Parts of a Biogas Plant

The feed material is mixed with water in the influent collecting tank The fermentation slurry flows through the </span>inlet into the digester. The bacteria from the fermentation slurry are intended to produce biogas in the digester. For this purpose, they need time. Time to multiply and to spread throughout the slurry. The digester must be designed in a way that only fully digested slurry can leave it. The bacteria are distributed in the slurry by stirring (with a stick or stirring facilities). The fully digested slurry leaves the digester through the </span>outlet into the slurry storage.</span>

The biogas is collected and stored until the time of consumption in the gasholder. The gas pipe carries the biogas to the place where it is consumed by gas appliances. Condensation collecting in the gas pipe is removed by a water trap.

Depending on the available building material and type of plant under construction, different variants of the individual components are possible. The following (optional) components of a biogas plant can also play an important role and are described seperatly: Heating systems, pumps, weak ring.

Influent Collecting Tank

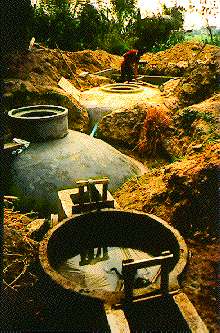

|

Installation of a fixed-dome plant in Thailand: The influent collecting tank is in front of the photo, the digester and the outlet are located behind it.[1] |

Size and Homogenization

Fresh substrate is usually gathered in an influent collecting tank prior to being fed into the digester. Depending on the type of system, the tank should hold one to two days' substrate. An influent collecting tank can also be used to homogenize the various substrates and to set up the required consistency, e.g. by adding water to dilute the mixture of vegetable solids (straw, grass, etc.), or by adding more solids in order to increase the bio-mass. The fibrous material is raked off the surface, if necessary, and any stones or sand settling at the bottom are cleaned out after the slurry is admitted to the digester. The desired degree of homogenization and solids content can be achieved with the aid of an agitator, pump or chopper. A rock or wooden plug can be used to close off the inlet pipe during the mixing process.

Location

A sunny location can help to warm the contents before they are fed into the digester in order to avoid thermal shock due to the cold mixing water. In the case of a biogas plant that is directly connected to the stable, it is advisable to install the mixing pit deep enough to allow installation of a floating gutter leading directly into the pit. Care must also be taken to ensure that the low position of the mixing pit does not result in premature digestion. For reasons of hygiene, toilets should have a direct connection to the inlet pipe.

Inlet and Outlet

The inlet (feed) and outlet (discharge) pipes lead straight into the digester at a steep angle. For liquid substrate, the pipe diameter should be 10-15 cm, while fibrous substrate requires a diameter of 20-30 cm. The inlet and the outlet pipe mostly consist of plastic or concrete.

Position

Both the inlet and the outlet pipe must be freely accessible and straight, so that a rod can be pushed through to eliminate obstructions and agitate the digester contents. The pipes should penetrate the digester wall at a point below the lowest slurry level (i.e. not through the gas storage). The points of penetration should be sealed and reinforced with mortar.

The inlet pipe ends higher in the digester than the outlet pipe in order to promote more uniform flow of the substrate. In a fixed-dome plant, the inlet pipe defines the bottom line of the gas-holder, acting like a security valve to release over-pressure. In a floating-drum plant, the end of the outlet pipe determines the digester's (constant) slurry level.

Inlet and outlet pipe must be placed in connection with brick-laying. It is not advisable to break holes into the spherical shell afterwards, this would weaken the masonry structure.

Toilet Connection at the Inlet

--> Household Toilets can be connected to a Biogas Digester.

Digester

No matter which design is chosen, the digester (fermentation tank) must meet the following requirements:</span>

- Water/gastightness - watertightness in order to prevent seepage and the resultant threat to soil and groundwater quality; gastightness in order to ensure proper containment of the entire biogas yield and to prevent air entering into the digester (which could result in the formation of an explosive mixture).

- Insulation - if and to which extent depends on the required process temperature, the local climate and the financial means; heat loss should be minimized if outside temperatures are low, warming up of the digester should be facilitated when outside temperatures are high.

- Minimum surface area - keeps cost of construction to a minimum and reduces heat losses through the vessel walls. A spherical structure has the best ratio of volume and surface area. For practical construction, a hemispherical construction with a conical floor is close to the optimum.

