Liquefied Petroleum Gas (LPG)

Liquefied Petroleum Gas (LPG) is considered a clean and environmentally-friendly source of energy. As an energy source for cooking it can reduce the negative health impacts of 2.6 billion people who currently cook with inefficient biomass stoves that emit harmful smoke and particles.

The potential of LPG as an alternative cooking fuel is know for several years now. In 2001, a joint study of the World Bank and the World LPG Association (WLPGA) describes the potential of Liquefied Petroleum Gas (LPG) for an improved supply in impoverished countries in the following way:

„Liquefied Petroleum Gas (LPG) is a clean and environmentally-friendly source of energy. To protect the environment LPG could be made available to replace wood and biomass in all households in all developing countries.” (World Bank und WLPGA, 2001)

Today, LPG plays an increasingly important role in cooking energy interventions. In order to estimate the long-term potential of LPG as a fuel in the cooking energy sector, this article presents key aspects regarding the use of LPG as a cooking fuel in low-income households. At the end of each chapter, further links are provided to allow for a deeper exploraiton of each of the presented topics.

Facts & Figures about LPG

What is LPG?

LPG stands for 'Liquefied Petroleum Gas' denoting mainly propane, butane and mixes of the two. These hydrocarbons are sourced during petroleum extraction and its refining process and thus count as fossil fuels.

Under normal atmospheric conditions LPG is a colourless and odourless gas. Under pressure, LPG becomes liquid. This process leads to the reduction of the volume to 1/260 of the gaseous aggregate state.

In relation to other fuels, the energy density of LPG (27.5 MJ/kg) is high (~ 10-times higher than wood). As a result, transport and storage of LGP is easier than it is for wood (Practical Action, 2003).

Liquefied Gas is heavier than air and can therefore create 'lakes' on the ground. To prevent explosions and to recognise leakages, it is a common practice to mix odorous substances into the gas.

Further Information:

These factsheets present different characteristics of different cooking fuels

An article about the differences between Compressed Natural Gas (CNG), Liquefied Natural Gas (LNG) and hydrogen.

This website (German) of the German Association of Liquid Gas communicates news information and events.

Supply and Demand of LPG

LPG Supply

1. How is LPG produced?

LPG is a by-product of the fossil fuel industry; it is separated during petroleum and gas extraction as well as during raw oil refining where it is separated from other types of energy (heavy oil, diesel etc.).

45% of global LPG production is a product of the refinery process. The remaining 55% of LPG stocks are separated as accompanying products during oil and gas extraction.

a. LPG from petroleum gas and oil extraction (55%)

Depending on its origin, natural gas is made up of gases and liquids to varying degrees. As commercially used gas has to consist almost purely of methane, the extracted raw gas needs to be cleaned. In this process, gases that are not desired in the commercial gas distribution have to be removed. Propane and butane are used as LPG. 1 - 10% of the total 'raw petroleum gas' will become LPG (WLPGA, 2014).

During oil extraction, LPG appears as an accompanying gas. Depending on the origin, each ton of extracted petroleum contains 25 - 800 m³ accompanying gas. This is immedialely extracted in order to stabilise the raw oil. These accompanying gases are then either processed or burnt on the spot. As part of the latter process - known as flaring - approximately 140 billion m³ of potential LPG are burnt every. This is equal to approx. 70 million tons (or 5 % of the global gas consumption) and a value loss of 30 - 35 billion USD (Roenn, 2013).

b. LPG from the refining process (45 %)

LPG is separated from other derivatives in oil and gas refineries. Commonly 4 - 5 % of the total raw oil can be extracted as LPG. This value can sink to 1 % in relation to other oil products depending on the quality of the raw oil, the technical standard of a given refinery and current market prices for propane and butane in comparison to other oil products (WLPGA, 2014).

2. How much LPG is produced?

230 million tons of LPG were produced in 2008. By 2012, the global production had risen to 274 million tons (equivalent to a 19% increase).

Between 2011 and 2012 production rose another 3%. This growth that can almost exclusively be attributed to the gas extraction sector- whose LPG production capacities grew 6%. This especially includes the US-led expansion of shale gas extraction 'fracking'- since the expansion of 'fracking' US LPG production rose by 8%. (Leija and Gist, 2013).

