Photovoltaic Solar Cooking Without Batteries Using PTC Ceramic Heaters

Overview

Photovoltaic solar cookers usually use conventional Ni-Cr resistors or an induction process. In both cases, it is essential to have a regulated electrical current, hence the need for a battery and its power electronic auxiliaries for charging and discharging. The PTC ceramic resistors presented below have a flexibility of operation that is well suited to the variability of the energy supplied by the photovoltaic panels. The ceramic cooker can be operated either manually or automatically. In its manual version, the cooker reaches an uncompressible level of simplicity: a cooker associated with a photovoltaic solar panel. In the automatic version, a small control electronics module (no longer power electronics) adapts the number of ceramic heating elements to the current amount of sunlight. The article below gives an overview of the design of a photovoltaic cooker with PTC ceramic resistors.

Brief History of Cooking Energies

Since the conquest of fire, wood has been the main source of energy. For convenience, it was gradually replaced by charcoal, wood charcoal, gas or paraffin, whose heat capacity by weight is much greater.But then, coal, gas or paraffin, i.e. fossil fuels, replaced wood out of necessity, because wood sometimes does not renew itself at the same rate as it is harvested: a first in the history of humanity! And now there is a risk that fossil fuels will no longer be able to meet our needs. For the moment, they are in sufficient quantities, but beyond a few speculative jolts, it seems inevitable that the price curve can only rise, to the point where fossil fuels become difficult to access for the poorest part of the population. Grid electricity, which is mainly fossil fuel derived energy, follows the same path.

Another solution is to use the mother of all energies, i.e. the sun.For several decades, a great deal of engineering and imagination has been devoted to solar thermal cooking, see for example Luther Krueger's "Museum of Solar Cookers" in Minneapolis, USA.[1] Meanwhile, to provide electrical power to space satellites, the emerging photovoltaic technology has made great strides. The exorbitant initial costs have followed a steady downward curve[2][3], which now crosses the upward curve of other energies. What about using photovoltaic energy for cooking? Articles appeared on the subject around 2013[4]. Since then, the price of photovoltaic collectors has continued to fall. The cards have been reshuffled and solar cooking is now economically viable[5][6].

But when it comes to implementing it, there are two obstacles to overcome.

Two obstacles; and a solution?

The first obstacle comes from the inflexible laws of electricity. To transform electricity into heat, it is customary to use so-called "nickel-chromium" resistors, which can be found everywhere: electric radiators, toasters, hair dryers.... They are calculated by the manufacturer to withstand a certain power, and even a little extra margin; but beyond a certain threshold, they burn out. Nickel-chromium resistors therefore require a voltage-regulated current to function normally. The induction plate process, which is a significant improvement over Ni-Cr resistors, also requires a properly regulated current. The photovoltaic panel supplies an electric current that varies constantly in voltage and intensity. However, the laws of electricity teach us that if we double the voltage, the power (i.e. the quantity of heat) is four times greater; the same goes for the current. The risk of burnout is therefore permanent. Conversely, if the voltage and/or current decreases, then the heat production collapses, again more than proportionally.

The second obstacle comes from the photovoltaic panel. The electricity production of the panel depends on the amount of sunlight it receives, which is easy to understand, but it also depends - and this is much less intuitive - on the load applied to it. It is advisable to constantly track this maximum power point, for example with the help of a Maximum Power Point Tracking regulator (MPPT)[7], which is a power electronics component that plays a dual role: optimising the panel's production and also controlling the battery's charge

A solution: the battery? Technically, the fact of interposing a battery with its regulator makes it possible to solve all the problems mentioned above: the panel is used at its optimum, the battery is charged according to the rules of the art, and the resistors of the cooker have a correctly regulated electric current. In addition, because the battery is an energy storage device, it is possible to cook outside the hours of sunshine. But this is not without its problems. -The battery is expensive; even though its price has decreased significantly, it is still the most expensive component of a photovoltaic cooking system. -It has a limited lifespan of about four years, and much less in a high temperature environment. -Its use remains delicate despite the automation of the main tasks: charge control, discharge control, depth of discharge[8].-Finally, a battery is particularly polluting.