- Structural stability - sufficient to withstand all static and dynamic loads, durable and resistant to corrosion.

Internal and External Forces

Two relevant forces act on the digester. The external active earth pressure causes compressive forces within the masonry. The internal hydrostatic and gas pressures causes tensile stress in the masonry. Thus, the external pressure applied by the surrounding earth must be greater at all points than the internal forces. Round and spherical shapes are able to accept the highest forces and distribute them uniformly. Edges and corners lead to peak tensile stresses which can result in cracking.

Shapes of Digesters

From the standpoint of fluid dynamics and structural strength, an egg-shaped vessel is about the best possible solution. This type of construction, however, is comparatively expensive, so that its use is usually restricted to large-scale sewage treatment plants. The Chinese fixed-dome designs are of similar shape, but less expensive. The hemispherical CAMARTEC design is optimized in structural strength, but does not make optimal use of the excavation required.

Simplified versions of such digester designs include cylinders with conical covers and bottoms. They are much easier to build and are sometimes available on the market as prefabricated units. Their disadvantage lies in their less favorable surface-volume ratio. The cylinder should have a height equal to its diameter. Prone cylinders have become quite popular on farms, since they are frequently the more favorable solution for small-scale bio-methanation. Cuboid digesters are often employed in batch-fed systems used primarily for fermenting solid material, so that fluid dynamics are of little interest.

|

Construction of the digester neck with steel reinforcement[2] |

Gasholders

Basically, there are different designs of construction for gasholders used in simple biogas plants

Floating-drum Gasholders

Most floating-drum gas-holders are made of 2-4 mm thick sheet steel, with the sides made of thicker material than the top in order to compensate for the higher degree of corrosive attack. Structural stability is provided by L-bar bracing that also serves to break up surface scum when the drum is rotated. A guide frame stabilizes the gas drum and prevents it from tilting and rubbing against the masonry. The two equally suitable and most frequently used types are:

- an internal rod & pipe guide with a fixed (concrete-embedded) cross pole (an advantageous configuration in connection with an internal gas outlet);

- external guide frame supported on three wooden or steel legs.

For either design, substantial force can be necessary to rotate the drum, especially if it is stuck in a heavy layer of floating scum. Any gas-holder with a volume exceeding 5 m3 should be equipped with a double guide (internal and external).

All grades of steel normally used for gas-holders are susceptible to moisture-induced rusting both in- and outside. Consequently, a long service life requires proper surface protection, including:

- thorough de-rusting and de-soiling

- primer coat of minimum 2 layers

- 2 or 3 cover coats of plastic or bituminous paint.

The cover coats should be reapplied annually. A well-kept metal gas-holder can be expected to last between 3 and 5 years in humid, salty air or 8-12 years in a dry climate.

Materials regarded as suitable alternatives to standard grades of steel are galvanized sheet metal, plastics (glass-fiber reinforced plastic (GRP), plastic sheeting) and ferro-cement with a gas-tight lining. The gas-holders of water-jacket plants have a longer average service life, particularly when a film of used oil is poured on the water seal to provide impregnation.

Fixed-dome Gasholders

A fixed-dome gas-holder can be either the upper part of a hemispherical digester (CAMARTEC design) or a conical top of a cylindrical digester (e.g. Chinese fixed-dome plant). In a fixed-dome plant the gas collecting in the upper part of the dome displaces a corresponding volume of digested slurry.

The following aspects must be considered with regard to design and operation:

- An overflow into and out of the compensation tank must be provided to avoid over-filling of the plant.

- The gas outlet must be located about 10 cm higher than the overflow level to avoid plugging up of the gas pipe.

- A gas pressure of 1 m WC or more can develop inside the gas space. Consequently, the plant must be covered sufficiently with soil to provide an adequate counter-pressure.

- Special care must be taken to properly close the man hole, which may require to weigh down the lid with 100 kg or more. The safest method is to secure the lid with clamps.

The following structural measures are recommended to avoid cracks in the gas-holder:

- The foot of the dome (gas-holder) should be stabilized by letting the foundation slab project out enough to allow for an outer ring of mortar.

