Difference between revisions of "Alcohol Stoves"

***** (***** | *****) |

***** (***** | *****) |

||

| Line 265: | Line 265: | ||

<br/> | <br/> | ||

| + | |||

| Line 271: | Line 272: | ||

=== Further Information on Plantoil<br/> === | === Further Information on Plantoil<br/> === | ||

| − | *Reinhard K. Henning (2006): [http://www.underutilized-species.org/Documents/PUBLICATIONS/jatropha_curcas_africa.pdf Jatropha curcas L. in Africa]. Assessment of the impact of the dissemination of “the Jatropha System” on the ecology of the rural area and the social and economic situation of the rural population (target group) in selected countries in Africa. This paper gives a good overview on production of the Physic Nut in Africa and the variety of its use. Special attention is paid the use of plant oil as a fuel. An overview of existing cooker models is given including technical details. | + | *Reinhard K. Henning (2006): [http://www.underutilized-species.org/Documents/PUBLICATIONS/jatropha_curcas_africa.pdf Jatropha curcas L. in Africa]. Assessment of the impact of the dissemination of “the Jatropha System” on the ecology of the rural area and the social and economic situation of the rural population (target group) in selected countries in Africa. <br/>This paper gives a good overview on production of the Physic Nut in Africa and the variety of its use. Special attention is paid the use of plant oil as a fuel. An overview of existing cooker models is given including technical details. |

| − | *[http://www.artfarm.co.zw/articles/The Jatropha System.htm The Jatropha System | + | *[http://www.artfarm.co.zw/articles/The Jatropha System.htm The Jatropha System- An Integrated Approach of Rural Development in Tropical & Subtropical Countries.]<br/>The very comprehensive homepage provides a good overview of the role of Jatropha in different countries, technical aspects of oil extraction, different cooker models developed so far, a selection of projects working in the field of Jatropha use as well as a large amount of literature on the issue. |

<br/> | <br/> | ||

Revision as of 12:15, 17 June 2015

Basics | Policy Advice | Planning | Designing and Implementing (ICS Supply)| Technologies and Practices | Designing and Implementing (Woodfuel Supply)| Climate Change

What are liquid biomass fuels?

Liquid fuels derived from biomass are sometimes referred to as 'biofuel'.

They can be divided into two main groups:

- Alcohols

- Oils

The latter are also called 'plant oil´ or straight vegetable oil (SVO) to distinguish them from non-renewable fossil oils. Biofuels are generally bioadegrable and have lower sulfur content than liquid fossil fuels. Liquid biofuels are normally marketed by volume (liters, gallons), not by weight (kg, pounds). They are renewable sources of energy, if the biomass is harvested from sustainably managed sources.

Both alcohols and oils require considerable energy input during their production to convert the original feedstock into a liquid fuel: alcohols need to be distilled and oils need to be pressed.

Why deal with the use of liquid biomass as a fuel?

Projects promoting the use of liquid biomass fuels for cooking are often driven by this kind of vision:

|

“Instead of cutting down trees for firewood, the smallholder farmer grows crops with oil seeds which he can harvest every year. By pressing the oil, he is generating plant oil which he can either sell to the world market or use for his own cooking needs. Thus, he is protecting the environment, cooking on a powerful modern fuel and is improving his income situation”. |

There are several advantages to using liquid biomass fuels:

- First, liquid fuels in general have a cutting-edge advantage over solid fuels when it comes to the use for transport, where the fuel container has to move with the engine. This is not nedded for a cook-stove which remains stationary in one place.

- Second, alcohols and oils are more energy-dense than wood. For example, the alcohols methanol and ethanol have an energetic value of approx. 20-23 MJ/kg and 25-30 MJ/kg, respectively. Plant oils are even more energy dense and range between 39 and 50 MJ/kg. Kerosene has usually between 43 and 47 MJ/kg. Air-dry wood, on the other hand ranges around 16 MJ/kg. (Charcoal, however and can range between 27-30 MJ/kg).

- Third, with an appropriate burner that can regulate the mix of oxygen and the fuel, it is easy to burn liquid fuels cleaner than solid fuels as liquid biomass fuels generally have low emissions of particulate matter (soot). Liquid fuels can also be very convenient to use as the power output can be regulated 'by the turn of a knob'. They are clean to handle and easy transport in bulk or in small containers like recycled bottles.

