Click here to register!

Difference between revisions of "Electrical-Mechanical Equipment"

***** (***** | *****) |

***** (***** | *****) m |

||

| (20 intermediate revisions by 6 users not shown) | |||

| Line 1: | Line 1: | ||

| − | |||

| − | + | [[Portal:Hydro|► Back to Hydro Portal]] | |

| − | |||

| − | {| cellpadding="0" border="1" | + | = Overview = |

| + | |||

| + | -> See article [[Micro Hydro Power (MHP) Plants|Micro Hydro Power (MHP) Plants]] | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | = Turbine Types<br/> = | ||

| + | |||

| + | A [[Steffturbine - Hydropower Turbine|turbine]] converts the energy in falling water into shaft power. There are various types of turbine which can be categorized in one of several ways. The choice of turbine will depend mainly on the pressure head available and the design flow for the proposed hydropower installation. As shown in table 2 below, turbines are broadly divided into three groups; high, medium and low head, and into two categories: impulse and reaction.<br/> | ||

| + | |||

| + | The difference between impulse and reaction can be explained simply by stating that the impulse turbines convert the kinetic energy of a jet of water in air into movement by striking turbine buckets or blades - there is no pressure reduction as the water pressure is atmospheric on both sides of the impeller. The blades of a reaction turbine, on the other hand, are totally immersed in the flow of water, and the angular as well as linear momentum of the water is converted into shaft power - the pressure of water leaving the runner is reduced to atmospheric or lower. | ||

| + | |||

| + | {| align="right" cellpadding="0" border="1" style="width: 100%" | ||

|- | |- | ||

| − | | | + | | style="vertical-align: top" rowspan="2" | |

| − | '''<span>Turbine</span> ''' | + | '''<span>Turbine</span>'''<br/> |

| − | '''Runner''' | + | '''Runner''' |

| − | | | + | | style="text-align: center; vertical-align: top" colspan="3" | |

| − | '''<span>Head</span> ''' | + | '''<span>Head</span>''' |

| − | '''pressure''' | + | '''pressure''' |

|- | |- | ||

| − | | | + | | style="text-align: center; vertical-align: top" | |

| − | '''High''' | + | '''High''' |

| − | | | + | | style="text-align: center; vertical-align: top" | |

| − | '''Medium''' | + | '''Medium''' |

| − | | | + | | style="text-align: center; vertical-align: top" | |

| − | '''Low'''<br> | + | '''Low'''<br/> |

|- | |- | ||

| − | | | + | | style="vertical-align: top" | |

| − | Impulse | + | Impulse |

| − | | | + | | style="vertical-align: top" | |

| − | <span>Pelton | + | *<span>Pelton</span><br/> |

| − | </ | + | *Turgo |

| + | *Multi-jet Pelton<br/> | ||

| − | Turgo | + | | style="vertical-align: top" | |

| + | *<span>Crossflow</span><br/> | ||

| + | *Turgo | ||

| + | *Multi-jet Pelton<br/> | ||

| − | + | | style="vertical-align: top" | | |

| + | *Crossflow<br/> | ||

| − | | | + | |- |

| − | + | | style="vertical-align: top" | | |

| − | + | Reaction | |

| − | + | | style="vertical-align: top" | | |

| + | *<span>Francis</span><br/> | ||

| + | *Pump-as-turbine (PAT)<br/> | ||

| − | + | | style="vertical-align: top" | | |

| + | *<span>Propeller</span><br/> | ||

| + | *Kaplan<br/> | ||

| − | | | + | | style="vertical-align: top" | |

| − | + | <br/> | |

| − | | | + | |} |

| − | |||

| − | |||

| − | + | <br/> | |

| − | |||

| − | </ | ||

| − | + | <br/> | |

| − | + | <br/> | |

| − | |||

| − | </ | ||

| − | + | <br/> | |

| + | *For further information, click [[Steffturbine - Hydropower Turbine|here]].<br/> | ||

| + | *For information on Pump-as-Turbine, click [[:File:Pump as Turbine (PaT) Manual.doc|here]]. | ||

| − | + | <br/> | |

| − | |||

| − | | | + | [[Electrical-Mechanical Equipment#toc|►Go to Top]] |

| − | + | = Generators = | |

| − | |||

| − | |||

| − | < | + | *[[Thermo Electric Generators|Thermo Electric Generators]]<br/> |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | <br/> | |

