Difference between revisions of "Sustainable Energy for Cooling"

***** (***** | *****) |

***** (***** | *****) m (→Introduction) |

||

| (20 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

| + | <span class="link3">[[Energie durable pour le refroidissement|►French Version]]</span><br/> | ||

| + | {{Back to PA portal2}} | ||

| − | = Introduction<br/> = | + | = <span style="color:#00A3AD">Introduction</span><br/> = |

| − | One third of food production worldwide is lost every year. This is partly due to missing infrastructures for reliable electricity supply in rural areas of the Global South impeding the use of appropriate refrigeration technologies. | + | One third of food production worldwide is lost every year. This is partly due to missing infrastructures for reliable electricity supply in rural areas of the Global South impeding the use of appropriate refrigeration technologies. [https://www.powerforall.org/insights/dre-technologies/powering-clean-farm-fork-solutions-zerohunger-world Read more...] |

| − | [[Cooling for Agriculture|Cooling]] mostly relies on the usage of refrigerants which can have a high global warming impact and ozone depleting properties, being the cause of major climate and environmental problems. Especially low efficiency levels and high leakage rates of refrigeration equipment can increase emissions drastically. '''Direct emissions '''are caused by the release of a refrigerant which can occur because of leaks from pipes or during regular servicing of the equipment. The potential of reducing these emissions remains in adopting technologies that use natural refrigerants, an approach called [[Green Cooling Initiative|Green Cooling.]]<br/>'''Indirect emissions''' are caused by energy consumption and contribute to 2/3 of the total emissions. These depend on the source of electricity and can be reduced by raising energy efficiency and/or using renewable energies. Many innovative approaches have shown how clean energy solutions for cooling open up new opportunities, especially for off-grid areas while helping to mitigate climate change. | + | <span class="link3">[[Cooling for Agriculture|Cooling]] mostly relies on the usage of refrigerants which can have a high global warming impact and ozone depleting properties, being the cause of major climate and environmental problems. Especially low efficiency levels and high leakage rates of refrigeration equipment can increase emissions drastically. '''Direct emissions '''are caused by the release of a refrigerant which can occur because of leaks from pipes or during regular servicing of the equipment. The potential of reducing these emissions remains in adopting technologies that use natural refrigerants, an approach called [[Green Cooling Initiative|Green Cooling.]]<br/>'''Indirect emissions''' are caused by energy consumption and contribute to 2/3 of the total emissions. These depend on the source of electricity and can be reduced by raising energy efficiency and/or using renewable energies. Many innovative approaches have shown how clean energy solutions for cooling open up new opportunities, especially for off-grid areas while helping to mitigate climate change.<br/> |

| − | + | [[File:Food losses FAO.jpg|thumb|center|600px|Source: FAO.]]<br/> | |

| − | |||

| − | == < | + | = <span style="color:#00A3AD">Technologies</span><br/> = |

| − | + | The rising demand for cooling equipment in the Global South reveals the need to find clean energy solutions, as these can provide access to cooling technologies in off-grid regions, but also enhance environmental protection. Traditional off-grid approaches, like evaporative cooling, combined with new technologies that run on renewable energy and use environmentally friendly alternatives, present climate-friendly and affordable solutions.<br/>'''Evaporative cooling '''uses the cooling effect released during evaporation. It can be applied as a cooling technology by placing a clay pot within another clay pot, with a layer of wet sand in-between to provide water for evaporation. It can also be built as a large evaporative cooling chamber using brick walls with wet sand between each one and a straw and wood cover on top. As the device allows keeping temperatures low and humidity high, it’s particularly effective for storing vegetables. '''<span class="link3">[[Evaporative Cooling Devices|Read more…]]</span>'''<br/>'''Green Cooling''' approaches involve the use of natural refrigerants. In contrast to artificial refrigerants CFCs, HCFCs and HFCs, natural refrigerants are substances occurring in nature, including CO2, ammonia, hydrocarbons, air and water. Maximizing energy efficiency is another green cooling strategy, fostering a sustainable approach to private and commercial energy consumption, by including, for example, renewable energies. '''<span class="link3">[[Cooling|Read more…]]</span>'''<br/>'''Pre-cooling''' is the rapid removal of field heat shortly after crop harvest. It is one simple approach that reduces energetic consumption for cooling and enhances shelf-life afterwards. Due to biological factors, the methods and importance of pre-cooling vary among crops. Methods include shade, air cooling, water cooling, ice cooling and vacuum cooling. '''<span class="link3">[[Pre-cooling of Agricultural Products|Read more…]]</span>'''<br/>Among green cooling strategies, the '''Solar Ice Maker''' is one implementation example. Using solar energy to feed a refrigeration system where water can be frozen and used in refrigeration devices, this technology has different kinds of uses: it can be utilized for milk chilling, cooling down vegetables during harvest, and much more. Examples of different value chains where solar ice making devices have been employed are listed further below under Case Studies.<br/>Another cooling example that involves ice is the '''Water Chiller'''. Using a renewable energy source to freeze water, it creates cold air that is blown to a storage room for commodities like vegetables. '''<span class="link3">[[:File:Techsheet A3 solar ice maker V3.0.pdf|Read more…]]</span>'''<br/> | |