3. Where is LPG produced?

For a long time North America was the largest LPG producer. By now the Middle East is the leading LPG producing region. Local LPG processing capacities in the Middle East both from oil and gas were strengthened substantially in the last couple of years. In 2012, 67 million tons of LPG were produced in the Middle East alone.

In the next couple of years, North American production capacities are expected to grow again due to the expansion in the shale gas sector (PR Newswire, 2013). It is also expected that production will rise in West Africa, Australia, Russia and China (Argus, 2013). This increase is mainly possible through the development of refineries which allow the extraction of LPG.

4. How much LPG will be available in the future?

As a by-product of the oil production, the supply of LPG is directly dependent of the extraction of fossil fuels. As oil extraction rises, the increased production of LPG becomes possible. When it falls, LPG availability will also fall. Larger production capacities may open up from the discovery of new oil fields - e.g. in Antarctica or from the extraction of shale gas. Nevertheless, this poses significant environmental threats and is thus highly controversial.

More LPG may also be made available by using the presently burnt accompanying gases during oil or gas extraction (flaring). This currently adds up to 70 million tons of gas available as a ressource. The technology to exploit LPG from accompanying gases exist. First attempts to power villages from such accompanying gases are prepared as part of a High Impact Opportunities under SE4All (see SE4All).

LPG Demand

1. How much LPG is consumed where?

Global LPG consumption in 2008 stood at 230 million tons. By 2012, consumption rose to 265 million tons.

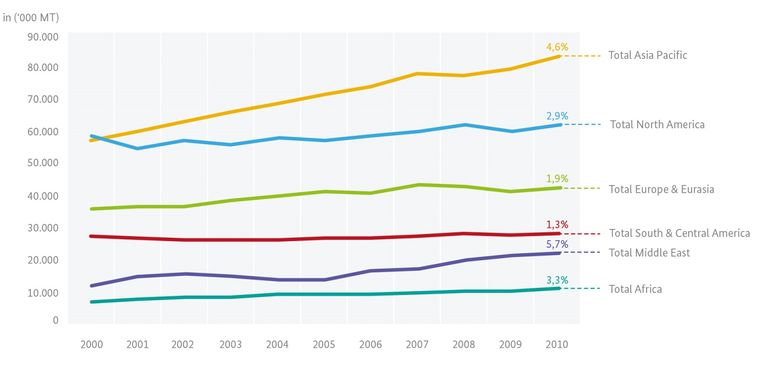

The largest proportion of the increase can be attributed to the Asian-Pacific region. Consumption there rose from 58,000 million tons to 80,000 million tons between 2000 and 2010. In 2011 the Asia-Pacific region made up 35 % of global consumption. Annual growth rates of 4.8 % in demand are anticipated until 2018 (PR Newswire, 2013).

<p style="text-align: center;"

Fig. 1. Global LPG consumption from 2002-2012 (adapted from Argus, 2013)

Regarding individual countries, China is the leading LPG consumer consuming 13.3 million tons, followed by India consuming 9.9 million tons. USA, Mexico and Brazil consume 7.5, 6.3 and 5 million tons of LPG per year.

2. What is LPG used for?

There are more than 2000 different uses for LPG. Globally most consumption occurs at the household level (49 %), followed by petrochemical usages (21.6 %), industrial usages (11.8 %), direct consumption in refineries and finally the agricultural sector (2 %). Other sectors (e.g. Auto gas) make up an aggregated 9.3 % of total LPG consumption (Stealthgas, 2013).

In industrial countries, LPG is used for the following purposes:

- Heating and Cooking - especially in locations that are not connected to local gas distribution systems.

- Auto gas - Consumption of auto gas is enhanced through low taxes. In 2008, more that 13 million cars ran on LPG globally. Industries are currently promoting the spread of car gas.

- Furthermore, LPG is used for cooling and in the Petrochemical industry. The petrochemical industry uses LPG for instance in the production of plastic (LPGas, 2013).

In developing countries LPG is popular as a cooking fuel. Users are predominately urban-dwellers in places where there is a supply network and people have a high disposable income available that is necessary for acquisition and running fuel costs.

