Difference between revisions of "Upgrading of Water Mills, Rehabilitation of Existing Power Plants"

***** (***** | *****) m |

***** (***** | *****) m |

||

| (30 intermediate revisions by 6 users not shown) | |||

| Line 1: | Line 1: | ||

| − | |||

| − | + | [[Portal:Hydro|► Back to Hydro Portal]] | |

| − | + | = Overview<br/> = | |

| − | == | + | <span style="display: none" id="1275045178539S"></span> |

| − | + | <br/> | |

| − | + | {| cellspacing="1" cellpadding="5" border="1" style="width: 763px" | |

| − | + | |- | |

| − | + | | style="width: 397px" | | |

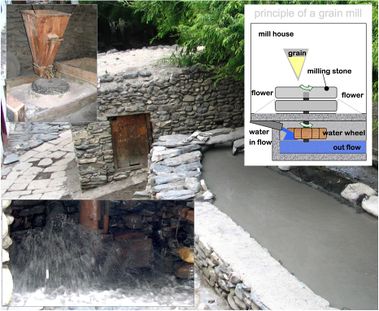

| − | + | [[File:Mill Nepal.jpg|left|379px|Water powered traditional grain mill in Mustang, Nepal|alt=Water powered traditional grain mill in Mustang, Nepal]]<br/> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | | style="width: 337px" | [[Grain Mill|Flour milling]] is an essential process in food processing since ancient times. Water as driving force for milling may be the oldest form of machinery not powered by human or animals. In many regions water driven mills are operated till today.<br/>Upgrading mills to electrical power generation is a logical step which took place also in central Europe during early times of electrification. Principally it’s simple. The rotating shaft of the waterwheel has to be connected with a generator instead of the mill. Even between usage of mill or generator can be switched. For efficient power output the (mostly wooden) waterwheels are to be replaced by turbines.<br/><br/><u>Advantages</u> of upgrading or rehabilitation of of existing mills or mhpp are the existing infrastructure. The location is suitable, management structures may still exist, land ownership is normally clear and often even constructions can still be used.<br/>Organisation and management are main factors for sustainable operation of a mhpp. If such structures are already functionally established, success is near at hand.<br/> | |

| − | + | |- | |

| + | | style="width: 397px" | <u>Difficulties</u> may occur as such site are often relatively small. Especially professional development support than has to deal with many small sites. This is usually more difficult to handle than one bigger site.<br/>Even if existing structures are in good conditions, turbine, generator, controller and esp. the power lines require substantial amount of money.<br/> | ||

| + | | style="width: 337px" | <u>[[File:Infobox Kincir.jpg|right|312px|A common, self made, water driven generators in rural Indonesia|alt=A common, self made, water driven generators in rural Indonesia]]</u> | ||

| + | |} | ||

| − | < | + | <br/> |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | = Micro Hydro Powered Grain Milling = | |

| − | |||

| − | |||

| − | + | '''By villagers in Barpak, Nepal ©Adam Harvey/Practical Action''' | |

| − | + | Maintenance costs (insurance and water abstraction charges, where they apply) are a comparatively minor component of the total - although they may be an important consideration in marginal economic cases. For further details of the economics of micro-hydro power see the case study on the Micro-hydro Scheme in Zimbabwe '''Ownership, management''' Programmes promoting the use of micro-hydro power in developing countries have concentrated on the social, as well as the technical and economic aspects of this energy source. Technology transfer and capacity building programmes have enabled local design and manufacture to be adopted. Local management, ownership and community participation has meant that many schemes are under the control of local people who own, run and maintain them. Operation and maintenance is usually carried out by trained local craftspeople. '''Low-cost grid connection''' Where the power from a micro-hydro scheme is used to provide domestic electricity, one method of making it an affordable option for low-income groups is to keep the connection costs and subsequent bills to a minimum. Often, rural domestic consumers will require only small quantity of power to light there houses and run a radio or television. | |

| − | + | <u><span>There are a number of solutions that can specifically help low-income households to obtain an electricity connection and help utilities meet their required return on investment. These include:</span></u> | |

| − | + | *<span>Load limited supply. Load limiters work by limiting the current supplied to the consumer to a prescribed value. If the current exceeds that value then the device automatically disconnects the power supply. The consumer is charged a fixed monthly fee irrespective of the total amount of energy consumed. The device is simple and cheap and does away with the need for an expensive meter and subsequent meter reading.</span> | |

| + | *<span><span>Reduced service connection costs. Limiting load supply can also help reduce costs on cable, as the maximum power drawn is low and so smaller cable sizes can be used. Also, alternative cable poles can sometimes be found to help reduce costs.</span></span> | ||

| + | *<span><span>Pre-fabricated wiring systems. Wiring looms can be manufactured 'ready to install' which will not only reduce costs but also guarantee safety standards.</span></span> | ||

| + | *<span><span>Credit. Credit schemes can allow householders to overcome the barrier imposed by the initial entry costs of grid connection. Once connected, energy savings on other fuels can enable repayments to be made. Using electricity for lighting, for example, is a fraction of the cost of using kerosene.</span></span> | ||