However, despite these advantages, the comparative advantage of liquid biomass fuels in relation to a solid fuel needs to be assessed on a case-by-case basis. For example, will the considerable extra effort needed to press oil out of oily seeds or to distill precious alcohol be outweighed by the advantages regarding convenience and clean burning of the liquid biofuel in a cookstove? This is relevant both for the economic viability of using liquid biomass fuels as well as the CO2-balance.

Production of Alcohols

Alcohols are commonly produced by energy-intensive distillation of fermented sugar-rich organic matter like sugar cane, maize, grain, cassava, sweet potato etc. These are often staple foods for human nutrition. Straw, grass and wood can also be used, though with less yield. The lightest, simplest alcohol with the lowest flash-point is methanol, followed by ethanol and butanol.

Methanol can also be produced from fossil natural gas at less cost compared to ethanol derived from biomass, but it is highly dangerous.

Ethanol can be further processed into gel fuel, by adding a gelling agent and some more water. Studies in Malawi showed that the heating value of gel fuel was between 16 and 18 MJ/kg. This means that a kg of gel fuel contains approximately the same energy as a kg of dry firewood, or two thirds of charcoal.

Economic viability of the production of cooking-appropriate alcohol fuels depends on the scale and degree of purity that needs to be reached: the more water, the less power output when burning the fuel. Worldwide people produce ‘drinking alcohol’ in their backyards. But this alcohol produced at household level usually does not exceed 50% alcohol, the rest is water. It is not suitable as a cooking fuel. Even 70% rubbing alcohol that contains up to 30% water is not recommendable as a fuel, because of the low power output. Rectified ethanol between 90 and 96 % purity is good enough for use in a cookstove, yet difficult to obtain at household level. Fuel-grade ethanol for blending with transport fuel must contain less than 1% water. This last step of distillation is extremely energy intensive and requires sophisticated industrial-size technology and production skills.

Although alcohol can be distilled from a large variety of feedstock with rather simple means, it is rarely possible for a user to produce his or her own ethanol at household level for cooking, as this requires more sophisticated distilling equipment and skills than to produce ‘drinking alcohol’. In some countries, licensing issues also come into play. Small-scale alcohol production units have not yet taken root on a broader scale. If economically viable, they could contribute to local employment generation and ease fuel constraints. For the time being people have to purchase the industrially produced alcohol fuels on the market. Market prices of ethanol are often dictated by the petroleum import price due to the use of ethanol for blending with transport fuels.

For a user, it is a bad deal if he has to pay the same price for a litre of ethanol as for a liter of paraffin, because he gets a third less of the energy content. In places where kerosene or LPG are subsidized, this discrepancy becomes more severe and ethanol a less viable fuel for cooking.

Alcohol fuels are highly flammable. They vaporize and can be ignited at room temperature. The purified ethanol can be used either directly in a stove, or it can be thickened with a gelling agent. The downside of the gelled fuel is that another 15% of water is added, thus diluting the energy value of the gel.

Production of Oils

Plant oils are pressed from oil-rich parts of plants, usually seeds e.g. sunflower, rape, mustard, groundnut, cotton etc. or any nuts from trees like palms, pongamia, tung seeds etc. Seeds that are not suitable for human consumption include jatropha and castor seed.

Presses can range from simple hand-presses (RAM-type) and screw-presses to hydraulic presses requiring tri-phase electricity.

Once plant oils are pressed, they need to be cleaned, filtered and sometimes refined, before they can be used as fuel in a burner.

Other combustible oils can be processed from animal fats. These are usually refined into biodiesel and biokerosene for use as cooking fuel.

Competing Uses: 'Food' versus 'Fuel' Debate

In the view of the current food versus fuel debate, smallholder farmers have to make decisions on the use of their resources.

As with any other cash crop, farmers have competing options:

- Food versus Fuel: the same crop can be consumed as food or used for fuel for cooking;

- Cash versus Fuel: the same crop can be used for cash income (e.g. soap making) or as fuel for cooking;

- Seed versus Fuel: a special form of “cash versus fuel” is the use of seeds for farmers own planting (or as a commodity sold for planting) rather than for producing oil. This is a particular problem in expansion phases where the value of seed used as planting material is considerably higher than compared to the value of the same seed as raw material for oil.

