Economic Analyses of Wind Energy Projects

Methodology of a project analyses from a system perspective

Following the World Bank Handbook for Economic Analysis of Investment Operations[1], the main purpose of an economic analysis is to help to design and select projects that contribute to the welfare of a country. Whereas the financial analysis evaluates the project from the point of view of the operating company or Independent Power Producer (IPP), the economic

analysis evaluates the project from the point of view of the whole economy of the country.

The purpose of the investigation is to compare from a macroeconomic standpoint the benefits of the project with the costs it incurs, as is customary in any cost-benefit analysis. The standard of evaluation for costs and benefits is a monetary quantification. To the greatest possible extent, the project impacts are evaluated in terms of economic market prices. Shadow prices are employed, i.e., internal accounting prices that free the day-to-day (market) prices from multifarious biases. In other words, shadow prices represent an attempt to illuminate the actual costs of a product or service for the economy as a whole. In comparison with micro- and macro-economic prices, shadow prices are devoid of taxes and charges, duties and subsidies.

The economic analysis is conducted in the form of equalising the value of getting wind farms introduced to the power system to the induced savings in the power system in terms of avoided costs of thermal power generation. The incremental economic cost of the wind farm output is defined as the difference between the economic costs of the wind farm and the avoided economic cost (economic benefits) of a fossil power plant, which can be regarded as 'business as usual'-case for the country the analysis is applied for. As this article is based on a feasibility study for a wind park project in ethiopia[2], the power plant used for comparison is a diesel power plant.

The economic benefits or the costs of power generation with a (diesel) power plant comprise:

- capital costs of the plant;

- fuel costs;

- variable and fixed operating costs;

- external costs of (diesel) power generation.

These categories fit for most other types of fossil fuel driven plants. As diesel power plants are a very common type of generation unit in developing countries this example should be used in this article[3].

The economic costs for power generation with the wind energy project are accounted for:

- capital costs of the wind park,

- fixed operating costs of the wind power installation,

- external costs of wind power generation - leakage costs

From an economic point of view, the project is profitable, if during the period of time in question the cost of generating electricity with the wind park is lower than the cost of generating electricity with the diesel power plant. In other words: the costs incurred

for building and operating the discussed wind park must be lower than the utility value, or economic benefits, which it provides. The economic benefits are measured here in terms of avoided costs (savings). If the wind park is built, the operating costs, and the external costs, of diesel-based power generation will be avoided.

Pertinent to the cost categories for the diesel systems, differentiation can be made for the following economising effects:

- Capital effects: These account for savings on capital costs and fixed operating costs, because the result is, thanks to the wind power project, less money will have to be spent on new equipment and spare parts for the diesel power plants.

- Fuel and lubrication oil substitution. The wind turbines avoid fuel consumption of the diesel system. The difference between non-fuel operating costs of the diesel power plant and O&M costs of the wind park is also accounted for here.

- External effects. These stand for the reduced level of harmful emissions.

Since costs and benefits arise at different points in time, the time factor must be accounted for in the form of cash-flow discounting, hence bringing costs and benefits in line with a uniform initial date. A so-called standard discount rate (SDR) is used for discounting. The SDR is defined as the interest rate at which the company discounts a marginal future increase in consumption to its present value. This makes it possible to summarise and compare costs and benefits, each as a single factor.

The following profitability criteria can be used to quantify the outcome of the economic analysis:

- Benefits-cost ratio (B/C). The present values of the benefits are divided by the present values of the costs, and the project is profitable if the resultant benefits-cost ratio is greater than one.

- Economic Internal Rate of Return (EIRR). The internal interest is the social discount rate at which the present values of costs and benefits are equal.

- Economic Net Present Value (ENPV). Present value is the financial-mathematical expression used for the sum of the discounted values of a time series. The net present value is the difference between the present value of the benefits and the present value of the costs. The project is profitable, if the net present value is positive.

The discount rate (the opportunity cost of capital) applied in the calculation of the ENPV must be determined to calculate the economic benefits of a project. Its value depends on local market conditions, especially common interest rates and other financial parameters in the project country. In the feasibility study for Ethiopia the discount rate has been set at 10 %, in accordance with conversations held with the national electricity utility. Also, this rate was considered by the Ministry of Economic Development and Co-operation as appropriate for Ethiopia at the time of the study (2006). The indicated discount rate has also been applied in other recent feasibility studies carried out for Ethiopia

Economic Benefits

In the economic analysis the identified benefits are:

- (i) the avoided capital costs,

- (ii) the avoided fuel costs,

- (iii) avoided O&M costs and

- (iv) the avoided emissions.