On the subject of lithium batteries: according to a study by the Catholic University of Louvain on rare metals [9] published on 25 April 2022, the EU-27 will need thirty-seven times more lithium in 2050 than it does today. Will there be enough left over for the cookers in developing countries?

On the subject of rare metals, let us recall here that contrary to a sometimes stubborn belief, there are no rare metals in photovoltaic panels, read the ADEME document "Terres rares, énergies renouvelables et stockage d'énergies" [10], October 2020.

The challenge is now to design a solar cooking device without a battery. We propose below, as part of the solution, the use of PTC ceramic resistors.

PTC Ceramic Resistors

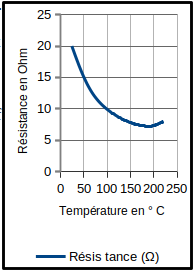

Like all resistors, ceramic material produces heat when an electric current flows through it. But as it heats up, its electrical resistance decreases. At 200°C the resistance is divided by three compared to the ambient temperature, so its heating power is multiplied by three. Then, beyond 200°C, the resistance increases sharply until it becomes very high, the electric current can no longer flow, and heat production stagnates[11][12][13][14].

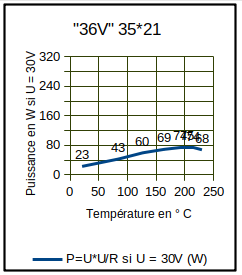

On the right : Example of the variation of the resistance of a ceramic as a function of its temperature, in the temperature range of interest.

Ceramic resistors are very present in everyday life, although they are little known by the general public .Small ceramic heaters, available in most household electrical goods stores, sold as auxiliary heaters, are a good example. Small and light, they are necessarily equipped with a fan that permanently drives out the calories produced by the ceramic, without which the heat production would stagnate. In cars, ceramic heaters are used to warm up the oil in winter, without the risk of overheating. Electronic engineers are familiar with ceramic resistors, sold under the name of... resettable circuit breakers: if there is an excess of current in the circuit, the ceramic heats up and above 200°, the resistor blocks the flow of electricity; then, when the temperature has dropped, the current flows again. Ceramic resistors can be found in DIY glue guns: the stagnation temperature corresponds to the melting heat of the glue, so there is no need for a thermostat (you don't hear a thermostat being triggered like with an iron). the characteristics of the ceramic heating elements are very interesting for our cooker - the heating elements do not burn out. - the temperature of 200° is more than sufficient for all cooking with water, braising, steaming, etc., except for cooking in oil and grilling. - the temperature of 200° is lower than the ignition temperature of cotton; it is therefore possible to insulate the entire cooker with cotton towels, for example. And the yields are multiplicative! (and so are the losses...)

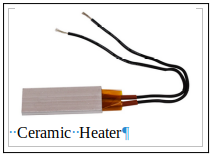

The resistors used for our cooker are available mainly in China, under the name of "ceramic heaters", or "PTC heaters". They consist of a ceramic wafer placed between two very thin aluminum plates on which the electrical wires (+ and -) are soldered, wrapped in a silicone film (?) for electrical insulation. The whole is inserted in a rectangular aluminum tube.

The only indication available to the buyer is the recommended voltage: 12, 24, 36, 48, 110, 220 V, whereas "a resistor does not operate under a nominal voltage, so there can be no nominal power; in principle, the manufacturer indicates a maximum permissible power, which must not be exceeded". There is also no data sheet, the professional document that accompanies any electrical or electronic component. The price varies from €0.40 to €0.80 for large quantities; it is eight times higher for individual purchases.

It is now possible to sketch a cooker with ceramic heating elements: Several resistors are installed under a heating plate; the user of the cooker has two or three switches and a small Wattmeter. He adapts the number of resistors to the current sunshine, looking for the best operating point of the solar collector, and can check his choice by reading the Wattmeter. In case of constant sunshine, no monitoring is necessary. If the solar flux varies, the resistors adapt. In the event of significant variation, the user can modify the number of resistors. In case of a very large increase of the electric flux, the resistors are self-regulating and cannot be destroyed. The operation of the cooker can be automated, for example by means of a microcontroller like Arduino. The temperature of the heating elements does not exceed 200°C, so the entire cooker is insulated with cotton towels, for example. A cloudy passage has little effect on the cooking process. We can now move on from the sketch to the design of the cooker.

