Tomato Processing by Solar Energy

This article presents a case study on solar powered tomato processing in Ethiopia.

Project

TAMPA (Tigray Agricultural Marketing Promotion Agency) started in April 2014 in collaboration with the Sustainable Land Management Program (GIZ SLMP) the promotion of micro and small enterprises for tomato processing using renewable energy. The target groups are cooperatives of tomato farmers producing in remote areas without access to electrical power (2014: only 14% of the Ethiopian population has access to grid power).

Many agro processing steps need both thermic energy (heat) and electrical energy (power), both will be obtained from the sunlight. In Tigray, the availability of solar power is reliable and regular in the dry season. The tomato season starts around end of November and ends in the month of June. Then, the processing period will last for 7 months = 210 days. This climate smart technology helps to reduce post-harvest losses and enhances the tomato farmers to add value on their raw products.

The end products are tomato paste/sauce, tomato juice, dried tomatoes and tomato powder. These are conservable without cooling (paste 6 months, juice 1 month, dried tomatoes/powder up to 1 year) and allow the producers to receive better prices for their commercial products:

- 3,150 kg of fresh tomatoes are processed to 1,260 kg long conservable tomato paste, packed into 3,150 bags of each 200 gram plus 1,260 bags of 500g

- 1,050 kg of fresh tomatoes are processed to 735 liter of tomato juice, packed in 1,470 bottles (‘Highland’) of each 0.5 liters

- 5,000 kg of fresh tomatoes will be sun-dried to 675 kg dried tomato slices, and 75 kg tomato powder, packed into vacuum-sealed polyethylene bags

Please note: The solar system is all year around available and can be used for other income generating activities, like television, video, lighting, battery charging, water cooking, sterilization, other food processing, office services like scan/print/internet/email….

|

|

|

| Solar reflector used for tomato processing © TAMPA |

Processing of tomatoes in Tembien © TAMPA |

Tomato paste sterile packed into PET-bags © TAMPA |

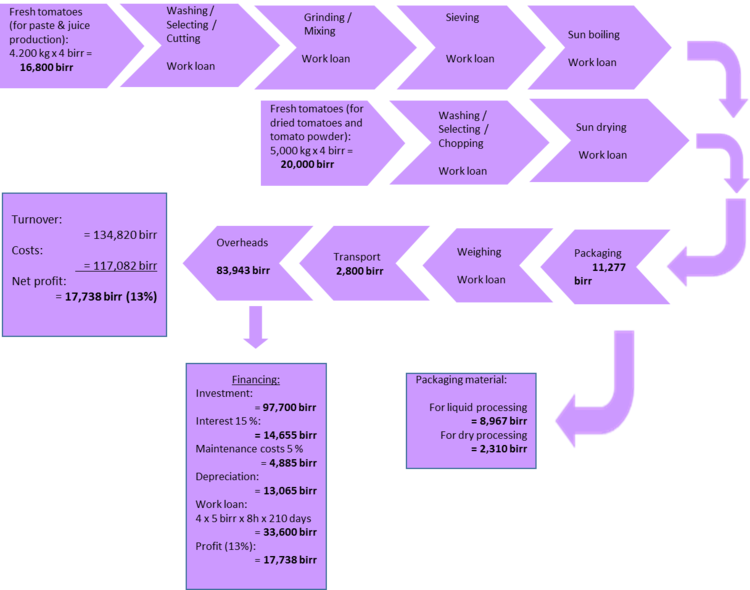

The quantified tomato processing value chain design (liquid and dry):

Financial Plan

Costs

Fix costs (= overheads) = 83,943 birr + Variable costs = 50,877 birr

Total costs = 134,820 birr

Annual turnover

Liquid tomato products: 1,260 bags of paste, 500 g x 25.0 birr = 31,500 birr 3,150 bags of paste, 200 g x 12.0 birr = 37,800 birr 1,470 bottles of juice, 0.5l x 12.0 birr = 17,640 birr Dry tomato products: 3,360 bags of slices, 200 g x 10.5 birr = 35,280 birr 2,520 bags of powder, 30 g x 5.0 birr = 12,600 birr

Total turnover = 134,820 birr

Investment costs and depreciation

| Description |

Purchase prize (ETB)per unit |

Purchase prize (ETB)total |

Supplier |

Depreciation years |

Depreciation (ETB)/a |

| 2 solar panels, 90 Wp |

6,000 |

12,000 |

LYDETCO 0911207283 |

20 |

600 |

| 1 regulator, 12 V/20A |

2,500 |

2,500 |

LYDETCO 0911207283 |

10 |

250 |

| 2 lorry batteries, 12 V/120 Ah |

4,000 |

8,000 |

Mekele shops |

4 |

2,000 |

| 1 metal stand for solar panels |

2,500 |

2,500 |

Sami metal shop Mekele |

20 |

125 |