Business Plan for Solar Processing of Tomatoes

This article presents the business plan of the project "Solar Powered Processing of Tomatoes" by TAMPA (Tigray Agricultural Marketing Promotion Agency) and the Sustainable Land Management Program (GIZ SLMP) in Ethiopia.

General

Economic development in remote rural areas in Ethiopia can be enhanced by value adding on farmers’ agricultural raw products. Small scale agro processing must lead to consumable end products, which are food safe, conservable, transportable and marketable. Agro processing depends on availability of electrical power, and this is a critical issue: Actually, in 2014, only 14% from the 90 million Ethiopians have access to grid power, and from the rural population (67 million people) only 2 %.

The use of renewable energy from the sun might be an appropriate alternative in remote areas. Many agro processing steps need both thermic energy (heat) and electrical energy (power), both can be obtained from the sunlight. In Tigray, the availability of solar power is reliable and regular in the dry season, when the weather is not cloudy. This period lasts about 9 months in Tigray, from October to June. The tomato season starts around end of November and ends in the month of June. Then, the processing period will last for 7 months = 210 days.

A room of 16 m2 should be sufficient as processing site. It will be built by the farmers’ men power contribution, stones are available onsite and construction material like cement, metal sheets for the roof and a metal door/window as well as tiles will be supplied by the GIZ SLM Program. The solar panel will be placed on a metal stand, which allows daily cleaning to maintain its power for battery charging and processing work. Also, the stand allows turning around of the panel, by adjusting the direction, an optimal output from the sunlight may be obtained in case of need. Special attention will be given to train the processing team in technical aspects of the photovoltaic power system. This includes the handling of the precious inverter, the regular cleaning of the panel and the maintenance of the acid batteries.

In a first phase, the processing activities are limited to tomato processing activities only. In other phases the commercial activities should be extended to oil seeds processing, animal feed production and agro-products packaging, e.g. appropriate honey packaging.

Tomato processing is the core business activity of this micro enterprise. It should help on the one hand tomato farmers of the area to get rid of their excess production in the peak season in January/February against reasonable payment. On the other hand, tomatoes will be value added to long conservable end products like paste, juice/sauce, tomato powder and dried tomato slices.

Turnover in the first phase arises from annual sale of the following commercial products:

- 3,150 kg of fresh tomatoes are processed to 1,260 kg long conservable tomato paste, packed into 3.150 bags of each 200 gram plus 1,260 bags of 500g

- 1,050 kg of fresh tomatoes are processed to 735 liter of tomato juice, packed in 1,470 bottles (‘Highland’) of each 0.5 liters

- 5,000 kg of fresh tomatoes will be sun-dried to 675 kg dried tomato slices, and 75 kg tomato powder, packed into vacuum-sealed polyethylene bags

Marketing Plan

Tomatoes are easily perishable. If fully ripened, they spoil within one-days-time. Processed tomato products have several advantages, they are….

- conservable without cooling

- value added to ready-made healthy and tasty products through crushing, mixing, sieving, cooking, sterilizing and by adding spices

- daily used in nearly every household in Ethiopia for food preparation

- a value added product from traditionally grown tomatoes, harvested over 9 months a year

- easy to cultivate by the farmers and give high yields, over 10 tons/ha

Farmers must aim on selling most of their production as fresh tomatoes. But in case, the prize which they get from wholesale is extremely low, it could be partly processed by the micro enterprise that is located in the environment of the fields so that no considerable losses may occur during transport procedures from their fields to the processing unit. This is important, because tomatoes that are bound to being processed must be as ripe as possible. The micro enterprise does not provide considerable storage capacity for tomatoes. Tomatoes which are purchased by the enterprise from the farmers must be processed within the following 3 days.

The annual processing capacity is around 10 tons, due to a total of 210 sunny days, allowing the 4 solar cookers to process and sterilize about 20 kg of fresh tomatoes a day. A solar dryer of 10m2 (5m x 2m) assures the drying of another 5 tons of fresh tomatoes from which the final product will be 675 kg of dried tomato-slices and 75 kg of tomato powder.