| − | + | == Established Producers of Hydro Generators == | |

Marelli | Marelli | ||

| − | === | + | == Induction Motor as Generator == |

| + | |||

| + | = Controller - Function Principles<br/> = | ||

| + | |||

| + | [[File:Mhp-scheme.jpg|thumb|center|605px|Elements of a Micro Hydro Power Scheme|alt=Elements of a Micro Hydro Power Scheme]]<br/> | ||

| + | |||

| + | A Load- or Flow- controller ensures that the '''power output does not exceed the power demand''' and power output is stable (e.g. 230V, 50 Hz). | ||

| + | |||

| + | Water turbines, like petrol or diesel engines, will '''vary in speed as load is applied''' or relieved. Although not such a great problem with machinery which uses direct shaft power, this speed variation will seriously '''affect frequency and voltage''' output from a generator. | ||

| + | |||

| + | Traditionally, hydraulic or mechanical speed governors altered flow as the load varied. Nowadays usually electronic load controller (ELC) are used. These prevent speed variations by continuously adding or subtracting an artificial load ('''load controller'''). In that in effect, the turbine is working permanently under full load and the ELC diverts excess energy into a dump load, mostly a heater.</span> The traditional kind of equalizing power in and output by controlling the flow is usually also automatised ('''flow control'''). Thereby the ELC steers a valve which regulates the amount of water inflowing. | ||

| + | |||

| + | In case of more power demand than supply the controller cuts off single users (clusters) in order to keep voltage and frequency constant for the others (first and second class connections). Load or flow controller are placed between generator output and the consumer line.<br/> | ||

| + | |||

| + | [[Electrical-Mechanical Equipment#toc|►Go to Top]]<br/> | ||

| + | |||

| + | == Controller Types == | ||

| + | Fluctuating energy demand requires a mechanism which either regulates the water input into the turbine (= flow control) or by diverting excess energy from the consumer connection (= ballast load). | ||

| + | For small micro or pico hydropower sites it's sometimes not easy to find the right controller. There is a lower price limit of several 100 USD even for only 1 or 2 kW power. In such cases there may be thought of manual control. | ||

| + | [[Electrical-Mechanical Equipment#toc|►Go to Top]] | ||

| + | === Load Control === | ||

| − | + | The electric load controller (ELC) keeps outgoing Voltage and Frequency stable. Therefore the load on the generator has to be kept stable. The controller adds and subtracts an artificial load (heater) in a way to neutralise the fluctuations on the consumer side. | |

| − | + | [[File:Controler.jpg|thumb|right|734px|Controler|alt=Controler.jpg]] | |

| − | < | + | <br/> |

| − | + | <br/> | |

| − | + | === Ballast Load === | |

| − | + | If energy demand is temporarily low the excess energy is dumped. It's converted into heat by some heat elements either in water or air. To increase an mhp's overall efficiency such excess power could be utilised as well. Therefore some storage technology would be required. Battery charging, freezers, water pumping or heat storage may be options. | |

| − | |||

| − | or | ||

| − | |||

| − | such | ||

| − | |||

| − | |||

| − | |||

| − | + | Regarding intelligent load management: [[:File:Operation and Maintenance of Small Hydro.pdf|Operation and Maintenance of Small Hydro]] by Dr Nigel Smith, Dr Philip Taylor and Tim Matthews | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | <br/> | |

| − | </ | ||

| − | + | === Flow Control === | |

| − | + | regulates the amount of water into the turbine in order to match power output and power demand. Nowadays flow control is done mostly via electronics, which steer a valve | |

| − | + | [[File:Flow-control.jpg|thumb|center|834px|principle flow control|alt=principle flow control]] | |

| − | + | <u>Manual Flow Control:</u> | |

| − | + | In very small schemes often all power for lighting and TV is used constantly. Then energy consumption barely alters or does only at certain times. In such cases it can be even practical to train an operator who open / closes a valve manually to stabilise the Voltage. This allows to disclaim a controller, which saves costs and potentially flaws. | |

| − | + | <br/> | |

| − | [[ | + | [[Electrical-Mechanical Equipment#toc|►Go to Top]] |

| − | = | + | = Load Factor = |

| − | + | The load factor is the amount of power used divided by the amount of power that is available if the turbine were to be used continuously. Unlike technologies relying on costly fuel sources, the 'fuel' for hydropower generation is free and therefore the plant becomes more cost effective if run for a high percentage of the time. If the turbine is only used for domestic lighting in the evenings then the plant factor will be very low. If the turbine provides power for rural industry during the day, meets domestic demand during the evening, and maybe pumps water for irrigation in the evening, then the plant factor will be high. | |

| − | + | It is very important to ensure a high plant factor if the scheme is to be cost effective and this should be taken into account during the planning stage. Many schemes use a 'dump' load (in conjunction with an electronic load controller - see below), which is effectively a low priority energy demand that can accept surplus energy when an excess is produced e.g. water heating, storage heaters or storage cookers. | |

| − | + | [[Electrical-Mechanical Equipment#toc|►Go to Top]] | |

| − | + | = Further Information = | |

| − | [[ | + | *[[Control Equipment - Hydropower|Control Equipment - Hydropower]]<br/> |

| + | *[[Hydropower - Equipment|Hydropower - Equipment]]<br/> | ||

| + | *[[Steffturbine - Hydropower Turbine|Steffturbine - Hydropower Turbine]] | ||

| − | + | <br/> | |

| − | + | [[Electrical-Mechanical Equipment#toc|►Go to Top]] | |

| − | + | = References = | |

| − | + | *General:[[Micro Hydro Power (MHP) Manuals|Micro hydro Power Manuals]] | |

| + | *[[:File:Good and bad of mini hydro power vol.1.pdf|Good and Bad of Mini Hydro Power]] | ||

| + | *[[:File:Hydro scout guide ET may10.pdf|Micro Hydro Power Scout Guide]] | ||

| + | *[http://practicalaction.org/micro-hydro-power-2 Micro-Hydro Power: Practical Action] | ||

| − | < | + | <references /><br/> |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[Category:Hydro]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Latest revision as of 10:45, 9 September 2014

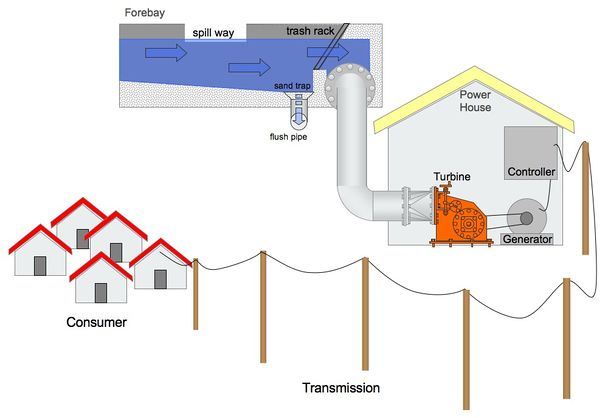

Overview

-> See article Micro Hydro Power (MHP) Plants

Turbine Types

A turbine converts the energy in falling water into shaft power. There are various types of turbine which can be categorized in one of several ways. The choice of turbine will depend mainly on the pressure head available and the design flow for the proposed hydropower installation. As shown in table 2 below, turbines are broadly divided into three groups; high, medium and low head, and into two categories: impulse and reaction.

The difference between impulse and reaction can be explained simply by stating that the impulse turbines convert the kinetic energy of a jet of water in air into movement by striking turbine buckets or blades - there is no pressure reduction as the water pressure is atmospheric on both sides of the impeller. The blades of a reaction turbine, on the other hand, are totally immersed in the flow of water, and the angular as well as linear momentum of the water is converted into shaft power - the pressure of water leaving the runner is reduced to atmospheric or lower.

|

Turbine Runner |

Head pressure | ||

|

High |

Medium |

Low | |

|

Impulse |

|

|

|

|

Reaction |

|

|

|

Generators

Established Producers of Hydro Generators

Marelli

Induction Motor as Generator

Controller - Function Principles

A Load- or Flow- controller ensures that the power output does not exceed the power demand and power output is stable (e.g. 230V, 50 Hz).

Water turbines, like petrol or diesel engines, will vary in speed as load is applied or relieved. Although not such a great problem with machinery which uses direct shaft power, this speed variation will seriously affect frequency and voltage output from a generator.

Traditionally, hydraulic or mechanical speed governors altered flow as the load varied. Nowadays usually electronic load controller (ELC) are used. These prevent speed variations by continuously adding or subtracting an artificial load (load controller). In that in effect, the turbine is working permanently under full load and the ELC diverts excess energy into a dump load, mostly a heater.</span> The traditional kind of equalizing power in and output by controlling the flow is usually also automatised (flow control). Thereby the ELC steers a valve which regulates the amount of water inflowing.