| − | = < | + | == <span style="color:#00A3AD">Cold Storage of Agricultural Products</span> == |

| − | + | Cold storage facilities are crucial to minimize post-harvest losses; however, losses occur at every step in the post-harvest cycle, and thus cold storages cannot be considered as independent solutions to prevent post-harvest spoilage but as one component that needs to be integrated in a cold chain network from the point of harvest to the point of purchase by the end consumer. During the different stages in the post-harvest cycle, temperature control and the adequate handling of the produce are crucial to minimize post-harvest losses. '''<span class="link3">[[Cold Storage of Agricultural Products|Read more…]]</span>'''<br/> | |

| − | == | + | = <span style="color:#00A3AD">Actors & Innovations</span> = |

| − | In the emerging dairy industry in East Africa, the demand is expected to double in the coming years. However, only 15 percent of milk produced reaches the formal market, partly due to the lack of access to a reliable power grid for cooling. As there had been a lack of solutions available on the market to provide milk chilling technologies at micro-scale, SimGas together with SNV developed a small-scale biogas-powered milk chiller for smallholder farmers in Kenya, Tanzania and Rwanda. [ | + | Creative approaches and innovations in the cooling field span from solar photovoltaic systems to biogas-powered models, facilitating access to cooling in rural areas without grid-access. The use of climate-smart systems for cooling leads to fewer post-harvest losses, higher food security and lower costs for food preservation. It can also result in higher incomes and independency, and helps mitigating climate change. The number of green innovators supported by effective business models keeps rising and promises a sustainable transition for development.<span style="color:#00A3AD"></span><br/><span style="color:#00A3AD"></span> |

| + | |||

| + | == <span style="color:#00A3AD">Biogas Milk Chilling for Dairy Farmers</span><br/> == | ||

| + | |||

| + | In the emerging dairy industry in East Africa, the demand is expected to double in the coming years. However, only 15 percent of milk produced reaches the formal market, partly due to the lack of access to a reliable power grid for cooling. As there had been a lack of solutions available on the market to provide milk chilling technologies at micro-scale, SimGas together with SNV developed a small-scale biogas-powered milk chiller for smallholder farmers in Kenya, Tanzania and Rwanda. '''<span class="link3">[[Biogas Milk Chilling to Increase Productivity and Incomes of Dairy Farmers|Read more…]]</span>'''<br/> | ||

[[File:Biogas Cooling in Kenya-Woman with milk cans.JPG|thumb|center|600px|Woman using SimGas Technology to cool her milk in Kenya (GIZ/Kameweru).|alt=Biogas Cooling in Kenya-Woman with milk cans.JPG]] | [[File:Biogas Cooling in Kenya-Woman with milk cans.JPG|thumb|center|600px|Woman using SimGas Technology to cool her milk in Kenya (GIZ/Kameweru).|alt=Biogas Cooling in Kenya-Woman with milk cans.JPG]] | ||

| − | |||

| − | Cold Hubs are large walk-in storage rooms for fresh vegetables which include a refrigeration system that runs on solar power. Developed by ILK Dresden and the Smallholder Foundation, this innovation can save huge amounts of perishable food (storage capacity of up to 2 tons) and can be used off-grid, being especially suitable for rural areas, where large amounts of food need to be stored before joining the market. [[ColdHubs - Solar Cold Rooms in Nigeria|Read more…]]<br/> | + | == <br/><span style="color:#00A3AD">ColdHubs</span><br/> == |

| + | |||

| + | Cold Hubs are large walk-in storage rooms for fresh vegetables which include a refrigeration system that runs on solar power. Developed by ILK Dresden and the Smallholder Foundation, this innovation can save huge amounts of perishable food (storage capacity of up to 2 tons) and can be used off-grid, being especially suitable for rural areas, where large amounts of food need to be stored before joining the market. '''<span class="link3">[[ColdHubs - Solar Cold Rooms in Nigeria|Read more…]]</span>'''<br/> | ||