Competition

Tomato paste

There is a modern processing factory (‘MERTI”) in South Ethiopia, producing good quality tomato paste. The paste is sold in cans in many shops, also in Tigray. Actually the sales price is ETB 65 for a can of 850 g content. Tomato paste produced by rural micro enterprise will fill a gap by offering smaller quantities for sale, as it meets the customers’ desire: 200 g and 500 g packed in attractive polyethylene bags (PET-bags). These bags have the advantage that its content is visible for the customer (deep red color); they are strong enough to be transported without damaging and they are easy to open by pulling a prepared part of the plastic.

There is also imported tomato paste for sale in the shops. Cans of 400g content cost ETB 33, and small aluminum packs of 70 grams cost ETB 7, in both cases quality is low.

By summarizing, the micro enterprise is able to offer good quality tomato paste, comparable to the competitive product from MERTI. The offered packages meet the demand of the customers for purchase of smaller quantities and the prizes are much lower in comparison to the competitors. Proven by a food quality laboratory in Germany in August 2014, the locally produced paste is a food safe commercial product, sterile and long conservable without cooling (minimum: 5 months). It will be sold to retailers for ETB 12 (200g package) or ETB 25 (500g package). This prize is extremely cheap and unbeatable by other competitors.

Tomato juice / tomato sauce

The second product is pasteurized tomato juice, sold in 500 ml PET-bottles. It is exactly the same product as the tomato paste except its water content is higher: 70% in comparison to 40%. This means the juice can also serve as ready-made tomato sauce, spices (black pepper and salt) are already added during the processing process. Tomato juice can only be found in supermarkets as imported juice, 1 liter costs ETB 60, and its taste appears artificial in comparison to the natural flavor of the locally produced one.

The juice/sauce is pasteurized and conservable for at least 1 month without cooling. The final sales prize to retailers will be 12 birr per 0.5l-bottle (‘highland’).

Dried tomatoes

Fresh tomatoes are dried in the sun for 3-4 days to reduce the moisture content to a maximum of 15 %. Dried tomatoes are conservable for about 1 year. They will be offered in polyethylene bags of 200 g net weight, each for 10.5 birr.

Tomato powder

Tomato powder is obtained, when grinding the above mentioned dried tomatoes by mortar or a hammer mill. They will be packed into small polyethylene bags of 30 gram, each will be offered for 5 birr.

Marketing strategy

The products should be sold within in the woreda Kola Tembien. If necessary, they can be sold also in other woredas of Tigray. As the dried tomatoes are sold at a high prize in Addis-Abeba (60 birr for 100 gram), dried tomatoes from Tigray could be surely competitive, as they are offered for 10.5 birr per 200 gram for retailers.

The enterprise must have a distribution point in the woreda capital Abi Adi. This could be any existing shop from where the products are distributed to retailers. They should be brought regularly once in a week (around 50 bottles of juice, plus 150 packages of tomato paste, plus 200 packages of dried tomatoes and tomato powder) during the production period (December to June) from the production site in the field to the distribution point in the town by public transport. The retailers will provide themselves from this point with the products they need for sale in their shops.

Drinking tomato juice is not yet much common in Ethiopia. For that, most of the juice might be purchased and used for preparation of tomato sauce by adding oil, onions and Berbere before bringing it to boil.

A promotion campaign could be considered to offer the tasty natural tomato juice in the numerous juice shops in towns: It could be sold for ETB 8 per glass of juice (250ml) to final consumers in the already existing juice shops.

Production plan

Tomatoes will be processed from October to June. Depending on sunny days which are essential for the use of solar energy, in the region of Tigray one can estimate the seven-months-period from November/December to May/June as intensive production period. Thus, the micro enterprise will process during 210 days per year.

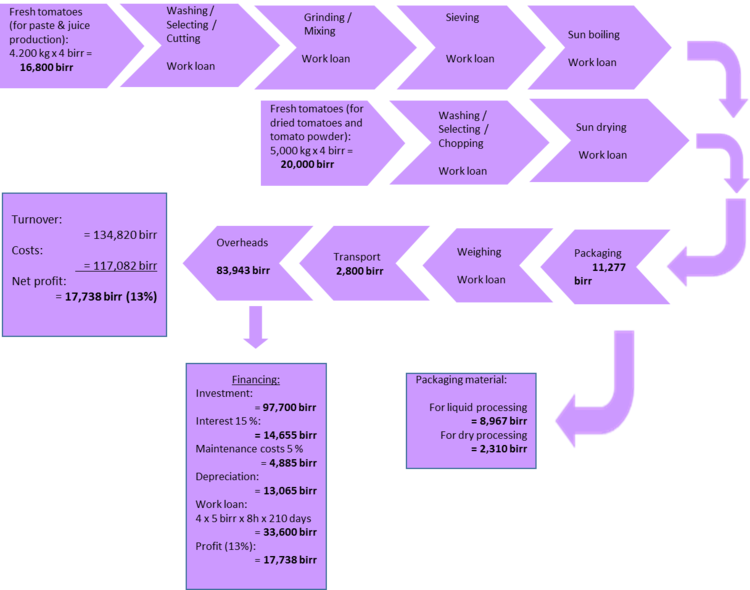

2 different value chains are involved, as shown below: The liquid tomato processing value chain and the dry processing value chain. Liquid products are tomato paste and tomato juice or tomato sauce. Dried tomatoes are offered as tomato slices and tomato powder.

Raw material

Fresh ripe tomatoes of good quality will be supplied by the surrounding tomato farmers from the village. The enterprise will purchase 44 kg/day for 4 birr/kg starting in December 2014 during 210 days until June. The total amount of 36,800 birr will be paid directly upon delivery to the related tomato farmers

Washing

Before being processed, tomatoes will be washed by hand in a water basin with clean water. Cleaned tomatoes will be cut in 2 pieces by knife in order to verify inner quality

Crushing/mixing

Then filled in an electrical mixer by portions of about 1 kg, crushed and mixed with added spices (salt and pepper).

Sieving

After spilling the content into a fine metal sieve, the seeds will be separated

Boiling/evaporating

Around 7 liter of the liquid is spilled in each of 3 black painted cooking pots and brought to boil on 3 solar cookers in a clean and wind protected open site. The boiling process serves to evaporate water: in case of tomato juice/sauce 30 % of water need to be evaporated which takes about 1 hour boiling time. Tomato paste is a more concentrated product: at least 60 % of water need to be evaporated by the force of the sun which takes at least 3 hours per cooking pot of 7 liter content

Cutting / chopping

Tomatoes which are bound to be dried with the sun dryer are cut in small slices of 0.5 cm each

Sun drying

The slices are exposed to the sun light at an open air sun dryer for around 4 days. The capacity is 100 kg fresh tomatoes, thus around 25 kg/day

Packaging

Tomato paste will be packed into polyethylene bags and sealed with an electric sealing machine. The bags have 2 different sizes: 200g and 500g content, after filling the bags they are weight in order to determine the net weight allowing exact prize calculation. Tomato juice is filled up to the top into new polyethylene ‘Highland’ bottles of 0.5 liter content at a temperature of at least 60° Celsius, in order to guarantee pasteurization and vacuum packaging. Dried tomatoes are packed as slices in 200g PET-bags and tomato powder in 30 g PET-bags.

Sterilization

One of the 4 solar cookers is permanently boiling water, the tomato paste packages will be sterilized inside for about 30 minutes. This final procedure makes them sterile and long conservable (at least 4 months) without cooling. As the ‘Highland’ bottles are not proved from boiling water, a final bottle sterilization is not possible, which makes them conservable for only 1 month without cooling (3 months by refrigerator cooling, e.g. in juice shops)

Transport

The products will be brought to the towns for commercializing by public transport till the distribution point in the woreda capital of Abi Adi. The solid packaging material facilitates transportation on dirt roads without considerable losses

Overheads

Overheads summarize all fix costs, such like credit/opportunity costs, work loan, maintenance costs, and depreciation and benefit (15%).