Relationship between demand and supply

Since 2007, the global production capacity of LPG is growing faster than demand: In 2012, there were 9.7 million tons of LPG availalbe in excess. This gap is currently widening. In 2012, for example, consumption rose by 2 % whereas production rose by 3 %.

Despite excess capacities, LPG remains scarce in many regions - especially in the rural areas of developing countries (see e.g. Chandra, 2010). This is mainly due to lacking supply networks, which are not able to supply households with the excess LPG. Furthermore, the target group 'poor households' which is a large potential customer group often targeted in international initiatives tends to dispose of too little income to afford LPG. This will be discussed further below.

The excess amount of LPG is thus often processed. LPG is used in petrochemical industries or in the production of Liquid Natural Gas (Argus, 2013).

Further Information:

Short overview of results of statistical research of Argus and WLPGA concerning the production and consumption of LPG.

A PowerPoint presentation on plans of the Indian government concerning LPG consumption and development.

A World Bank sponsored study of LPG markets in 20 different countries.

Short overview of results of a market survey by Transparency Market Research about the future development of LPG markets.

Documentary (in German) about gas flaring and technical solutions to extract accompanying gases.

Supply routes of LPG

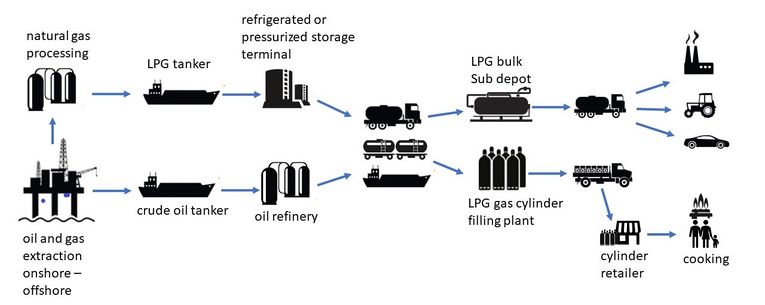

A number of different steps are necessary from the production-that is the extraction- of LPG until it reaches the end-consumer. This requires infrastructure for its distribution.

It starts with Step 1 - Production. LPG is separated from petroleum gas or oil. As described above, this ensures the stabilisation of the petroleum or the cleansing of the gas. In this process 55 % of global production is extracted.

In Step 2 - Transport, the remaining petroleum gas or oil as well as the separated LPG is transported through ships, pipelines and trains.

While oil and gas is transported to refineries, LPG is transported in special storage facilities where it is already put under pressure. This is Step 3 - Refinery and Storage. As described above further LPG is separated and gained in refineries (45 % of global production).

In Step 4 – Further Transport, LPG is transported from refineries or large warehouses to smaller warehouses or cylinder charging stations.

Figure 2. Route of LPG from production to the end-consumer (adapted from WLPGA, 2014)

In Step 5- Cylinder charging and Storage, LPG is filled into smaller cylinders or stored in warehouses for consumption.

This is followed by Step 6- Distribution, where cylinders or small quantities of LPG are distributed to the end-consumer. This is done mainly through Lorries.

In the last Step 7- End-consumer, the route from production to the customer is finalised. Depending on the circumstances smaller cylinder merchants can locally store LPG and fill it into smaller cylinders. Alternatively, they can be sold directly to the consumer in small cylinders. Bigger customers in industries usually dispose of larger storage tanks.

Further Information:

A short film (German) about the supply routes of LPG from the North Sea to the end-consumer.

LPG as a Cooking Fuel for Low-Income Households

General factors concerning the choice of cooking fuels

The selection of the type of fuel during cooking is contingent of several factors. Factors influencing the decision are availability, affordability, habits and the usability of the fuel. The prevailing use of fire food in many developing countries is primarily because it is cheap (often free) and widely available. In the future wood will remain the primary cooking fuel for rural households (GIZ, 2014).

An increase in LPG usage could reduce the total usage of wood, coal and kerosene. This is already the case in some cities where LPG was widely available leading to higher consumption rates. It should nevertheless be noted that households to not completely replace one fuel by another. Instead, they use a mix of fuels and a singular fuel in a given moment is chosen depending on the characteristic of the fuel (heating up time, type of food prepared, income etc.).

LPG Cooking Systems

A typical cooking system which uses LPG is made up of a steel cylinder filled with LPG, a pressure controller, a tube connecting the cylinder to the pressure controller and the burner, and finally the burner itself. The burner can consist of one or more cooking tops.

The size of the system depends on the size of the cylinder. Cylinders exist in various sizes e.g.: 2.7 kg, 6 kg, 12 kg or 16 kg. A survey in 20 countries showed that low-income countries households mainly use cylinders smaller than 6 kg (Weltbank, 2011).

Nevertheless, the majority of currently available LPG cylinders are larger (up to 47.5 kg). This proves problematic for low-income households both in the acquisition as well as the recharge of LPG. In low-income countries, the limited availability of small cylinders acts as a barrier to improving LPG supply.

LPG stoves tend to have an efficiency of 55 and 60%. A 14 kg LPG stove with equipment costs approximately 66$. The life-cycle is 5-8 years.

Advantages and disadvantages of LPG as a cooking fuel for low-income households

Advantages of LPG as a cooking fuel

The main advantages of LPG provision of low-income households in comparison to conventional fuels (wood, wood charcoal) are:

The use of LPG reduces the interior air pollution by 90% in comparison to traditional ways of burning biomass e.g.: three-stone fire (WHO, 2011; Polsky and Ly, 2012). As LPG burns almost completely, the proportion of pollutants is reduced.

CO2 emissions are relatively low. Greenhouse gases are reduced by 5-16 times per prepared meal compared to coal (Bailis et al., 2003). If LPG was used, the wood consumption can be substantially reduced - 45 kg of LPG is sufficient to produce the thermic energy of about half a ton of wood. In regions with low biomass availability, or in regions where more than the sustainably available amount of biomass is burnt, LPG could lead to a significant relief of biomass resources.

3. Further advantages

LPG stoves quickly supply heat and work more efficient than stoves which burn biomass. The simple and precise regulation simplifies the cooking process and can save time.

Due to its high energy density, LPG is easily transportable.

Disadvantages of LPG as a cooking fuel

The disadvantages of LPG as a cooking fuel are the following:

1. Availability

In 2002 it was calculated that 120 billion tons of LPG are necessary to supply 2 billion people with cooking fuels (UNDP, 2000). This equates to 60 kg of LPG per head which currently equates to half of the global production. Such quantities of LPG are currently not available to be used as a cooking fuel. It results that the following goals must be met for an efficient LPG supply as a cooking fuel:

- new sources must be found (shale gas through fracking, oil extraction in the arctic).

- current extraction processes must become more efficient (higher LPG share as a refining product, accompanying gas)

or

- uses in other sectors must be reduced (e.g. reduced use of conventional gas for heating, decreased use in the petrochemical industry, reduced use of autogas, etc.).

2. Costs

In most countries in which an improved LPG provision would be reasonable, the LPG market is underdeveloped or non-existent. The development of available structures would require substantial financial means. These entail:

a. Costs of developing the market / infrastructure investments

The development of the LPG market is bound up with significant investments. The necessary investments include:

- production capacities need to be built or developed

- in case of LPG import, import facilities must be available - in case of demand fluctuations, individual countries must be able to store large quantities of LPG

- Smaller storage and filling stations must be developed to supply LPG to the customers

It is difficult to estimate the costs of developing an LPG market and no reports are known thus far that provide accurate numbers. However, the infrastructure costs can be expected to be very high and increasing with transportation complexities.

b. Upfront investment costs for the consumer

Next to investment into supply infrastructure, consumers also require capital to buy individual components such as a stove which can use LPG. A LPG cylinder system with a 14 kg cylinder costs approx. 66 US$. This acts as a barrier for many households and is a disadvantage in relation to competing cooking fuels like wood, coal and kerosene. For example, the average costs for a kerosene stove are 83 % lower (TDL, 2013). Improved wood or wood charcoal stoves can be obtained for 2 US$.

c. Running costs for the consumer

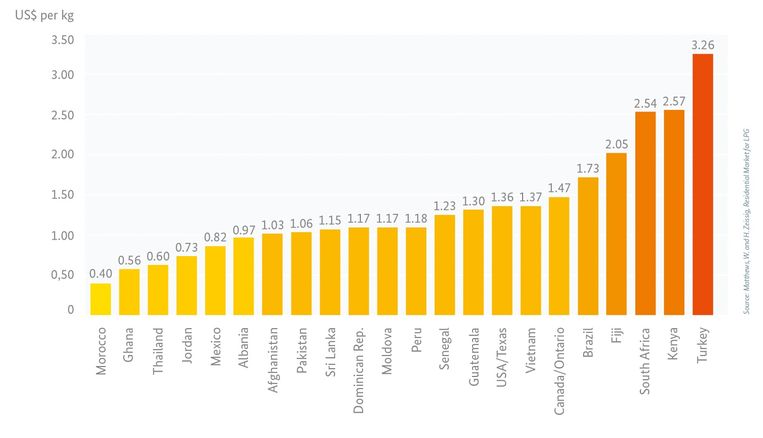

In November 2010, the international market price for LPG was at 850 US$ per ton. The World Bank estimates that the supply chain adds approx. 300 US$ per ton before the LPG reaches the final consumer. This equates to a net price of about 1.15 US$ per kg of LPG (excluding taxes and subsidies). In the 20 countries in which the local price of LPG was surveyed, 6 countries were found to have prices within 0.10 US$ of this price level. In the remaining 14 countries larger price variations were found (the two extremes being Morocco with 0.40 US$ / kg and Turkey with 3.26 US$ / kg).

Figure 3. LPG prices for the end-consumer in December 2010 (adapted from Matthews and Zeissig, 2011)

The price of LPG decreases in line with the bought quantity and shorter travel routes. Low-income households in rural areas will thus pay a higher price for LPG. This is a disadvantage to wood and coal, given that wood is often free and coal fairly cheap. Furthermore, low-income households can often not afford bulk buys.

d. Insecurities regarding price development

A further disadvantage of LPG is its fluctuating cost. In India the price of unsubsidized LPG cylinders of 14.2 kg increased by 20 % within one year (ToI, 2014). Information regarding long-term price development of LPG are not available in an aggregated format. In many regions potential customers therefore reject changing their cooking fuel use to LPG. In South Africa, a household survey stated that households decided not to use LPG due to the insecure price developments (Burger, 2010).

Tabular overview of the advantages and disadvantages of LPG as a cooking energy fuel

The following table summarises the most important advantages and disadvantages of LPG as a cooking fuel for low income households:

Advantages |

Disadvantages |

|

Overall

|

Overall

|

|

Economic Macro

Micro

|

Economic Macro

Micro

|

|

Social

|

Social

|

|

Environment

|

Environment

|

Table 1. Overview of advantages and disadvantages of LPG as a cooking fuel

Further Information:

Fuel Factsheets show different cooking fuels.

A study sponsored by the World Bank reviewing 20 countries

LPG as a Cooking Fuel for Low-Income Households - the Interventionist Perspective

Challenges for an improved supply of cooking fuels through LGP

The challenges that arise when working towards an improved supply of LPG as a cooking fuel in low-income households can be divided into five areas:

1. Administration

A centrepiece in the development of functioning LPG market is effective regulation. This is relevant both for the establishing of market structures and the security of consumers. The report from the World LPG Association presents the most important aspects to be considered in the regulation of LPG markets. The report contains different sales models, ways to handle cylinders and outlines the definition and regulation of safety standards (see WLPGA, 2013).

Furthermore, long-term commitments from politicians are helpful to obtain foreign investments. Subsidies are also important in this regard (IEA, 2011).

These subsidies must be carefully tailored if poor households are to be effectively targeted.

2. Availability

In many countries the private sector already supplies LPG to high-income households in urban areas. However, many countries and rural areas in particular still lack supply infrastructure. These regions are unlikely to be covered by the private sector alone. Therefore, interest groups such as the World LPG Association (WLPGA) lobby for increased public sector investments. The private sector can be partially involved in these costs, if a supply strategy is in development (IEA, 2011).

Next to the provision of decentralised distribution networks, filling stations are important for the supply of rural areas. LPG should always be disposable, as a secure supply would increase people's acceptance of LPG. Acceptance is likely to fall if supply is unstable.

3. Affordability

As soon as supply is assured, affordability becomes the largest barrier to an increased use of LPG. Subsidies are necessary both for initial and running costs if LPG is to be made available for low-income households.

a. Subsidising initial costs

Subsidising the initial costs allows access to LPG usage. Nevertheless, subsidies of the equipment without subsidies of running costs could lead to a situation in which families cannot afford to actually use LPG. This would lead to 'dead' investments (IEI, 2004).

b. Subsidising running costs

Subsidising the fuel makes sense when LPG is to be made availabe for low-income households.Different precautions measures have to be taken. For instance, the amount of low-priced LPG could be limited through coupons that are distributed to the poor households. Subsidised cylinders can be marked with colours to prevent subsidised LPG being sold-on to other households (IEI, 2004). The grading of subsidies according to usage ensures that households with low consumption pay a comparitively low price. According to this model, large-scale consumers can be made to pay a progressively rising tariff that cross-subsidises poor users with limited consumption (IEI, 2004).

c. Who pays for the subsidies?

LPG subsidies would require large investment sums. The financing of hardware costs could stem from various sources. Microcredit institutions could distribute credits. Alternatively, LPG entrepreneurs could remain owners of the cylinders and demand rent or a deposit from the customers. The distribution of smaller cylinders would decrease the overall amount of capital or subsidies required.

Regarding the running costs, there are various possibilities to keep the costs of LPG subsidies low. Subsidies of kerosene could be shifted to the LPG sector which would encourage a 'fuel switch' without increased costs for the public sector. In Indonesia such a switch from kerosene to LPG subsidies saved the government 6.9 million US$ p.a.. It has to be ensured that low-income consumers to not carry the burden of potential price increases as this is the target group most likely to become incapable of paying for the running costs.

d. Guidelines for subsidies

Badly defined subsidies can decrease incentives to invest, decrease efficiency, encourage wasteful behaviour and burden public finances (Matthews and Zeissig, 2011). As consumers quickly grow accustomed to subsidies, reducing subsidies is difficult realise once they were introduced. The following points should therefore be considered in the design of different subsidy programs of LPG for low-income households:

- Subsidies for system components can be more cost-efficient and requires less monitoring than investments in fuel

- Subsidies for rural households must be targeted and transparent as without necessary restrictions subsidy regulations are often ignored

- Time-bound subsidies reduce costs but can cause to market collapse once subsidies are withdrawn

- The price structure in relation to other fuels should be aligned with the energy supply strategy of a given country

The private sector should be involved in all financing plans, for instance by taking responsibility for the distribution of small cylinders.

4. Awareness

LPG is considered as a modern, clean and easy-to-use fuel. Nevertheless, educational campaigns are sometimes useful. Especially health and environmental benefits should be underlined to target groups. The correct utilisation should be advocated in order to avoid accidents. Also, consumer confidence regarding the correct filling of cylinders needs to be raised. In underdeveloped LPG markets consumers sometimes obtain less LPG than what they have paid for.

Technical solutions to this problem such as see-through cylinders have been developed by Ragasco. Such cylinders allow the consumer to check the filling level him/herself. Yet, such cylinders are not established on the market.

5. Security of supply

Current production surpluses of 9.7 million tons allow for the increased distribution of LPG to low-income households. Nevertheless, it should be considered that prices will rise as soon as demand exceeds production. At this point, the distribution of the limited LPG ressource will be determined by the purchasing power of the customers. As prices rise, low-income households will be the first to be excluded from an adequate LPG supply. This is important to consider as many low-income households are already excluded due to the LPG price level as they are today.

a. Short and middle-term security of supply for low-income households

The demand for LPG of the petrochemical industry rose markedly in the US and the Middle East. It is expected that petrochemical industries will absorb current supply surpluses as long as prices remain low (PR Newswire, 2013). Increased demand is also expected in the autogas sector. Overall LPG consumption is expected to rise by 4.4 % p.a. between 2012 and 2018.