Basic Diesel Power Plant Data

As already mentioned, the basic data for this study was based on one existing Diesel Power Plant located in the northern part of Ethiopia. This heavy fuel operated DPP commenced commercial operation in July 2004. The plant consists of four state-of-the-art 18 cylinder, V-type, 4-stroke, medium speed Wärtsilä diesel engines type 38 coupled to ABB alternators: each genset is rated at 9,991 kW (site capacity at alternator terminals). The net plant capacity exported to the grid at full load is 38 MW. The production and the sale of Wärtsilä type 38 diesel gensets was stopped by Wärtsilä within the course of strengthening Wärtsiläs engine and alternator portfolio. The type 38 was replaced by the type 46. The Wärtsilä 12V46 genset has a similar capacity as the 18V38

genset. The engine speed of the type 46 is 500 rpm.

Avoided Capital Costs

The economic feasibility is determined comparing a wind project with an equivalent diesel power plant alternative. The wind parks relative to the equivalent diesel based generation has been considered in terms of energy production. If the wind park would not be installed, additional energy would have to be provided by new diesel generators at higher costs.

The chosen DPP is especially suited for the analysis, since its annual generation is similar to the estimated energy production of the wind park. The capacities of the diesel units at this power plant have to be adapted to the prevailing site conditions. For comparison with the Ethipian wind project the DPP capacities are derated. Due to the importance of this fact, for the correct interpretation of the calculated capital costs and operation costs, the influence of the site conditions on the engines capacity have to be further analysed. If a wind energy project should be compared to another type of fossil fuel plants, information about the sensitivity of this plant (e.g. a gas-turbine) towards site conditions has to be gathered.

Diesel engines are internal combustion engines whose capacity is mainly influenced by the following site conditions:

- altitude of the site,

- combustion and

- cooling air temperature.

ISO 3046 Part 1 specifies the standard reference conditions, declarations of power, consumption and test methods for diesel engines. The ISO standard reference conditions are used as normative conditions for all diesel engines. The ISO conditions are as follows:

- Barometric pressure: 100 kPa (corresponds to 100 m altitude)

- Air temperature: 25°C

- Relative humidity: 30%

- Charge air coolant temperature: 25°C

Except for the humidity value, an increase of these values results in reduced capacity of the diesel engine. ISO 3046 Part 1 specifies also the algorithms for the derating calculations. The site reference conditions for the Ethiopian site for the regarded DPP are as follows:

- Site altitude: 1,200 m

- Air temperature: 30°C

- Relative humidity: 30% (estimated)

- Charge air coolant temperature: 40°C

The ISO capacity at alternator terminals of each Wärtsilä unit is 11,058 kW. The site capacity is 9,991 kW. This comparison shows, that each diesel genset is derated by 9.65% due to the site conditions, mainly due to the site altitude. This diesel power plant would deliver approximately 9.65% more capacity, if it was installed between 0 and 300 meters above sea level. This comparison is important for the interpretation of the result of the economic analysis, since the derated capacity of the plant increases the specific costs of the plant compared to a non-derated plant by approximately 9-10%.

- The gross plant capacity (= at alternator terminals) is 4 x 9,991 kW = 39,964 kW.

- The net plant capacity (= capacity exported to the grid) is 4 x 9,500 kW = 38,000 kW.

- The difference between both values (= 1,964 kW = 4.9%) is the auxiliary power consumption of

the plant.

The avoided capacity costs refer to the investment costs that would occur when installing a DPP like the investigated 40 MW plant. The avoided capacity costs were calculated at USD 817.61/kW. Due to strong continued demand for diesel power plants over the last few years, and limited production capacity of the diesel engine & genset manufacturers, the specific costs of diesel power plants (EPC contracts) are slightly, though continuously increasing.

Avoided Fuel Costs

A possibility to determine fuel costs is calculation by fuel prices and the fuel consumption of the diesel gensets[4]. The fuel prices have to be calculated as delivered to the site. The considered DPP in the Ethiopian feasibility study is laid out for continuous operation on cheap heavy fuel oil (HFO). Expensive light fuel oil (LFO) is only needed as back-up fuel: used during start-up and shut

down of the diesel engines, and when HFO is not available due to technical problems of the transfer and/or fuel treatment systems.

For the case of the Ethipian site HFO is a residual oil produced during the refinery process of crude oil. It has a lower quality and higher viscosity than LFO and consequently a lower price than LFO.

Depending on its viscosity, HFO must be kept heated during transport in order to avoid problems during loading and unloading due to high viscosity.

