Green Hydrogen

Overview

Falling costs for hydrogen produced with renewable energy, combined with the urgency of cutting greenhouse-gas emissions, has given green hydrogen unprecedented political and business momentum. Its potential role for the energy transition and the road to net zero has raised high expectations over the last years and months.

This article sheds light on (green) hydrogen, its use, market and costs, as well as its advantages and disadvantages.

What is Hydrogen?

Hydrogen (H2) is the simplest and lightest element as well as the most abundant element in the universe. Each atom of hydrogen has only one proton and one electron. Hydrogen occurs naturally on earth only in compound form with other elements in liquids, gases, or solids. Hydrogen combined with carbon (hydrocarbons) exists in petroleum, natural gas, and coal. Hydrogen combined with oxygen is water (H2O).[1][2]

As a secondary source of energy, hydrogen carries energy produced from other resources like fossil fuels, water, or biomass. To produce hydrogen by separating it from other elements (electrolysis), it needs more energy than hydrogen provides when converted to useful energy. Hydrogen has the highest energy content of any common fuel by weight (about three times more than gasoline), but it has the lowest energy content by volume (about four times less than gasoline). [1]

It is very clean-burning and when combined with oxygen in a fuel cell, hydrogen produces heat and electricity with only water vapor as a by-product.[3]

Production of Hydrogen

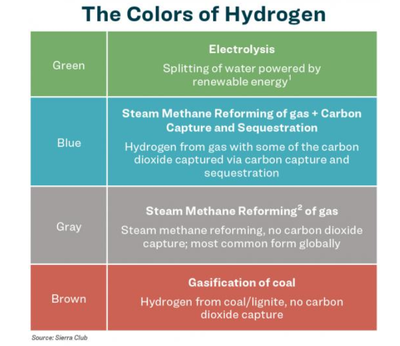

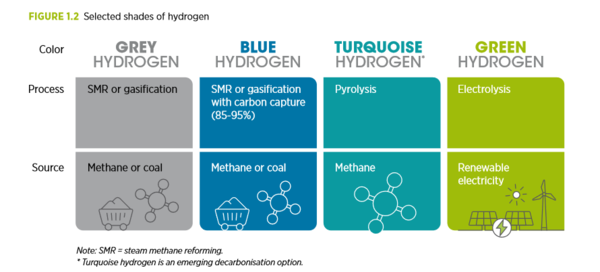

There are different methods of hydrogen production, which determines how climate-friendly the hydrogen is. There is a color scheme used to distinct these different production methods:[4][5][6][7]

- Grey hydrogen is produced by splitting fossil fuels like methane (CH4) (sourced from natural gas) or coal with steam into H2 and CO2. Every ton of hydrogen produced from natural gas also produces 8–10 tons of CO2. Since hydrogen produced from coal produces significantly higher CO2 emissions (20-35x), it is sometimes also called brown or black hydrogen instead of grey.

- Blue hydrogen is produced as well by splitting methane or coal with steam, but unlike grey hydrogen, most (not all) CO2 emissions are captured and stored for reducing its climate impact.

- Turquoise hydrogen: using processes such as pyrolysis, the methane is split into H2 and solid carbon black which can be more easily stored. At the moment, turquoise hydrogen is still at the pilot stage.

- Green hydrogen is produced by splitting water into hydrogen and oxygen using renewable electricity. No emissions occur.

Besides this color scheme, sometimes the wording “low-carbon hydrogen” is used. This refers to both green hydrogen and blue hydrogen, see IEA (2022): Africa Energy Outlook.

Below find two common color schemes of hydrogen from Sierra Club and IRENA 2020.