| + | *<span><span>Community involvement. Formation of community committees and co-operatives who are pro-active in all stages of the electrification process can help reduce costs as well as provide a better service. For example, community revenue collection can help reduce the cost of collection for the utility and hence the consumer.</span></span> | ||

| − | + | <span><span>Micro-hydro systems are designed to operate for a minimum of twenty years if they are properly looked after. By making a small charge for use, communities can accumulate enough money to pay for the replacement of the unit at the end of its useful life.</span></span> | |

| − | == | + | == Further Information<br/> == |

| − | + | *Upgrading Watermills in Tanzania: [http://hydrosystem.de/publications/remote_tanzania.html hydrosystem.de] | |

| − | + | *Traditional mills in Nepal: [http://web.media.mit.edu/~nathan/nepal/ghatta/ghattas.html web.media.mit.edu] | |

| − | + | *[[Grain Mill|Grain Mill]]<br/> | |

| − | |||

| − | |||

| − | |||

| − | < | + | <br/> |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | = | + | = <span><span>References</span></span><br/> = |

| − | <span> | + | #<span><span>[http://en.howtopedia.org/wiki/How_to_Plan_a_Micro_Hydro-power_Plant How to plan a micro hydro power plant?]</span></span> |

| − | |||

| − | |||

| − | + | <span><references /></span> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | [[Category:Indonesia]] | ||

| + | [[Category:Micro_Hydro]] | ||

[[Category:Hydro]] | [[Category:Hydro]] | ||

Latest revision as of 11:25, 11 June 2015

Overview

|

|

Flour milling is an essential process in food processing since ancient times. Water as driving force for milling may be the oldest form of machinery not powered by human or animals. In many regions water driven mills are operated till today. Upgrading mills to electrical power generation is a logical step which took place also in central Europe during early times of electrification. Principally it’s simple. The rotating shaft of the waterwheel has to be connected with a generator instead of the mill. Even between usage of mill or generator can be switched. For efficient power output the (mostly wooden) waterwheels are to be replaced by turbines. Advantages of upgrading or rehabilitation of of existing mills or mhpp are the existing infrastructure. The location is suitable, management structures may still exist, land ownership is normally clear and often even constructions can still be used. Organisation and management are main factors for sustainable operation of a mhpp. If such structures are already functionally established, success is near at hand. |

| Difficulties may occur as such site are often relatively small. Especially professional development support than has to deal with many small sites. This is usually more difficult to handle than one bigger site. Even if existing structures are in good conditions, turbine, generator, controller and esp. the power lines require substantial amount of money. |

Micro Hydro Powered Grain Milling

By villagers in Barpak, Nepal ©Adam Harvey/Practical Action

Maintenance costs (insurance and water abstraction charges, where they apply) are a comparatively minor component of the total - although they may be an important consideration in marginal economic cases. For further details of the economics of micro-hydro power see the case study on the Micro-hydro Scheme in Zimbabwe Ownership, management Programmes promoting the use of micro-hydro power in developing countries have concentrated on the social, as well as the technical and economic aspects of this energy source. Technology transfer and capacity building programmes have enabled local design and manufacture to be adopted. Local management, ownership and community participation has meant that many schemes are under the control of local people who own, run and maintain them. Operation and maintenance is usually carried out by trained local craftspeople. Low-cost grid connection Where the power from a micro-hydro scheme is used to provide domestic electricity, one method of making it an affordable option for low-income groups is to keep the connection costs and subsequent bills to a minimum. Often, rural domestic consumers will require only small quantity of power to light there houses and run a radio or television.

There are a number of solutions that can specifically help low-income households to obtain an electricity connection and help utilities meet their required return on investment. These include:

- Load limited supply. Load limiters work by limiting the current supplied to the consumer to a prescribed value. If the current exceeds that value then the device automatically disconnects the power supply. The consumer is charged a fixed monthly fee irrespective of the total amount of energy consumed. The device is simple and cheap and does away with the need for an expensive meter and subsequent meter reading.

- Reduced service connection costs. Limiting load supply can also help reduce costs on cable, as the maximum power drawn is low and so smaller cable sizes can be used. Also, alternative cable poles can sometimes be found to help reduce costs.

- Pre-fabricated wiring systems. Wiring looms can be manufactured 'ready to install' which will not only reduce costs but also guarantee safety standards.

- Credit. Credit schemes can allow householders to overcome the barrier imposed by the initial entry costs of grid connection. Once connected, energy savings on other fuels can enable repayments to be made. Using electricity for lighting, for example, is a fraction of the cost of using kerosene.

- Community involvement. Formation of community committees and co-operatives who are pro-active in all stages of the electrification process can help reduce costs as well as provide a better service. For example, community revenue collection can help reduce the cost of collection for the utility and hence the consumer.

Micro-hydro systems are designed to operate for a minimum of twenty years if they are properly looked after. By making a small charge for use, communities can accumulate enough money to pay for the replacement of the unit at the end of its useful life.

Further Information

- Upgrading Watermills in Tanzania: hydrosystem.de

- Traditional mills in Nepal: web.media.mit.edu

- Grain Mill

References