Hydro Power Basics

Principle of Hydropower

A mass of water moving down a height difference contains energy. This can be harvested. Moving water drives some waterwheel/turbine. This rotation either drives machinery directly (e.g. mill, pump, hammer, thresher, ...) or is coupled with a generator which produces electric power.

Hydropower is probably the first form of automated power production which is not human/animal driven. Moving a grind stone for milling first, developed into the driving of an electrical generator. Next to steam it was for long the main power source for electricity.

Its continual availability does not require any power storage (unlike wind/solar power). It is mainly mechanical hardware. This makes it relative easy to understand and repair-/maintain-able. In smaller units its environmental impact becomes neglect-able (see: environmental impact assessment) .

In order to create electricity from Hydropower, two parameters are critical:

- Flow; or the minimum amount of water that is constantly available throughout the entire year

- Head; the difference in height

These specific conditions limit generalising and standartisation of "how to install hydropower plants". Choosing the right location and planning requires some specific knowledge. With knowledge of water flow and height difference the potential power can be estimated.

Measuring Head & Flow

First step to judge a sites hydropower potential is to measure/estimate head and flow.

- Head (the vertical distance between the intake and turbine)

- Flow (how much water comes down the stream)

Head is very often exaggerated as is the flow rate, which varies over the year!

Wrong data occurs frequently. Confirmation of existing data is highly recommended!

Head and flow are the two most important facts of a hydro site. This will determine everything about the hydro system—volume of civil constructions, pipeline size, turbine type and power output. Inaccurate measurements result in low efficiency, high cost and scarcity of power.

For sophisticated methods how to inquire a sites feasibility, please check the Manuals section.

"Layman's book: How to develop a Small Hydro Site" may be a good start.

Methods of head and flow measurement without sophisticated tools

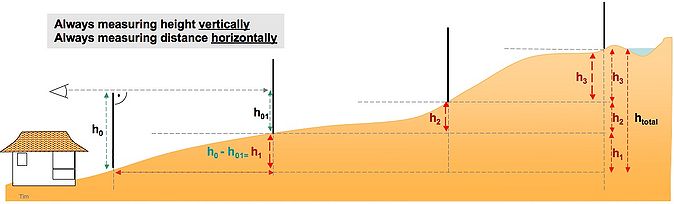

Estimation of height can be done easiest if there is a steep slope (waterfall)by rope. Principle of a step by step head measurement:

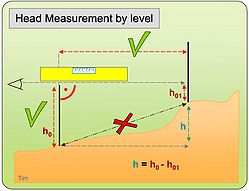

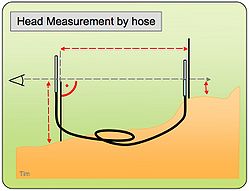

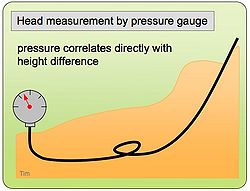

By measuring total height step by step, it's crucial to do the bearing strictly horizontally. Ensure that by using a level or a water filled hose. Widely available are hoses and pressure gauges which allow the easiest method of height measurement. As longer the hose as less steps have to be taken to measure the total head.

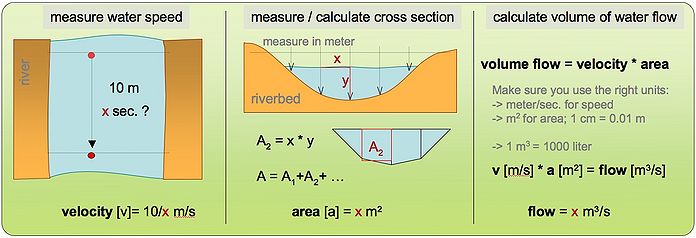

Estimation of flow is very difficult without measurement. A quick and easy way to measure is the floating method

First, measure the waters speed at an steady flowing part of the river. Therefore drop some item and stop the time it needs for a certain distance to float. Second, do a sketch of the rivers cross section by measuring its depth every 20-50 cm so you come up with a grid showing the rivers profile from side to side. With this data its cross sections area can be calculated easily. Finally the flow volume results from (water) speed x (section) area.