Ceramic Resistors and the Cooker

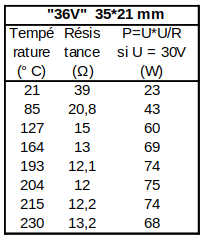

Almost all of the choices made below are not imperative, there are many variants available to the designer, and many choices have been made by successive approaches. A first choice concerns the operating voltage of the installation. For reasons of user safety, we do not wish to exceed a voltage of 40 volts, i.e. a panel producing a voltage of 40 volts in open circuit, and therefore approximately 22 to 28 V in the usual steady state. Resistors stamped "36 volts", dimensions 35 x 21 x 5 mm, are used here; "48 volts" resistors would also be suitable. Resistors stamped "24 volts" were not used. Given the limited information provided by the manufacturer or seller, it is essential to test the ceramics on a test bench.

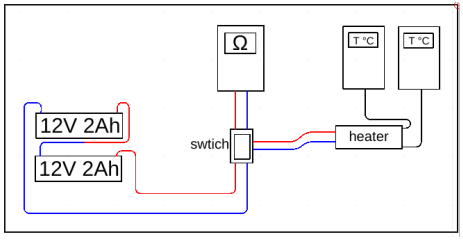

The ceramic test bench The resistance is held, for example, between two pieces of wood, and instrumented by one or two thermometers. Power supply: 24 V DC (2x12Volt / 2 Ah); 24V AC should also be suitable. In the center of the device: a three-position switch. The operator powers the resistor while observing the thermometers; then he flips the switch and reads the Ohm value, after the temperature measurement has stabilised somewhat. Seven or eight measure-ments, spaced about 30°C apart, are sufficient.

The measurements The first two columns are the measurement records. The third column shows the calculated power of the resistivity, for a voltage of 30 V, according to the formula P = U*U / R The graph below shows the power values. The operating temperature of the heating plate is estimated at 150°C. In fact, it varies according to the temperature of the cooking vessel, depending on whether it is being heated or maintained at temperature. The corresponding power is noted graphically: 65 W. The arrangement of the ceramics under the hotplate is carried out according to these elements.

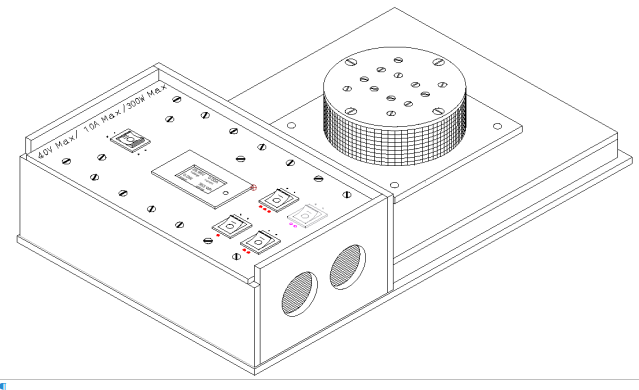

The arrangement of the ceramics : For a 300 W peak panel, six ceramic resistors called "36 V", dimensions 35*21 mm, measured/calculated power: 65 W at 150° C are installed. They are arranged in three groups: - one group of 3 ceramics - a group of 2 - a group of 1. The user will have three switches on his cooker, allowing him to set the powers on 6 levels.

Construction of the cooker Below: a one-piece cooker made from plywood, which can be built by a craftsman. It is also possible to have the control unit separate from the heating element. The aluminum heating plate is cut out of 5 mm sheet metal. The Wattmeter, which is to the cooker operator what the compass is to the sailor, is available on the web for less than 9 €. The insulation, which surrounds the heating block and the cooking vessel, is not shown. From this basic model, a multitude of different cookers can be designed.

The Regulation of the Cooker

The role of regulation The energy supplied by a solar panel depends partly on the amount of sunlight at any given time, but also on the load applied to it. This is too complex to describe here, but it can be found in all books on solar panels. Usually, in battery installations, the charge controller between the panel and the battery is responsible for tracking down the best power point, the MPPT. At first sight, the regulation of the cooker therefore consists of searching for the MPPT by putting into operation the appropriate number of ceramics, among the six ceramics installed under the cooker's heating plate. But the power of these ceramics varies according to their temperature, which varies according to the temperature of the contents of the cooking vessel. The temperature of the contents rises during the heating period and stagnates during the actual cooking process. All of this sounds complicated, but in practice it is very easy to control.

