Pumps for Biogas Plants

Overview

Pumps are required to bridge differences in height between the levels of slurry-flow through the biogas unit. They can also be required to mix the substrate or to speed up slow flowing substrates. If substrates have a high solids content and do not flow at all, but cannot be diluted, pumps or transport belts are essential.

Pumps are driven by engines, are exposed to wear and tear and can be damaged. They are costly, consume energy and can disrupt the filling process. For these reasons, pumps should be avoided where possible and methods of dilution and use of the natural gradient be utilized instead.

If pumps cannot be avoided, they can be installed in two ways:

- Dry installation: the pump is connected in line with the pipe. The substrate flows freely up to the pump and is accelerated while passing through the pump.

- Wet installation: the pump is installed with an electric engine inside the substrate. The electric engine is sealed in a watertight container. Alternatively, the pump in the substrate is driven by a shaft, the engine is outside the substrate.

Types of Pumps

There are two predominant types of pump for fresh substrate: centrifugal pumps and positive-displacement pumps (reciprocating pumps). Centrifugal pumps operate on the principle of a rapidly rotating impeller located in the liquid flow. They provide high delivery rates and are very robust, i.e. the internals are exposed to little mechanical stress. They do, however, require a free-flowing intake arrangement, because they are not self-priming (regenerative).

Practically all centrifugal pump characteristics are geared to water. They show the delivery rates for various heads, the achievable efficiency levels, and the power requirement for the pump motor. Consequently, such data cannot be directly applied to biogas systems, since the overall performance and efficiency level of a pump for re-circulating slurry may suffer a serious drop-off as compared to its standard "water" rating (roughly 5-10%).

Rotary Pumps

Rotary pumps operate with a rotor which presses the liquid against the outside wall of the rotor chamber. Due to the geometry of the chamber the liquid is pushed into the outlet pipe. Rotary pumps are very common in liquid manure technology. They are simple and robust and used mainly for substrates of less than 8% solids content. The quantity conveyed per time unit depends largely on the height of lift or the conveying pressure. The maximum conveying pressure is between 0,8 and 3.5 bar. The quantity that can be conveyed varies from 2 to 6 m3per min. at a power input of 3 - 15 kW. Rotary pumps cannot, usually, be used as a sucking device. As a special form of rotary pumps, the chopper pump deserves mentioning. It's rotor is equipped with blades to chop substrates with long fibers like straw and other fodder parts before pumping them up. Both wet and dry installation is possible with rotary pumps.

Limitation of a Centrifugal Pump

Sometimes, namely when the substrate is excessively viscous, a centrifugal pump will no longer do the job, because the condition of the substrate surpasses the pump's physical delivery capacity. In such cases, one must turn to a so-called positive-displacement or reciprocating type of pump in the form of a piston pump, gear pump or eccentric spiral pump, all of which operate on the principle of displacing action to provide positive delivery via one or more enclosed chambers

Positive Displacement Pumps

Positive displacement pumps are normally used for substrates with higher solids content. They pump and suck at the same time. Their potential quantity conveyed is less dependent on the conveying pressure than with rotary pumps. The direction of pumping / sucking can be changed into the opposite direction by changing the sense of rotation.This matches pump control more closely to precision metering of the substrate.The pressure stability of these self-priming pumps is better than that of rotary pumps, which means that delivery rate is much less dependent on head.

Positive- displacement pumps are relatively susceptible to interfering substances, so it makes sense to install comminutors and foreign-matter separators to protect the pumps against coarse and fibrous constituents in the substrate[4]n biogas units, mainly the eccentric spiral pump and the rotary piston pump (both positive displacement pumps) are used. For better access, a dry installation is the preferred option.

Eccentric Spiral Pump or Rotary-displacement pumps

This pump has a stainless steel rotor, similar to a cork screw, which turns in an elastic casing. The action of the rotor produces an advancing space in which the substrate is transported. Eccentric spiral pumps can suck from a depth of up to 8.5m and can produce a pressure of up to 24 bar. The are, however, more susceptible to obstructive, alien elements than rotary pumps. Of disadvantage is further the danger of fibrous material wrapping round the spiral.