Example:

A ball drifts 10 m in 12 s => speed = 10m/12s = 0.12 m/s.

Cross section => A1= 25 cm * 40 cm (0.25 m * 0.4 m) = 0.1 m2 ; A1+A2+ ... = A = 0.5 m2

Flow volume = 0.12 m/s * 0.5 m2 = 0.06 m3/s => 60 l/s

To estimate a sites potential cost its necessary to know additionally:

- Pipeline (penstock) length

- Electrical transmission line length (from turbine to consumer). As smaller the sites power output as higher the power lines cost share

- Number of potential customers

Units and power estimations

Power: watts [W] or Kilowatts [kW] 1 kW = 1000W

Flow: 1 m³/s = 1000 l/s

Gross heat: height difference the water "falls down"

Net head: a little smaller than gross head. Gross head deducted by energy loss due to friction in penstock

Potential power is calculated as follows:

Power [W] = Net head [m] x Flow [ l/s] x 9.81 [m/s²] (est. gravity constant) x 0.5 (turbine/generator efficiency)

Potential power is estimated as follows:

Power output [W] = height [m] * flow [l/s] * 5

More accurate estimations take into consideration:

- exact net head (intake to powerhouse)

- exact flow (constant during the year?)

- combined efficiency of turbine and generator (depends on quality, est. 60% = 0.6)

Example:

A 6 m high waterfall has 300 liter/sec => potential power est. : 6 m * 300 l/s * 5 = 9000 W = 9 kW

Classification

by Size

Hydropower installations can be classified by size of power output, although the power output is only an approximate diversion between different classes. There is no international consensus for setting the size threshold between small and large hydropower.

For the United Nations Industrial Development Organization (UNIDO) and the European Small Hydropower Association (ESHA) and the International Association for Small Hydro a capacity of up to 10 MW total is becoming the generally accepted norm for small hydropower plants (SHP). In China, it can refer to capacities of up to 25 MW, in India up to 15 MW and in Sweden small means up to 1.5 MW, in Canada 'small' can refer to upper limit capacities of between 20 and 25 MW, and in the United States 'small' can mean 30 MW.

The German Federal Ministry for Environment, Nature Conservation and Nuclear Safety mentioned that a SHP is < 1 MW everything above is a large hydro electric plant and usually comes along with a large dam. The International Commission on Large Dams (ICOLD) defines a large dam as a dam with a height of 15 m or more from the foundation. If dams are between 5-15 m high and have a reservoir volume of more than 3 million m3, they are also classified as large dams. Using this definition, there are over 45 000 large dams around the world.

Small hydro can be further subdivided into mini, micro and pico:

| Mini (MH) |

< 1 MW | grid connected | special know how required |

| Micro | < 100 kW | partially grid con. | professional know how required |

| Pico (PH) | < 10 kW | island grids | small series units produced locally; professional equipment available |

| Family (FH) | < ~1 kW | single households/clusters | often locally handmade solutions; professional equipment available |

There is no binding definition how Mini hydropower output is to be classified. Rules for communication avoiding misunderstandings: Generally the terms can be used "downwards compatible". Pico- is also Mini- but not visa versa. Specific terms (Pico, Family) should be used only if they are required to indicate specifics. The spectrum needs higher diversification as smaller it becomes as there are certain differences in technique, usage, applicability and the grade of of ability to replicate them.

Comments:

- all installations require "special" knowhow

- there are "over the counter" pico turbines available for "self installation"

- Micro hydro is perhaps the most mature of the modern small-scale energy supply technologies used in developing countries. There are thought to be tens of thousands of plant in the “micro” range operating successfully in China[1], Nepal, Sri Lanka, Pakistan, Vietnam and Peru.

