Difference between revisions of "Do It Yourself - Solar Cooling Units"

***** (***** | *****) |

***** (***** | *****) |

||

| (68 intermediate revisions by 7 users not shown) | |||

| Line 1: | Line 1: | ||

| + | |||

| + | <br/>{{#widget:YouTube|id=Lypj3m9q340|height=450|width=800}} | ||

= Background<br/> = | = Background<br/> = | ||

| − | The University of Hohenheim has been carrying out research on solar cooling for the last 5 years. A [[ | + | The University of Hohenheim has been carrying out research on solar cooling for the last 5 years. A [[Solar Milk Cooling with Insulated Milk Cans|smart solar ice-maker]] has been developed and applied for milk cooling. Up to now, 18 Systems have been successfully assessed together with local partners in [[Hohenheim Milk Cooling System - Implementation in Tunisia|Tunisia]], [[Hohenheim Milk Cooling System - Implementation in Kenya|Kenya]] and [[Hohenheim Milk Cooling System - Implementation in Colombia|Colombia]] showing its technical feasibility. Since 2017, the economic feasibility is under study in cooperation with partners of the private sector and in synergy to several on-going public initiatives. The project is financed by the GIZ programme ''Powering Agriculture - Sustainable Energy for Food''. |

| + | |||

| + | <br/> | ||

<br/> | <br/> | ||

= Description<br/> = | = Description<br/> = | ||

| − | |||

| − | |||

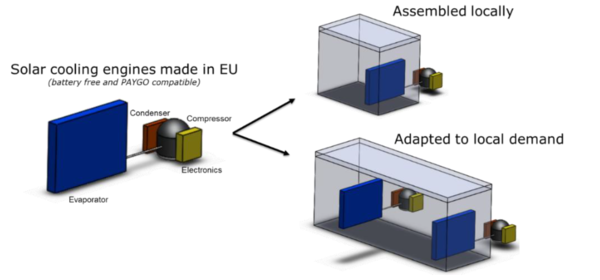

| + | The developed Do It Yourself - Solar Cooling Unit is a promising solution to promote refrigeration equipment for food value-chains. Under provision of technical support, local companies and entrepreneurs can design and produce small and medium scale solar cooling systems. This allows to reduce the final price of the technology, while creating specialized jobs locally. By following the approach described here, high-tech components (such as the cooling units and electronic controls) can be imported, while the manufacturing of the insulated box can be carried out locally. This way, entrepreneurs have the possibility to adapt the technology to the local market and offer distribution and maintenance under their own product brand. | ||

| + | <br/> | ||

| + | |||

| + | [[File:System and scaling.PNG|border|center|600px|alt=System and scaling.PNG]] | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | <br/> | ||

= Example Cooling Systems (for local assembly) = | = Example Cooling Systems (for local assembly) = | ||

| Line 16: | Line 26: | ||

== Example System 1: Smart ice-maker for ice-based milk/fish cooling == | == Example System 1: Smart ice-maker for ice-based milk/fish cooling == | ||

| − | This system is based on the Hohenheim smart ice-maker (modified STECA refrigerator PF166-H) but suitable for local production. It uses two cooling units and applies force convection for a daily production of around 25 kg ice per day. Batteries are optional but preferred in this system in order to increase the daily ice production. The system can store up to 50 kg ice. | + | This system is based on the Hohenheim smart ice-maker (modified STECA refrigerator PF166-H) but suitable for local production. It uses two cooling units and applies force convection for a daily production of around 25 kg ice per day. Batteries are optional but preferred in this system in order to increase the daily ice production. The system can store up to 50 kg ice, which can be used for different purposes, e.g. for [[Solar Milk Cooling with Insulated Milk Cans|milk cooling]] or fish cooling. |

| + | |||

| + | <br/> | ||

| + | |||

| + | [[File:Example System 1 - Overview.JPG|thumb|left|360px|Example System 1 for ice production|alt=Example System 1 - Overview.JPG]] [[File:Example System 1 - Cooling units.JPG|thumb|right|360px|Cooling units in the back the system|alt=Example System 1 - Cooling units.JPG]]<br/><br/>[[File:Smart Ice Maker Inside view.JPG|thumb|left|360px|Inside view of system|alt=Smart Ice Maker Inside view.JPG]][[File:Fans within the smart ice maker.JPG|thumb|right|360px|Fans in the system for better heat transfer|alt=Fans within the smart ice maker.JPG]] | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | <br/> | ||