The light fuel (LFO) used at the considered DPP varies between 45 and 80 centi Stokes (cSt) at 50°C, and the HFO used, has a maximum viscosity of 180 cSt at 50°C. The annual fuel consumption recorded in the operation log books of the regarded DPP can

be divided as follows:

- HFO consumption: 82%

- LFO consumption: 18%

Considering the same lower heating value (LHV) for HFO and LFO, the above mentioned percentages do not need to be corrected and can be directly used for the fuel consumption cost calculations. The fuel consumption of diesel units of a state-of-the-art DPP is measured by means of volumetric fuel flow meters with thermal correction and automatic data transfer to the control system of the plant (history/data record). Together with the produced energy (kWh; GWh) a specific fuel consumption can be calculated, which is normally given in g/kWh, referred to the alternator s terminal.

Fuel losses occurring during the fuel treatment (water & sediment drainage, separation and filtering of fuel) should be added to the above mentioned specific consumption, since the lost fuel/water/sediment volume was also purchased by the Owner. These losses were estimated in this case to 3% of the specific consumption.

The fuel consumption is normally based on a LHV of fuel of 42.7 MJ/kg. Other LHV values can be also applied by calculating the specific consumption by means of a linear relation between the two LHVs.

The fuel consumption of a diesel genset is also subject to derating based on the prevailing site conditions like the gensets capacity. The gensets consumption is normally given as ISO based value and as site based value. In case of the Wärtsilä 18V38 genset, the ISO fuel consumption is 182.1 g/kWh (@ LHV 42.7 MJ) at the alternators terminals, ±5% tolerance.

This represents an electrical efficiency of the gensets of 46.3% at ISO conditions. Considering the site conditions, the site fuel consumption of each unit is 200.3 g/kWh (@LHV 42.7 MJ) at the alternator s terminals, ±5% tolerance. This represents an electrical efficiency at site of the genset of 42.1 %.

Including 3% losses inside the plant, the net plant fuel consumption of each genset is 206.3g/kWh (@ LHV 42.7 MJ). Including 5% tolerance the value is 216.6 g/kWh.

For the economic analysis a fuel consumption of 207.0 g per generated kilo watt hour at the alternator s terminals was considered. This corresponds to a net plant heat rate of 8,839 kJ/kWh. Fuel prices vary strongly, proportional to the volatile price development of crude oil prices. The fuel oil prices consists normally of the following components:

- Fuel price at port of loading

- Cost of sea transport and insurance

- Cost at port of unloading: pumping, taxes, transport to fuel depot

- Cost of land transport (tank truck) and insurance

According to the national electricity utility (EEPCO), the HFO 180 price at Djibouti harbour (Ethiopia) amounted to 3.6949 ETB per litre as per May 2006. Considering the above mentioned density and an exchange rate of 1 USD = 8.61 ETB, the price of HFO 180 is 446.51 USD/Mt. The price for LFO at Djibouti port is 3.7754 ETB per litre corresponding to USD 0.4379. With a maximum density of 0.90, the metric ton is equivalent to 1,111.1litres. Consequently, the LFO price is 486.65 USD/Mt.

The fuel finally delivered by dealers from the depot to the considered DPP has the following price increment covering the transport, service charges and profit of the dealers:

- HFO: 0.4151 ETB/liter = USD 50.16/Mt[5]

- LFO: 0.4146 ETB/liter = USD 53.44/Mt

The final fuel prices at the regarded DPP are as follows:

- HFO: USD 516.45 /Mt = USD 0.4958/litre = 4.2737 ETB/liter

- LFO: USD 559.87 /Mt = USD 0.5039/litre = 4.3435 ETB/liter

With a specific HFO price of 11.88 USD/GJ and a net plant heat rate of 8,839 kJ/kWh, the specific fuel cost is 0.106 USD/kWh.

Avoided non-Fuel Costs

Depending on the plant load factor, operating hours and fuel price, the fuel costs represents more than 80% of the total operation costs of a DPP. The remaining costs, the (non-) fuel O&M costs consist of fixed and variable costs. The fixed O&M costs include all those cost items which will be incurred irrespective of an operation of the plants operation status.

These fixed costs include costs for personnel, insurance, management and administration, as well as general maintenance costs. The general maintenance cost component includes costs of administration for services, consumables, materials, supplies procured, costs of postage, telephone, facsimile, reproductions and travel expenses.

The variable O&M costs include such cost components which are only incurred if the plant is operating. These costs comprise of lubrication oil and other consumables like chemicals, etc. Variable costs for the power plant also include the cost for overhauls including spare parts.

Each diesel engine has to undergo service and maintenance every 1500/3000/6000/12000/24000 and 36000/48000 operation hours. After 12000/24000 and 36000/48000 operation hours the diesel engines undergo major maintenance works, which are very cost intensive. This means that the below mentioned specific variable O&M costs (6 USD/MWh) for HFO operated DPP s of similar design and configuration is an average value calculated within one whole operation cycle until major overhaul at 36000/48000 operation hours.