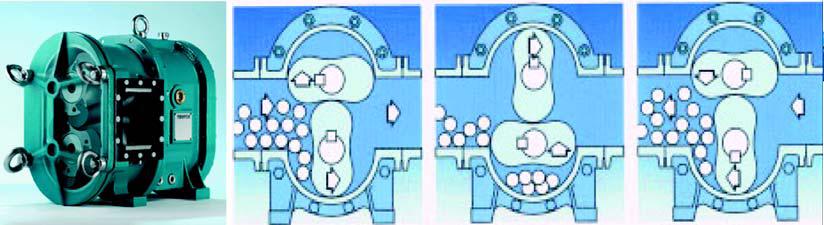

Rotary Piston Pump

Rotary displacement pumps have two counter-rotating rotary pistons with between two and six lobes in an oval body. The two pistons counter-rotate and counterroll with low axial and radial clearance, touching neither each other nor the body of the pump. Their geometry is such that in every position a seal is maintained between the suction side and the discharge side of the pump. The medium is drawn in to fill the spaces on the suction side and is transported to the discharge sideUnknown Object.

They can pump and suck as well and achieve pressures of up to 10 bar. The potential quantity conveyed ranges from 0.5 to 4 m3/min. The allow for larger alien objects and more fibrous material than eccentric spiral pumps.

| rotary pumps | chopper pumps | eccentric spiral pump | rotary piston pump | |

|---|---|---|---|---|

| solids content | < 8 % | < 8 % | < 15 % | < 15 % |

| energy input | 3 - 15 kW | 3 - 15 kW | 3 - 22 kW | 3 - 20 kW |

| quantity conveyed | 2 - 6 m3/min | 2 - 6 m3/min | 0,3 - 3,5 m3/min | 0,5 - 4 m3/min |

| pressure | 0,8 - 3,5 bar | 0,8 - 3,5 bar | < 25 bar | < 10 bar |

| structure of substrate | medium long fibers | long fibers | short fibers | medium long fibers |

| max. size of obstructive elements | approx. 5 cm | depending on choppers | approx. 4 cm | approx. 6 cm |

| intake | not sucking | not sucking | sucking | sucking |

| suitability | suitable for large quantities; simple and robust built | suitable for long-fiber substrates which need to be chopped up. | Suitable for high pressures, but susceptible to obstructive bodies | higher pressures than rotary pumps, but higher wear and tear |

| price comparison | cheaper than positive displacement pumps | depending on choppers | similar to rotary piston pump | similar to eccentric spiral pump |

Pump Delivery lines

Pump delivery lines can be made of steel, PVC (rigid) or PE (rigid or flexible), as well as appropriate flexible pressure tubing made of reinforced plastic or rubber. Solid substrate, e.g. dung, can also be handled via conveyor belt, worm conveyor or sliding-bar system, though none of these could be used for liquid manure. When liquid manure is conducted through an open gutter, small weirs or barrages should be installed at intervals of 20-30 m as a means of breaking up the scum layer.

Each such barrier should cause the scum to fall at least 20-30 cm on the downstream side. All changes of direction should be executed at right angles (90°). Depending on the overall length, the cross gutter should be laid some 30-50 cm deeper than the main gutter. Transitions between a rectangular channel and a round pipe must be gradual. An inclination of about 14% yields optimum flow conditions. The channel bottom must be laid level, since any slope in the direction of flow would only cause the liquid manure to run off prematurely. All wall surfaces should be as smooth as possible.

Industrial transport of Substrate

The transport of stackable substrates is a feature of wet digestion plants through to material infeed or to the stage of wetting down to mash with make-up liquid. Most of the work can be done with loaders of conventional design. It is only when automated feeding takes over that scraper-floor feeders, overhead pushers and screw conveyors are used. Scraper-floor feeders and overhead pushers are able to move virtually all stackable substrates horizontally or up slightly inclined planes. They cannot be used for metering, however. They permit very large holding tanks to be used. Screw conveyors can transport stackable substrates in virtually any direction. The only prerequisites are the absence of large stones and comminution of the substrate to the extent that it can be gripped by the worm and fits inside the turns of the worm's conveyor mechanism. Automatic feeder systems for stackable substrates are often combined with the loading equipment to form a single unit in the biogas plant[1

References