== Example System 2: Battery-free refrigerator for milk and vegetables == | == Example System 2: Battery-free refrigerator for milk and vegetables == | ||

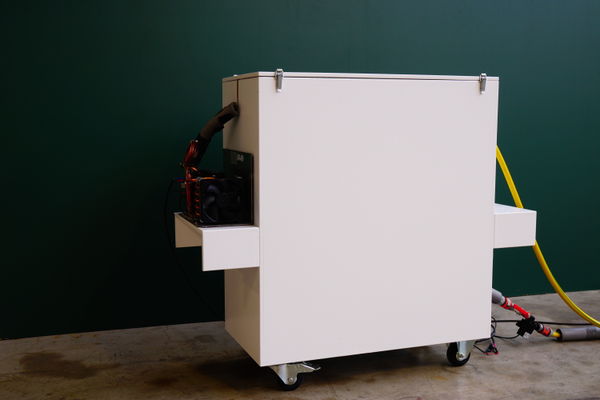

| − | This refrigerator uses a single cooling unit which integrates ice-storage. Therefore, the refrigerator operates at a temperature range between 4-8°C all over the day while the compressor only works during sun radiation hours. | + | This refrigerator uses a single cooling unit which integrates ice-storage. Therefore, the refrigerator operates at a temperature range between 4-8°C all over the day while the compressor only works during sun radiation hours.<br/><br/>[[File:Refrigerator Front View.JPG|thumb|center|600px|Battery-free refrigerator for milk and vegetables|alt=Refrigerator Front View.JPG]]<br/><br/>[[File:Refrigerator Inside View.JPG|thumb|left|360px|Refrigerator with open door|alt=Refrigerator Inside View.JPG]] [[File:Refrigerator Ice Packs.JPG|thumb|right|360px|Ice packs in the back of the fridge|alt=Refrigerator Ice Packs.JPG]] |

| + | |||

| + | <br/> | ||

| + | |||

| + | <br/> | ||

== Example System 3: Ice-storage system for cold rooms or chilled water == | == Example System 3: Ice-storage system for cold rooms or chilled water == | ||

| Line 26: | Line 50: | ||

This scalable system operates with one cooling unit which produces ice in a water bath (Ice storage). The system provides with water at around 4°C to a heat exchanger with a fan which then produces cold air for cooling rooms. An alternative application for the chilled water is the cooling of milk by introducing milk-cans in a chilled water bath. | This scalable system operates with one cooling unit which produces ice in a water bath (Ice storage). The system provides with water at around 4°C to a heat exchanger with a fan which then produces cold air for cooling rooms. An alternative application for the chilled water is the cooling of milk by introducing milk-cans in a chilled water bath. | ||

| + | <br/>[[File:Example System 3 - Overview.JPG|thumb|center|600px|Ice-storage system for cold rooms or chilled water|alt=Example System 3 - Overview.JPG]]<br/><br/>[[File:Example System 3 - Open cover.JPG|thumb|left|360px|System with open cover|alt=Example System 3 - Open cover.JPG]] [[File:Example System 3 - Ice Storage.JPG|thumb|right|360px|Ice within the storage tank|alt=Example System 3 - Ice Storage.JPG]] | ||

| + | <br/> | ||

| + | |||

| + | [[File:Solar Water Chiller Big - Construction.jpg|thumb|left|360px|Scaled up solar water chiller with 6 cooling units under construction]] [[File:Solar Water Chiller Big.JPG|thumb|right|360px|Scaled up solar water chiller with 6 cooling units installed in Mali for application in a cold room]] | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | <br/> | ||