Manual control and automatic control In the case of manual regulation, the user has six levels of adjustment: the user makes a choice, that can be verified with a wattmeter . When the weather is fine, the user can go about his business without worrying about the cooker. The automatic regulation is done with a small microcontroller, for example an Arduino. The algorithm, which is rudimentary, is of the "Perturbe and Observe" type: two voltage and current sensors transmit the information to the microcontroller, which calculates the instantaneous power. It then slightly modifies the number of ceramics in operation, checks the effect on the instantaneous power and confirms or denies the previous modification, etc. The automatic control has 13 levels, so it is more precise than the manual control, but there is no need to overcomplicate the use of a manual cooker.

In the event of a malfunction, there can be no damage. If the resistors are overloaded, the ceramic material plays its regulating role. If the resistors are underpowered, the cooking process continues somewhat like a "Norwegian pot".

The Results obtained

Some examples of baking. They were carried out with a panel of 1.66 m², peak power 280 W.

- - Rice: 300g rice, 500g water, total cooking time: 55 min.

- - Onions 250g, tomatoes 800g, total cooking time: 1h 30 min

- - 3 chicken thighs 680g, onions 145g, fennel 175g, courgettes 270g, red pepper 225g, green pepper 215g, crushed tomatoes 200g. Cooked in a Lagostina pressure cooker (3.5 litres); temperature rise to 110°C: 1 hour, then cooked for 15 minutes.

- - Chicken Basquaise: 4 chicken legs with drumstick and onions, to be browned. Then add 200g tomatoes and 200g peppers. Heat up to 100°: 35 minutes; then cook from 100 to 115°: 20 minutes. Cooked in a Lagostina pressure cooker 3.5 litres. Continuous sunlight 930 W/m², constant power of the cooker: 220W.

- - Coral lentil dahl: browned onions 210 g, tomatoes 400g, lentils 300g, coconut milk 400 ml, 1/4 litre of stock; heating up to 100°: 3/4 hour, sunshine 900 to 960 W, almost constant power of the cooker at 220 W. Then, cooking as a Norwegian pot for half an hour without power supply; during this half hour, the temperature dropped from 100 to 90°C.

A method of measuring the performance of the cooker: the litre of water brought to the boil. The time taken to bring 1 litre of water to the boil is measured; this provides a good indication of the performance of the collector + cooker package. However, one may wish to be more precise in order to perform rudimentary thermal calculations, in which case the notion of "boiling" is not precise enough: small boil? Big boil? What about atmospheric pressure, or the altitude of the measurement site? The solution is to measure the starting temperature, then measure the time needed to reach the temperature of 97°C.

For example: starting temperature 25°C, ending temperature 97°C, in 40 minutes, for 1000g of water. The heat mass of the water is 4.18 Joules. Amount of energy: (97-25) * 4.18 *1000= 300,960 J Duration of the operation: 40 *60 = 2,400 seconds Useful power of the cooker: 300,960 / 2,400 ≈ 125 W

Some measurements of the litre of water brought to the boil, Panel 1.66 m², 280 W peak.

- - under 870 W : 38 mn -

- ??? W : 38 mn

- - under 760 to 800 W : 50 mn

- - under 790 to 870 W : 38 mn

- - under 920 W : 40 mn

Some additional notes

Energy storage for cooking after sunset: the battery allows cooking outside the hours of sunshine; in the case of a cooker without a battery, a substitute would be the storage of thermal energy for a few hours, for example with a phase change material[15]. It should also be noted that the ceramic cooker can operate perfectly well on a battery.

Domestic hot water: the use of PTC heaters for the production of domestic hot water, even in industrialised countries, greatly simplifies the installation by eliminating complications such as pipes, recirculation pumps, problems of freezing, overheating, maintenance, etc.

Lighting and telephony: in the absence of a battery, these devices can be recharged with a DC-DC converter, worth a few euros, connected to the panel, which supplies telephones and lanterns either directly or via a small "USB Power Bank".

