Knowledge fuels change

For over a decade, Energypedia has shared free, reliable energy expertise with the world.

We’re now facing a serious funding gap.

Help keep this platform alive — your donation, big or small, truly matters!

Thank you for your support

Concentrating Solar Power (CSP) - Basics and Introduction

Basics and Technology of CSP

|

For a short introduction to Concentrating Solar Power, the idea behind and the general plant design as well as its benefits and obstacles, please feel free to watch the video provided by SolarReserve.

General

CSP Systems are replacing fossil fuels with CO2-emission free energy and therefore reduce the overall greenhouse gas emissions. According to Greenpeace the energy pay back time of an CSP plant can amount to just 5 months depending on its configuration and size.[1] CSP Plants can remain in operation for almost 40 years and thus demonstrate its durability and reliability.

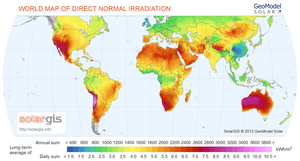

Solar Resource

The favourable regions to apply CSP Technology are open for discussion. However, a good indicator to identify CSP potentials is the direct normal irradiation (DNI). Maps can show the distribution of DNI all over the world and thus give a first clue as to where CSP power plants should be built. For further reference please also see the Project Database of CSP Power Plants and overlay the DNI map with it.

Mainly the MENA region, western USA, Southern Africa, Australia and parts of South America.

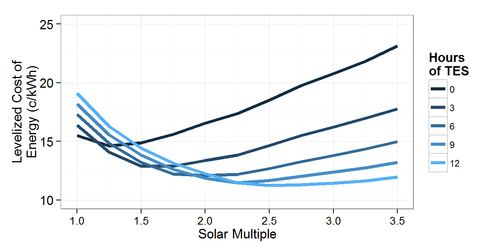

Generation Costs

Generation costs are currently at reasonable levels and still dropping. They range from 150 US-$/ MWh to 200 US-$/ MWh.[2] The diagram below is taken from the report of the NREL. Hours of TES meaning the thermal storage capacity of the power plant: the time measured in hours that the given power plant can run at rated power output with the storage as its only energy source. The Solar Multiple describes the relation of the installed solar power to the power of the motor block. An over-sized power plant (SM > 1) produces more energy at full solar power intake than the motor can transform. It therefore needs storage facilities to divert the power surplus; otherwise the energy gets spilled.

The SunShot Initiative Concentrating Solar Power Research and Development is trying to reach generation costs of 60 US-$/ MWh by addressing technical barriers for solar fields, receivers and power plants.[3] For more information on levelized cost of energy/ generation costs also see the Cost Analysis of the International Renewable Energy Agency.

Environmental Impacts

According to investigations done by the European Academies Science Advisory Board Concentrating Solar Power plants potentially impact the environment in the following ways.

- Atmospheric pollution from fuel combustion (in hybrid operation) and during production and construction of equipment (lifecycle emissions)

- Impacts on flora and fauna

- Water consumption

- Land use and visual impact

- Consumption of energy and materials

- Noise of cooling towers when applying air or evaporation cooling

- Smell and potential pollution of soil and water and fire hazard for systems using synthetic oil heat transfer fluid, which is considered a hazardous material.[4][5]

Technology

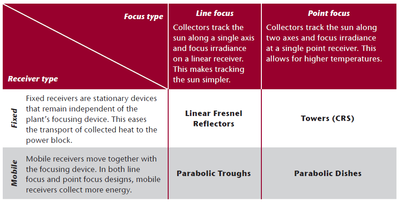

In CSP power plant design there are four main collector technologies that are being applied. These technologies have to be picked site-specific and shall be discussed here. A good overview is provided by the International Energy Agency in its Technology Roadmap on Concentrating Solar Power.

CSP technology, being quite different from the more popular photovoltaic equpiment, concentrates sunlight to effectively create heat to raise steam. However, there are different types of technology working under title of CSP. In the following chapters, the idea of the “parabolic trough”, the “power tower”, the “Fresnel mirror system” (or simply “linear Fresnel”) and the “dish” will be presented.

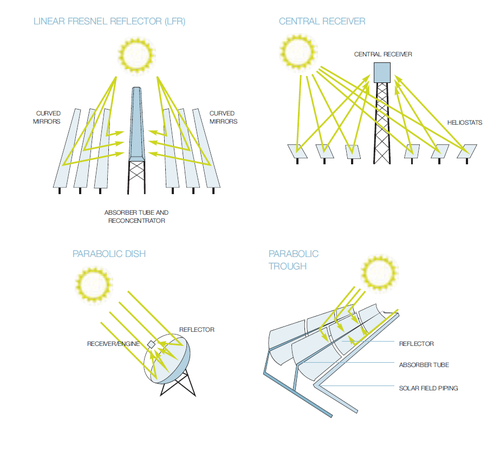

Parabolic Trough

These receivers are mobile applications. They are moving on a 1-axis-tracking system according to the sun's movement. It is a simpler application for tracking the sun than a point focus system (power tower or dishes) that needs to track the sun along two axes. This system, however, consists of parallel rows of reflectors or mirrors. Absorber tubes made of stainless steel serve as the heat collectors. The selective coating on these absorber tubes allows to absorb high levels of solar radiation while only few energy is lost again through infra-red radiation. The absorber tubes are insulated in an evacuated glass envelope. The heat transfer fluid used is synthetic oil. The oil is transferred through the tubes to a heat exchanger which heats and then superheats water into superheated steam. The steam is then expanded in a turbine which runs a generator to produce electricity. The water is then cooled, condenses and returns to the heat exchangers.