| + | |||

| + | == <span style="color:#00A3AD"><br/>Biogas-Powered Evaporative Cooling for the Dairy Industry</span><br/> == | ||

| + | The growing dairy industry throughout sub-Saharan Africa suffers from a lack of proper refrigeration options, which causes farmers to lose 20-50 percent of their milk to spoilage. The University of Georgia Research Foundation (UGARF) together with the Smallholder Fortunes’ small scale demonstration dairy farm in Uganda have developed the EvaKuula: a biogas unit that works with cow manure and allows a mild heat treatment of the milk, followed by a gentle evaporative cooling process, keeping the milk fresh overnight. Working with local manufacturers, financing models are being developed to bring the local production to commercial scale. Using the EvaKuula, smallholder dairy farmers not only profit from access to clean energy, which can be used for lighting and cooking, but also reduce greenhouse gas emissions from cow manure fermentation. 42 farmers (50 percent of them being women) have so far benefitted from the deployment of this device. '''<span class="link3">[[Biogas-Powered Evaporative Cooling for Uganda’s Dairy Industry|Read more…]]</span>''' | ||

| − | == < | + | == <span style="color:#00A3AD">DIY Solar Cooling</span><br/> == |

| − | + | The University of Hohenheim developed an approach that allows entrepreneurs, engineers, etc. in the Global South to assemble their own solar cooling systems, adapted to the local context and needs. The vendors and manufacturers of these simple but effective systems only need to import one piece while all other material can be obtained from the domestic market - making these systems much more cost-effective than comparable refrigeration systems that are wholly imported from abroad. '''<span class="link3">[[Do It Yourself - Solar Cooling Units|Read more ...]]</span>'''<br/> | |

| − | == | + | = <span style="color:#00A3AD">Case Studies</span><br/> = |

| − | + | An increasing number of cooling technologies based on renewable energies are being used in different steps of the agricultural value chain. The following case studies provide an insight to the diversity of solutions, and the benefits obtained from implementing climate-smart cooling technologies in rural environments.<br/> | |

| + | == <span style="color:#00A3AD"><br/>SunDanzer: Solar Powered Refrigeration for Kenyan Dairy Farms</span><br/> == | ||

| − | = | + | In Kenya, 85 percent of dairy farms do not have access to refrigerated storage and transportation due to limited electrification in rural areas, leading to dramatic losses from milk spoilage. SunDanzer together with Winrock International have developed an affordable small-scale portable cooling system: the photovoltaic refrigerator (PVR) runs on solar energy and uses phase-change materials – substances capable of storing and releasing large amounts of energy – and therefore needs no battery. Additionally, the innovators have developed milk can blankets to retain the temperature during transportation. 60 solar-powered milk cooling refrigerators have been installed so far in Kenya and two in Rwanda. Users of SunDanzer’s refrigerators have stated that the technology has delivered many benefits, including increased financial security for households, increased food preservation, and saved time. '''<span class="link3">[[SunDanzer: Solar-Powered Refrigeration for Kenyan Dairy Farms|Read more...]]</span>''' |

| − | An | + | == <span style="color:#00A3AD">Reducing Milk Spoilage through Solar-Powered Chilling</span><br/> == |

| + | |||

| + | Perishable food worth of 10 billion US Dollars is wasted annually in India because of unreliable cold-chain supply networks. Especially in farming areas and villages, the lack of reliable electricity is a challenge for running refrigeration systems. With India being the largest consumer and producer of milk in the world, Promethean Power Systems together with Hatsun Agro and Orb Energy have developed a solar milk cooling system that uses an innovative thermal energy battery pack. Charging on intermittent power sources such as solar power and/or a few hours of grid electricity, it allows changing the local food situation considerably. '''<span class="link3">[[Reducing Milk Spoilage through Solar Powered Milk Chilling|Read more...]]</span>''' | ||

| + | |||

| + | == <span style="color:#00A3AD">SunChill Solar Cooling for Horticultural Preservation</span><br/> == | ||

| + | |||

| + | An innovation designed by Rebound Technologies (United States) aims to reduce post-harvest losses and enhance food consumption quality. The first versions of the SunChill cooling system have been tested in Mozambique and after being validated, a commercialization and expansion to the market is planned. The solar off-grid refrigeration system allows to immediately cool down food during harvest and provides continued product cooling at markets or central processing facilities. SunChillTM transforms 50 °C solar thermal energy into 10 °C refrigeration, doubling shelf life and creating access to nutritional fruits and vegetables. The innovation is also expected to create manufacturing and service-based employment. By the end of the project, Promethean sold over 600 units, enabling 25,000 dairy farmers to chill their milk without diesel generators and to get their milk to the market safely. '''<span class="link3">[[SunChill: Solar Cooling for Horticultural Preservation|Read more...]]</span>''' | ||

| + | |||

| + | == <span style="color:#00A3AD">Solar Milk Cooling with Insulated Milk Cans</span><br/> == | ||

| + | |||

| + | Profitable milk production without cooling technologies can be a challenge. Firstly, milk produced on small- to medium-scale farms is usually transported to milk collection facilities. The spoilage caused by bacterial growth during transportation due to warm temperatures leads to milk being refused by vendors. Secondly, many farmers do not sell their evening milk to the collection centres, as it cannot be stored adequately overnight. Instead, they sell the milk to neighbours or use it themselves. This can increase the on-farm losses and reduce income. The solar milk cooling system developed by the University of Hohenheim (Germany) uses solar energy for ice production. The produced ice is used to cool the milk by putting it into an ice-compartment of an insulated milk can. This system allows lower temperatures during transportation and overnight storage, increasing the farms production and income. On-field implementations have taken place in Tunisia (10 installed systems), Kenya (4 installed systems), and Colombia (also 4 installed systems). '''<span class="link3">[[Solar Milk Cooling with Insulated Milk Cans|Read more…]]</span>'''<br/> | ||

| − | == < | + | == <span style="color:#00A3AD">Reducing Seed Post-Harvest Losses with Silos</span><br/> == |

| − | + | Rodents, insects, fungi and rot destroy small farming families’ provisions of grain and legumes. The result is a not only lack of income but also increases the risk of malnutrition and hunger. Better storage of food grains helps to prevent unnecessary grain losses. | |

| − | + | Tanzania´s agricultural policy has introduced metal silos to battle this problem. '''[https://www.helvetas.org/en/switzerland/what-we-do/how-we-work/our-projects/africa/tanzania/tanzania-storage-food-products Read more...]''' | |

| − | + | <span class="link3">In Mozambique, a local firm has developed a low-cost seed storage silo made of locally available materials and applying traditional construction techniques. '''[[Zero Emission Fridge for Rural Africa (ZEFRA)|Read more...]]''' | |

| − | == < | + | == <span style="color:#00A3AD">Preserving Food Using Mobile Solar-powered Cold Storages</span><br/> == |

| − | + | Worldwide, postharvest food losses account for more than 30% of the total food produced. In Kenya, this number is even higher with over 40-50% of the produced food lost/wasted during the entire food value chain and in Nigeria 45% of the postharvest is lost due to lack of cold storage. [https://www.powerforall.org/insights/dre-technologies/powering-clean-farm-fork-solutions-zerohunger-world Read more...] | |

| − | + | Solar Freeze, a company based in Kenya provides famers with solar-powered mobile cold storage for postharvest food preservation. Farmers can use their app to find the nearest cold storage and pay using M-PESA or cash. '''[http://www.solarfreeze.co.ke/ Read more...]''' | |

| − | + | In India, there are local companies such as [https://www.ecozensolutions.com/ Ecozen] and [https://milaap.org/fundraisers/connect-our-farmers TAN90] which provide similar cold storage services to the farmers. Another example of a similar company is the [https://www.inspirafarms.com/ Inspira Farms]. | |

| − | |||

| − | = Publications & Tools<br/> = | + | = <span style="color:#00A3AD">Publications & Tools</span><br/> = |

The refrigeration and air conditioning (RAC) sector is expected to account for 13 percent of global greenhouse gas (GHG) emissions by 2030. With an increasing importance of the sector in the Global South, and the impact caused by the use of conventional climate damaging refrigerants, research and development of low-cost climate-friendly solutions is pivotal. The RAC sector can provide different climate-smart cooling technologies affordable for costumers in the Global South and improve living standards considerably without polluting.<br/> | The refrigeration and air conditioning (RAC) sector is expected to account for 13 percent of global greenhouse gas (GHG) emissions by 2030. With an increasing importance of the sector in the Global South, and the impact caused by the use of conventional climate damaging refrigerants, research and development of low-cost climate-friendly solutions is pivotal. The RAC sector can provide different climate-smart cooling technologies affordable for costumers in the Global South and improve living standards considerably without polluting.<br/> | ||

| − | == <br/>Implications of | + | == <br/><span style="color:#00A3AD">Implications of Natural Refrigerants for Cooling Technologies</span><br/> == |

| − | As the global warming potential (GWP) of conventional refrigerants (hydrofluorocarbons, HFCs) is 4,000 times higher than CO2, the pressure on manufacturers to develop climate friendly RAC equipment has risen in the last few years. Natural refrigerants have very good environmental and technical performance, and are sustainable as their extraction from unlimited sources does not harm the environment. Even though they are less expensive and therefore commercially available for almost any type of equipment, barriers still hinder their wide-scale introduction. The report presented in this article explains the main challenges faced by manufacturers along three examples from Bangladesh, Swaziland and South Africa. [[Implications of natural refrigerants for cooling technologies|Read more...]]<br/> | + | As the global warming potential (GWP) of conventional refrigerants (hydrofluorocarbons, HFCs) is 4,000 times higher than CO2, the pressure on manufacturers to develop climate friendly RAC equipment has risen in the last few years. Natural refrigerants have very good environmental and technical performance, and are sustainable as their extraction from unlimited sources does not harm the environment. Even though they are less expensive and therefore commercially available for almost any type of equipment, barriers still hinder their wide-scale introduction. The report presented in this article explains the main challenges faced by manufacturers along three examples from Bangladesh, Swaziland and South Africa. '''<span class="link3">[[Implications of natural refrigerants for cooling technologies|Read more...]]</span>'''<br/> |

| − | == <br/>Ice-Making as a Productive Application in Green Mini-Grid (GMG) Systems<br/> == | + | == <span style="color:#00A3AD"><br/>Ice-Making as a Productive Application in Green Mini-Grid (GMG) Systems</span><br/> == |

| − | Productive Use (PU) activities, which refer to the utilisation of electricity for income and employment generation, can catalyse rural development and sustainable economic growth. The increasing demand for energy and the increasing household income can accelerate the success of green mini-grid (GMG) projects. The presented guide is designed to help practitioners assess whether ice-making for food preservation (in this case, fish) is an appropriate and financially viable application and provides guidance on how to operationalize ice-making PU. It is organized as a series of tools that help establish a set of best practices for off-grid electrification initiatives. The tools include: a feasibility checklist, a business model guidance, technical considerations and requirements for appropriate mini-grid sizing, a detailed financial model assessing various scenarios, and a guide on monitoring and evaluation. [[Ice-Making as a Productive Application in Green Mini-Grid (GMG) Systems|Read more…]] | + | Productive Use (PU) activities, which refer to the utilisation of electricity for income and employment generation, can catalyse rural development and sustainable economic growth. The increasing demand for energy and the increasing household income can accelerate the success of green mini-grid (GMG) projects. The presented guide is designed to help practitioners assess whether ice-making for food preservation (in this case, fish) is an appropriate and financially viable application and provides guidance on how to operationalize ice-making PU. It is organized as a series of tools that help establish a set of best practices for off-grid electrification initiatives. The tools include: a feasibility checklist, a business model guidance, technical considerations and requirements for appropriate mini-grid sizing, a detailed financial model assessing various scenarios, and a guide on monitoring and evaluation. '''<span class="link3">[[Ice-Making as a Productive Application in Green Mini-Grid (GMG) Systems|Read more…]]</span>''' |

| − | == How Access to Energy can Influence Food Losses<br/> == | + | == <span style="color:#00A3AD">How Access to Energy can Influence Food Losses</span><br/> == |

| − | + | The FAO Report “How Access to Energy can Influence Food Losses” highlights the crucial interlinkages between access to energy and food losses in developing countries. It identifies the main stages of the food value chain where increasing access to energy can play a dominant role in reducing food losses directly, by making food processing possible, as well as indirectly by acting as the main enabling factor affecting the rate at which cooling technologies are adopted. It outlines low cost and off-grid post-harvest technologies such as cooling and solar drying that can be made available in developing countries. Most importantly, it assesses the technical and economic feasibility since access to capital can be a significant barrier hindering its implementation in the developing world. '''<span lang="en-gb">[http://www.fao.org/3/a-i6626e.pdf Read more...]</span>''' | |

