Difference between revisions of "Evaporative cooling chamber"

***** (***** | *****) |

***** (***** | *****) |

||

| Line 19: | Line 19: | ||

<br/>[[File:Crates in ECC.png|thumb|center|400px|Vegetables stored in an evaporative cooling chamber]]<br/> | <br/>[[File:Crates in ECC.png|thumb|center|400px|Vegetables stored in an evaporative cooling chamber]]<br/> | ||

| + | |||

| Line 35: | Line 36: | ||

Below is a detailed step-by-step process for building an ECC:<ref> Verploegen, E.; Rinker, P.; Edoh Ognakossan, K. (2018). Evaporative Cooling Best Practices Guide. Copyright © Massachusetts Institute of Technology (Accessed on Oct 16,2018). https://d-lab.mit.edu/sites/default/files/inline-files/Evaporative%20Cooling%20Best%20Practices%20Guide.pdf </ref><br/><br/> | Below is a detailed step-by-step process for building an ECC:<ref> Verploegen, E.; Rinker, P.; Edoh Ognakossan, K. (2018). Evaporative Cooling Best Practices Guide. Copyright © Massachusetts Institute of Technology (Accessed on Oct 16,2018). https://d-lab.mit.edu/sites/default/files/inline-files/Evaporative%20Cooling%20Best%20Practices%20Guide.pdf </ref><br/><br/> | ||

| − | [[File:Making ECC 1.png|left|200px|alt=Making ECC 1.png]]<br/><br/>1) Make a foundation of approximately 165 cm x 115 cm with bricks. The dimensions can vary according to the storage volume needed<br/><br/><br/><br/><br/><br/> | + | [[File:Making ECC 1.png|left|200px|alt=Making ECC 1.png]]<br/><br/>1) Make a foundation of approximately 165 cm x 115 cm with bricks. The dimensions can vary according to the storage volume needed<br/><br/><br/><br/><br/><br/><br/> |

| − | [[File:Making ECC 2.png|left|200px|alt=Making ECC 2.png]]2) Mount the double wall at approximately a height of 67.5 cm leaving a cavity of 7.5 cm wide between the walls<br/><br/><br/><br/><br/><br/><br/> | + | [[File:Making ECC 2.png|left|200px|alt=Making ECC 2.png]]2) Mount the double wall at approximately a height of 67.5 cm leaving a cavity of 7.5 cm wide between the walls<br/><br/><br/><br/><br/><br/><br/><br/> |

| − | [[File:Making ECC 3.png|left|200px|alt=Making ECC 3.png]]3) Wet the walls of the chamber with water<br/><br/><br/><br/><br/><br/> | + | [[File:Making ECC 3.png|left|200px|alt=Making ECC 3.png]]3) Wet the walls of the chamber with water<br/><br/><br/><br/><br/><br/><br/> |

[[File:Making ECC 4.png|left|200px|alt=Making ECC 4.png]]4) Fill the cavity between the two walls with wet sand. It is better to use the sand from a nearby river if possible.<br/><br/><br/><br/><br/><br/> | [[File:Making ECC 4.png|left|200px|alt=Making ECC 4.png]]4) Fill the cavity between the two walls with wet sand. It is better to use the sand from a nearby river if possible.<br/><br/><br/><br/><br/><br/> | ||

Revision as of 17:18, 16 October 2018

Overview

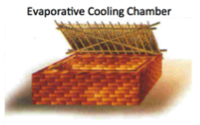

Evaporative cooling chambers (ECCs) are a subset of Evaporative cooling devices, which are simple and inexpensive ways to keep vegetables fresh without the use of electricity. Evaporation of water from a surface removes heat, creating a cooling effect, which can improve vegetable storage shelf life. ECCs are relatively large compared to the more common household clay pot cooler, and are therefore most suitable for farmers with large production quantities, farming groups, or farming cooperatives.

History

The brick ECC was originally developed in India by Susanta K. Roy and D.S. Khuridiya in the early 1980s to address fruit and vegetable post-harvest losses, especially in rural areas where electricity is non-existent.[1][2] Roy and Khuridiya’s ECC design is composed of a double brick wall structure, supported by a base layer of brick, and covered with a straw mat.

Suitability

ECCs provide the most benefits when they are used in low humidity climates (less than 40% relative humidity), the temperature is relatively hot (maximum daily temperature greater than 25 °C), water is available to add to the device between one and three times per day, and the device can be located in a shady and well-ventilated area.