Global Production Numbers

According to IRENA, each year 120 million tons of hydrogen are produced globally, mostly based on natural gas and coal (95% of production)[6]. 5% of the global hydrogen production is produced by electrolysis but not with renewable energy sources. Only 0.02% of today’s pure hydrogen production is coming from renewable sources.[8]

Production of Green Hydrogen

The production of green hydrogen not only needs renewable electricity but requires fresh water. To produce one ton of hydrogen, 9,000 liters of water must be consumed.[9]

Since the optimal production sites for green hydrogen are often located in water-scarce areas, ensuring environmentally sustainable water extraction and consumption practices is essential to scale up and maintain global production capacity.[10] In areas with access to sea water, one solution could be to desalinate water which, however, would need an additional 1kWh of electricity per m3 of purified water.[9]

Overview on Hydrogen production and energy generated:

| One ton of hydrogen needs | 9000 l of water for electrolysis |

| 50 MWh for PEM and Alkaline electrolysis[11] | |

| (9 MWh additional need in case of water needs to be

desalinated, resulting total energy demand of 59 MWh) | |

| One ton of hydrogen generates | 33.3 MWh of electricity[11] |

Costs of Green Hydrogen

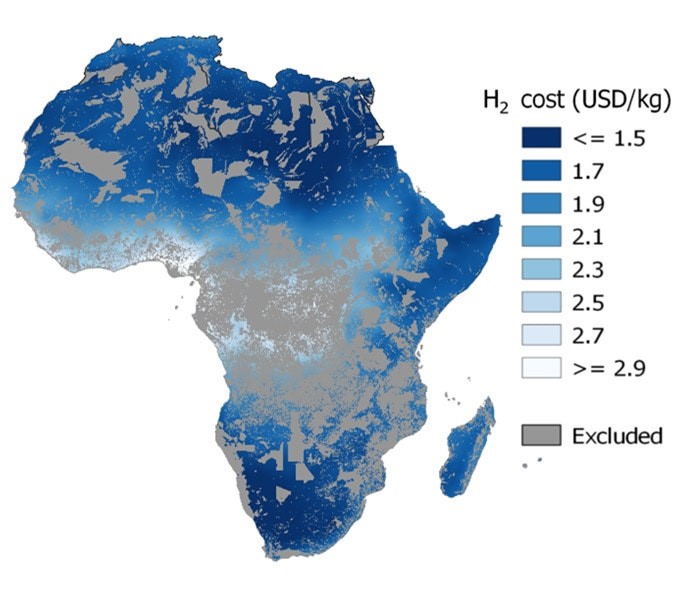

According to the IEA, green hydrogen costs between USD 2.5 and USD 6/kg, whereas grey hydrogen costs around 1 USD per kg (produced using Middle East gas), but can be as high as 3 USD/kg in other regions.[12]

Despite declining costs, green hydrogen is still 2-3 times more expensive than blue hydrogen, which is also considered “clean” as the carbon is captured and stored. The most relevant cost component for green hydrogen is the cost of the renewable energy needed for the electrolysis. To make green hydrogen competitive, low electricity costs are thus a necessary precondition. With declining renewable energy costs, the cost of producing green hydrogen will also go down. The second largest cost component is the electrolyzer, which need a cost reduction in investment and construction and an increase in performance and durability for making green hydrogen cost competitive.[8]

According to a recent report from IEA, global declines in the cost of hydrogen production could allow Africa to deliver green hydrogen to Northern Europe at internationally competitive price points by 2030. With further cost declines, Africa has the potential to produce 5,000 megatons of hydrogen per year at less than USD 2 per kg—equivalent to global total energy supply today.[13]

Another cost component of green hydrogen might be desalination, as many hydrogen plants are planned to be built in sunny, arid regions where water is scarce and thus sea water or brackish groundwater may be needed to use. Depending on the size and location of the plant, desalination costs USD 0.70-3.20 per m3 of purified water, adding additional cost to the production of green hydrogen.[9]