Production

During the processing season November to June the total production will be as follows:

Products for commercialization (daily output):

- 20 kg fresh tomatoes for liquid processing = 15 kg for tomato paste + 5 kg for tomato juice. The end products are 6 kg paste + 3.5 litre juice:

= 6 bags of 500g polyethylene bags + 15 bags of 200g polyethylene bags + 7 bottles tomato juice filled into 0.5l new “highland” bottles

- 24 kg of fresh tomatoes for dry processing = 3,240 g dried tomato slices + 360 g tomato powder

= 16 bags of 200g dried tomato slices + 12 bags of 30 g dried tomato powder

Financial plan

Investment costs and depreciation

The table below shows investment assets, small material, depreciation time and depreciation costs per year.

| Description |

Purchase prize (ETB)per unit |

Purchase prize (ETB)total |

Supplier |

Depreciation years |

Depreciation (ETB)/a |

| 2 solar panels, 90 Wp |

6,000 |

12,000 |

LYDETCO 0911207283 |

20 |

600 |

| 1 regulator, 12 V/20A |

2,500 |

2,500 |

LYDETCO 0911207283 |

10 |

250 |

| 2 lorry batteries, 12 V/120 Ah |

4,000 |

8,000 |

Mekele shops |

4 |

2,000 |

| 1 metal stand for solar panels |

2,500 |

2,500 |

Sami metal shop Mekele |

20 |

125 |

| 1 wooden/metal box for batteries (60x70x40cm), with metal cover |

1,600 |

1,600 |

Carpenter Mekele |

10 |

160 |

| Cables, fuses, switches, sockets |

1,000 |

1,000 |

Mekele shops |

5 |

200 |

| 1 Inverter, sine 500 W, with switch/fuse |

20,000 |

20,000 |

LYDETCO 0911207283 |

5 |

4,000 |

| 4 Solar cookers, parabolic dish, SK 14 |

4,500 |

18,000 |

Bereket Solar Addis Abeba (0911 225131) |

20 |

900 |

| 1 Mixer, 220 V, 200 – 400 W |

1,000 |

1,000 |

Mekele shops |

1 |

1,000 |

| 1 Sealing machine, twin sealing, 220V, 65W |

8,300 |

8,300 |

Germany / TAMPA |

10 |

830 |

| 1 Balance, digital, 0 – 5000g |

500 |

500 |

Addis Abeba shops |

2 |

250 |

| 1 Balance, analog, 20kg |

500 |

500 |

Mekele market & shops |

5 |

100 |

| 1 Balance, analog, 20kg |

500 |

500 |

Mekele market & shops |

5 |

100 |

| 1 Water container with water tap and metal stand, 20 liters for tomato washing |

2,000 |

2,000 |

Mekele metal workshops |

10 |

200 |

| Sieves, spoons, washing pans, baskets |

1,000 |

1,000 |

Mekele market |

2 |

500 |

| 1 Sterilization kettle, 20 liter |

1,500 |

1,500 |

Mekele market & shops |

10 |

150 |

| 1 Sterilization thermometer (110°Celsius) |

300 |

300 |

Mekele market & shops |

3 |

100 |

| 1 Working table, 3m x 1m |

2,000 |

2,000 |

Mekele carpenter |

3 |

100 |

| 1 solar dryer, 5m x 2m |

15,000 |

15,000 |

Mekele metal workshops |

10 |

1,500 |

| Total (ETB) |

97,700 |

13,065 |

Variable costs per year

Raw material (fresh tomatoes)

9,200 kg x 4 birr = 36,800 birr

Packaging costs

1 role of polyethylene endless tube (Germany), 250 m, 0.6 cm Ø = 420 birr 1 role of polyethylene endless tube (Germany), 250 m, 0.8 cm Ø = 830 birr