- A rated break/pivot ring should be provided at a point located between 1/2 and 2/3 of the minimum slurry level. This in order to limit the occurrence or propagation of cracks in the vicinity of the dome foot and to displace forces through its stiffening/articulating effect such that tensile forces are reduced around the gas space. Alternatively, the lowest point of the gas-holder should be reinforced by a steel ring or the whole gas-holder be reinforced with chicken mesh wire.

Normally, masonry, mortar and concrete are not gas-tight, with or without mortar additives. Gas-tightness can only be achieved through good, careful workmanship and special coatings. The main precondition is that masonry and plaster are strong and free of cracks. Cracked and sandy rendering must be removed. In most cases, a plant with cracked masonry must be dismantled, because not even the best seal coating can render cracks permanently gas-tight.

Some tried and proven seal coats and plasters:

- multi-layer bitumen, applied cold (hot application poses the danger of injury by burns and smoke-poisoning; solvents cause dangerous/explosive vapors). Two to four thick coats required;

- bitumen with aluminum foil, thin sheets of overlapping aluminum foil applied to the still-sticky bitumen, followed by the next coat of bitumen;

- plastics, e.g. epoxy resin or acrylic paint; very good but expensive;

- paraffin, diluted with 2-5% kerosene, heated up to 100°C and applied to the preheated masonry, thus providing an effective (deep) seal. Use kerosene/gas torch to heat masonry.

- multi-layer cement plaster with water-proof elements

In any case, a pressure test must be carried out before the plant is put in service.

Plastic Gasholders

Gas-holders made of plastic sheeting serve as integrated gas-holders, as separate balloon/bag-type gas-holders and as integrated gas-transport/storage elements. For plastic (sheet) gas-holders, the structural details are of less immediate interest than the question of which materials can be used.

Separate Gasholders

Differentiation is made between:

- low-pressure, wet and dry gas-holders (10-50 mbar). Basically, these gas-holders are identical to integrated and/or plastic (sheet) gas-holders. Separate gas-holders cost more and are only worthwhile in case of substantial distances (at least 50-100 m) or to allow repair of a leaky fixed-dome plant. This type of separate gas-holder is also used to buffer extreme differences between gas-production and gas-use patterns.

- medium- or high-pressure gas-holders (8-10 bar / 200 bar)

Biogas plant with seperate gasholder in Nicaragua[3] Biogas plant with seperate gasholder in Nicaragua[3] |

Neither system can be considered for use in small-scale biogas plants. Even for large-scale plants, they cannot be recommended under the conditions in most developing countries. High-pressure gas storage in steel cylinders (as fuel for vehicles) is presently under discussion. While that approach is possible in theory, it would be complicated and, except in special cases, prohibitively expensive. It would also require the establishment of stringent safety regulations.

Gas Pipe, Valves and Accessories

Biogas Piping

At least 60% of all non-functional biogas units are attributable to defect gas piping. Utmost care has to be taken, therefore, for proper installation. For the sake of standardization, it is advisable to select a single size for all pipes, valves and accessories.

The requirements for biogas piping, valves and accessories are essentially the same as for other gas installations. However, biogas is 100% saturated with water vapor and contains hydrogen-sulfide. Consequently, no piping, valves or accessories that contain any amounts of ferrous metals may be used for biogas piping, because they would be destroyed by corrosion within a short time. The gas lines may consist of standard galvanized steel pipes. Also suitable (and inexpensive) is plastic tubing made of rigid PVC or rigid PE. Flexible gas pipes laid in the open must be UV-resistant.

Steel Pipes

Galvanized steel water supply pipes are used most frequently, because the entire piping system (gas pipe, valves and accessories) can be made of universally applicable English/U.S. Customary system components, i.e. with all dimensions in inches. Pipes with nominal dimensions of 1/2" or 3/4" are adequate for small-to-midsize plants of simple design and pipe lengths of less than 30 m. For larger plants, longer gas pipes or low system pressure, a detailed pressure-loss (pipe-sizing) calculation must be performed.

