Difference between revisions of "Transforming Biomass Waste Into Electricity"

***** (***** | *****) m |

***** (***** | *****) m |

||

| Line 66: | Line 66: | ||

*[[Biomass Gasification (Small-scale)|Biomass Gasification (Small-scale)]] ([http://star-www.giz.de/dokumente/bib-2010/gtz2010-0885en-electricity-generation-biomass.1.pdf GIZ Publication 2011]) | *[[Biomass Gasification (Small-scale)|Biomass Gasification (Small-scale)]] ([http://star-www.giz.de/dokumente/bib-2010/gtz2010-0885en-electricity-generation-biomass.1.pdf GIZ Publication 2011]) | ||

*<span dir="auto">[[Small-scale Power Generation from Biomass Vol2|Small-scale Electricity Generation from Biomass Part II]]: (</span>[[:File:Small-scale Electricity Generation From Biomass Part-2.pdf|PDF on energypedia]]) | *<span dir="auto">[[Small-scale Power Generation from Biomass Vol2|Small-scale Electricity Generation from Biomass Part II]]: (</span>[[:File:Small-scale Electricity Generation From Biomass Part-2.pdf|PDF on energypedia]]) | ||

| − | *[[Biomass | + | *[[Building Markets for Efficient Biomass Power Provision|Biomass Mini-Grids for Palm Oil Producing Communities]] |

*[[Biomass Potential in the Indonesian Agroindustry|Biomass Potential in the Indonesian Agroindustry]] | *[[Biomass Potential in the Indonesian Agroindustry|Biomass Potential in the Indonesian Agroindustry]] | ||

*<span class="mw-headline" id="The.C2.A0Role_of_Bioenergy_in_Agriculture">[[Bioenergy in Powering Agriculture#The.C2.A0Role of Bioenergy in Agriculture|The Role of Bioenergy in Agriculture]]</span> | *<span class="mw-headline" id="The.C2.A0Role_of_Bioenergy_in_Agriculture">[[Bioenergy in Powering Agriculture#The.C2.A0Role of Bioenergy in Agriculture|The Role of Bioenergy in Agriculture]]</span> | ||

| Line 78: | Line 78: | ||

<div>For more information, visit [[Www.vikingheatengines.com|www.vikingheatengines.com]].</div></div> | <div>For more information, visit [[Www.vikingheatengines.com|www.vikingheatengines.com]].</div></div> | ||

| + | [[Category:Agriculture]] | ||

| + | [[Category:Electricity]] | ||

| + | [[Category:Colombia]] | ||

| + | [[Category:Norway]] | ||

| + | [[Category:Waste-to-energy]] | ||

[[Category:Biomass]] | [[Category:Biomass]] | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Revision as of 06:44, 15 May 2018

Overview

There's a big lack of electricity in rural areas. At the same time, farms and mills in these off-grid areas produce large quantities of biomass waste that is either burned or dumped in open fields. This article presents one solution that addresses both these challenges, essentially killing two birds with one stone.

The Challenge

Rice mills, and especially rice farms, are often located in rural areas where power is either unavailable or unreliable. To power their facilities and energy-intensive processes, they use diesel generators that are expensive to run and pollute the air. In addition, the drying of rice, which is required to allow for storage, transportation and milling, is an energy intensive process and poses a significant cost burden on the rice producers.

Solution: Heat and Electricity Co-generation from Biomass Waste

TEOPOWER minimizes the volume of rice husk waste and other types of biomass waste such as sawdust, olive pits, bagasse, coffee pulp and soya bean residue by turning it into green electricity and heat, essentially killing two birds with one stone.

Main Benefits

• Provides renewable heat and electricity from an agricultural waste product at less than EUR 0.10 (USD 0.11) per kWh

• Reduces a rice mill's overall operating costs by eliminating the need for electricity generation from diesel generators

• Reduces the costs for drying of rice by eliminating the use of diesel, gas or wood

• Eliminates agricultural waste and hazardous disposal practices, and thereby complies with more stringent environmental standards

• Turns agricultural waste into valuable ash to be used for fertilization and thereby reduces the need for fertilizers

• Can reduce up to 2 400 tonnes of CO2 per year

• Allows for easy operation and simple maintenance/servicing

• Provides a typical payback period of between 2 to 5 years

• Fast implementation (takes less than 4 weeks to set up)

Main Beneficiaries

Small to medium-sized farmers and agricultural producers, such as rice millers in rural, off-grid areas.

