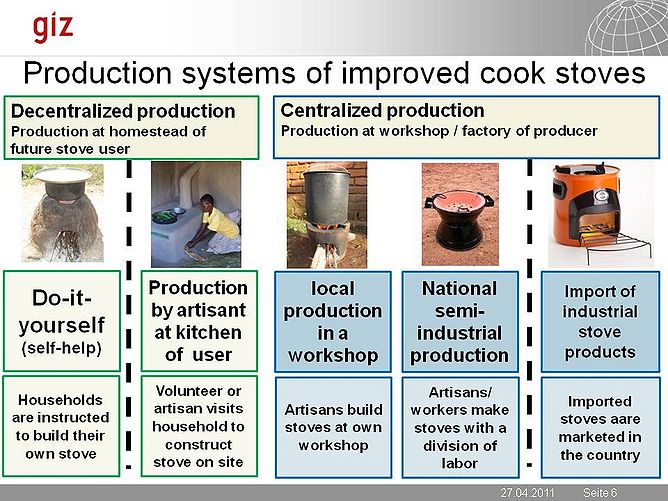

As manifold as the types of stoves available, there are also different modes of stove production to be distinguished.

In most of our interventions, we focus on the three options in the center of this slide. Self-help “do-it-yourself” stoves tend to be of very low quality (sometime even worse than the baseline stove) due to the low skill level/lack of practice in stove construction. The option of imported industrial stoves is a rather new development which has not been tried yet at large scale in GIZ stove interventions.

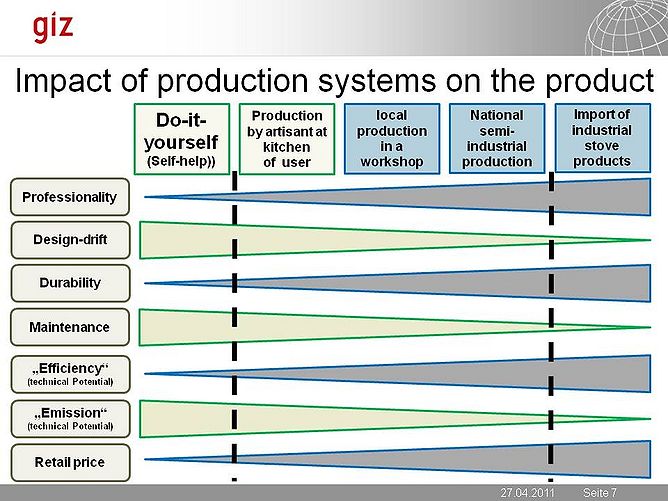

More specialized producers (e.g. in the semi- or industrial production) have more routine in the production of ICS. Combined with tooling and quality control mechanisms, the stoves will have less cases of design drift as compared to fixed stoves being built from scratch at the customer’s house. (Semi-)Industrial stoves commonly are made out of metal. As the manufacturing is done according to defined standards, the (semi-) industrial stoves tend to be more durable as the locally build stoves out of mud, bricks or cement. Hence the latter require more attention in terms of maintenance. Standardized production allows for the observation of important dimensions and principles. Therefore, the (semi-) industrial stoves often provide higher technical potentials for “efficiency” (reduced specific consumption) and for reduced emissions. The actual realization of these potentials is dependent on the user behavior. While many technical aspects favor the standardized, centralized production, the retail costs of these stoves are often higher as compared to their local competition because of cheaper materials, informal price setting and lower transportation costs.

There are new trends to “cross the borders” of these categories:

- Industrial pre-manufactured stove components used in local fixed-stove construction;

- Industrial flat-pack assembly kits imported for in-country assembly and sales.

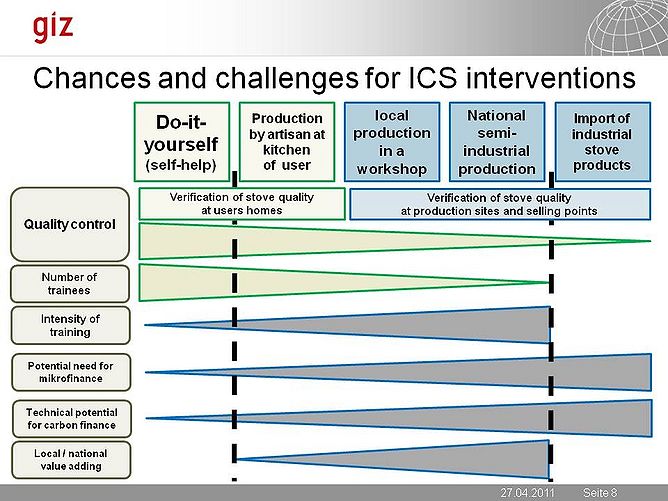

The different production systems provide different chances and challenges for the implementing organization. Decentralized production requires verifying the quality of the stoves at the site of construction at the homes of the users. This is a huge effort as compared to visiting the production or selling points of portable stoves.

While specialized workers in the (semi-)industrial production potentially require a more intense training, the decentralized production systems tend to have lower numbers of stoves produced per producer per year. For the same annual production, far more producers have to be trained and supervised as compared to the centralized production.

(Semi-)industrial stoves tend to be more expensive than locally produced stoves in a rural environment. Hence the potential needs for microfinance to lower the investment barrier tend to be higher for the more expensive products. Another reason is that - depending on the country – microfinance tends to be found more frequently in urban as compared to rural settings. On the other hand, rural households have lower cash incomes which increase the need for assistance if investments are required.

More efficient stoves have a higher carbon saving as compared to less efficient stoves if compared with the same baseline stove. This applies even more if the more efficient stove has been manufactured in a standardized manner as the technical potential for savings can easily be assessed. Locally build fixed stoves can be all different in their individual performance as for example a small variations of the air inlet of the chimney may either result into too much draft (reducing the efficiency) or too little draft (smoke in the kitchen). The monitoring for the carbon saving verification in the field would require much more effort.

Planning of ICS interventions

The planning of interventions to enhance the production of ICS should not be done in isolation. The production is part of an overarching value chain which starts with the access to the required inputs and comprises all the steps including the distribution, sale and utilization of the stoves.

There is no benefit in training future producers on stove production, if…

- They cannot access the inputs;

- They have no access to markets;

- If the product does not sell;

- If the product is not used.

Planning of activities to enhance ICS production

Piloting ICS Production

Scaling-up of ICS production capacities