When installing a gas pipe, special attention must be paid to:

- gas-tight, friction-type joints

- line drainage, i.e. with a water trap at the lowest point of the sloping pipe in order to empty water accumulation

- protection against mechanical impact

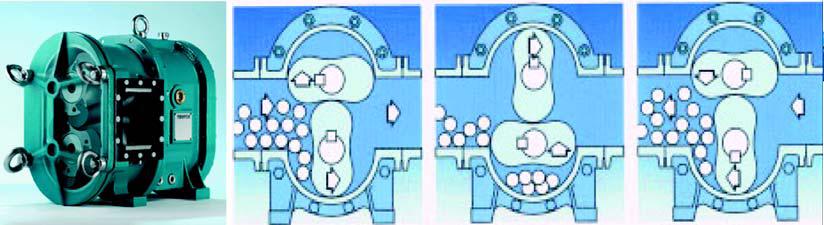

|

Stirring device for a european biodigester[4] |

Stirring Facilities

Optimum stirring substantially reduces the retention time. If agitation is excessive, the bacteria have "no time to eat". The ideal is gentle but intensive stirring about every four hours. Of similar importance is the breaking up of a scum layer which has lost contact with the main volume of substrate and is, therefore, not further digested. This top layer can form an impermeable barrier for biogas to move up from the digester to the gas holder.

As a rule of thumb it can be stated that stirring facilities are more important in larger plants than in small scale farm plants.

Stirring facilities in the digester[5] Stirring facilities in the digester[5] |

Types of Stirring Facilities

- The impeller stirrer has given good results especially in sewage treatment plants.

- The horizontal shaft stirs the fermentation channel without mixing up the phases. Both schemes originate from large-scale plant practice.

- For simple household plants, poking with a stick is the simplest and safest stirring method.

Preparation & Comminution

The nature and extent of substrate preparation influence the general usability of substrates with regard to the proportion of entrained interfering substances, so they factor directly into the availability of plant technology. Moreover, a suitable preparation process can have a positive effect on the digestion-process transient, which in turn affects utilisation of the substrates' energy potential.</span>

Sorting and removal of interfering substances

The necessity for sorting and removal of interfering substances depends on the origin and the composition of the substrate. Stones are the most common; they generally settle out in the of a biogas plant pre-digester pit, where from time to time they have to be removed from the bottom. Separators for dense materials are also used, generally sited directly in the substrate pipe in front of the feed conveyor. Other matter has to be removed manually at the point of substrate delivery or during filling of the feed hoppers. There is considerable likelihood that biowaste materials may contain interfering substances.

Whenever material of this nature is used as co-substrate, every effort should be made to ensure that it is not freighted with interfering substances. Most farming operations would not have the resources to install complex sorting facilities with mechanical lines or sorting boxes comparable with those in dedicated biowaste processing plants. Modular-box or garage digesters, by contrast, are virtually unaffected by interfering substances, because wheeled loaders and grabs are the primary means of substrate transport and there is no contact with pumps, valves or screw conveyors or other components of similar nature that would be easily damaged by interfering substances[6].

Comminution

Comminution increases the aggregate substrate surface area available for biodegradation and consequently for methanisation. Broadly speaking, although breaking down the size of the particles effectively accelerates the rate of biodegradation, it

does not necessarily increase gas yield. The interplay of dwell time and degree of comminution is one of the factors influencing methane production. Hence the importance of adopting the appropriate technology. The equipment for comminuting solid substrates

can be sited externally upstream from the point of infeed, in the pre-digester pit, pipe or digester. The range of equipment includes chippers, mills, crushers and shafts and screw conveyors with rippers and cutters. Shafts with paddles and bladed screw

conveyors are very common in combined receiving and metering units. Given the extent of their application, the properties of these comminution devices are summarised separately for handling direct solids metering by combined receiving and metering units and processing by mills and chippers.

By contrast with comminution of solids before transfer to pre-digester pit, pipeline or digester, liquids with solid or fibrous content can be comminuted directly in the pre-digester pit, in other mixing tanks or in the pipeline. This can be necessary in the case of

substrates and substrate mixtures the consistency of which could threaten the operability of the feeder (generally a pump). Separate comminution agitators sited in the pit upstream of the digester constitute one means of comminution. In-pipe, directly linked

comminution and pumping is common, however, and the same applies to combination comminution/ pumping units. These units are generally powered by electric motors, and some are designed to be driven off a tractor PTO.

Characteristic values and process parameters of comminutors in combined receiving and metering units

| Characteristic values | Standard commercially available units are capable of handling up to 50 m3 a day (the substrate receiving

or holding vessel can be sized for a much larger capacity) |

| Suitability |

Usual silages, CCM, animal (including poultry) manure, bread waste, vegetables • Toothed rollers or bladed worm-type mixers are more suitable for long-fibre substances |

| Advantages & Disadvantages |

+ High throughput rates |

| Designs |

|

For more detailed information check the FNR Guide to biogas.

Wetting down to mash, homogenising

Substrates have to be wetted down to mash in the wetdigestion process to render them pumpable by increasing their water content, so that they can be pumped into the digester. This generally takes place in the predigester pit or other containers, just before the substrate is introduced into the digestion process. The liquid used for wetting down to mash is liquid manure, liquid digestate (from pressings), process water or – in exceptional cases – fresh water. Using liquid digestate can reduce fresh-water consumption. A further advantage is that even before it reaches the digester, the substrate is inoculated with seed bacteria from the digestion process. Consequently, this procedure can be applied to particularly good effect after hygienisation or in the process known as the plug flow process. The use of fresh water as make-up liquid should be avoided whenever possible, on account of the high costs involved. If water from cleaning processes is used as the make-up liquid for wetting down to mash, it has to be borne in mind that disinfectants can impede the digestion process because substances of this nature have a negative effect on the microorganism population inside the digester.

The homogeneity of the substrate is of major importance in terms of the stability of the digestion process. Severe fluctuations in loading and changes in substrate composition require the microorganisms to adapt to the variations in conditions, and this is generally linked to drops in gas yield. Pumpable substrates are usually homogenised by agitators in the pre-digester pit. However,

homogenisation can also take place inside the digester, if different substrates are pumped in directly and/or are introduced into the digester via a solids infeed[6].

Hygienisation

Compliance with statutory criteria for some substance groups that are critical from the epidemiological and phytohygienic standpoint can necessitate integrating thermal pretreatment into the biogas plant. Pretreatment consists of heating the substances to a temperature of 70 °C for at least one hour. Autoclaving is another method of killing germs. In this process the substrate is pretreated for 20 minutes at 133 °C and a pressure of 3 bar. This method is much less common in the sector than hygienisation at 70 °C, however. The size of the vessels used for hygienisation depends on throughput rate, and the same applies to energy input,

so hygienically problematic co-substrates are generally hygienised before being fed into the digester. This is a simple way of ensuring that only the problematic substances are hygienised, so the hygienisation stage can be made more economical (partial-flow hygienisation). Full-flow hygienisation of all the feedstock or the predigested material is also possible. One advantage of

pre-digester hygienisation is a certain degree of thermal decomposition of the substrate, which subsequently – and depending on its properties – is more readily fermentable.

Hygienisation can be undertaken in airtight, heated stainless-steel tanks. Tanks of the conventional type for livestock fodder are often used. Hygienisation is monitored and documented by instrumentation for fill level, temperature and pressure. The post-hygienisation temperature of the substrate is higher than the process temperature prevailing inside the digester. Consequently,

the hygienised substrate can preheat other substrates or it can be fed directly into and thus heat the digester. If there is no provision for utilising the waste heat of the hygienised substrate, suitable means must be used to cool it to the digester's temperature level.

Heating Systems

Normally, because of the rather high involved costs, small-scale biogas plants are built without heating systems. But even for small scale plants, it is of advantage for the bio-methanation process to warm up the influent substrate to its proper process temperature before it is fed into the digester. If possible, cold zones in the digester should be avoided (see also substrate temperature).

In the following, a number of different ways to get the required amount of thermal energy into the substrate are described.

In principle, one can differentiate between:

- direct heating in the form of steam or hot water, and

- indirect heating via heat exchanger, whereby the heating medium, usually hot water, imparts heat while not mixing with the substrate.

Direct Heating

Direct heating with steam has the serious disadvantage of requiring an elaborate steam-generating system (including desalination and ion exchange as water pretreatment) and can also cause local overheating. The high cost is only justifiable for large-scale sewage treatment facilities.

The injection of hot water raises the water content of the slurry and should only be practiced if such dilution is necessary.

Indirect Heating

Indirect heating is accomplished with heat exchangers located either inside or outside of the digester, depending on the shape of the vessel, the type of substrate used, and the nature of the operating mode.

- Floor heating systems have not served well in the past, because the accumulation of sediment gradually hampers the transfer of heat.