Use of Green Hydrogen

Industry

So far, the focus of the (potential) use of (green) hydrogen has been on energy-intensive industrial sectors such as steel, transportation, chemicals, etc. These so-called hard-to abate sectors are challenging to electrify and thus need clean alternatives. The use of green hydrogen will be more easy in sectors which already use grey hydrogen like ammonia production, iron, but more difficult in sectors such as shipping or aviation.[4]

Actually, there are a few low-carbon hydrogen projects underway or in planning stage in Egypt, Mauritania, Morocco, Namibia and South Africa. These are focused mainly on using renewables-based power to produce ammonia for fertilizer.[14]

Further (potential) use cases include:

Electricity Generation

There are two ways for using hydrogen to generate carbon-free electricity: either through fuel cells or through combustion turbines and engines. When used in a fuel cell, the only byproducts of hydrogen are heat and water vapor. When combusted like gas, hydrogen produces not only electricity but the combustion also results in nitrogen oxide (NOx), a harmful pollutant. Furthermore, for combustion in turbines, hydrogen needs to be blended with gas at a rate of 5-20, max 30%, thus not decreasing CO2 emissions substantially.[15]

Buildings

Since existing heating and cooking appliances can only handle hydrogen blending of 5-20 percent by volume, the use of hydrogen would not reduce emissions significantly. For hydrogen to be used in higher concentration levels, new appliances would be needed. Furthermore, hydrogen is extremely flammable, also in small concentrations. Given these conditions, replacing gas with hydrogen in buildings would not be reasonable. At least not at this stage.[15]

Storage of Renewable Energy

Green hydrogen could be used as a long-term storage option: In times of surplus renewable energy, additional unused electricity could be used to produce hydrogen, which would then be stored. During periods of additional demand or low renewable energy production, this hydrogen would be burned in fuel cells to generate emission-free electricity.[15]

In addition, the same process could be used to transport renewable energy in form of green hydrogen over long distances, e.g., from regions with high renewable energy potential but low demand, to regions with less abundant renewable energy sources but high electricity demand.[4]

Transport and storage

Hydrogen is less dense than gas, which makes it hard to store and requires more space than gas for the same amount of energy. Today hydrogen is most commonly stored as a gas or liquid in high-pressure tanks for small-scale mobile and stationary applications.[16] For future large-scale application further options are needed. There are several options, one being compressing it into underground salt caverns.[17][12]

Hydrogen can also be converted into a liquid for long-term storage, which requires very cold temperatures. Another option would be to convert hydrogen into liquid ammonia with the advantage of using already existing infrastructure for safe storage and transportation.[15]

When required, hydrogen can be converted back into power. All these processes require a lot of energy, thus also influencing the cost of hydrogen.

Given its low energy density, hydrogen is also difficult to transport over long distances. Blending it into existing gas pipelines could be a cost-effective option, but this also comes with a lot of challenges. For example, only a fraction of gas can be replaced with hydrogen; end users would need more gas volume to get the same amount of energy due to the lower energy density of hydrogen; pipelines and other technical parts are prone to embrittlement and corrosion; different burning characteristics increase the danger of flames spreading; in addition, blending green hydrogen with fossil gas would mean further greenhouse gas emissions.[15][16]

Advantages and disadvantages of Green Hydrogen

Advantages and Benefits of Green Hydrogen[12]

- Its production doesn’t produce CO emissions

- It burns cleanly in fuel cells, releasing only water and energy

- Stores more energy per unit of weight than most other fuels

- Could be used to store excess renewable energy in times of high generation, to transport energy from one place to another, or as a fuel

- Could be used to decarbonize “hard to abate” sectors

Disadvantages and Challenges of Green Hydrogen[12]

- Production is expensive

- Bulky and expensive to transport and store.

- High energy losses along the production process, requiring a huge amount of renewable energy

- Always more efficient to use RE directly, if possible.

- Supply and value chains for hydrogen use are complex.

- Hydrogen is extremely flammable, and can catch fire even in small concentrations. Thus it needs new safety standards and societal acceptance.

- When hydrogen is combusted, it does not produce carbon emissions, but it does produce NOx emissions up to six times worse than those released by methane combustion.[15] While there are methods of controlling NOx emissions at gas power plants, those technologies are only effective at controlling NOx at a blend of 30 percent hydrogen or less.

- In areas of scarce water availability, the production of green hydrogen could contribute to water stress in local communities.

- Questions of land use and sustainable water consumption have to be considered.[10]

Green Hydrogen Case Studies

Do you have a case study on green hydrogen you want to share? Please add it here! Or get in touch with info@energypedia.info

For case studies see also this publication by ESMAP (2020): Green Hydrogen in Developing Countries

Further Reading

- Mulako Dean Mukelabai, Upul K.G. Wijayantha, Richard E. Blanchard (2022): Renewable hydrogen economy outlook in Africa. In: Renewable and Sustainable Energy Reviews, Volume 167, October 2022, 112705

- Heinrich Böll Stiftung (2022): Green hydrogen – hype or beacon of hope? Opportunities, risks and strategies for green hydrogen production in the global south.

- Heinrich Böll Stiftung (2022): Pastoralism and large-scale REnewable energy and green hydrogen projects

- Heinrich Böll Stiftung (2022): Technical potential & challenges of REnewable hydrogen. Issues in the global South

- GIZ (2022): Promoting a South African Green Hydrogen Economy (H2.SA)

- ESMAP (2020): Green Hydrogen in Developing Countries

- IEA (2019): The Future of Hydrogen: Seizing today's opportunities

- IEA (2019): Hydrogen: A renewable energy perspective

- IRENA (2018): Hydrogen from renewable power: Technology outlook for the energy transition

- Journal of Cleaner Production (2018): Environmental sustainability of renewable hydrogen in comparison with conventional cooking fuels

References

- ↑ 1.0 1.1 https://www.eia.gov/energyexplained/hydrogen/

- ↑ https://www.britannica.com/science/hydrogen

- ↑ https://www.nrel.gov/research/eds-hydrogen.html

- ↑ 4.0 4.1 4.2 https://www.weforum.org/agenda/2021/12/what-is-green-hydrogen-expert-explains-benefits/

- ↑ https://www.eia.gov/energyexplained/hydrogen/production-of-hydrogen.php

- ↑ 6.0 6.1 IRENA (2020), Green Hydrogen: A guide to policy making

- ↑ Clean Techncia (2021): Hydrogen Heating & Cooking Would Cost Homeowners $100,000+ Extra Over 15 Years

- ↑ 8.0 8.1 IRENA (2020): Green Hydrogen Cost Reduction: Scaling up Electrolysers to Meet the 1.5⁰C Climate Goal

- ↑ 9.0 9.1 9.2 https://www.rechargenews.com/energy-transition/vast-majority-of-green-hydrogen-projects-may-require-water-desalination-potentially-driving-up-costs/2-1-1070183

- ↑ 10.0 10.1 https://www.powerfuels.org/news/veranstaltungen/2021/water-consumption-for-the-production-of-green-hydrogen/

- ↑ 11.0 11.1 https://www.carboncommentary.com/blog/2021/6/11/some-rules-of-thumb-of-the-hydrogen-economy

- ↑ 12.0 12.1 12.2 12.3 https://www.carbonbrief.org/in-depth-qa-does-the-world-need-hydrogen-to-solve-climate-change/

- ↑ https://www.iea.org/reports/africa-energy-outlook-2022/key-findings

- ↑ IEA: Africa Energy Outlook 2022

- ↑ 15.0 15.1 15.2 15.3 15.4 15.5 https://www.sierraclub.org/articles/2022/01/hydrogen-future-clean-energy-or-false-solution

- ↑ 16.0 16.1 IEA (2019): The Future of Hydrogen

- ↑ Paul Breeze (2018): Power System Energy Storage Technologies. Chapter 8: Hydrogen Energy Storage.