In can nonetheless be anticipated that LPG will be available for consumption by low-income households. This is due to anticipated increases in LPG production raising quicker than consumption levels.

Furthermore, unused accompanying gases can be used to supply low-income households. In Nigeria, where large parts of the population use traditional cooking fuels and LPG-consumption remains low despite available oil resources, the usage of accompanying gases would be viable.

Whilst accompanying gases are used for electrification programs through SE4All-Initatives, there are no known programs which specialise in LPG supply through using accompanying gases. This is the case despite the existence of the technological know-how.

b. Long-term security of supply for low-income households

Since LPG supply is directly related to the availability of finite oil and gas deposits, supply for low-income households cannot be guaranteed in the long-term. To the contrary; as demand increases and availability decreases, prices will rise and thus increase the costs for low-income households.

Thus to ensure the long-term supply of LPG for low-income households, the development of supply strategies should be agreed with representatives of both politics and industry. As described above, demand is state-aided in various sectors (autogas, petrochemical industries etc.); this already threatens supply of low-income households in the middle-term.

To realistically ensure the goal of ' universal access to clean cooking fuels by 2030' stated by the IEA through 50% use of LPG, the following conflicts should be consciously avoided:

- Conflicts between producing and importing countries

- Conflicts between consumers on a household level, car gas and petrochemical industries

- Conflicts between demand centres in the city and rural areas

Tabular overview of challenges

|

Barrier |

Characteristics |

|

1. Regulation |

|

|

2. Availability |

|

|

3. Affordability |

|

|

4. Awareness |

|

|

5. Supply security |

|

Table 2. Overview of the most important challenges in the use of LPG as a cooking fuel

Further Information:

This case study from Indonesia presents the experiences from shifting from Kerosene to LPG.

This website contains publications of 'Global Alliance on Clean Cook stoves.

This case study documents the experiences of a programme which aimed to increase LPG-usage in Senegal.

Activities of international Organisations

United Nations Development Programme (UNDP)

UNDP is developing a regional project which, as part of the SE4All-Initiative, enables access to modern cooking fuels for 500,000 households. With partners from the private sector and local NGOs, mainly Asia is targeted to reduce existing barriers which inhibit the improved supply of LPG. Activates to improve LPG supply are identified as action plans and established through multi-stakeholder meetings and market surveys. Through dialogue and facilitation of cooperation with the relevant actors, strategies to enable market developments are devised. The initiative is presented in a Vimeo video: 500.000 Smoke Free Households

World LPG Association (WLPGA)

WLPGA is an interest group of the global LPG industry. Its goal is to increase the demand of LPG and establish good business practice and safety standards. Through lobbying, knowledge management and consulting, the group increases LPG consumption and enhances market development.

In 2012, WLPGA started the 'Cooking for Life' campaign. Its goal is to to enable one billion people access to LPG as a cooking fuel by 2030. The campaign involves government representatives, representatives from the health sector, energy industry and NGOs. Next to the prevention of 500,000 deaths per year due to 'indoor air pollution', the campaign states that it protects 2.65 million hectares of forest (this equals 51% of global annual deforestation).

To this end different resources and approaches are made available. Experiences of successful programmes should be made accessible and communicated. More information is available on the website of the campaign: Cooking for Life

Global LPG Partnership (GLPGP)

GLPGP is a partner of the UN-Initiative SE4All. The partnership was developed by ETG, a LPG industry company considered by WLPGA, a national LPG company and various other actors. A global private-public partnership was chosen as a structure for this partnership. The goal of the partnership is to work on the political requirements for investments which ensures a reliable LPG supply in developing countries.

The implementation of GLPGP starts in Ghana, Cameroon, Kenya, Uganda and Tanzania. Initially, a capital fund of 250 million US$, as well as 250 million US$ credit for investments is made available. This fund is enhanced through a 250 million US$ concessional fund which targets the financing and building of local trading networks. These funds should provide access to LPG for approx. 70 million people and create 150.000 new jobs. Through this, 2 % of African forests are protected annually.

More information is available on the internet website of SE4All: Global LPG Partnership