- In-vessel heat exchangers are a good solution from the standpoint of heat transfer as long as they are able to withstand the mechanical stress caused by the mixer, circulating pump, etc. The larger the heat-exchange surface, the more uniformly heat distribution can be effected which is better for the biological process.

- On-vessel heat exchangers with the heat conductors located in or on the vessel walls are inferior to in-vessel-exchangers as far as heat-transfer efficiency is concerned, since too much heat is lost to the surroundings. On the other hand, practically the entire wall area of the vessel can be used as a heat-transfer surface, and there are no obstructions in the vessel to impede the flow of slurry.

- Ex-vessel heat exchangers offer the advantage of easy access for cleaning and maintenance.

While in Northern countries, often a substantial amount of the produced biogas is consumed to provide process energy, in countries with higher temperatures and longer sunshine hours, solar-heated water can be a cost-effective solution for heating. Exposing the site of the biogas plant to sunshine, e.g. by avoiding tree shade, is the simplest method of heating.

Pumps

Pumps become necessary parts of a biogas unit, when the amounts of substrate require fast movement and when gravity cannot be used for reasons of topography or substrate characteristics. Pumps transport the substrate from the point of delivery through all the stages of fermentation. Therefore, several pumps and types of pumps may be needed. Pumps are usually found in large scale biogas units.

There are two predominant types of pump for fresh substrate: centrifugal pumps and positive-displacement pumps (reciprocating pumps). Centrifugal pumps operate on the principle of a rapidly rotating impeller located in the liquid flow. They provide high delivery rates and are very robust, i.e. the internals are exposed to little mechanical stress. They do, however, require a free-flowing intake arrangement, because they are not self-priming (regenerative).

Practically all centrifugal pump characteristics are geared to water. They show the delivery rates for various heads, the achievable efficiency levels, and the power requirement for the pump motor. Consequently, such data cannot be directly applied to biogas systems, since the overall performance and efficiency level of a pump for re-circulating slurry may suffer a serious drop-off as compared to its standard "water" rating (roughly 5-10%).

Rotary Pump

Rotary pumps are commonplace in liquid-manure pumping. They are eminently suitable for runny substrates.

A rotary pump has an impeller turning inside a fixed body. The impeller accelerates the medium, and the resulting increase in flow velocity is converted into head or pressure at the rotary pump's discharge nozzle. The shape and size of the impeller can

vary, depending on requirements. The cutter-impeller pump is a special kind of rotary pump. The impeller has hardened cutting edges designed to comminute the substrate.

Limitation of a Centrifugal Pump

Sometimes, namely when the substrate is excessively viscous, a centrifugal pump will no longer do the job, because the condition of the substrate surpasses the pump's physical delivery capacity. In such cases, one must turn to a so-called positive-displacement or reciprocating type of pump in the form of a piston pump, gear pump or eccentric spiral pump, all of which operate on the principle of displacing action to provide positive delivery via one or more enclosed chambers.

Positive Displacement Pumps

Positive displacement pumps offer multiple advantages. Even for highly viscous substrate, they provide high delivery and high efficiency at a relatively low rate of power consumption. Their characteristics - once again for water - demonstrate how little the delivery rate depends on the delivery head. Consequently, most of the characteristics show the delivery rate as a function of pump speed.

The main disadvantage as compared to a centrifugal pump is the greater amount of wear and tear on the internal occasioned by the necessity of providing an effective seal between each two adjacent chambers.

The speed of a positive-displacement pump can be varied to control delivery rate. This matches pump control more closely to precision metering of the substrate.The pressure stability of these self-priming pumps is better than that of rotary pumps, which means that delivery rate is much less dependent on head. Positive- displacement pumps are relatively susceptible to interfering substances, so it makes sense to install comminutors and foreign-matter separators to protect the pumps against coarse and fibrous constituents in the substrate[6].

Rotary-displacement pumps and eccentric singlerotor screw pumps are the most commonly used. Eccentric single-rotor screw pumps have a rotor shaped like a corkscrew running inside a stator made of an elastically resilient material. The action of the rotor produces an advancing space in which the substrate is transported.