| − | + | [[Category:Powering_Agriculture]] | |

| + | [[Category:Water-Energy-Food_Nexus]] | ||

| + | [[Category:Energy_Access]] | ||

| + | [[Category:Sustainability]] | ||

| + | [[Category:Cooling]] | ||

Latest revision as of 10:15, 19 October 2020

| ►Back to the WE4F Portal |

Introduction

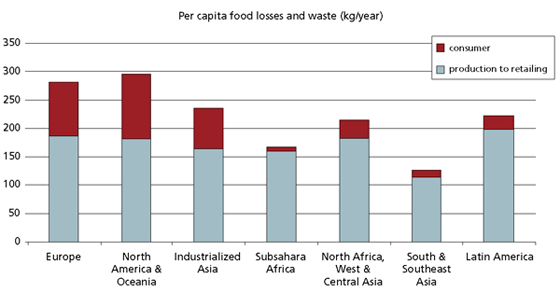

One third of food production worldwide is lost every year. This is partly due to missing infrastructures for reliable electricity supply in rural areas of the Global South impeding the use of appropriate refrigeration technologies. Read more...

Cooling mostly relies on the usage of refrigerants which can have a high global warming impact and ozone depleting properties, being the cause of major climate and environmental problems. Especially low efficiency levels and high leakage rates of refrigeration equipment can increase emissions drastically. Direct emissions are caused by the release of a refrigerant which can occur because of leaks from pipes or during regular servicing of the equipment. The potential of reducing these emissions remains in adopting technologies that use natural refrigerants, an approach called Green Cooling.

Indirect emissions are caused by energy consumption and contribute to 2/3 of the total emissions. These depend on the source of electricity and can be reduced by raising energy efficiency and/or using renewable energies. Many innovative approaches have shown how clean energy solutions for cooling open up new opportunities, especially for off-grid areas while helping to mitigate climate change.

Technologies

The rising demand for cooling equipment in the Global South reveals the need to find clean energy solutions, as these can provide access to cooling technologies in off-grid regions, but also enhance environmental protection. Traditional off-grid approaches, like evaporative cooling, combined with new technologies that run on renewable energy and use environmentally friendly alternatives, present climate-friendly and affordable solutions.

Evaporative cooling uses the cooling effect released during evaporation. It can be applied as a cooling technology by placing a clay pot within another clay pot, with a layer of wet sand in-between to provide water for evaporation. It can also be built as a large evaporative cooling chamber using brick walls with wet sand between each one and a straw and wood cover on top. As the device allows keeping temperatures low and humidity high, it’s particularly effective for storing vegetables. Read more…

Green Cooling approaches involve the use of natural refrigerants. In contrast to artificial refrigerants CFCs, HCFCs and HFCs, natural refrigerants are substances occurring in nature, including CO2, ammonia, hydrocarbons, air and water. Maximizing energy efficiency is another green cooling strategy, fostering a sustainable approach to private and commercial energy consumption, by including, for example, renewable energies. Read more…

Pre-cooling is the rapid removal of field heat shortly after crop harvest. It is one simple approach that reduces energetic consumption for cooling and enhances shelf-life afterwards. Due to biological factors, the methods and importance of pre-cooling vary among crops. Methods include shade, air cooling, water cooling, ice cooling and vacuum cooling. Read more…

Among green cooling strategies, the Solar Ice Maker is one implementation example. Using solar energy to feed a refrigeration system where water can be frozen and used in refrigeration devices, this technology has different kinds of uses: it can be utilized for milk chilling, cooling down vegetables during harvest, and much more. Examples of different value chains where solar ice making devices have been employed are listed further below under Case Studies.

Another cooling example that involves ice is the Water Chiller. Using a renewable energy source to freeze water, it creates cold air that is blown to a storage room for commodities like vegetables. Read more…

Cold Storage of Agricultural Products

Cold storage facilities are crucial to minimize post-harvest losses; however, losses occur at every step in the post-harvest cycle, and thus cold storages cannot be considered as independent solutions to prevent post-harvest spoilage but as one component that needs to be integrated in a cold chain network from the point of harvest to the point of purchase by the end consumer. During the different stages in the post-harvest cycle, temperature control and the adequate handling of the produce are crucial to minimize post-harvest losses. Read more…

Actors & Innovations

Creative approaches and innovations in the cooling field span from solar photovoltaic systems to biogas-powered models, facilitating access to cooling in rural areas without grid-access. The use of climate-smart systems for cooling leads to fewer post-harvest losses, higher food security and lower costs for food preservation. It can also result in higher incomes and independency, and helps mitigating climate change. The number of green innovators supported by effective business models keeps rising and promises a sustainable transition for development.