- Competition for land: the same piece of land can be used to grow a fuel crop or any other crop (e.g. food or cash crop)

- Competition for water: for irrigated production and limited access to water, the scarce resource can be applied to grow various products.

The mode of production of oil plants can accommodate some of the concerns above:

- Intercropping: e.g. jatropha trees are planted within the food producing fields with enough space between them to allow enough light for the food crops;

- Fieldside cropping: e.g. jatropha is planted as a hedge around fields or around the house.

- Use of degraded land: e.g. jatropha grown on land which is no longer suitable for crop production (with lower yields of crop)

- The processing of oil at smallholder level is another important area to be observed. It comprises both the pressing of the oil as well as the filtering of fiber out of the oil.

It is sometimes rational for a farmer NOT to use their liquid biomass as a fuel for cooking:

- Oil is often more valued for soap-making or as food, rather than as fuel.

- Ethanol fetches higher prices on the market for human consumption.

Cooking with Alcohol Fuels

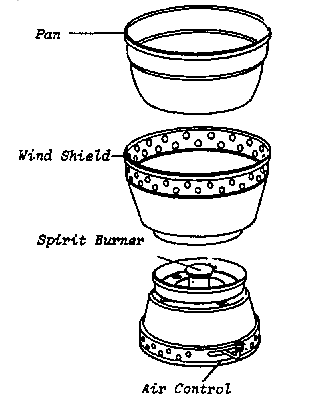

A stove to burn alcohol fuels can be very simple. The main components of the burner are shown here[1]:

Cooking with Ethanol

Advantages of cooking with ethanol:

- Very clean combustion with negligible emissions and no soot

- Can safely be used indoors; eliminates Household Air Pollution (HAP)

- Heat available instantly after ignition

- Provides a safe alternative to LPG when not pressurized

- Produced from a variety of feedstocks, many of which are sustainable

- Intrinsically cheap

Disadvantages of cooking with ethanol:

- Low heating value when further diluted with water to make gel-fuel

- High flammability, burns at low temperatures

- Currently weak supply chains for household use

Experiences of Cooking with Ethanol

At present, ethanol stoves and fuel are consumed for household energy use in areas where they have been fostered and promoted by studies and commercial projects. Nations worldwide have invested in large and medium-scale biofuel production to cut the use of costly, unsustainable petroleum-based fuels. As worldwide production capacity increases, so does the potential for ethanol to meet cooking and lighting energy demands worldwide. Alcohol fuels are increasingly recognized by the international community as a clean liquid fuel solution of the future. Ethanol projects, along with LPG and solar groups, lead the clean fuel advocacy efforts of the Global Alliance for Clean Cookstoves since its inception in 2010.

Ethanol and ethanol-based gel-fuel are quite common in niche applications, where clean combustion, safety and convenience are required: e.g. marine markets, camping, catering services and restaurants. Because ethanol can be made from a variety of low-cost, simple feedstocks, it is an intrinsically cheap fuel. Ethanol fuel can be produced at a scale which suits the community in demand. For example, In Ethiopia ethanol is sourced from the government-owned Sugar Corporation to meet the cooking demand of several thousand households and ethanol for household energy use is recognized an official priority of the National Biofuels Policy.

In humanitarian interventions where energy for cooking is in large and urgent demand and resources are extremely scarce, ethanol stoves and fuel have shown considerable success.

The most documented ethanol stove model is the CleanCook Stove produced by Dometic AB and promoted by Project Gaia and CleanStar Mozambique.

CleanCook Ethanol Stove

The "CleanCook" Stove is available as a single or double-burner model for households and institutions. The CleanCook is a non-pressurized alcohol stove with a refillable fuel canister that contains a porous fiber that adsorbs alcohol and retains it in a manner that prevents spills, leaks, fires and explosions. The power output per burner is rated at 1.5 kW, with a 3kw burner currently under development (2013). Both ethanol and methanol fuels (denatured to prevent ingestion) can be combined at advised proportions. Project Gaia and Gaia Associations have achieved an excellent history of safety by employing stringent training protocols for staff and end users. The cost of the CleanCook stove models range from $57-110 USD[2]. Project Gaia employs various financing schemes including sustainable loan programs and carbon finance to deliver affordable alcohol stoves and fuel to energy poor households.[3]

Project Gaia and its Ethiopian sister organization, Gaia Association, have lab and field tested alcohol stoves since 2005. Project Gaia and Gaia Association have disseminated an estimated 10,000 ethanol stoves to households around the world. To date, alcohol stoves have been used by households in Ethiopia, Nigeria, South Africa, Malawi, Madagascar, Mozambique, Vietnam, Brazil and Haiti. Click here to access country study/project reports. The largest number of households using alcohol stoves is in the UNHCR refugee camps near Jijiga, Eastern Ethiopia where 3,500+ households rely on the CleanCook stove and ethanol fuel as their main source of energy. Project Gaia currently leads four community-based, small-scale ethanol distillation projects in Ethiopia, Nigeria and Haiti. These projects aim to allow communities to produce clean cooking fuel using local feedstocks, simultaneously adding value to agricultural markets by taking advantage of co-products of the distillation process[4].

A private venture capital firm CleanStar Mozambique has promoted the CleanCook stove in a commercial project based in Maputo. CleanStar has sourced ethanol fuel primarily from excess cassava crop purchased from farmers[5].

Further Information and Links on Ethanol Fuel

- HEDON Household Energy Network: This network provides information on all aspect of ethanol as a household fuel

- The ‘Cookstove Fuels’ section of the Global Alliance for Clean Cookstoves

- Project Gaia website ‘About Alcohol Fuels’

- The Bioenergy Wiki for ‘Ethanol’

Cooking with Methanol[6]

Methanol-use for cooking is still in its infancy. This is partially due to the fear of the potentially damaging health effects should the fuel be accidentally ingested. Project Gaia had a pilot study in Nigeria with Methanol (made from fossil flare gases): people were mainly satisfied with the stove, but complained that the fuel was not regularly available.

-> Cooking with methanol in the CleanCook stove, Nigeria

Further Information on Methanol

- HEDON Household Energy Network. Visit Hedon and type ‘Methanol’ in the search box.

Cooking with Plant Oils

Plant oil fuels pose the challenge that they have a high viscosity and only ignite at temperatures above 200° Celsius. Depending on the oil type, simple wick-stoves are not suitable and sometimes preheating of the oil with another fuel that burns at lower temperatures is needed. Pressurizing enhances the performance and power-output, but adds more challenges and cost to the stove.

Plant oil differs from other liquids when used for cooking. Below are some advantages and disadvantages.

Advantages:

- Safety: Plant oil is has a high viscosity and a higher flame point as compared to kerosene. For the user, this has the advantage of safety (it does not ignite spontaneously and is not so explosive when spilled).

- Smell: Most plant oils also do not emit undesirable odours (it does not smell as intensive as kerosene).

- Fast cooking: Plant oil has a high energy content (only 5% less than kerosene). Hence it produces a powerful flame if used in a pressurized stove. Cooking large quantities can be done quickly.

Disadvantages:

- Pre-heating: The advantages on safety and smell come at the expense that it usually needs to be preheated with another fuel (e.g. ethanol or methanol) in order to be ignited. This pre-heating is another cost factor and it consumes time.

- Simmering: The linked disadvantage is that it is difficult to simmer: in a pressurized regulating the plant-oil supply down for small heat poses a challenge.

- Cleaning: Plant oils contain fiber, the amount of which depends on the kind of oil and the quality of the filter method applied. As the oil is burned as gas, the fiber remains behind and tends to clog the burner (depending on the type of stove). This requires regular cleaning of stove and nozzles.

- Noise: if burned in a pressurized system, cooking on plant oil can be quite noisy. It requires muffling of the sound.

Experiences of Cooking with Plant Oil

During the last decades, projects have sought to design household appliances for cooking and heating that use plant oil.

