Click here to register!

Hohenheim Milk Cooling System - Implementation in Kenya

Introduction

Smallholder dairy farms are the major providers of marketed milk in Kenya, becoming even stronger when associating in cooperatives. These groups are mostly constrained by a lack of cooling systems, reduced hygienic conditions, minimum cleaning procedures and in some cases problems with cattle health, which results in high microbial contamination.

Under warm climatic conditions, raw milk can exceed the maximum bacterial count after two to five hours without cooling resulting in a lack of quality and leading to high rates of rejected milk at the different stages of collection. Therefore, drawing on the experience of a successful research project in Tunisia, the solar milk cooling group is testing solar-based cooling systems that can be operated independently offering an off grid solution for remote areas in Kenya.

This research aims the development of dairy value chains in an integrated approach to improve productivity and reduce losses along the value chain.

Siaya county

January 2016 until December 2017:

The work is supported by the Program of Accompanying Research for Agricultural Innovation – PARI and GIZ initiatives in Kenya (Powering Agriculture-PA and Green Innovation Centres – GIC).

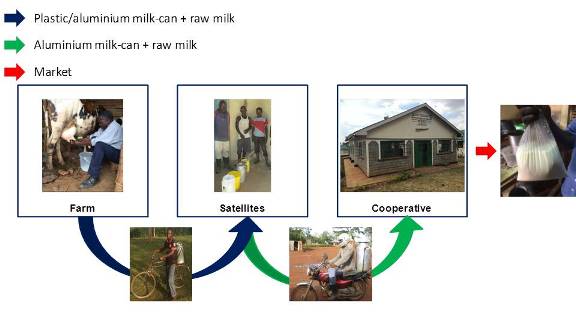

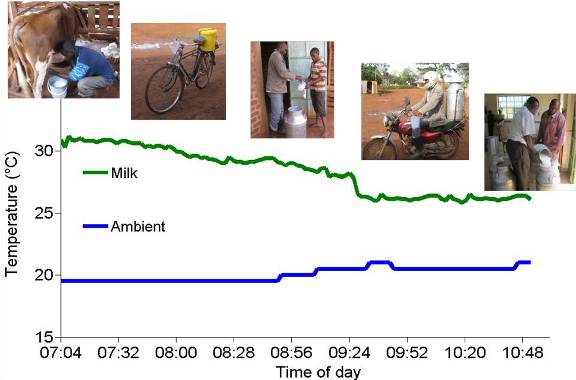

The success for the implementation of this innovative technology relies on the plastic insulated milk can. As a first stage of the introduction of the technology, measurements on milk temperature during transport were collected from milking to the moment of retailing at SAM Malanga dairy cooperative society in Siaya county (located at 0.06 N, 34.29 E). The target was the establishment of the state of the art in the region. Milk temperature profiles were genertated over the transport time to the cooperative as it is shown in Figure 2. By performing this procedure, a low milk quality could be expected.

Figure 2. Ambient temperature and milk temperature during transport from the farm to the cooperative.

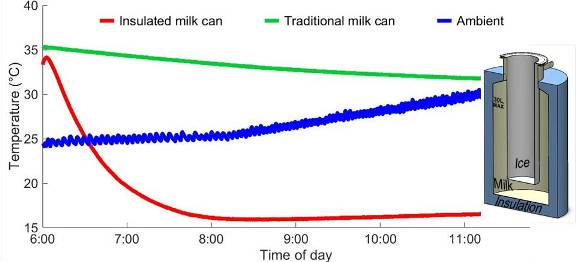

Base on this initial information, milk temperature profile was evaluated in the insulated milk can and compare with a traditional milk can (aluminum milk can) following the protocol for the stainless steel insulated milk can for Tunisia. Figure 3 shows the similar performance of the stainless steel milk can, which will result in preservation of milk quality.

Figure 3. Cooling performance of the insulated milk can under laboratory conditions (climate chamber) for 30 Liter milk and 6 kg ice.

Currently, the evaluation is being performed in collaboration with PA, GIC, Jaramogi Oginga Odinga University of Science and Technology (JOOUST), SAM Malanga dairy cooperative society. The first stage of this research is covering the installation and monitoring the system at the cooperative. Further research will focus in the evaluation of the system in early stages of milk handling (satellites and farm).