Biogas Milk Chilling for Dairy Farmers

In the emerging dairy industry in East Africa, the demand is expected to double in the coming years. However, only 15 percent of milk produced reaches the formal market, partly due to the lack of access to a reliable power grid for cooling. As there had been a lack of solutions available on the market to provide milk chilling technologies at micro-scale, SimGas together with SNV developed a small-scale biogas-powered milk chiller for smallholder farmers in Kenya, Tanzania and Rwanda. Read more…

ColdHubs

Cold Hubs are large walk-in storage rooms for fresh vegetables which include a refrigeration system that runs on solar power. Developed by ILK Dresden and the Smallholder Foundation, this innovation can save huge amounts of perishable food (storage capacity of up to 2 tons) and can be used off-grid, being especially suitable for rural areas, where large amounts of food need to be stored before joining the market. Read more…

Biogas-Powered Evaporative Cooling for the Dairy Industry

The growing dairy industry throughout sub-Saharan Africa suffers from a lack of proper refrigeration options, which causes farmers to lose 20-50 percent of their milk to spoilage. The University of Georgia Research Foundation (UGARF) together with the Smallholder Fortunes’ small scale demonstration dairy farm in Uganda have developed the EvaKuula: a biogas unit that works with cow manure and allows a mild heat treatment of the milk, followed by a gentle evaporative cooling process, keeping the milk fresh overnight. Working with local manufacturers, financing models are being developed to bring the local production to commercial scale. Using the EvaKuula, smallholder dairy farmers not only profit from access to clean energy, which can be used for lighting and cooking, but also reduce greenhouse gas emissions from cow manure fermentation. 42 farmers (50 percent of them being women) have so far benefitted from the deployment of this device. Read more…

DIY Solar Cooling

The University of Hohenheim developed an approach that allows entrepreneurs, engineers, etc. in the Global South to assemble their own solar cooling systems, adapted to the local context and needs. The vendors and manufacturers of these simple but effective systems only need to import one piece while all other material can be obtained from the domestic market - making these systems much more cost-effective than comparable refrigeration systems that are wholly imported from abroad. Read more ...

Case Studies

An increasing number of cooling technologies based on renewable energies are being used in different steps of the agricultural value chain. The following case studies provide an insight to the diversity of solutions, and the benefits obtained from implementing climate-smart cooling technologies in rural environments.

SunDanzer: Solar Powered Refrigeration for Kenyan Dairy Farms

In Kenya, 85 percent of dairy farms do not have access to refrigerated storage and transportation due to limited electrification in rural areas, leading to dramatic losses from milk spoilage. SunDanzer together with Winrock International have developed an affordable small-scale portable cooling system: the photovoltaic refrigerator (PVR) runs on solar energy and uses phase-change materials – substances capable of storing and releasing large amounts of energy – and therefore needs no battery. Additionally, the innovators have developed milk can blankets to retain the temperature during transportation. 60 solar-powered milk cooling refrigerators have been installed so far in Kenya and two in Rwanda. Users of SunDanzer’s refrigerators have stated that the technology has delivered many benefits, including increased financial security for households, increased food preservation, and saved time. Read more...

Reducing Milk Spoilage through Solar-Powered Chilling

Perishable food worth of 10 billion US Dollars is wasted annually in India because of unreliable cold-chain supply networks. Especially in farming areas and villages, the lack of reliable electricity is a challenge for running refrigeration systems. With India being the largest consumer and producer of milk in the world, Promethean Power Systems together with Hatsun Agro and Orb Energy have developed a solar milk cooling system that uses an innovative thermal energy battery pack. Charging on intermittent power sources such as solar power and/or a few hours of grid electricity, it allows changing the local food situation considerably. Read more...

SunChill Solar Cooling for Horticultural Preservation

An innovation designed by Rebound Technologies (United States) aims to reduce post-harvest losses and enhance food consumption quality. The first versions of the SunChill cooling system have been tested in Mozambique and after being validated, a commercialization and expansion to the market is planned. The solar off-grid refrigeration system allows to immediately cool down food during harvest and provides continued product cooling at markets or central processing facilities. SunChillTM transforms 50 °C solar thermal energy into 10 °C refrigeration, doubling shelf life and creating access to nutritional fruits and vegetables. The innovation is also expected to create manufacturing and service-based employment. By the end of the project, Promethean sold over 600 units, enabling 25,000 dairy farmers to chill their milk without diesel generators and to get their milk to the market safely. Read more...