= Features and Interoperability = | = Features and Interoperability = | ||

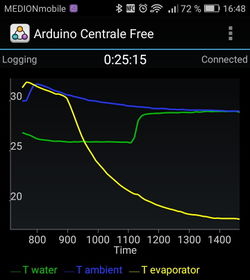

| − | Following main features are implemented in every single solar cooling unit: | + | Following main features are implemented in every single solar cooling unit: [[File:RemoteControl.jpg|thumb|right|250px|Monitoring of the cooling system temperatures per smartphone]] |

| + | |||

| + | <br/> | ||

*Cooling units specially design for a plug and play local assembly | *Cooling units specially design for a plug and play local assembly | ||

| Line 38: | Line 74: | ||

*Remote monitoring | *Remote monitoring | ||

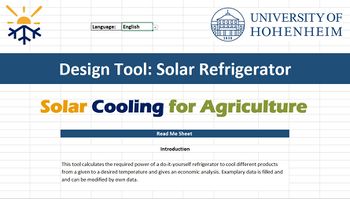

| − | Every single control unit can be programed by the final manufacturer in dependence of the application. Design tools for the sizing of | + | Every single control unit can be programed by the final manufacturer in dependence of the application. Design tools for the sizing of PV panels according to location and |

| + | |||

| + | application are available. | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | <br/> | ||

| + | <br/> | ||

| + | <br/> | ||

= Transport = | = Transport = | ||

| − | Transport of cooling units to target countries: | + | Transport of cooling units to target countries:[[File:TransportCoolingUnits.PNG|thumb|right|150px|8 Cooling units on one EUR Pallet|alt=TransportCoolingUnits.PNG]] |

<br/>8 Cooling units (ready for Plug&Play) can be transported in one EUR Pallet: | <br/>8 Cooling units (ready for Plug&Play) can be transported in one EUR Pallet: | ||

| Line 53: | Line 97: | ||

<br/>A saving of around 75% of transport cost is expected in comparison of importing solar refrigerators/systems.<br/>Size per solar cooling unit: 250x600x630mm (LxBxH) 11Kg | <br/>A saving of around 75% of transport cost is expected in comparison of importing solar refrigerators/systems.<br/>Size per solar cooling unit: 250x600x630mm (LxBxH) 11Kg | ||

| + | <br/> | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | = Workshop Material<br/> = | ||

| + | |||

| + | Please find the following files from the Solar Cooling Workshops: | ||

| + | |||

| + | <br/>[[File:Cooling Manuel eng.jpg|thumb|left|350px|Construction manual for the DIY Solar Cooling Systems - English Version|link=https://energypedia.info/wiki/File:Construction_Manual_-_English.docx]] [[File:Cooling Manuel fra.jpg|thumb|right|350px|Construction manual for the DIY Solar Cooling Systems - French Version|link=https://energypedia.info/wiki/File:Manuel_de_Construction_-_Francais.docx]]<br/> | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | <br/><br/>[[File:Solar Refrigerator.jpg|thumb|left|350px|Excel-based design tool for solar refrigerators - multiple languages|link=https://energypedia.info/wiki/File:Solar_Refrigerator_Design_Tool.xlsx]] [[File:Solar Water Chiller.jpg|thumb|right|350px|Excel-based design tool for solar water chillers for coldrooms - multiple languages|link=https://energypedia.info/wiki/File:Solar_Water_Chiller_for_Cold_Rooms.xlsx]] | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | |||

| + | = Projects<br/> = | ||

| + | |||

| + | [[Establishment_of_a_Training_Course_for_Small-scale_Solar_Cooling|Bürgerenergie Small Project Fund (Establishment of a Training Course at SERC, Kenya)]] | ||

| + | |||

| + | [[Promotion_of_solar_refrigeration_for_agricultural_value-chains_(PA_Project)|Powering Agriculture Project - Promotion of solar refrigeration for agricultural value-chains]]<br/> | ||

| + | |||

| + | |||

| + | = Additional information<br/> = | ||

| + | |||

| + | [[Workshop - Do It Yourself - Solar Cooling Units in Mali (September 2019)|Workshop - Do It Yourself - Solar Cooling Units in Mali (September 2019)]] | ||

| + | |||

| + | [[Workshop - Do It Yourself - Solar Cooling Units in Kenya (March 2019)|Workshop - Do It Yourself - Solar Cooling Units in Kenya (March 2019)]]<br/> | ||