Additionally, storage conditions must meet users’ needs for scale of storage needed and optimal conditions for different vegetables throughout the year. The cost of the ECC must be affordable and justified by the benefits be realized due to its improved storage.[3][4]

Construction

The size of an ECC can be chosen to meet a range of user storage needs; however, the cost can vary significantly based on desired size and local cost of materials. Because ECCs can be constructed over a range of sizes, it is important to select an appropriate size according to the need, to avoid over-building and spending more money than is needed.

Evaporative cooling chambers (ECCs) can be made from locally available materials including bricks, sand, wood, dry grass, gunny/burlap sack, and twine. The space in between the two brick walls is filled with sand, which retains the water that is added. If the evaporative cooling chamber is not build in an area that is well shaded, a shed must be constructed to provide shade. Inside the ECC, food is placed in unsealed plastic containers, which keep the vegetables off the ECC’s floor and allows them to breathe and be exposed to the cool, humid air inside the device.

Below is a detailed step-by-step process for building an ECC:[5]

1) Make a foundation of approximately 165 cm x 115 cm with bricks. The dimensions can vary according to the storage volume needed

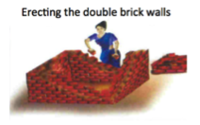

2) Mount the double wall at approximately a height of 67.5 cm leaving a cavity of 7.5 cm wide between the walls

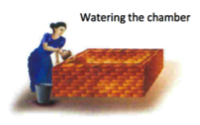

3) Wet the walls of the chamber with water

4) Fill the cavity between the two walls with wet sand. It is better to use the sand from a nearby river if possible.

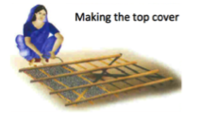

5) Make a frame from wood the same size as the foundation (165 cm 5) x 115 cm). Cover the wood frame with straw, dry grass, or burlap sack and secure with rope or twine.

6)The cover goes over the evaporative cooling chamber to keep the cool air inside the chamber

7) Store your products in plastic crates or baskets in the chamber. Plastic crates containing products must be arranged on top of each other

8) Place a clear plastic sheet over the plastic baskets containing the fruits and vegetable ECC in operation to extend the shelf life of fruits and vegetables.

9) If the evaporative cooling chamber is not build in an area that is well shaded, a shed must be constructed to provide shade.

Additionally, videos on construction are available.[6][7][8]

Best Practices for Use

It is important that ECCs are correctly used to ensure maximum cooling performance benefit for the user. Improper use decreases the potential benefits and results in a lower cost-benefit ratio. Before starting to build an ECC, a location should be chosen that is close to water, exposed to wind/breeze, and if possible where there is shade to avoid the need of a cover. ECCs should be reinstalled every 3 years with new bricks. The cover of the ECC should be opened as infrequently as possible to keep the cool air in. The sand between the bricks must be kept wet, installing an irrigation system can make this process simpler. Additionally water should be sprinkled on the cover 1-3 times per day.

The vegetables that need storage should be carefully considered, since not all produce can be stored together because some release ethylene, which can accelerate ripening or reduce postharvest quality. Like any device for storing food, the ECCs should be kept clean. The surface of the interior cooling space should be sponged off regularly.

References

- ↑ Roy, K. S., & Khurdiya, D. S. (1982). Keep vegetables fresh in summer (Vol. 27). Indian Horticulture.

- ↑ Roy, S. K., & Khurdiya, D. S. (1985). Zero Energy Cool Chamber (Vol. 43). India Agricultural Research Institute: New Delhi, India. Research Bulletin.

- ↑ Roy, S. K. (1989). On-farm storage technology can save energy and raise farm income. Amity Science, Technology & Innovation Foundation. http://ucce.ucdavis.edu/files/datastore/234-2143.pdf

- ↑ Odesola, I. F., & Onwuka, O. (2009). A Review of Porous Evaporative Cooling for the Preservation of Fruits and Vegetables. (Vol. 10). The Pacific Journal of Science and Technology. https://www.researchgate.net/publication/228406788

- ↑ Verploegen, E.; Rinker, P.; Edoh Ognakossan, K. (2018). Evaporative Cooling Best Practices Guide. Copyright © Massachusetts Institute of Technology (Accessed on Oct 16,2018). https://d-lab.mit.edu/sites/default/files/inline-files/Evaporative%20Cooling%20Best%20Practices%20Guide.pdf

- ↑ Build your own Zero Energy Cooling Chamber (ZECC) (World Vegetable Center): https://www.youtube.com/watch?v=enOjVc-kN7Q

- ↑ Zero Energy Cooling Chamber (Indian Society of Agribusiness Professionals): https://www.youtube.com/watch?v=C8_D5TI-NoI

- ↑ Storage Structure For Fruits Vegetables (Ministry of Food Processing Industries, Government of India): https://www.youtube.com/watch?v=95RRdoySdjA&t=245s