Solar Milk Cooling with Insulated Milk Cans

Profitable milk production without cooling technologies can be a challenge. Firstly, milk produced on small- to medium-scale farms is usually transported to milk collection facilities. The spoilage caused by bacterial growth during transportation due to warm temperatures leads to milk being refused by vendors. Secondly, many farmers do not sell their evening milk to the collection centres, as it cannot be stored adequately overnight. Instead, they sell the milk to neighbours or use it themselves. This can increase the on-farm losses and reduce income. The solar milk cooling system developed by the University of Hohenheim (Germany) uses solar energy for ice production. The produced ice is used to cool the milk by putting it into an ice-compartment of an insulated milk can. This system allows lower temperatures during transportation and overnight storage, increasing the farms production and income. On-field implementations have taken place in Tunisia (10 installed systems), Kenya (4 installed systems), and Colombia (also 4 installed systems). Read more…

Reducing Seed Post-Harvest Losses with Silos

Rodents, insects, fungi and rot destroy small farming families’ provisions of grain and legumes. The result is a not only lack of income but also increases the risk of malnutrition and hunger. Better storage of food grains helps to prevent unnecessary grain losses.

Tanzania´s agricultural policy has introduced metal silos to battle this problem. Read more...

In Mozambique, a local firm has developed a low-cost seed storage silo made of locally available materials and applying traditional construction techniques. Read more...

Preserving Food Using Mobile Solar-powered Cold Storages

Worldwide, postharvest food losses account for more than 30% of the total food produced. In Kenya, this number is even higher with over 40-50% of the produced food lost/wasted during the entire food value chain and in Nigeria 45% of the postharvest is lost due to lack of cold storage. Read more...

Solar Freeze, a company based in Kenya provides famers with solar-powered mobile cold storage for postharvest food preservation. Farmers can use their app to find the nearest cold storage and pay using M-PESA or cash. Read more...

In India, there are local companies such as Ecozen and TAN90 which provide similar cold storage services to the farmers. Another example of a similar company is the Inspira Farms.

Publications & Tools

The refrigeration and air conditioning (RAC) sector is expected to account for 13 percent of global greenhouse gas (GHG) emissions by 2030. With an increasing importance of the sector in the Global South, and the impact caused by the use of conventional climate damaging refrigerants, research and development of low-cost climate-friendly solutions is pivotal. The RAC sector can provide different climate-smart cooling technologies affordable for costumers in the Global South and improve living standards considerably without polluting.

Implications of Natural Refrigerants for Cooling Technologies

As the global warming potential (GWP) of conventional refrigerants (hydrofluorocarbons, HFCs) is 4,000 times higher than CO2, the pressure on manufacturers to develop climate friendly RAC equipment has risen in the last few years. Natural refrigerants have very good environmental and technical performance, and are sustainable as their extraction from unlimited sources does not harm the environment. Even though they are less expensive and therefore commercially available for almost any type of equipment, barriers still hinder their wide-scale introduction. The report presented in this article explains the main challenges faced by manufacturers along three examples from Bangladesh, Swaziland and South Africa. Read more...

Ice-Making as a Productive Application in Green Mini-Grid (GMG) Systems

Productive Use (PU) activities, which refer to the utilisation of electricity for income and employment generation, can catalyse rural development and sustainable economic growth. The increasing demand for energy and the increasing household income can accelerate the success of green mini-grid (GMG) projects. The presented guide is designed to help practitioners assess whether ice-making for food preservation (in this case, fish) is an appropriate and financially viable application and provides guidance on how to operationalize ice-making PU. It is organized as a series of tools that help establish a set of best practices for off-grid electrification initiatives. The tools include: a feasibility checklist, a business model guidance, technical considerations and requirements for appropriate mini-grid sizing, a detailed financial model assessing various scenarios, and a guide on monitoring and evaluation. Read more…

How Access to Energy can Influence Food Losses

The FAO Report “How Access to Energy can Influence Food Losses” highlights the crucial interlinkages between access to energy and food losses in developing countries. It identifies the main stages of the food value chain where increasing access to energy can play a dominant role in reducing food losses directly, by making food processing possible, as well as indirectly by acting as the main enabling factor affecting the rate at which cooling technologies are adopted. It outlines low cost and off-grid post-harvest technologies such as cooling and solar drying that can be made available in developing countries. Most importantly, it assesses the technical and economic feasibility since access to capital can be a significant barrier hindering its implementation in the developing world. Read more...