EEPCos figures on variable and fixed O&M costs provided for the reference years 2004 to June 2006 are very low, even considering that the power plant has recently started commercial operation. Among other reasons, this is due to a low plant load factor. Since the annual fix non-fuel O&M costs provided by EEPCo could not be considered as representative for the whole period of analysis31, moderate international standard cost estimates settled at 100.000 USD for fix non-fuel O&M costs per year were applied in the economic analysis.

The estimation of avoided non-fuel variable O&M costs per year for the Diesel Power Plant has been considered according to the Consultant s experience from similar African Diesel Power Plants and according the following data:

| Net plant capacity | 38,000 kW |

| Assumed plant load factor, DPP as base load plant | 75 % |

| Net plant energy production at HV side of step-up transformers | 249,660 MWh/year |

| Specific variable O&M costs for HFO operated DPP s of similar design and configuration all over the world (source Evaluation of Institution of Diesel and Gas Turbine Engineers (IDGTE) Working Cost and Operational Report 1997 |

6 USD/MWh |

| Estimated annual expenditure for variable O&M costs | USD 1,497,960 |

Avoided Emissions

The avoided CO2 emissions are calculated considering that a DPP with an efficiency of 43 % emits 670 gr. of CO2 per kWh would be used, in case the wind park was not realised. The calculation follows the formula:

In the feasibility study for the Ethiopian wind energy site Mesobo-Harena an estimation of energy yields based on a wind measurement campaign and data analysis is carried out for 4 scenarios differing in type, size and number of selected turbines. The amount of CO2 related to the amount of energy in kWh generated by the wind turbines is regarded as the CO2 avoided, if the wind park is built instead of the DPP. The results of applying the above formula to each Scenario are summarised in the table:

| Avoided emissions of the DPP (tCO2) |

Scenario I Enercon E48 |

Scenario II Enercon E53 |

Scenario III Vestas V52 | Scenario IV Gamesa G58 |

|---|---|---|---|---|

| Annual emissions avoided |

58365 |

67211 |

59640 |

67969 |

| Total avoided emissions (tCO2) |

1167127 |

1344219 |

1192800 |

1359387 |

In the economic analysis the wind park is compared with a diesel power plant. Thus, the avoided emissions refer to the DPP. The economic monetary quantification of the avoided emissions has been based on the Mitigation Cost Approach. In the Mitigation Cost Approach, the use of USD20/CO2 tonnes is considered as a reasonable estimate for the shadow price of carbon emissions and it is consistent with the existing work by many experts:

- Anderson et al. (1990, 1993) estimated a present-day USD25/CO2 tonnes shadow price using a carbon accumulation-backstop technology model based on the Hotelling rule;

- Fankhauser (1995, 1996) estimates a global damage function for climate change, and derives a range of USD6-45/CO2 tonnes shadow price, with a best estimate of USD20/CO2 tonnes;

- The Federation of American Scientists arrived at a shadow price of USD10-20/CO2 tonnes based on a Delphi-type assessment;

And simulations of the global carbon offset market performed by the Norwegian research group, ECON, indicate a future market price for carbon of USD10-30/tC; - whereas in ADB's Economic Evaluation of Environmental Projects (March 1996), Appendix H, Average Annual Global Climate Change Damages for Carbon Emissions are estimated at USD7.85-USD17.66/CO2 tonnes for 1991 to 2000, increasing to 8.90

USD/CO2 tonnes - 20.03 USD/CO2 tonnes for 2011 to 2020, and decreasing thereafter.

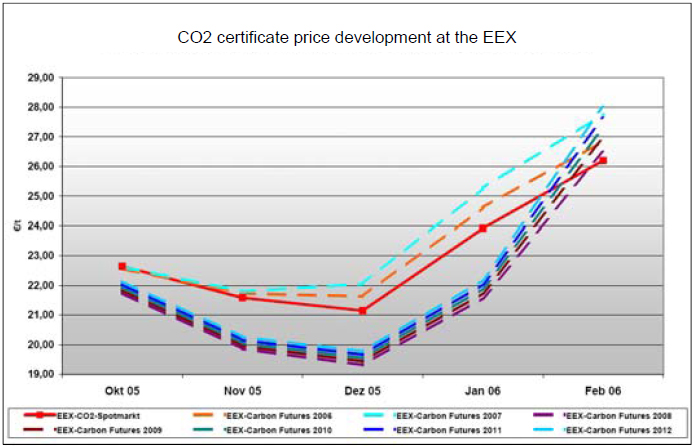

The value has been also compared to the prices of CO2 emissions in the European Emissions Trading System at the European Energy Exchange (EEX) based in Leipzig (Germany). As showed in the figure below, prices have been over 20 / CO2 tonnes (24 USD/ CO2 tonnes) almost all the time since October 200532, so that a price of 20 USD/ CO2 tonnes has been applied in the economic analysis.

The detailled description of the DPP containing all information about investment and Operation/Maintenance-costs is used to calculate the benefits of the wind project in terms of avoided costs and emissions. Evaluating price development for CERs allows and estimation of potential returns generated by emission reductions.

As and overview of the reference plant used for the economic analysis of the Mesobo-Harena wind park a summary of all assumptions is given in the following table.

| Item |

Assumed Data for reference DPP |

|---|---|

| Project Implementation Start Date |

2006 |

| Construction Period |

18 months |

| Commercial Operation Date |

2007 |

| Tax and Duties |

Tax-free status |

| Exchange Rate ETB/USD |

8.6199 : 1 (Exchange rate of March 8 2006) |

| Net Plant Capacity |

38,000 kW |

| Plant Load Factor |

75% |

| Average Saleable Capacity |

249,660 MWh/year |

| Capital Costs |

817.61 USD/kW |

| Fixed non-fuel O&M Cost |

USD 100,000 p.a. |

| Variable non-fuel O&M Cost |

USD 1,497,960 p.a. |

| Heat rate |

8,839 kJ/kWh |

| Specific Heavy fuel oil (HFO180) Fuel Cost |

0.10690 USD/kWhnet (assumed share 82%) |

| Specific Light fule oil (HFO) Fuel Cost |

0.11589 USD/kWhnet (assumed share 18%) |

Based on these assumptions and combined with the estimated energy output of the wind park, the size of a DPP can be determined, which would be able to replace the power production of the proposed wind park. As a feasibility study usually contains the analysis of different technical options concerning turbine types, the DPP assumptions have to be compared to all technical wind park scenarios. In the following table the necessary DPP-capacity related to the proposed turbine types for the Mesobo-Harena wind parks are presented.

| Scenario |

Enercon E48 |

Enercon E53 |

Vestas V52 |

Gamesa G58 |

|---|---|---|---|---|

| Estimated Output (kWh) |

85103000 |

98016000 |

86975000 |

99122000 |

| Diesel power plant - sufficient nominal capacity (MW) to replace energy output |

13 |

15 |

13 |

15 |

| Number of Diesel units |

2 |

3 |

2 |

3 |

Besides direct economic benefits of a wind project several indirect benefits could be taken into account:

- the generation of power will become more diversified,

- the dependence on imported diesel fuel will decline,

- depending on the policy goals pursued by the government of a country, the realization of a wind project could be an example of a successful policy implementation

Economic Costs

In an economic analysis, the identified economic costs are

- (i) capital costs - investment costs - of the wind park,

- (ii) operating costs of the wind power installation, and

- (iii) leakage costs.

Investment Costs of the Wind Park

The list of investment cost items of a wind park specified for the financial analysis is also necessary for the economical assessment. The list generally contains the following items:

- Turbines incl. Erection

- Sea transport and inland transport

- Crane, if necessary incl. sea transport

- Crane works

- Installation

- Civil works

- Road access

- Crane pads

- Foundations / basements

- Cable trenches

- Control building

- Required electrical equipment

- Extension of substation

- Civil works for new substation

- Transformer (132kV / 33kV)

- Auxiliary equipment of substation

- 132 kV components

- Overhead lines (OHL)

- Wind park cabling, earthing, Scada

- distribution stations on site

- Electrical equipment inside control building

- Auxiliary transformer at control building

- Equipment for maintainance team (e.g. tools, cars)

- Engineering (international and local)

- Mitigation measures

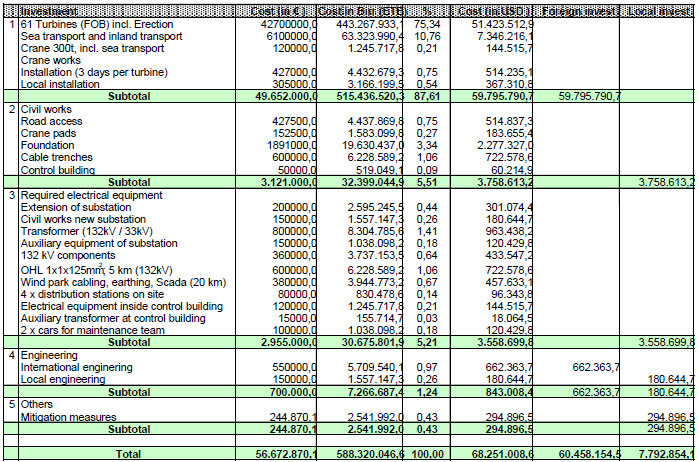

The specified costs of these items for the example of the Mesobo-Harena wind park (taken from the feasibility study) are presented in the following table. As the purpose of this article is to explain the principle ideas of an economic analysis, only one of the proposed scenarios (with turbine type Enercon E48) is presented[6]:

Economic Operation and Maintenance Costs of the Wind Park

If the wind park project is realised by developers and investors, which are not located permanently in the project country, O&M costs must be divided into foreign and local costs. It depends on technical infrastructure and capacities for training and education of staff for operation and maintenance, whether an substantial part of these tasks can be attended by local workers. As the requirements of know-how for repair processes is substantially higher than the tasks of maintenance, often a large share of repairs is done by specialized staff of the turbine producer, while maintenance can be predominantly done by local technicians.

The following Tables include a detail of the annual O&M costs for the Mesobo - Harena Wind Park considered in economic values.

Besides this permanently incurring costs, major revisions and an overhaul should be calculated with operation and maintenance costs. Major revisions include exchanges of central parts additionally to the permanently conducted check of wear and tear parts.

For the Mesobo-Harena wind park these costs are assumed to be 5% of the total investment costs.

Decommissioning and restorage of the project site after project lifetime has to be taken into account. For the Mesobo-Harena this costs were estimated as 1% of the initial investment costs.

Leakage Costs of the Wind Park

Leakage is defined by the United Nations Framework Convention on Climate Change (UNFCCC) in its Guidelines for Completing CDM Project Design Documents, Version 02[7], as the net change of antropogenic emissions by sources of GHG which occurs outside the project boundary, and which is measurable and attributable to the project activity.

For the determination of leakages the following questions have to be answered: Does the project cause any significant emissions during its operation at other sites? Is the emission reduction counterbalanced by the emissions of other activities caused indirectly by the projects implementation?

For the Mesobo-Harena project no leakages have been identified.

Results of an economic analysis

The economic appraisal of a wind park project is carried out by comparing the cash flow associated with construction and operation the wind power scheme with the cash flow of construction and operation the equivalent least cost thermal alternative plant (in case of the Mesobo-Harena wind park this is a diesel power plant). In the appraisal, the avoided costs of thermal generation are regarded as benefits attributable to the Wind Power Project. The difference between the costs of the wind power project and the benefits of the avoided thermal power and energy are determined over the operational period (20 years for the Mesobo-Harena park).

There are many economic parameters available for the appraisal of a project. Three main parameters - used for the Mesobo-Harena project are described here: the Economic Internal Rate of Return, the Benefit/Cost Ratio, and the Economic Net Present value calculated at a 10 % discount rate.

Economic Cash-flow Projections

Cash flow projections associated with construction and operation the wind parks are compared with the cash flow projections of construction and operation the equivalent least cost thermal alternative plant. The avoided costs of thermal generation are regarded as benefits attributable to the wind park project. The difference between the costs of the wind park project and the benefits of the avoided thermal power and energy are determined over the operational period of the project. Further the economic benefits of avoided emissions have to be quantified.

EIRR and NPV

- the EIRR is defined as the discount rate that causes the present value of the project costs to be equal to the present value of the benefits. The EIRR indicates the actual profit rate of the total investment outlay. The project is feasible if the EIRR is greater than the agreed economic discount rate. It is given by the following equation:

where n denotes calculation period (years) and R denotes discount rate. As indicated in the assumptions, the discount rates for the basic scenarios at the Mesobo-Harena wind project are 10 %. - The ENPV of an investment is the present (discounted) value of future cash inflows minus the present value of the investment and any associated future cash outflows.

B/C Ratio

In the Benefit/Cost (B/C) Ratio, the total discounted benefits are divided by the total discounted costs. Projects with a benefit-cost ratio greater than 1 have greater benefits than costs as well as positive net benefits. The higher the ratio, the greater are the benefits relative to the costs.

As an example the results for the four different scenarios of the Mesobo-Harena wind park are presented in the following table.

| Discount rate |

Wind Turbine Type (Scenario |

Key Economic Parameters | ||

|---|---|---|---|---|

| EIRR [%] |

B/C Ratio |

ENPV (Mio USD) | ||

|

8% 10% 12% |

Enercon E48 |

11,87 |

1,19 |

14,57 |

| 1,09 |

6,69 | |||

| 0,99 |

-0,41 | |||

| 8%

10% 12% |

Enercon E53 |

15,05 |

1,36 |

27,89 |

| 1,23 |

18,87 | |||

| 1,13 |

8,89 | |||

| 8%

10% 12% |

Vestas V52 |

11,00 |

1,15 |

11,70 |

| 1,05 | 3,37 | |||

| 0,96 | -2,96 | |||

| 8%

10% 12% |

Gamesa G58 |

16,64 |

1,43 |

32,42 |

| 1,30 | 23,48 | |||

| 1,19 | 12,82 | |||

The results of the economic analysis are positive, showing that the wind park in all four Scenarios and at a discount rate of 10 % is economically feasible. The highest results are produced by the Scenario with the Gamesa G58 followed by the Scenario with Enercon E53 wind turbines, Scenario I with Enercon E48 and Scenario III with Vestas V52.