- Historically the term hydropower developed from naming very small units towards nowadays huge dams. Then there where new terms created to separate different clusters. All of them are hydropower. What is considered "mini or "micro" may be defined once and forever ... or not. If there are different opinions on this topic you're welcome to open a discussion group on this.

by Facility Type

Hydropower plants can be classified in three categories according to operation and type of flow (see figure a-d).

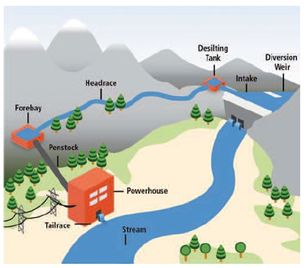

a) Run-of-river (RoR),

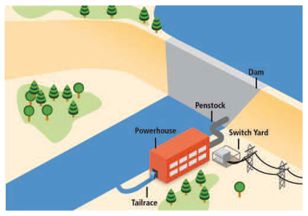

b) storage (reservoir) and

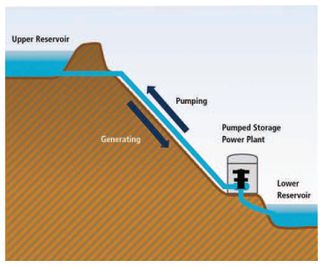

c) pumped storage HPPs all

In addition, there is a fourth category (d) called in-stream technology, which is a young and less-developed technology. Whereas pumped storage HPPs are only economical attractive in large scales, run-of-river and storage can be small and large.

a) Run-of-River Hydropower Plant

b) Hydropower Plant with Reservoir

c) Pump Storage Hydropower Plant

Statistic on Hydro Power

Hydropower Potential

will be added until april 2012

Existing Generation

will be added until April 2012

Micro Hydro Power Shemes

Components of a Micro Hydro system (overview)

Grid connection for MHP's

Hydropower usually operates 24 h / day. Most mhp's are connected by a grid to their consumers. If a connection towards the national or main grid is available, electricity can be fed in there. Often micro or pico hydropower units are installed in remote areas. There they feed an isolated grid. In such grid the mhp is usually the only power source. The power produced has to be leveled equal with the power consumed (see controller).

Battery storage is no must like at solar or wind power projects. This is a big advantage as it reduces costs and maintenance significantly. Charging stations can nevertheless extend a mhp's effectiveness by utilising power in times of low demand (late night). Like this, even consumers which are too far from the station to be connected by transmission cable can be served via rechargeable batteries .

Storage basin or dams

Small hydropower plants usually use (part-) river flow as driving force. Storage basins or even dams can buffer water. So demand peaks or (short) periods of water shortage can be bridged. As such infrastructures is costly and sophisticated, it's only used if there is a clear financial revenue; e.g. electricity supply for remote industries. Standard elements for mhp ====

Construction a mhp consists of: divertion constructions in the river, Guiding water per canal and pipe, the electrical-mechanical equipment to turn water power into electricity plus transmission lines and house connections. Nevertheless if it is community based, main challenge will be the social setup. The people of the community who will build / use the mhp have to be introduced, trained, learned and encouraged to organise, operate and manage their power station. A sustainable working mhp scheme requires users who are enabled to understand "their" system.

|

forebay, spillway, trash rack, penstock (incl. breather pipe, trust & support blocks) |

electro-mechanical equipment: generator and crossflow turbine mounted on base frame |

|

Information of chances and efforts a hydropower plant requires |

Participation of community |

Organisation & Management |

For an overview or possible impacts on a mhp's success, check out the mhp-tree-diagram

Suitable conditions for micro-hydro power

Again, "head and flow" matter. The best geographical areas for exploiting small-scale hydro power are those where there are steep rivers flowing all year round. The Andes, the Himalayas, islands with moist marine climates, such as the Caribbean Islands, the Philippines and Indonesia are widely suitable. Laos, Vietnam and wide parts of China use Micro Hydropower in large numbers.

