Difference between revisions of "Modern Solar Drying in Afghanistan"

***** (***** | *****) |

***** (***** | *****) m |

||

| Line 1: | Line 1: | ||

= Overview<br/> = | = Overview<br/> = | ||

| − | The project Modern Solar Drying in [[Afghanistan Energy Situation|Afghanistan]] aimed at testing of small solar dryers to improve the quality of solar dried fruits in Afghanistan, the promotion of the technology amongst the population, the development of capacity building and the launch of a small solar food business. The project partner was [http://solarcooking.wikia.com/wiki/Afghan_Bedmoschk_Solar_Centre Afghan Bedmoschk Solar Center e.V.], a NGO specialised in environmental protection, education and development aid. The project was part of the [https://www.ises.org/index.php?id=98 ISES Solar Food Processing Project.]<br/><br/> | + | The project Modern Solar Drying in [[Afghanistan Energy Situation|Afghanistan]] aimed at the testing of small solar dryers to improve the quality of solar dried fruits in Afghanistan, the promotion of the technology amongst the population, the development of capacity building and the launch of a small solar food business. The project partner was [http://solarcooking.wikia.com/wiki/Afghan_Bedmoschk_Solar_Centre Afghan Bedmoschk Solar Center e.V.], a NGO specialised in environmental protection, education and development aid. The project was part of the [https://www.ises.org/index.php?id=98 ISES Solar Food Processing Project.]<br/><br/> |

= Technology and Processing<br/> = | = Technology and Processing<br/> = | ||

| − | In Afghanistan, due to the dry climate, the drying of fruits and vegetables is a common way to preserve them. Traditionally, the edibles are cut in pieces and placed on flat | + | In Afghanistan, due to the dry climate, the drying of fruits and vegetables is a common way to preserve them. Traditionally, the edibles are cut in pieces and placed on flat grounds such as a rooftop. This method has some drawbacks as the food is not protected against dust, dirt and insects. [[File:Wisions solar tunnel dryer.jpg|thumb|right|300px|A schematic drawing of a solar tunnel dryer, © WISIONS]]As an alternative, solar tunnel dryers of 2x1 m in size, small versions of the [http://www.innotech-ing.de/Innotech/english/Tunneldryer.html Hohenheim Solar Tunnel Dryer], were tested under Afghan conditions. Their small size allows farmers to test and evaluate the technology in a useful and non-expensive way. The dryers were distributed as a package, which included training about the set-up, use and maintenance, storing and marketing and a set of packaging materials. Training was offered in German and Persian. During the process of drying, the products were dried from 7kg to 0,4 to 1kg. The drying process took 3 to 5 days. The dried products were packed into 200gr packages and sold using newly-designed labels in Dari and English.<br/><br/> |

| − | <br/> | ||

= Results and Lessons Learnt<br/> = | = Results and Lessons Learnt<br/> = | ||

| − | The project resulted in positive outcomes. Overall, 42 dryers were installed and training provided. There is a | + | The project resulted in positive outcomes. Overall, 42 dryers were installed and training provided. There is a strong interest for solar food processing in Afghanistan thanks to favorable natural conditions for this method of preserving food (sunny and dry climate), availabel raw materials and the traditionaly widespread use of it. However, a marketing campaign was not succesful because of the difficult political situation. The end prices of the dried products were also too high for selling them to the general public in Kabul: a potential marketing campaign should therefore target wealthier end- consumers. The potential for larger scale production and distribution is economically viable as a higher quality of dried products leads to higher prices and thus higher income for farmers.<br/> |

| + | [[Category:Powering_Agriculture]] | ||

| + | [[Category:Afghanistan]] | ||

| + | [[Category:Solar]] | ||

[[Category:Agriculture]] | [[Category:Agriculture]] | ||

| − | |||

| − | |||

| − | |||

Revision as of 12:33, 25 February 2015

Overview

The project Modern Solar Drying in Afghanistan aimed at the testing of small solar dryers to improve the quality of solar dried fruits in Afghanistan, the promotion of the technology amongst the population, the development of capacity building and the launch of a small solar food business. The project partner was Afghan Bedmoschk Solar Center e.V., a NGO specialised in environmental protection, education and development aid. The project was part of the ISES Solar Food Processing Project.

Technology and Processing

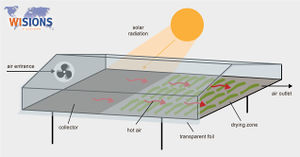

In Afghanistan, due to the dry climate, the drying of fruits and vegetables is a common way to preserve them. Traditionally, the edibles are cut in pieces and placed on flat grounds such as a rooftop. This method has some drawbacks as the food is not protected against dust, dirt and insects.

As an alternative, solar tunnel dryers of 2x1 m in size, small versions of the Hohenheim Solar Tunnel Dryer, were tested under Afghan conditions. Their small size allows farmers to test and evaluate the technology in a useful and non-expensive way. The dryers were distributed as a package, which included training about the set-up, use and maintenance, storing and marketing and a set of packaging materials. Training was offered in German and Persian. During the process of drying, the products were dried from 7kg to 0,4 to 1kg. The drying process took 3 to 5 days. The dried products were packed into 200gr packages and sold using newly-designed labels in Dari and English.

Results and Lessons Learnt

The project resulted in positive outcomes. Overall, 42 dryers were installed and training provided. There is a strong interest for solar food processing in Afghanistan thanks to favorable natural conditions for this method of preserving food (sunny and dry climate), availabel raw materials and the traditionaly widespread use of it. However, a marketing campaign was not succesful because of the difficult political situation. The end prices of the dried products were also too high for selling them to the general public in Kabul: a potential marketing campaign should therefore target wealthier end- consumers. The potential for larger scale production and distribution is economically viable as a higher quality of dried products leads to higher prices and thus higher income for farmers.