Production of domestic hot water: PTC ceramic heaters coupled with photovoltaic collectors would be very well suited for the production of domestic hot water, without the hassle of pipes, pumps, regulators, anti-freeze or anti-overheating devices, etc. See PTC Ceramic water boiler [16]: it's not academic, it's not optimised, but it's simple and it works !

The quality of the switches, known as "rocker switches", is very important. Firstly, the voltage is low, but the current is high. After switching, if the inner contact blades are only loosely in contact with each other, they will heat up; this is lost energy for cooking, and is a risk of accident. Manufacturers of good quality switches state a maximum contact resistance of 50 milliOhm in their data sheets. Do not hesitate to check this value with an ohmmeter after delivery. Secondly, a particularity of direct current is that it causes arcing when the switch is operated, resulting in abnormal wear of the contacts. This can be easily remedied by inserting ordinary diodes into the circuit, but this is a departure from our original point.

A small and apparently bizarre phenomenon

Let's say a cooker is in operation, but the cooking vessel is removed; the hot plate rises in temperature to the point of stagnation, then the Wattmeter indicates almost no power, even though it is a sunny day; but there is no malfunction.

All you have to do is put a container back on the plate and pour in a glass of cold water...

And to conclude, some thoughts on non-technical aspects. The world of renewable energies is the realm of diversity. Firstly, because energy supplies are shrinking: we must therefore "use all kinds of wood" - without handicapping the future. Secondly, because situations are very diverse, so there is no one-size-fits-all solution for cooking; as always, the right tool for the right circumstances must be used.

Further Information

The work on the cooker was carried out by the small team "photovoltaic solar cooking", in the city of Brest (Brittany) in France, during the years 2019-2020. The team members are retired from the industry, and their work has no profit or commercial purpose.

For further information on building a ceramic cooker, see photovoltaic-solar-cooking.org

For further information about cooking energy, visit the Improved Cooking portal on energypedia.

Reference

- ↑ Luther Krueger 2015 Museum of Solar Cookers Minneapolis http://www.consolfood.org/wp-content/uploads/2015/12/CSF-Webinar-Museum.pdf

- ↑ https://www.ledevoir.com/environnement/701346/le-prix-des-panneaux-solaires-en-chute-libre-depuis-20-ans . sourc: IPCC 2022

- ↑ https://ourworldindata.org/search?q=solar+PV+modules+prices 2019 sourc : Lafond et al.(2017) & IRENA database ; for more accuracy, download the .csv and/or the .svg file

- ↑ 4 Batchelor S (2013). Is it time for Solar electric cooking for Africa? Gamos Concept note http://www.gamos.org/images/documents/Is%20it%20time%20for%20Solar%20electric%20cooking%20for%20Africa%2018062013.pdf

- ↑ Energy Sector Management Assistance Program. 2020. Cooking with Electricity: A Cost Perspective. World Bank, Washington, DC. © World Bank. License: CC BY 3.0 IGO. https://openknowledge.worldbank.org/handle/10986/34566

- ↑ John Leary 2021 Battery-supported eCooking: A transformative opportunity for 2.6 billion people who still cook with biomass https://doi.org/10.1016/j.enpol.2021.112619

- ↑ https://fr.wikipedia.org/wiki/Maximum_power_point_tracker

- ↑ Reinout Vader 2011 https://www.victronenergy.com/upload/documents/Book-Energy-Unlimited-EN.pdf

- ↑ https://eurometaux.eu/metals-clean-energy/

- ↑ https://librairie.ademe.fr/energies-renouvelables-reseaux-et-stockage/492-terres-rares-energies-renouvelables-et-stockage-d-energies.html

- ↑ © EPCOS AG 2012. https://www.tdk-electronics.tdk.com/download/531162/d78540dfe0589d2bd90cabef477c90b9/pdf-general-technical-information.pdf

- ↑ https://en.wikipedia.org/wiki/Thermistor .

- ↑ http://en.hn-yongli.com then search for " PTC heaters with shell "

- ↑ http://www.tiancheng-ptc.com/en/company.htm

- ↑ California Polytechnic State University 2019 https://core.ac.uk/download/pdf/219382184.pdf

- ↑ https://www.youtube.com/watch?v=jzfVHSCsU44