12.5 Scenario Analysis

A scenario analysis has been carried out for the wind park scenario with the highest EIRR,

highest B/C Ratio and highest net benefits, i.e., the Scenario IV (57 Gamesa G58 turbines).

Changes in (i) avoided capacity costs, (ii) diesel fuel prices, (iii) CO2 penalties and (iv) electricity

generation and their impact on the EIRR have been evaluated.

Change in avoided Capacity Costs

As indicated previously, avoided capacity costs are calculated as the difference between

capacity costs of installing a DPP and the capacity costs of implementing a wind park. These

avoided capacity costs are negative since the investment costs of the wind park are higher

than the costs of the DPP.

The effect of increasing and reducing the wind park investment costs has been studied in two

cases:

Best Case: Investment costs 10 % lower than in the Base Case.

Worst Case: Investment costs 10 % higher than in the Base Case.

Change in Fuel Prices

Oil prices oscillate along the time. (Figure 12-4 for the development of the crude price in USD

per barrel (bbl) from April 2004 to March 200635).

35 Source: www.tecson.de

Feasibility Study for Wind Park Development in Ethiopia and Capacity Building

Mesobo-Harena Wind Park Site

August 2006, Final Report - page 208

final report mesobo-harena

Figure 12-4: Crude price (USD/bbl) from April 2004 to March 2006

The impact of oil price variations (i.e., oscillations in the HFO crude oil price at DPP

516.45 USD/Mt and in the LFO oil price at DPP 559.87 USD/Mt-) , have been

analysed in the scenario analyses by modelling two cases:

Best Case: with an annual increase of 2 % on HFO & LFO prices at the DPP;

Worst Case: with an annual decrease of 2 % HFO & LFO prices at the DPP.

reflects the three scenarios used in the economic analysis, where in year 2028 HFO

prices are expected to increase until 798.42 USD/Mt and LFO until 865.55 USD/Mt

in the Best Case and to decrease until 331.13 USD/Mt for HFO and 358.97 USD/Mt

for LFO in the Worst Case.

Feasibility Study for Wind Park Development in Ethiopia and Capacity Building

Mesobo-Harena Wind Park Site

August 2006, Final Report - page 209

final report mesobo-harena

Figure 12-5: Scenario analysis: HFO and LFO price development

Change in Emission (CO2) Penalties

Two cases have been tested in the scenario analysis in the costs of mitigating CO2 emissions

(penalties for emitting CO2), which were set at 20 USD/t in the base case:

Best Case: emissions penalty is set at 25 USD/t and

Worst Case: emissions penalty is set at 15 USD/t.

Change in Electricity Generation

The base case has been calculated assuming a Probability of Exceedance of 75 % (P75).

For the scenario analysis two further cases have been considered:

Best Case: Probability of Exceedance of 50 % (P50);

Worst Case: Probability of Exceedance of 90 % (P90).

A definition of the Probability of Exceedance can be found in Section 7 (Energy Production

Estimation).

12.5.1 Results: Economic Scenario Analysis

The scenario analysis shows that the variable with the highest impact on the EIRR is the

investment cost of the wind park followed by the electricity generation estimates. The best

results are obtained when decreasing investment costs by 10 %, whereas the impact on

20.00

120.00

320.00

420.00

520.00

620.00

720.00

820.00

920.00

2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021 2022 2023 2024 2025 2026 2027 2028

Year

USD/Mt

Base Case (HFO) Best Case (HFO) Worst Case (HFO)

Base Case (LFO) Best Case (LFO) Worst Case (LFO)

Feasibility Study for Wind Park Development in Ethiopia and Capacity Building

Mesobo-Harena Wind Park Site

August 2006, Final Report - page 210

final report mesobo-harena

EIRR of increasing emission penalties is from an economic point of view very low. The

following table summarises the results obtained in the sensitivity analysis.

Table 12-15: Summary Results of Scenario Analysis

12.6 Conclusions: Economic Analysis

The economic appraisal of the Mesobo - Harena Wind Park scheme has been carried out by

comparing the cash flow associated with construction and operation the wind park with the

cash flow of construction and operation the equivalent least cost thermal alternative plant36.