| + | |||

| + | |||

| + | [[:File:2019-03-08-DIY-solar-cooling-Manual-University-of-Hohenheim.pdf|DIY Solar Cooling Manual]]<br/> | ||

| + | DIY Solar Cooling TechSheet:<br/> | ||

| − | = | + | [[File:DIY Solar Cooling TechSheet.pdf|180px|DIY Solar Cooling - TechSheet|alt=DIY Solar Cooling - TechSheet]]<br/> |

| − | + | [[Category:Powering_Agriculture]] | |

| + | [[Category:Cooling]] | ||

| + | [[Category:Solar]] | ||

Latest revision as of 13:05, 10 March 2020

Background

The University of Hohenheim has been carrying out research on solar cooling for the last 5 years. A smart solar ice-maker has been developed and applied for milk cooling. Up to now, 18 Systems have been successfully assessed together with local partners in Tunisia, Kenya and Colombia showing its technical feasibility. Since 2017, the economic feasibility is under study in cooperation with partners of the private sector and in synergy to several on-going public initiatives. The project is financed by the GIZ programme Powering Agriculture - Sustainable Energy for Food.

Description

The developed Do It Yourself - Solar Cooling Unit is a promising solution to promote refrigeration equipment for food value-chains. Under provision of technical support, local companies and entrepreneurs can design and produce small and medium scale solar cooling systems. This allows to reduce the final price of the technology, while creating specialized jobs locally. By following the approach described here, high-tech components (such as the cooling units and electronic controls) can be imported, while the manufacturing of the insulated box can be carried out locally. This way, entrepreneurs have the possibility to adapt the technology to the local market and offer distribution and maintenance under their own product brand.

Example Cooling Systems (for local assembly)

Example System 1: Smart ice-maker for ice-based milk/fish cooling

This system is based on the Hohenheim smart ice-maker (modified STECA refrigerator PF166-H) but suitable for local production. It uses two cooling units and applies force convection for a daily production of around 25 kg ice per day. Batteries are optional but preferred in this system in order to increase the daily ice production. The system can store up to 50 kg ice, which can be used for different purposes, e.g. for milk cooling or fish cooling.

Example System 2: Battery-free refrigerator for milk and vegetables

This refrigerator uses a single cooling unit which integrates ice-storage. Therefore, the refrigerator operates at a temperature range between 4-8°C all over the day while the compressor only works during sun radiation hours.

Example System 3: Ice-storage system for cold rooms or chilled water

This scalable system operates with one cooling unit which produces ice in a water bath (Ice storage). The system provides with water at around 4°C to a heat exchanger with a fan which then produces cold air for cooling rooms. An alternative application for the chilled water is the cooling of milk by introducing milk-cans in a chilled water bath.

Features and Interoperability

Following main features are implemented in every single solar cooling unit:

- Cooling units specially design for a plug and play local assembly

- Battery free compatible

- Usage of climate-friendly natural refrigerants (R600a)

- PAYGO compatibility (currently Angaza)

- Remote monitoring

Every single control unit can be programed by the final manufacturer in dependence of the application. Design tools for the sizing of PV panels according to location and

application are available.

Transport

Transport of cooling units to target countries:

8 Cooling units (ready for Plug&Play) can be transported in one EUR Pallet:

- Dimensions(L x B x H):1400 x 800 x 1200 mm

- Aprox. 90kg total weight

A saving of around 75% of transport cost is expected in comparison of importing solar refrigerators/systems.

Size per solar cooling unit: 250x600x630mm (LxBxH) 11Kg

Workshop Material

Please find the following files from the Solar Cooling Workshops:

Projects

Bürgerenergie Small Project Fund (Establishment of a Training Course at SERC, Kenya)

Powering Agriculture Project - Promotion of solar refrigeration for agricultural value-chains

Additional information

Workshop - Do It Yourself - Solar Cooling Units in Mali (September 2019)

Workshop - Do It Yourself - Solar Cooling Units in Kenya (March 2019)

DIY Solar Cooling TechSheet: