Difference between revisions of "Evaporative Cooling Devices"

***** (***** | *****) |

***** (***** | *****) m |

||

| (34 intermediate revisions by 2 users not shown) | |||

| Line 2: | Line 2: | ||

= Overview<br/> = | = Overview<br/> = | ||

| − | Evaporative cooling devices are simple and inexpensive ways to keep vegetables fresh without the use of electricity. Evaporative cooling devices include household capacity clay pot coolers and larger storage | + | Evaporative cooling devices are simple and inexpensive ways to keep vegetables fresh without the use of electricity. Evaporative cooling devices include household capacity clay pot coolers, commonly known as "Zeer Pots," and the larger storage [[Evaporative cooling chamber|Evaporative cooling chamber]] (ECC), also known as "zero energy cool chamber" (ZECC). These devices function according to a basic principle called “evaporative cooling,” where the evaporation of water from a surface removes heat, creating a cooling effect. |

| + | |||

| + | [[File:Evaporative cooling diagram.png|thumb|center|400px|Diagram of a clay pot cooler with a pot-in-pot configuration, covered by a wet cloth.]]<br/> | ||

| + | |||

| + | Evaporative cooling can improve vegetable [[Cold Storage of Agricultural Products|storage]] shelf life by providing a stable storage environment with low temperature and high humidity, which reduces the rate of respiration and water loss and spoilage in most vegetables. The improved storage environment can have positive impacts including reduced post-harvest losses, less time spent traveling to the market, monetary savings, and increased availability of vegetables for consumption. | ||

| + | |||

| + | [[File:Clay pot cooler ECC collage.png|thumb|center|400px|Left: A clay pot cooler with a pot-in-pot configuration<br/>Right: An evaporative cooling chamber (ECC) constructed from bricks with a cover made from dry grass and wood]]<br/> | ||

| + | |||

| + | Clay pot coolers have been used for centuries to help farmers reduce food spoilage and waste, increase their income, and limit the health hazards of spoiled foods. Clay pot coolers are typically used at the household level due to their simple construction and relatively small size. The pot-in-pot design – commonly known as the “Zeer pot” – was popularized in 1995 by Mohammed Bah Abba in Nigeria.<ref>http://growinginclusivemarkets.org/media/cases/Nigeria_PotInPot_2011.pdf</ref><br/> | ||

Evaporative cooling chambers (ECCs) – also known as “zero energy cool chambers (ZECCs)” – are large capacity evaporative cooling devices that are typically used by larger producers or community groups with up to 50 members. The brick ECC was originally developed in India by Susanta K. Roy and D.S. Khuridiya in the early 1980s <ref>Roy, K. S., & Khurdiya, D. S. (1982). Keep vegetables fresh in summer (Vol. 27). Indian Horticulture.</ref><ref>Roy, S. K., & Khurdiya, D. S. (1985). Zero Energy Cool Chamber (Vol. 43). India Agricultural Research Institute: New Delhi, India. Research Bulletin.</ref> to address fruit and vegetable post-harvest losses, especially in rural areas without electricity.<br/> | Evaporative cooling chambers (ECCs) – also known as “zero energy cool chambers (ZECCs)” – are large capacity evaporative cooling devices that are typically used by larger producers or community groups with up to 50 members. The brick ECC was originally developed in India by Susanta K. Roy and D.S. Khuridiya in the early 1980s <ref>Roy, K. S., & Khurdiya, D. S. (1982). Keep vegetables fresh in summer (Vol. 27). Indian Horticulture.</ref><ref>Roy, S. K., & Khurdiya, D. S. (1985). Zero Energy Cool Chamber (Vol. 43). India Agricultural Research Institute: New Delhi, India. Research Bulletin.</ref> to address fruit and vegetable post-harvest losses, especially in rural areas without electricity.<br/> | ||

| + | [[File:Previous vegetable storage methods.png|thumb|center|400px|Deteriorating vegetables in need of improved storage: eggplants and tomatoes stored in a hanging metal dish (left), cabbages, eggplants, and peppers, and lettuce stored on a wet cloth (right)]]<br/> | ||

| + | |||

| + | <br/> | ||

| − | = Suitability<ref>https:// | + | <br/> |

| + | |||

| + | = Suitability<ref>https://bit.ly/2DrGXeP</ref><ref name="Best Practices">https://d-lab.mit.edu/resources/publications/evaporative-cooling-best-practices-guide</ref><br/> = | ||

Several factors should be assessed to determine if an evaporative cooling device will meet users needs in a particular setting. Specific operating conditions are required for the evaporative cooling device to operate effectively | Several factors should be assessed to determine if an evaporative cooling device will meet users needs in a particular setting. Specific operating conditions are required for the evaporative cooling device to operate effectively | ||

| Line 16: | Line 29: | ||

*The availability of a shady, well-ventilated location<br/> | *The availability of a shady, well-ventilated location<br/> | ||

| − | The storage conditions provided by evaporative cooling devices must meet users’ needs. Potential users should consider | + | The storage conditions provided by evaporative cooling devices must meet users’ needs. Potential users should consider |

*Optimal storage conditions for their different vegetables | *Optimal storage conditions for their different vegetables | ||

| Line 22: | Line 35: | ||

*Variations in the need for vegetable cooling and storage throughout the year | *Variations in the need for vegetable cooling and storage throughout the year | ||

| − | The cost of the evaporative cooling device must be affordable and justified by the benefits that will be realized due to its improved storage. Potential users should evaluate | + | The cost of the evaporative cooling device must be affordable and justified by the benefits that will be realized due to its improved storage. Potential users should evaluate |

| − | *Local availability and affordability of materials to construct the device, | + | *Local availability and affordability of materials to construct the device, |

*Potential benefits of evaporative cooling devices such as time and money saved, increased vegetable availability, improved hygiene and convenience.<br/> | *Potential benefits of evaporative cooling devices such as time and money saved, increased vegetable availability, improved hygiene and convenience.<br/> | ||

| + | [[File:Farmers with Vegetables.png|thumb|center|400px|Farmers in need of improved vegetable storage in Bankass, Mopti, Mali]]<br/> | ||

= Construction = | = Construction = | ||

| Line 34: | Line 48: | ||

Clay pot coolers are composed of two clay pots with the same shape but different sizes. One pot is placed inside the other and the space between the two containers is filled with sand, which retains the water added. Food is placed inside the interior pot, and both pots are covered with a lid or a damp piece of cloth. The pot-in-dish design is a variant of the clay pot cooler: a clay pot is placed on top of a plastic or metal dish filled with sand and covered.<br/> | Clay pot coolers are composed of two clay pots with the same shape but different sizes. One pot is placed inside the other and the space between the two containers is filled with sand, which retains the water added. Food is placed inside the interior pot, and both pots are covered with a lid or a damp piece of cloth. The pot-in-dish design is a variant of the clay pot cooler: a clay pot is placed on top of a plastic or metal dish filled with sand and covered.<br/> | ||

| − | The first step of making a clay pot cooler is forming the clay pots, if using the pot-in-pot design, two pots should be formed of similar shape with one being smaller so that it can fit inside the other. Many potters use round concrete molds embedded in the ground and a pestle to beat a clump of clay into a spherical pot, however a complete spherical shape is not ideal. Alternatively, different sized basins made of plastic or metal can be used as molds if they have the desired dimensions. The clay pots are then completely dried, a process which may take 3-7 days. After drying the pots are fired, this process varies region to region but generally takes place over a large fire. After setting the fire, the pots should remain there for around 24 hours before being removed, cooled, and utilized to build clay pot coolers. To assemble the clay pot coolers, one pot is placed inside the other, in the pot-in-pot design, and the space in between is filled with sand. In the pot-in-dish design, the pot is placed in a dish of sand.<ref>https://d-lab.mit.edu/resources/publications/evaporative-cooling-best-practices-guide</ref><ref>https://practicalaction.org/video-zeer-pot-fridge</ref><br/> | + | [[File:Woman Clay Pot.JPG|thumb|right|x201px|A woman forming a clay pot in Burkina Faso]]The first step of making a clay pot cooler is forming the clay pots, if using the pot-in-pot design, two pots should be formed of similar shape with one being smaller so that it can fit inside the other. Many potters use round concrete molds embedded in the ground and a pestle to beat a clump of clay into a spherical pot, however a complete spherical shape is not ideal. Alternatively, different sized basins made of plastic or metal can be used as molds if they have the desired dimensions. The clay pots are then completely dried, a process which may take 3-7 days. After drying the pots are fired, this process varies region to region but generally takes place over a large fire. After setting the fire, the pots should remain there for around 24 hours before being removed, cooled, and utilized to build clay pot coolers. To assemble the clay pot coolers, one pot is placed inside the other, in the pot-in-pot design, and the space in between is filled with sand. In the pot-in-dish design, the pot is placed in a dish of sand.<ref name="Best Practices">https://d-lab.mit.edu/resources/publications/evaporative-cooling-best-practices-guide</ref><ref>https://practicalaction.org/video-zeer-pot-fridge</ref> |

| + | |||

| + | [[File:Pot assembly collage.png|thumb|center|300px|Left: The bottom of the outer pot is filled with sand<br/>Top right: The inner clay pot being placed in the outer pot<br/>Bottom right: The space between the pots filled with sand]] | ||

| + | |||

| + | <br/> | ||

=== Evaporative Cooling Chambers === | === Evaporative Cooling Chambers === | ||

| − | Evaporative cooling | + | An [[Evaporative cooling chamber|Evaporative cooling chamber]] (ECC) can be made from locally available materials including bricks, sand, wood, dry grass, gunny/burlap sack, and twine. Roy and Khuridiya’s ECC design is composed of a double brick wall structure, supported by a base layer of brick, and covered with a straw mat. The space in between the two brick walls is filled with sand, which retains the water that is added. If the evaporative cooling chamber is not build in an area that is well shaded, a shed must be constructed to provide shade. Inside the ECC, food is placed in unsealed plastic containers, which keep the vegetables off the ECC’s floor and allows them to breathe and be exposed to the cool, humid air inside the device.<ref name="Best Practices">https://d-lab.mit.edu/resources/publications/evaporative-cooling-best-practices-guide </ref><ref>https://www.youtube.com/watch?v=enOjVc-kN7Q</ref><br/> |

| − | <div class="csc-textpicHeader csc-textpicHeader-26"> | + | |

| + | [[File:ECC with cover.png|thumb|center|300px|An evaporative cooling chamber (ECC) under a shade cover made from wood, straw, and plastic]] | ||

| + | |||

| + | <br/> | ||

| + | <div class="csc-textpicHeader csc-textpicHeader-26"></div> | ||

= Best Practices for Use<br/> = | = Best Practices for Use<br/> = | ||

It is important that evaporative cooling technologies are correctly used to ensure maximum cooling performance benefit for the user. Improper use decreases the potential benefits and results in a lower cost-benefit ratio. ECCs and clay pot coolers must be places in a shady and well ventilated location. Exposure to wind and good ventilation increase the evaporation process. The evaporative cooling device should be watered frequently enough so that the sand is kept wet at all times, in order to enable the continuous cooling process. This frequency depends on the evaporation rate and the device’s water storage capacity. The opening on top of the ECC should be covered with woven straw or cloth, supported by a wood frame, and clay pot cooler should be covered with a lid, a plate, a wet cloth folded several times.<br/> | It is important that evaporative cooling technologies are correctly used to ensure maximum cooling performance benefit for the user. Improper use decreases the potential benefits and results in a lower cost-benefit ratio. ECCs and clay pot coolers must be places in a shady and well ventilated location. Exposure to wind and good ventilation increase the evaporation process. The evaporative cooling device should be watered frequently enough so that the sand is kept wet at all times, in order to enable the continuous cooling process. This frequency depends on the evaporation rate and the device’s water storage capacity. The opening on top of the ECC should be covered with woven straw or cloth, supported by a wood frame, and clay pot cooler should be covered with a lid, a plate, a wet cloth folded several times.<br/> | ||

| + | |||

| + | [[File:Clay pot cooler and ECC with covering.png|thumb|center|400px|Left: Covering a clay pot cooler<br/>Right: Covering an evaporative cooling chamber (ECC)]] | ||

Like the sand, the cloth should also be kept wet through the regular addition of water. The vegetables that need storage should be carefully considered. ECCs and clay pot coolers provide benefits if post-harvest vegetable spoilage is the result of exposure to high temperatures, low humidity, animals, or insects. <ref>https://d-lab.mit.edu/resources/publications/evaporative-cooling-technologies-improved-vegetable-storage-mali-evaluation</ref>However, not all produce can be stored together because some release ethylene, which can accelerate ripening or reduce postharvest quality. Like any device for storing food, the ECC or clay pot cooler should be kept clean. The surface of the interior cooling space should be sponged off regularly.<br/> | Like the sand, the cloth should also be kept wet through the regular addition of water. The vegetables that need storage should be carefully considered. ECCs and clay pot coolers provide benefits if post-harvest vegetable spoilage is the result of exposure to high temperatures, low humidity, animals, or insects. <ref>https://d-lab.mit.edu/resources/publications/evaporative-cooling-technologies-improved-vegetable-storage-mali-evaluation</ref>However, not all produce can be stored together because some release ethylene, which can accelerate ripening or reduce postharvest quality. Like any device for storing food, the ECC or clay pot cooler should be kept clean. The surface of the interior cooling space should be sponged off regularly.<br/> | ||

| − | + | ||

<br/> | <br/> | ||

| − | = References = | + | = Publications and Tools<br/> = |

| + | |||

| + | * | ||

| + | [https://www.engineeringforchange.org/news/clay-pot-coolers-keep-produce-fresh-without-electricity/ Clay Pot Coolers: Keep Produce Fresh Without Electricity] (2021): Engineering for Change. | ||

| + | |||

| + | *[[Publication - Evaluation of Evaporative Cooling Technologies for Improved Vegetable Storage in Mali - Evaluation|MIT D-Lab (2018). Evaluation of Evaporative Cooling Technologies for Improved Vegetable Storage in Mali - Evaluation]]: This publication evaluates the potential for for non-electric evaporative cooling devices (i.e. evaporative cooling chambers” (ECCs) and the clay pot coolers) to address post-harvest vegetable storage challenges in rural Mali.<br/> | ||

| + | *[http://d-lab.mit.edu/resources/publications/evaporative-cooling-decision-making-tool Evaporative Cooling Decision Making Tool]: This excel based tool helps to determine if evaporative cooling devices are suitable for a specific context, and to guide the calculation of potential financial savings.<br/> | ||

| + | *[[Publication - Evaporative Cooling Best Practices Guide|MIT D-Lab (2018). Evaporative Cooling Best Practices Guide:]] This guide provides best practices for:determining the suitability of evaporative cooling technologies for a specific context, construction and usage of clay pot coolers and evaporative cooling chambers and dissemination approaches | ||

| + | |||

| + | = References<br/> = | ||

<references /><br/> | <references /><br/> | ||

| + | |||

| + | [[Category:Africa]] | ||

| + | [[Category:Agriculture]] | ||

| + | [[Category:Cooling]] | ||

Latest revision as of 10:10, 7 April 2021

Overview

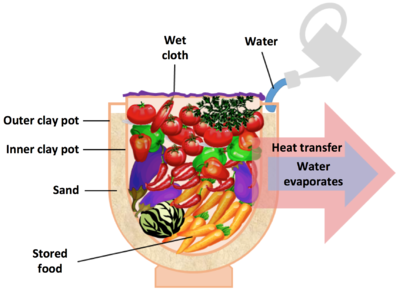

Evaporative cooling devices are simple and inexpensive ways to keep vegetables fresh without the use of electricity. Evaporative cooling devices include household capacity clay pot coolers, commonly known as "Zeer Pots," and the larger storage Evaporative cooling chamber (ECC), also known as "zero energy cool chamber" (ZECC). These devices function according to a basic principle called “evaporative cooling,” where the evaporation of water from a surface removes heat, creating a cooling effect.

Evaporative cooling can improve vegetable storage shelf life by providing a stable storage environment with low temperature and high humidity, which reduces the rate of respiration and water loss and spoilage in most vegetables. The improved storage environment can have positive impacts including reduced post-harvest losses, less time spent traveling to the market, monetary savings, and increased availability of vegetables for consumption.

Clay pot coolers have been used for centuries to help farmers reduce food spoilage and waste, increase their income, and limit the health hazards of spoiled foods. Clay pot coolers are typically used at the household level due to their simple construction and relatively small size. The pot-in-pot design – commonly known as the “Zeer pot” – was popularized in 1995 by Mohammed Bah Abba in Nigeria.[1]

Evaporative cooling chambers (ECCs) – also known as “zero energy cool chambers (ZECCs)” – are large capacity evaporative cooling devices that are typically used by larger producers or community groups with up to 50 members. The brick ECC was originally developed in India by Susanta K. Roy and D.S. Khuridiya in the early 1980s [2][3] to address fruit and vegetable post-harvest losses, especially in rural areas without electricity.

Suitability[4][5]

Several factors should be assessed to determine if an evaporative cooling device will meet users needs in a particular setting. Specific operating conditions are required for the evaporative cooling device to operate effectively

- Low relative humidity (less than 40%)

- High temperature (daily maximum above 25 °C)

- Access to water, which must be added for the evaporative cooling to work

- The availability of a shady, well-ventilated location

The storage conditions provided by evaporative cooling devices must meet users’ needs. Potential users should consider

- Optimal storage conditions for their different vegetables

- Scale of vegetable storage needed

- Variations in the need for vegetable cooling and storage throughout the year

The cost of the evaporative cooling device must be affordable and justified by the benefits that will be realized due to its improved storage. Potential users should evaluate

- Local availability and affordability of materials to construct the device,

- Potential benefits of evaporative cooling devices such as time and money saved, increased vegetable availability, improved hygiene and convenience.

Construction

Clay Pot Coolers

Clay pot coolers are composed of two clay pots with the same shape but different sizes. One pot is placed inside the other and the space between the two containers is filled with sand, which retains the water added. Food is placed inside the interior pot, and both pots are covered with a lid or a damp piece of cloth. The pot-in-dish design is a variant of the clay pot cooler: a clay pot is placed on top of a plastic or metal dish filled with sand and covered.

The first step of making a clay pot cooler is forming the clay pots, if using the pot-in-pot design, two pots should be formed of similar shape with one being smaller so that it can fit inside the other. Many potters use round concrete molds embedded in the ground and a pestle to beat a clump of clay into a spherical pot, however a complete spherical shape is not ideal. Alternatively, different sized basins made of plastic or metal can be used as molds if they have the desired dimensions. The clay pots are then completely dried, a process which may take 3-7 days. After drying the pots are fired, this process varies region to region but generally takes place over a large fire. After setting the fire, the pots should remain there for around 24 hours before being removed, cooled, and utilized to build clay pot coolers. To assemble the clay pot coolers, one pot is placed inside the other, in the pot-in-pot design, and the space in between is filled with sand. In the pot-in-dish design, the pot is placed in a dish of sand.[5][6]

Evaporative Cooling Chambers

An Evaporative cooling chamber (ECC) can be made from locally available materials including bricks, sand, wood, dry grass, gunny/burlap sack, and twine. Roy and Khuridiya’s ECC design is composed of a double brick wall structure, supported by a base layer of brick, and covered with a straw mat. The space in between the two brick walls is filled with sand, which retains the water that is added. If the evaporative cooling chamber is not build in an area that is well shaded, a shed must be constructed to provide shade. Inside the ECC, food is placed in unsealed plastic containers, which keep the vegetables off the ECC’s floor and allows them to breathe and be exposed to the cool, humid air inside the device.[5][7]

Best Practices for Use

It is important that evaporative cooling technologies are correctly used to ensure maximum cooling performance benefit for the user. Improper use decreases the potential benefits and results in a lower cost-benefit ratio. ECCs and clay pot coolers must be places in a shady and well ventilated location. Exposure to wind and good ventilation increase the evaporation process. The evaporative cooling device should be watered frequently enough so that the sand is kept wet at all times, in order to enable the continuous cooling process. This frequency depends on the evaporation rate and the device’s water storage capacity. The opening on top of the ECC should be covered with woven straw or cloth, supported by a wood frame, and clay pot cooler should be covered with a lid, a plate, a wet cloth folded several times.

Like the sand, the cloth should also be kept wet through the regular addition of water. The vegetables that need storage should be carefully considered. ECCs and clay pot coolers provide benefits if post-harvest vegetable spoilage is the result of exposure to high temperatures, low humidity, animals, or insects. [8]However, not all produce can be stored together because some release ethylene, which can accelerate ripening or reduce postharvest quality. Like any device for storing food, the ECC or clay pot cooler should be kept clean. The surface of the interior cooling space should be sponged off regularly.

Publications and Tools

Clay Pot Coolers: Keep Produce Fresh Without Electricity (2021): Engineering for Change.

- MIT D-Lab (2018). Evaluation of Evaporative Cooling Technologies for Improved Vegetable Storage in Mali - Evaluation: This publication evaluates the potential for for non-electric evaporative cooling devices (i.e. evaporative cooling chambers” (ECCs) and the clay pot coolers) to address post-harvest vegetable storage challenges in rural Mali.

- Evaporative Cooling Decision Making Tool: This excel based tool helps to determine if evaporative cooling devices are suitable for a specific context, and to guide the calculation of potential financial savings.

- MIT D-Lab (2018). Evaporative Cooling Best Practices Guide: This guide provides best practices for:determining the suitability of evaporative cooling technologies for a specific context, construction and usage of clay pot coolers and evaporative cooling chambers and dissemination approaches

References

- ↑ http://growinginclusivemarkets.org/media/cases/Nigeria_PotInPot_2011.pdf

- ↑ Roy, K. S., & Khurdiya, D. S. (1982). Keep vegetables fresh in summer (Vol. 27). Indian Horticulture.

- ↑ Roy, S. K., & Khurdiya, D. S. (1985). Zero Energy Cool Chamber (Vol. 43). India Agricultural Research Institute: New Delhi, India. Research Bulletin.

- ↑ https://bit.ly/2DrGXeP

- ↑ 5.0 5.1 5.2 https://d-lab.mit.edu/resources/publications/evaporative-cooling-best-practices-guide Cite error: Invalid

<ref>tag; name "Best Practices" defined multiple times with different content - ↑ https://practicalaction.org/video-zeer-pot-fridge

- ↑ https://www.youtube.com/watch?v=enOjVc-kN7Q

- ↑ https://d-lab.mit.edu/resources/publications/evaporative-cooling-technologies-improved-vegetable-storage-mali-evaluation