In case of more power demand than supply the controller cuts off single users (clusters) in order to keep voltage and frequency constant for the others (first and second class connections). Load or flow controller are placed between generator output and the consumer line.

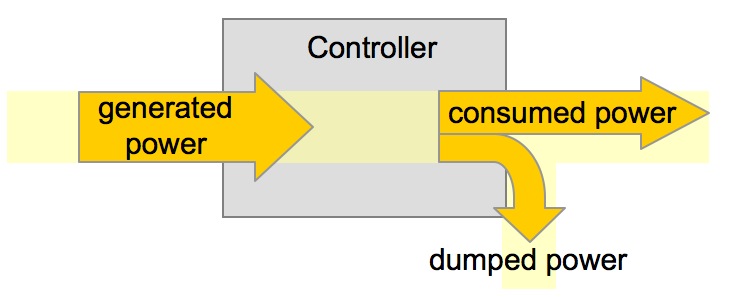

Controller Types

Fluctuating energy demand requires a mechanism which either regulates the water input into the turbine (= flow control) or by diverting excess energy from the consumer connection (= ballast load).

For small micro or pico hydropower sites it's sometimes not easy to find the right controller. There is a lower price limit of several 100 USD even for only 1 or 2 kW power. In such cases there may be thought of manual control.

Load Control

The electric load controller (ELC) keeps outgoing Voltage and Frequency stable. Therefore the load on the generator has to be kept stable. The controller adds and subtracts an artificial load (heater) in a way to neutralise the fluctuations on the consumer side.

Ballast Load

If energy demand is temporarily low the excess energy is dumped. It's converted into heat by some heat elements either in water or air. To increase an mhp's overall efficiency such excess power could be utilised as well. Therefore some storage technology would be required. Battery charging, freezers, water pumping or heat storage may be options.

Regarding intelligent load management: Operation and Maintenance of Small Hydro by Dr Nigel Smith, Dr Philip Taylor and Tim Matthews

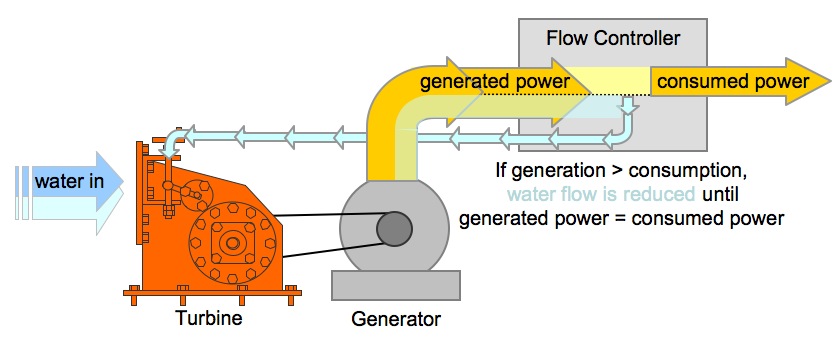

Flow Control

regulates the amount of water into the turbine in order to match power output and power demand. Nowadays flow control is done mostly via electronics, which steer a valve

Manual Flow Control:

In very small schemes often all power for lighting and TV is used constantly. Then energy consumption barely alters or does only at certain times. In such cases it can be even practical to train an operator who open / closes a valve manually to stabilise the Voltage. This allows to disclaim a controller, which saves costs and potentially flaws.

Load Factor

The load factor is the amount of power used divided by the amount of power that is available if the turbine were to be used continuously. Unlike technologies relying on costly fuel sources, the 'fuel' for hydropower generation is free and therefore the plant becomes more cost effective if run for a high percentage of the time. If the turbine is only used for domestic lighting in the evenings then the plant factor will be very low. If the turbine provides power for rural industry during the day, meets domestic demand during the evening, and maybe pumps water for irrigation in the evening, then the plant factor will be high.

It is very important to ensure a high plant factor if the scheme is to be cost effective and this should be taken into account during the planning stage. Many schemes use a 'dump' load (in conjunction with an electronic load controller - see below), which is effectively a low priority energy demand that can accept surplus energy when an excess is produced e.g. water heating, storage heaters or storage cookers.

Further Information

References

- General:Micro hydro Power Manuals

- Good and Bad of Mini Hydro Power

- Micro Hydro Power Scout Guide

- Micro-Hydro Power: Practical Action