Rotary displacement pumps have two counter-rotating rotary pistons with between two and six lobes in an oval body. The two pistons counter-rotate and counterroll with low axial and radial clearance, touching neither each other nor the body of the pump. Their geometry is such that in every position a seal is maintained between the suction side and the discharge side of the pump. The medium is drawn in to fill the spaces on the suction side and is transported to the discharge side[6].

Pump Delivery Lines

Pump delivery lines can be made of steel, PVC (rigid) or PE (rigid or flexible), as well as appropriate flexible pressure tubing made of reinforced plastic or rubber. Solid substrate, e.g. dung, can also be handled via conveyor belt, worm conveyor or sliding-bar system, though none of these could be used for liquid manure. When liquid manure is conducted through an open gutter, small weirs or barrages should be installed at intervals of 20-30 m as a means of breaking up the scum layer.

Each such barrier should cause the scum to fall at least 20-30 cm on the downstream side. All changes of direction should be executed at right angles (90°). Depending on the overall length, the cross gutter should be laid some 30-50 cm deeper than the main gutter. Transitions between a rectangular channel and a round pipe must be gradual. An inclination of about 14% yields optimum flow conditions. The channel bottom must be laid level, since any slope in the direction of flow would only cause the liquid manure to run off prematurely. All wall surfaces should be as smooth as possible.

Industrial transport of Substrate

The transport of stackable substrates is a feature of wet digestion plants through to material infeed or to the stage of wetting down to mash with make-up liquid. Most of the work can be done with loaders of conventional design. It is only when automated feeding takes over that scraper-floor feeders, overhead pushers and screw conveyors are used. Scraper-floor feeders and overhead pushers are able to move virtually all stackable substrates horizontally or up slightly inclined planes. They cannot be used for metering, however. They permit very large holding tanks to be used. Screw conveyors can transport stackable substrates in virtually any direction. The only prerequisites are the absence of large stones and comminution of the substrate to the extent that it can be gripped by the worm and fits inside the turns of the worm's conveyor mechanism. Automatic feeder systems for stackable substrates are often combined with the loading equipment to form a single unit in the biogas plant[1].

Weak Ring

The weak/strong ring improves the gas-tightness of </span>fixed-dome plants It was first introduced in Tanzania and showed promising results. The weak ring separates the lower part of the hemispherical digester, (filled with digesting substrate), from the upper part (where the gas is stored). Vertical cracks, moving upwards from the bottom of the digester, are diverted in this ring of lean mortar into horizontal cracks. These cracks remain in the slurry area where they are of no harm to the gas-tightness. The strong ring is a reinforcement of the bottom of the gas-holder, it could also be seen as a foundation of the gas-holder. It is an additional device to prevent cracks from entering the gas-holder. Weak and strong ring have been successfully combined in the </span>CAMARTEC design

Photo[7]: Construction of the weak/strong ring of a 16 m3, Tanzania Photo[7]: Construction of the weak/strong ring of a 16 m3, Tanzania |

Materials and Construction

The weak ring consists of mortar of a mixture of sand, lime and cement (15:3:1). The top of the weak ring restores the horizontal level. It is interrupted only by the inlet pipe passing through. The strong ring rests on the weak ring and is the first layer of the upper part of the hemispherical shell. It consists of a row of header bricks with a concrete package at the outside. In case of soft or uncertain ground soil one may place a ring reinforcement bar in the concrete of the strong ring. The brick of the strong ring should be about three times wider than the brickwork of the upper wall. A detailed description of the weak/strong ring construction can be found in Sasse, Kellner, Kimaro (1991).

Further Information

- Ringkamp, M.; Tentscher, W.; Schiller, H.: Preliminary results on: statical optimization of family-sized fixed-dome digesters. Tilche, A.; Rozzi, A. (ed.): Poster Papers. Fifth International Symposium on Anaerobic Digestion, Bologna 1988, pp. 321-324

- Sasse, L.; Kellner, Ch.; Kimaro, A.: Improved Biogas Unit for Developing Countries. Deutsche Gesellschaft für Technische Zusammenarbeit (GTZ) GmbH, Vieweg & Sohn Verlagsgesellschaft Braunschweig, 1991

dHohlfeld, J.; Sasse, L. (Deutsche Gesellschaft für Technische Zusammenarbeit): Production and utilization of biogas in rural areas of industrialized and developing countries. TZ-Verlagsgesellschaft mbH, Roßdorf, 1986, 278 S.</span>