Until recently, none of them got beyond the test phase. Some of the reasons for the past failure of plant oil cookers are:

- Plant oil cookers have a rather complicated design which is not easy to construct

- They may require ongoing maintenance

- Production of plant oil is labour-intensive and expensive

- The use of some plant oils as fuels competes with other uses, such as food crops, soap production etc., which are more profitable

- In most cases, production of fuelwood is much easier and much cheaper than production of plant oil

Protos the Plant Oil Stove

The University Hohenheim (Germany), in cooperation with Bosch and Siemens Home Appliances Group (BSH), developed protos the plantoilcooker. The basic idea was to develop a cookstove that can use a variety of plant oils; even recycled and filtered oil previously used for frying.

Field tests in the Philippines and in Tanzania have shown that households and small enterprises such as restaurants, that were previously cooking on 3-stone fires, can handle the Protos-stove. People stated that they enjoyed the comfort of cooking and said it was like cooking on gas, even if LPG was not available. Based on observations from the field tests, BSH developed a 'second generation' of the protos plantoilstove technology to increase efficiency, reducing noise, cleaning time and the cost of production.[7] The serial production was launched in May 2010 in Indonesia. Initial costs were considered to be around US$40 - 42, at a production rate of around 25,000-50,000 units in 2010.[8]

However, in 2012, BSH decided to conclude the Protos plant oil cooker project and to discontinue series production of the stove in Indonesia. The main reasons were as follows:[9]

- The stove was required to be of a high quality, safe and as easy as possible to use. Equally, however, it had to be cheap enough for people in developing countries to be able to afford it. The low purchasing power of the potential users had limited the use of the stove to a few individual projects.

- Plant oil cookers require a lot more cleaningn and maintenance than kerosene stoves as plant oil leaves residue in the burner when it evaporates.

- Due to the physical properties of plant oil the stove is technically complex. All varieties of plant oil have an extremely high flash point, which means that plant oil stoves require much higher operating temperatures and a longer pre-heating process than conventional stoves burning fossil fuel.

- No established market for sustainably cultivated plant oil in Indonesia.

- BSH faced serious difficulties in setting up a supply chain for sustainable cultivated plant oil.

BSH has freed all patents associated with the plant oil cooker technology. Construction plans, introduction guidelines and other technical information is available at: http://www.bsh-group.com/index.php?127656

Further Information

- Stove by BSH (protos). https://energypedia.info/wiki/Stove_by_BSH_(protos)

- A breath of fresh air: Protos the plant oil stove. In: Boiling Point 56, 2009. http://www.hedon.info/docs/BP56_Shiroff.pdf

- BSH: Protos. The Plant Oil Stove. http://www.bioenergylists.org/stovesdoc/bshg/Protos_E_0206_b.pdf

References

- ↑ http://www.hedon.info/BP33_EthanolStovesForMauritius?bl=y

- ↑ http://www.projectgaia.com/index.php

- ↑ http://www.hedon.info/View+Stove?itemId=8969

- ↑ http://www.projectgaia.com/index.php

- ↑ http://www.cleanstarmozambique.com/

- ↑ HEDON/Boiling Point

- ↑ https://energypedia.info/wiki/Stove_by_BSH_%28protos%29

- ↑ http://stoves.bioenergylists.org/taxonomy/term/1687

- ↑ Protos Plant Oil Cooker Project to Conclude. http://www.bsh-group.com/index.php?109906

Further Information on Plantoil

- Reinhard K. Henning (2006): Jatropha curcas L. in Africa. Assessment of the impact of the dissemination of “the Jatropha System” on the ecology of the rural area and the social and economic situation of the rural population (target group) in selected countries in Africa.

This paper gives a good overview on production of the Physic Nut in Africa and the variety of its use. Special attention is paid the use of plant oil as a fuel. An overview of existing cooker models is given including technical details. - Jatropha System.htm The Jatropha System- An Integrated Approach of Rural Development in Tropical & Subtropical Countries.

The very comprehensive homepage provides a good overview of the role of Jatropha in different countries, technical aspects of oil extraction, different cooker models developed so far, a selection of projects working in the field of Jatropha use as well as a large amount of literature on the issue.

References

This article was originally published by GIZ HERA. It is basically based on experiences, lessons learned and information gathered by GIZ cook stove projects. You can find more information about the authors and experts of the original “Cooking Energy Compendium” in the Imprint.