Electricity Output and CO2 Savings

A Collaboration between Norway and Colombia

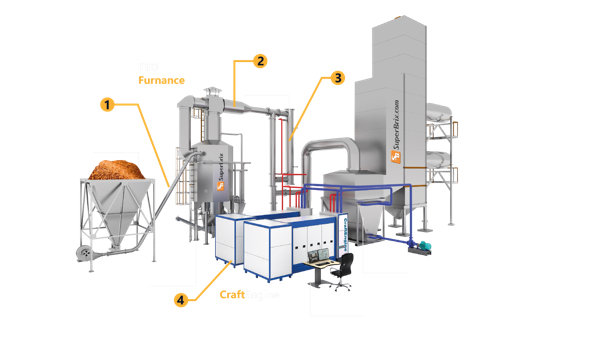

TEOPOWER combines Viking Heat Engine’s electricity-generating heat engine, the CraftEngine, with SuperBrix’s award-winning TEO biomass furnace. By using the CraftEngine’s electricity-generating capability, the TEOPOWER can produce electricity in addition to heat for the drying process.

Technologies Involved

SuperBrix has developed a line of cyclone biomass furnaces, the most recent being the TEO IV. In this model, rice husk is being fed into the combustion chamber along with ambient air, where it’s being burnt by using a high-velocity cyclone to allow for complete combustion. The ash falls to the bottom of the chamber, while the hot air/flue gas is emitted through the upper section of the chamber where post combustion transforms it into a clean flue gas. The ash is cooled and discharged by means of a screw conveyer. This ash is a soil additive, and used to enhance the productivity of rice farms.

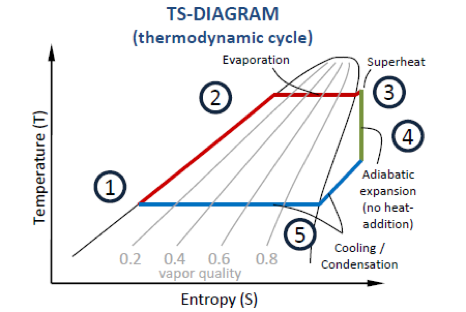

The CraftEngine operates on the principles of the Organic Rankine Cycle (ORC). Heat is transferred to the working fluid/refrigerant at a constant pressure, increasing the temperature and pressure of the working fluid until the boiling point is reached. The vapour then undergoes superheating, followed by adiabatic expansion in the piston engine (expander), causing a decrease in temperature and pressure, and thus generating power. Upon cooling in a condenser, the vapour is condensed to its original liquid state, allowing the process to be repeated.

1) High flexibility and adaption to almost any fluctuation in the heat source

2) Efficient use of low-temperature heat

3) Low capital costs due to mass-production design that uses standard piston engine manufacturing processes

4) Low operating costs

The TEOPOWER integrates the CraftEngine into the TEO process. By using the CraftEngine’s power-generating capability, the TEOPOWER can produce electricity and heat for drying processes.

The demo plant in Barranquilla is used as a showcase for potential customers as well as for testing of different types of bulk biomass wastes. Tests using saw dust, olive peats, bagasse and chicken manure are currently being scheduled.

Pilot Projects in Colombia

Market Potential

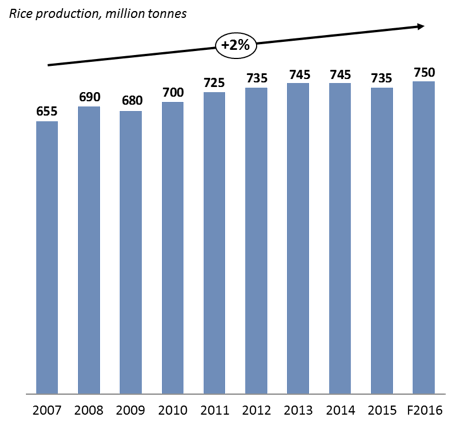

The rice market is well established, vast and growing. Rice, corn and wheat are the three most important food crops. The world rice production is currently at 750 million tons per year, and growing steadily at about 2 per cent annually, which is in line with the world population growth.

World rice production in million tons/year [3] (see illustration below):

Summary

Biomass waste can be utilized to be turned in much needed electricty in rural areas.

The TEOPOWER produces power from rice husk at less than EUR 0.10 per kWh, and can transform a rice facility into a self-sufficient renewable energy facility. By burning rice husk, the TEOPOWER can reduce up to 2 400 tonnes of CO2 per year. Other typical biomass waste products that fit the TEOPOWER scope include sawdust, olive pits, bagasse, coffee pulp, soya bean residue and more.

Further Information

- Biomass Gasification (Small-scale) (GIZ Publication 2011)

- Small-scale Electricity Generation from Biomass Part II: (PDF on energypedia)

- Biomass Mini-Grids for Palm Oil Producing Communities

- Biomass Potential in the Indonesian Agroindustry

- The Role of Bioenergy in Agriculture

- Portal:Solid Biomass

References

[1] U. S. D. o. Agriculture, “IndexMundi,” 2016. (Online)

[2] “Biomass to Energy Overview”. Internal VHE study paper

[3] “Food and Agriculture Organization of the United Nations Oct-2016,” [Online].

[4] “Alliance for Rural Electricifaction,” [Online].