In the appraisal, the avoided costs of thermal generation are regarded as benefits attributable

to the Mesobo - Harena Wind Park Project. The difference between the costs of the

Mesobo - Harena project and the benefits of the avoided thermal power and energy has

been determined over a 20 year operational period37. With regard to implementation of the

wind park, a fast track schedule has been adopted. Only a fast track schedule will come

close to meet EEPCO s short and long-term strategic installed capacity target. Under the fast

track implementation, construction proper will start in 2007, with the first energy feeding into

the ICS in 2007.

The comparison of the proposed Wind Power Project with an equivalent thermal plant has

been made for 4 different Scenarios (Enercon E48, Enercon E53, Vestas V52 and Gamesa

36 The least costs thermal alternative plant has been defined by EEPCo as a Diesel Power Plant.

37 Cash-flows are presented for 20 year operational period plus decommissioning in year 21.

Scenario Analy-

Variable sis

Best Case Worst Case

Avoided capacity costs EIRRInv(-10%

)

= 19.36% EIRRInv(+10%

)

= 14.46%

Change in fuel prices EIRRFuel Price(+

2%)

.

. = 19.76% EIRRFuel

Price(

-2%

)

= 13.45%

Emission penalties EIRR

(25USD/t)

= 17.35% EIRR

(15USD/t)

= 15.93%

Electricity Generation (P) EIRR

(P50)

= 19.35% EIRR

(P90)

= 14.13%

Feasibility Study for Wind Park Development in Ethiopia and Capacity Building

Mesobo-Harena Wind Park Site

August 2006, Final Report - page 211

final report mesobo-harena

G58). The results (Table 12-14) show that all scenarios are economically feasible, being the

best Scenario the wind park with Gamesa G58 wind turbines followed by Enercon turbines

type E53 and E48. Since all the scenarios produce an EIRR higher than the discount rate of

10 % settled by the Ministry of Economic Development and Co-operation38 for Ethiopia, all

the scenarios can be considered as economically feasible.

For the Scenario with the highest produced results, (Scenario IV with Gamesa wind turbines)

a sensitivity analysis has been carried out. Four variables have been subject to the sensitivity

analysis: (i) changes in avoided capital costs through an increase /decrease on the investment

costs of the wind park in +10 %/-10 %; (ii) changes of fuel prices, i.e., an annual increase/

decrease on fuel prices of +2 %/-2 %; (iii) an increase/decrease of the emission penalties

from 20 USD/t considered in the base case scenario to 25 USD/t and 15 USD/t considered

in the best and worst cases, respectively; and finally, (iv) an increase/decrease in electricity

output.

The results of the economic sensitivity analysis have shown that changes on the investment

costs of the wind park have the major influence on the economic results. If the investment

costs could be negotiated and reduced by 10 %, the EIRR would increase from 16.64 % to

19.36 %. ==

- ↑ World Bank (1996) Handbook on Economic AnalysisfckLRof Investment Operations, retrieved 19.7.2011 [[1]]

- ↑ The contents of this article have been prepared by the project team of the feasibility study of the Ethiopian wind park Mesobo-harena, conducted by the Deutsche Gesellschaft für internationale Zusammenarbeit (GIZ) in cooperation with the Austrian development agency and Lahmeyer international. Originally the contents have been published as: GTZ (2006) Feasibility Study for Wind Park Development in Ethiopia and Capacity Building - Mesobo-harena Wind Park Site), retrieved 11.7.2011

- ↑ The feasibility studyfckLRthe Consultant based the technical data and derived calculations for the capital costs of In the feasibility study for the Mesobo-Harena wind park in Ethiopia conducted by the Deutsche Gesellschaft für internationale Zusammenarbeit (GIZ) the diesel power plant, which is used as an example for the economic comparison with the wind park project, was based on one existing 40 MW diesel power plant (DPP) located in the northern part of Ethiopia. The financial data was adjusted where ever applicable to arrive at the estimated current market value of the existing plant.

- ↑ Distributed generator systems (gensets) are electric generating facilities that are sited at or near the electric user’s home or business. They may be integrated into the electric utility grid system so that the utility may be relied on for back-up power. In other cases, a genset may provide, at times, more power than is required by the host user and may deliver this power to the utility (often called “reverse metering”). Gensets may also provide emergency power for the host when there is a power outage on the grid. In other applications, gensets are placed off-grid – in rural farms or villages in undeveloped countries, for example.

- ↑ OECD (2006)

- ↑ For a complete description of all scenarios, see the feasibility study of the Mesobo-Harena wind park in Ethiopia conducted for the Deutsche Gesellschaft für internationale Zusammenarbeit (GIZ) [[2]]

- ↑ UNFCCC - Guidelines for completing the project desgin document (CDM-PDD) and the proposed new baseline and monitoring methodologies (CDM-NM), retrieved 21.7.2011 [[3]]