Cooking with Biogas

Introduction

Biogas is a mixture of mainly methane and carbon dioxide produced during the digestion of organic matter, such as animal and kitchen waste as well as crop residues, in the absence of oxygen.[1] Anaerobic bacteria ferment biodegradable matter into methane (40-70%), carbon dioxide (30-60%), hydrogen (0-1%) and hydrogen sulfide (0-3%). The ideal process temperature for the fermentation process is at about 35°C, which might require additional heat or insulation of the digester in regions with daily or seasonal temperature fluctuations.[2]

Viability of Biogas Production

Biogas production depends on the availability of sufficient biomass feedstock, water and space for the digester. As the biogas cannot be transported over long distances, the digester has to be placed close to the home of its user, which requires sufficient space. Yet, changing from a three-stone fire to using a biogas stove requires complex changes for a rural household, as well as for the user.

In order to check the viability of biogas in a certain area some basic points might be helpful to consider:

- The complex fermentation process in the biogas plant needs a continuous supply of suitable feedstock (preferably dung or other agricultural waste). This requires an appropriate farming system: a sufficient amount of livestock must be kept confined (no free-range grazing).

- It requires a continuous supply of water all year round, which can be a limiting factor in arid areas or areas with a pronounced dry season.

- Households must be able to afford the construction of a digester with a corresponding stove. The economic viability increases if the slurry from the digester can be applied as fertilizer on fields close-by.

- There must be enough labor available for the daily feeding and maintenance of the digester.

- Biogas might not be advisable in cultures where maintenance and preventive action is not a common habit.

- The rule of thumb says that 3-4 cows are needed to make biogas production viable at household level. This may be a problem especially for poorer families.

The Production of Biogas for Domestic Use

Biogas production for domestic cooking depends on an affordable appropriate digester at a suitable scale for domestic use. In any digester, the waste is mixed with water to create the right environment for the bacteria to decompose the biomass. As this is an anaerobic process, this has to happen without the presence of oxygen in an airtight tank. The biogas accumulates at the top of the tank where it is collected and taken by pipe to the user. The slurry has to be removed regularly from the tank. It can be used further, e.g. as agricultural fertilizer. Based on this principle a number of designs have emerged. Digesters come in many forms and sizes, which may range from 1 m3 for a small household unit to some 10 m3 for a typical farm plant and more than 1,000 m3 for a large installation.

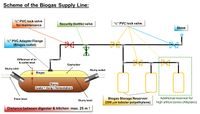

A small-scale biogas system for household use will typically consist of the following components:[2]

- Collection space: raw, liquid, slurry, semi-solid and solid animal, human or agricultural waste

- Anaerobic digester

- Slurry storage

- Gas handling: piping; gas pump or blower; gas meter; pressure regulator; and condensate drain(s).

- End-use device: cooker, boiler or lighting equipment

The article Types of Biogas Digesters and Plants displays various designs from different materials and at different costs.

The Use of Biogas for Cooking

For transporting biogas from the digester to the cooking place a tube is needed. Stoves for this system contain a valve to premix the biogas with the right amount of oxygen, a burner to combust the mixture and a structure to hold a cook-pot. Stoves and ovens for biogas application are similar to those of conventional appliances running on commercial gas-fuels. Most of these conventional appliances can be adapted for the use with biogas by special measures (particularly the modification of the burners) to ensure proper combustion and efficient use of energy.

Advantages:

- Biogas burns very cleanly, and produces fewer pollutants during cooking than any other fuel except electricity.

- Biogas provides instant heat upon ignition, no pre-heating or waiting time is required.

- Most biogas burners are able to regulate the flow-rate to turn down fire-power from high heat to small low heat for simmering.

- Biogas can be used for lighting as well.

- The by-product (slurry) from the digester can be used as fertilizer.

- Biogas is a renewable fuel that is ‘carbon negative’: unless there are leakages in the system, burning biogas in a cookstove releases less greenhouse gases than if the dung was left on the ground to decompose naturally.

Disadvantages:

- High investment costs for the digester, tubes, gas stove, and pots.

- Biogas can increase the workload of women as it is often made their task to run the digester. It is quite a physical burden to move all the biomass feedstock and water to feed the digester. Also the slurry must be removed and taken to the field.

- It is not viable for elderly or sick people to run a biogas plant on their own, if they don’t have labor to assist them in the maintenance of the digester.

- Installations (depending on material and location) must be protected against theft and damages. Especially metal tubes are a valuable good and often prone to theft.

- Cultural rules might limit the acceptance of handling dung or feces and their use as fuel for cooking.

- Cooking with biogas requires the change of cooking habits, which might prevent the adoption.

- Biogas is difficult to store and to transport to other consumers.

Experiences with Biogas

Already in the 1970 state-driven biogas programs started in India and China. A criticism of the Indian subsidized-scheme was that the program did not reach the poor and marginalized, possibly because maintaining a digester requires the dung from at least three or four cattle, more than poor families owned. Biogas projects are as well eligible for carbon financing, as the project of SKG Sangha in rural India shows.

SNV has supported the installation of biogas plants for households since 1989. Until 2009 around 300.000 biogas plants have been installed in African and Asian countries.[1]

About 110 000 biogas plants have been installed until 2005 in rural households in Nepal, with support from the Biogas Support Program.[3] Biogas dissemination in Nepal seems to be a successful example of a more market-oriented approach. The program, started in 1992, pursued a comprehensive strategy, supporting the start-up of companies into the biogas market. Strict enforcement of quality and design standards, and the introduction of comprehensive after-sales service, assured reliable functioning of the plants. The initial investment costs were kept down by subsidies and were enabled by a microfinance component. Every biogas plant can save up to four tons of fuelwood per year and thus the 120 000 biogas plants could reduce the fuelwood consumption of the country by about 3.5 million tons.[3] The annual CO2 savings vary between 13 000 tons and 157 000 tons, depending on whether the fuelwood was harvested from renewable sources in a sustainable manner or non-sustainably, and on the amount of kerosene replaced by biogas.

Energizing Development has supported the introduction of Low-Cost Polyethylene Tube Digesters in Bolivia. The digesters cost approx. 93 to 148 EURO. To operate a digester, the producer has to charge it day to day with 20 kg of cow dung (or other animal dung), mixed with 60 liters of water. Once the digester starts its operation (between 30 to 60 days), it produces around 4 - 5 hours of biogas daily, for cooking or other applications like use of gas lamps. Furthermore the digester provides daily 80 liters of ecologic fertilizer, which helps to increase the production of agriculture.

Further Information

- Biogas stoves, article on energypedia

- The Biogas Portal in energypedia provides comprehensive information about technological aspects, framework conditions, social and environmental impacts of biogas as well as general aspects and examples of program implementation from Bolivia, China, Indonesia, Nepal and Tanzania.

- An excellent introduction to biogas as a household fuel can be found at HEDON. The page also gives a number of links to helpful documents and homepages.

- Dissemination of Biogas Systems in Various Countries. This article provides links to biogas systems and experiences in various countries.

- Biogas in rural household energy supply: The Nepal Biogas Support Program by Mendis, M.S. and W.J. van Nees. The paper gives a detailed description of the Biogas Support Program in Nepal, which is the most successful project in this field to date. It also analyses the factors leading to the success of the program.

- Household biogas use in rural China: A study of opportunities and constraints by Chen, Y. et al. (2009)

- In India, ARTI developed a compact digester from water-tanks that can be installed on the flat roofs in urban areas and produce biogas with food waste.

- SNV Annual Report Highlights Biogas under Renewable Energy

References

- ↑ 1.0 1.1 SNV (2010): Biogas Support Programme fuels rural household energy supply in Nepal http://www.snvworld.org/files/publications/biogas_support_programme_fuels_rural_household_energy_supply_nepal_2010.pdf

- ↑ 2.0 2.1 http://www.climatetechwiki.org/technology/biogas-cook

- ↑ 3.0 3.1 Bajgain, B. and Shakya, I. (2005): The Nepal Biogas Support Program: A Successful Model of Public Private Partnership For Rural Household Energy Supply http://siteresources.worldbank.org/INTENERGY/Publications/20918309/NepalBiogasSupportProgram.pdf