Difference between revisions of "Small Scale Oil Seeds Processing"

***** (***** | *****) |

***** (***** | *****) |

||

| Line 114: | Line 114: | ||

*[[Energy within Food and Agricultural Value Chains|Energy within Food and Agricultural Value Chains]] | *[[Energy within Food and Agricultural Value Chains|Energy within Food and Agricultural Value Chains]] | ||

*[[PoweringAg Technology Database Source of Energy|PoweringAg Technology Database]] | *[[PoweringAg Technology Database Source of Energy|PoweringAg Technology Database]] | ||

| + | *[[Portal:Powering Agriculture|Powering Agriculture portal on energypedia]] | ||

<br/> | <br/> | ||

Revision as of 08:37, 8 December 2014

Project

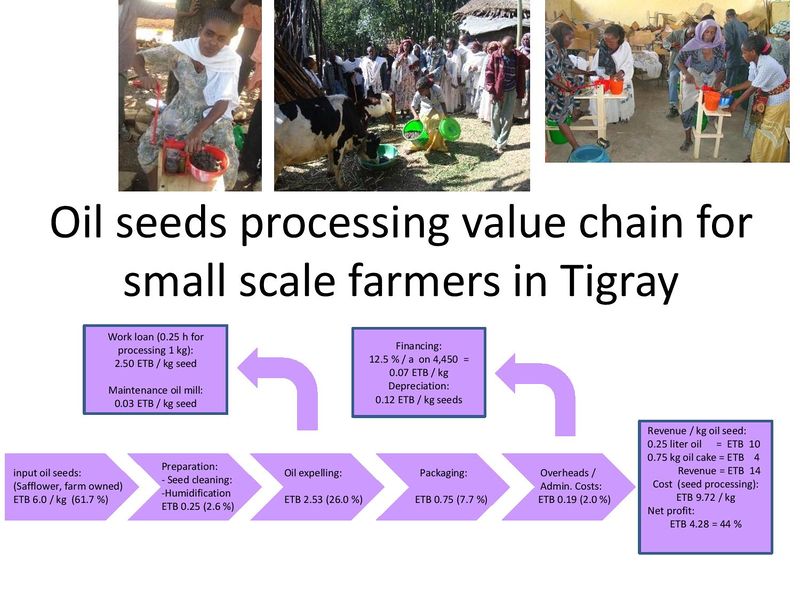

The Sustainable Land Management Program (GIZ SLMP) began in 2012 the promotion of small scale oil seeds processing in Tigray. The Tigray Agricultural Marketing Promotion Agency (TAMPA) started a collaboration with GIZ SLMP in 2013 for the promotion in Western, North Western and Central Zone of Tigray.

The target groups are oil seeds producing farmers organized in user groups. Actually, about 30 user groups (=300 households) were provided with one processing unit (manually operated oil expeller) for each group in the following 13 Woredas in Tigray:Raya Azebo, Enda Mehoni, Alaje, Kola Tembien, Tahtay Koraro, Tahtay Maichew, Medebay Zana, Laeley Adiabo, Kafta Humera, Wolkait, Tsegede, Alamata and Ofla.

The project enhances oil seed farmers to add value on their raw products. The final product is a healthy virgin oil from Noug (Niger Seed) or Suff (Safflower) which will improve nutrition of the farmer families and generate income.

The by-product is oil cake which serves as protein concentrate for animal feed.

Annual performance data

Annual performance data for 1 manually operated oil expeller (run as a business in team work):

- Production capacity per day: 5 liter oil (5 hours daily expelling work)

- Production capacity per year = 7,200 kg seeds processed = 1,800 kg edible oil + 5,400 kg oil cake

- Net profit per year: 7,200 kg x ETB 4.28 = ETB 30,816 (see below: | quantified value chain design)

Financing

| Description |

Purchase cost per unit |

Years of depreciation |

ETB/kg |

ETB/a |

| Oil mill |

2.200 |

10 |

0.030 |

220 |

| Workbench |

550 |

10 |

0.007 |

55 |

| Small material, balance |

1000 |

2 |

0.069 |

500 |

| Iron tools |

200 |

10 |

0.002 |

20 |

| Oil container with water top |

500 |

5 |

0.013 |

100 |

| Total (ETB) |

4450 |

0.121 |

895 |

Credit costs / Opportunity costs

Microfinance 12.5 % / a = ETB 4,450 / 12.5 % interest = ETB 556,25

Calculation due to the annual seeds processing quantity (7,200 kg) = 0.07 / kg

Repairs, maintenance

(Oil mills, 10 % / year = ETB 220 or per kg = (220: 7,200 kg/year) = 0.03 / kg

Depreciation

Calculation due to the annual seeds processing quantity (7,200 kg) = 0.12 / kg

Value Chain

Further Information

- Energy Situation Ethiopia

- GIZ Sustainable land management, Ethiopia

- Energy within Food and Agricultural Value Chains

- PoweringAg Technology Database

- Powering Agriculture portal on energypedia