Solar Milk Cooling with Insulated Milk Cans

Introduction

In many countries, milk is exclusively produced by small and medium sized dairy farms with daily milk output below 200l. Their milk is in most of the cases transported to milk collection facilities, without any form of cooling. In addition, lack of hygiene and cleaning procedures and problems with cattle health are the most common reasons of high bacterial growth during short-term storage of milk on the farm and during transportation.

Under warm climatic conditions, milk can exceed the maximum bacterial count prescribed by food safety laws after about two to five hours. During the hottest periods of the year, lack of quality can lead to high rates of refused milk at collection centers or dairy plants. Furthermore, due to low production volumes, evening milk is often not collected year round, thus causing additional on-farm losses. Small-scale solar powered milk cooling technologies can support the milk value chain at farm, cooperative and collecting center level by increasing productivity and giving access to price premiums and to additional markets.

Hohenheim System for On-farm Milk Cooling with Solar Energy

The milk cooling solution developed by the University of Hohenheim is based on a commercially available DC refrigerator, equipped with an adaptive control unit for its conversion to a smart ice-maker. It operates depending on the availability of solar energy. Do it yourself - solutions for solar ice making are also possible.

Cylindric tins are used for the production of ice, which is then put into the ice-compartment of the Insulated Milk Can. Depending on the amount of milk and ice, different cooling temperatures and storage times are reached.

| Volume refrigerator | 160 l |

| Daily ice production | 16 kg |

One system includes 24 reusable plastic blocks of 2 kg capacity and two 30l insulated milk cans with removable ice compartment. The smart ice-maker is powered by 600 Wp solar PV modules together with two batteries with a total capacity of around 1.5 kWh. Thanks to the thermal energy storage, in form of the 24 2 kg-Ice-blocks, the system is able to run autonomously for up to 5 days even during periods of low solar radiation and high ambient temperatures.[1]

Ice-Maker with Adaptive Control Unit[2]

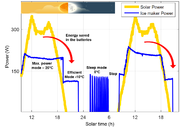

The implemented adaptive control unit allows the efficient use of conventional DC-Refrigerators for an intensive and reliable production of ice all over the year. The ice-maker is equipped with following features:

- Variable compressor speed in dependence of solar radiation and state of charge of the batteries.

- Operation of a fan in the inner chamber in order to increase freezing rate.

- Energy saving mode during night and rainy days.

- Use of batteries to increase daily ice production up to 30%.

- Storage of 50 kg ice blocks to assure a autonomy of at least 5 days under low radiation or high ambient temperatures.

Insulated Milk Cans

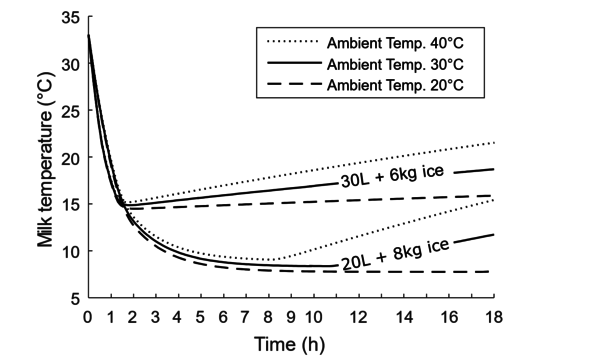

The milk-cans implemented are made of stainless-steel and have a capacity of 30 liter milk and 8 kg Ice. This allows a flexible use of them depending on the cooling requirements. The milk-can has been design to operate for two modes as described in following table.

|

|

30 Liter milk + 6kg Ice |

20 Liter milk + 8kg Ice |

|

Cooling temperature |

17°C after 90 min. |

Under 10°C after 150 min. |

|

Used for |

Transport of morning milk |

Storage of evening milk |

|

Milk quality preservation |

At least 6 hours |

At least 12 hours |

The cooling performance and bacterial growth were measured with real milk under lab conditions in a climate chamber. On-field milk quality assessments are currently carried out in order to confirm the potential of the system to retard bacterial growth depending on milk temperature and transport time under real working conditions.[1]

On-Field Implementations

In order to evaluate the potential of solar milk cooling systems under real conditions, on-field projects have been implemented in the following countries:

| Country | Project duration | Number of installed systems | More information |

| Tunisia | July 2015 until December 2017 | 10 | here |

| Kenya | January 2016 until May 2018 | 4 | here |

| Colombia | October 2017 until May 2018 | 4 | here |

Collaboration Partners

Research and Development:

Agricultural Engineering in the Tropics and Subtropics (University of Hohenheim)

Commercialization:

Field Assessments:

- International Center for Agricultural Research in the Dry Areas (ICARDA)

- Tunisian Ministry of Agriculture (INRAT, OEP, CRRA-IRESA, Groupment Interprofessionnel des Viandes Rouges et du Lait, National Veterinary School of Sidi Thabet)

- Delice

- GIZ Powering Agriculture and Green Innovation Centres for the Agriculture and Food Sector (Tunisia and Kenya)

Supported by:

Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH on behalf ofGerman Ministry for Economic Cooperation and Development (BMZ)

- Innovation Transfer into Agriculture - Adaptation to Climate Change (ITAACC)

- Sustainable Energy for Food - Powering Agriculture

- PARI - Program of Accompanying Research for Agricultural Innovation

Publications and Documents

- Technology sheet on solar milk cooling

- Technology sheet on solar ice making

- Article at Rural 21 - Solar powered cooling for enhancing milk value chains

- Publication: On-farm milk cooling solution based on insulated cans with integrated ice compartment

- User Guide of the on-farm solar milk cooling system

- Workshop on solar milk cooling in Columbia (youtube, spanish)

- Follow field activities in Facebook

- FAO Climate Smart Agriculture Sourcebook

Overview of Solar Milk Cooling Systems

References

- ↑ 1.0 1.1 2013-2016 Victor Torres Toledo, Ana Salvatierra Rojas, Alice Hack, Joachim Müller. University of Hohenheim. On going research at the Institute of Agriculture Engineering. Tropics and Subtropics Group.

- ↑ 2016 Victor Torres-Toledo, Klaus Meissner, Philip Täschner, Santiago Martınez-Ballester, Joachim MüllerfckLRDesign and performance of a small-scale solar ice-maker based on a DC-freezer and an adaptive control unit. fckLRSolar Energy Journal Publication.fckLRhttp://dx.doi.org/10.1016/j.solener.2016.10.022

- For further information, please contact the author of this article. https://www.uni-hohenheim.de/institution/fg-agrartechnik-in-den-tropen-und-subtropen