Power Tower

The power tower really lives up to its promise. Compared to other CSP technologies, it can create the highest degree of temperature. Surrounded by mirrors reflecting light onto an elevated and centered tower, the power tower generates heat of about 1,000 C°.[6] By transferring the reflected concentrated solar radiation to a fluid, steam is being produced that expands on a turbine in order generate the intended electricity.[7]

Linear Fresnel

This technology uses flat mirrors that are concentrating on one focal point. Water flows through the pipe which runs directly through the focal point of the mirrors. The Linear Fresnel arrangement approximates the parabolic shape of trough systems. It is a simple receiver design that facilitates direct steam generation. Thus, heat transfer fluids are not needed while applying this technology.

Dish / Engine

Parabolic dishes concetrate the sun's rays at a focal point in the centre of the dish. Most dishes use a 1-axis-trackig system, predominantly from north to south. The sun's energy, concentrated in the focal point, is given to a heat transfer fluid which is heated up to 750°C. Sometimes even gas transfer systems are applied. The fluid or gas is then used to drive a micro turbine or Stirling engine which is attached to the receiver.

Comparison

| Parabolic Trough |

Central Receiver/ Power Tower |

Parabolic Dish |

Fresnel Linear Reflector | |

|---|---|---|---|---|

| Applications |

Grid-connected plants, mid to high-process heat (Highest single unit solar capacity to date: 80 MWe. Total capacity built: over 500 MW and more than 10 GW under construction or proposed) |

Grid-connected plants, high temperature process heat (Highest single unit solar capacity to date: 20 MWe under construction, Total capacity ~50MW with at least 100MW under development) |

Stand-alone, small off-grid power systems or clustered to larger gridconnected dish parks (Highest single unit solar capacity to date: 100 kWe, Proposals for 100MW and 500 MW in Australia and US) |

Grid connected plants, or steam generation to be used in conventional thermal power plants. (Highest single unit solar capacity to date is 5MW in US, with 177 MW installation under development) |

| Advantages |

• Commercially available – over 16 billion kWh of operational experience; operating temperature potential up to 500°C (400°C commercially proven) • Commercially proven annual net plant efficiency of 14% (solar radiation to net electric output) • Commercially proven investment and operating costs • Modularity • Good land-use factor • Lowest materials demand • Hybrid concept proven • Storage capability |

• Good mid-term prospects for high conversion efficiencies, operating temperature potential beyond 1,000°C (565°C proven at 10 MW scale) • Storage at high temperatures • Hybrid operation possible • Better suited for dry cooling concepts than troughs and Fresnel • Better options to use non-flat sites |

• Very high conversion efficiencies – peak solar to net electric conversion over 30% • Modularity • Most effectively integrate thermal storage a large plant • Operational experience of first demonstration projects • Easily manufactured and mass-produced from available parts • No water requirements for cooling the cycle |

• Readily available • Flat mirrors can be purchased and bent on site, lower manufacturing costs • Hybrid operation possible • Very high spaceefficiency around solar noon. |

| Disadvantages |

• The use of oil-based heat transfer media restricts operating temperatures today to 400°C, resulting in only moderate steam qualities |

• Projected annual performance values, investment and operating costs need wider scale proof in commercial operation |

• No large-scale commercial examples • Projected cost goals of mass production still to be proven • Lower dispatchability potential for grid integration • Hybrid receivers still an R&D goal |

• Recent market entrant, only small projects operating |

| Source: Greenpeace International 2009 | ||||

Storage Techologies

Using different approaches to store the excess solar energy into thermal energy storages (TES) it is possible to run a CSP plant around the clock, 24 hours a day and therefore in baseload. For storing thermal energy so-called Phase Change Materials (i.e. water) are applied to make use of the latent heat. In addition thermal-chemical storages can offer even higher storage capacities making use of the chemical reactions taking place due to adsorption and absorption. A commonly used TES is molten salt while other TES are currently under investigation (see SunShot Initiative).

CSP Today

List of CSP projects

Click here to view, browse and add project information about CSP projects on Energypedia: CSP Projects.

See List of solar thermal power stations and List of concentrating solar thermal power companies (Wikipedia)

References

- ↑ Greenpeacce International - Concentrating Solar Power Global Outlook

- ↑ NREL - Estimating the Performance and Economic Value of Multiple Concentrating Solar Power Technologies in a Production Cost Model

- ↑ SunShot Concentrating Solar Power ResearchfckLRand Development - http://www1.eere.energy.gov/solar/pdfs/55467.pdf

- ↑ Trieb et al. - Concentrating Solar Power in a sustainable future electrictiy mix (https://energypedia.info/wiki/Concentrating_solar_power_in_a_sustainable_future_electricity_mix)

- ↑ European Academies Science Advisory Council - http://www.easac.eu/fileadmin/Reports/Easac_CSP_Web-Final.pdf

- ↑ Taggart, S. (2008), “Hot Stuff: CSP and the Power Tower”, in: Renewable Energy Focus, May/June 2008, pg. 52

- ↑ Taggart, S. (2008), “Hot Stuff: CSP and the Power Tower”, in: Renewable Energy Focus, May/June 2008, pg. 54