A locations, head, flow and number of consumers allow to calculate the available power share per consumer

Minimal Head may be 1-2 m. For considerable power then much water (> 1 m3) is required

Minimal Flow may be 20 l/s. Power is according to head output (see power estimation).

Mini Hydropower operates constantly and requires little maintenance. It is ideal for powering remote regions. Although grid connection is very feasible due to its very low operational costs.

Brief site assessment:

- location Data

- head, flow

- length of powerline

- length of penstock

- land use

=> a two page condensed site assessment

Flow measures in feasibility studies:

Flow data should be gathered over a period of at least one year where possible, so as to ascertain the fluctuation in river flow over the various seasons.

At least measures must be taken during dry season to assure that there is always enough water to power the turbine. Too little water results in power cut. If such is not clear to consumers from begin with it can seriously endanger the projects success.

Economics of microhydro systems

Productive use

Electricity is a key factor for productive businesses. Experience shows, this isn't an automatism very commonly. Additional income is generated only if the revenue is made from outside the community. Typically added value is created by subsequent processing of commodities. Exemplary: coffee roasting, fruit drying, freezing fish, ...

Cost

The major cost of a mhp scheme is for its site preparation and equipment. It's nearly 100 % upfront investment and very low running cost (operation and maintenance).

Cash usually is a scarce resource in rural areas of development countries. Part of a feasibility study has to be: how high tariffs have to be set to cover the costs. Its a must to, at least, break even operation & maintenance expenses. This money has to come from the users for electricity or el. services. A mhp can operate many decades if tariffs cover repair costs. In the long run a mhp's management is the crucial factor for its success.

Tariff setting

Tariff setting is a crucial element. In case the mhp management is community based, tariffs have to be set in acceptance with the community. Ensure sufficient high tariffs! Community discussion may be lengthy, be patient. Never leave the impression that mhp-electricity may be "for free".

Examples: Compare the cost for oil wig lighting with a single bulb. Compare "luxury" expenses with the comfort of el. lighting (cigarettes, drinking, ...). Explain the management function like how to run a business. Minimally the revenue has to cover the expenses. Check download section for an excel-tool which shows cost coverage.

Links: Tariffs,[http://energypedia.info/index.php/Metering_and_billing_systems Metering and Billing

es

Within a community based scheme extra revenue can be used for:

- social tariffs (elder, poor, school, ...)

- street lighting

- powering a drinking water pump

- community services (washing, freezing, ironing)

Availability of cash gives also other possibilities to gain additional revenues. E.g. to build storage capacities which can house a communities harvest; by gross deals during off season prices are high.

Financial benefits to the communities served are usually reduced expenses for oil, batteries and petrol to power lamps, radios and machines. Check potentials for productive use during feasibility study. Existing and planned machinery (type and power?)

Efforts

Main non financial efforts at microhydro installations are: the right choice of sites, their specific planning and supervision of quality standards; all this is esp. laborious in remote areas. If a scheme is community based, such plays a key role.

Some hints

- use run-of-the-river schemes where possible - storing water by dams is usually big(!) effort and expensive

- use existing infrastructure, e.g. irrigation canals, mills, old mhp-sites (rehabilitation).

- integrate local workshops (=> productive use);

- use locally manufactured equipment where possible - it reduces costs and creates local capacity (replicable know how)

- use of local materials for the civil works

- use of community labor not only reduces required money, it's absolute necessary to establish local commitment towards the installations

- use of HDPE (plastic) penstock reduces costs, has reduced lifetime and requires protection of sunlight

- electronic load controller - ensure stable voltage and frequency which does no harm to appliances. It allows additional automatized features like battery charging or freezing. As more sophisticated the appliances become as more required a load controller will be.

- high plant factor (efficiency) requires some planning for a well balanced load pattern of usually: machinery and consumptive use

- a mhp plant close to village avoids expensive distribution lines or even transformers.

- using pumps as turbines (PAT) - for pico hydro, it's reducing equipment costs, but also efficiency

- using motors as generators - it's widely available, reducing equipment costs, but also efficiency