30 g package = 0.6 cm Ø x 15 cm = 0.25 birr 200 g package = 0.6 cm Ø x 25 cm = 0.50 birr 500 g package = 0.8 cm Ø x 35 cm = 1.20 birr 1 new polyethylene bottle “Highland”, 0.5 litre = 4 birr

Daily output and packaging material needed: 6 bags of 500 g x 1.2 birr = 7.2 birr (x 210 days = 1,512 birr/year) 15 bags of 200 g x 0.5 birr = 7.5 birr (x 210 days = 1,575 birr/year) 7 bottles of 0.5l juice x 4 birr = 28 birr (x 210 = 5,880 birr/year) Sub-total = 8,967 birr/year

16 bags of 200g dried tomato slices x 0.5 birr = 8 birr (x 210 days = 1,680 birr/year) 12 bags of 30g tomato powder x 0.25 birr = 3.0 birr (x 210 days = 630 birr/year) Sub-total = 2,310 birr/year

Total packaging costs: 11,277 birr/ year

Transport costs

Weekly transport from Tabia Merere to Abi Adi (3 hours by bus) of around 49 bottles of juice (25 kg), plus 150 packages of tomato paste (42 kg), plus 196 packages of dried tomatoes and tomato powder (25 kg) = 92 kg/week x 28 weeks = 2,576 kg/11,760 items. The price for transport of 1 qtl (=100 kg) is around 20 birr. Supposing increased costs for the food items it can be estimated to spend 100 birr for transporting goods of about 100 kg total weight weekly. Transport costs will then be 100 birr x 28 weeks = 2,800 birr per year

Summary variable costs: Raw material = 36,800 birr + Packaging = 11,277 birr + Transport = 2,800 birr = Total Variable costs = 50,877 birr

Fix costs

Work loan

4 workers are employed out of the population (landless youth by preference) for 7 months per year. They work daily 8 hours, 5 birr/hour x 210 days (1,200 birr/worker/month). Work loan is considered then as fix cost = 33,600 birr

Credit costs / opportunity costs

As shown in the table above, the investment costs are 97,700 birr. 15% of annual credit costs are considered. Annual credit/opportunity costs are then 14,655 birr

Maintenance costs

5 % of investment costs = 4,885 birr per year

Depreciation

As shown in the table above = 13,065 birr per year

Profit (net)

Net profit (should be around 13 %) = 17,738 birr

Total Fix costs = 83,943 birr

+ Variable costs = 50,877 birr

Total costs = 134,820 birr

Annual turnover

Liquid tomato products: 1,260 bags of paste, 500 g x 25.0 birr = 31,500 birr 3,150 bags of paste, 200 g x 12.0 birr = 37,800 birr 1,470 bottles of juice, 0.5l x 12.0 birr = 17,640 birr Dry tomato products: 3,360 bags of slices, 200 g x 10.5 birr = 35,280 birr 2,520 bags of powder, 30 g x 5.0 birr = 12,600 birr

Total turnover = 134,820 birr

Net profit

17,738 birr (13%)

Management Plan

to be elaborated - only considerations:

Owner of the enterprise could be a cooperative out of the tomato producing farmer households in the tabia (110 households). The micro enterprise is run and managed professionally by 4 employees, by preference landless youth.

All farmers must aim to sell their products as fresh raw products. If the prize per kg drops too low (less than 4 birr/kg), tomatoes should be purchased by the enterprise for processing. But as the processing capacity of the enterprise is limited to around 45 kg per day, the group need to decide on how to share the capacity between the members of the cooperative.

The 4 employees will be trained at start intensively by TAMPA staff for 2 weeks consecutively. During this period of on-the-job-training in (December 2014), the 4 employees get only half of their salary. If farmers do not offer about 40 kg fresh tomatoes because they get better prizes from market sales, the staff needs to be reduced accordingly. The employees are not employed fix, their affordability depends on the daily processing activities.

The cooperative has to provide the running costs for the first month = about 8,500 birr. A bank account is needed as a saving account for depreciation, credit and benefit amounts and other revenues. Petty cash should be available at a save place on the site.